Patents

Literature

32results about How to "Reduce one-time investment costs" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

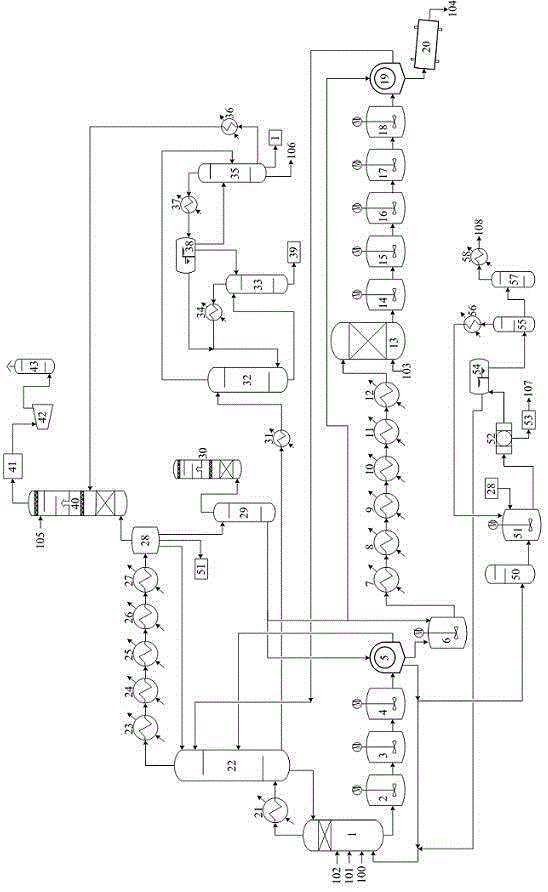

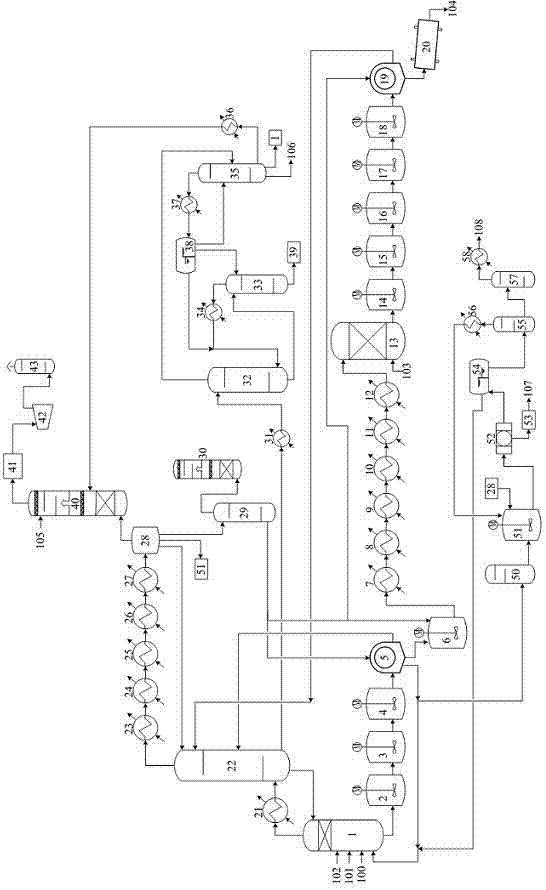

PTA production method with low energy consumption, low material consumption andlow refuse discharge

ActiveCN105001073AEfficient recyclingEmission reductionOrganic compound preparationCarboxylic compound separation/purificationBenzoic acidSlurry

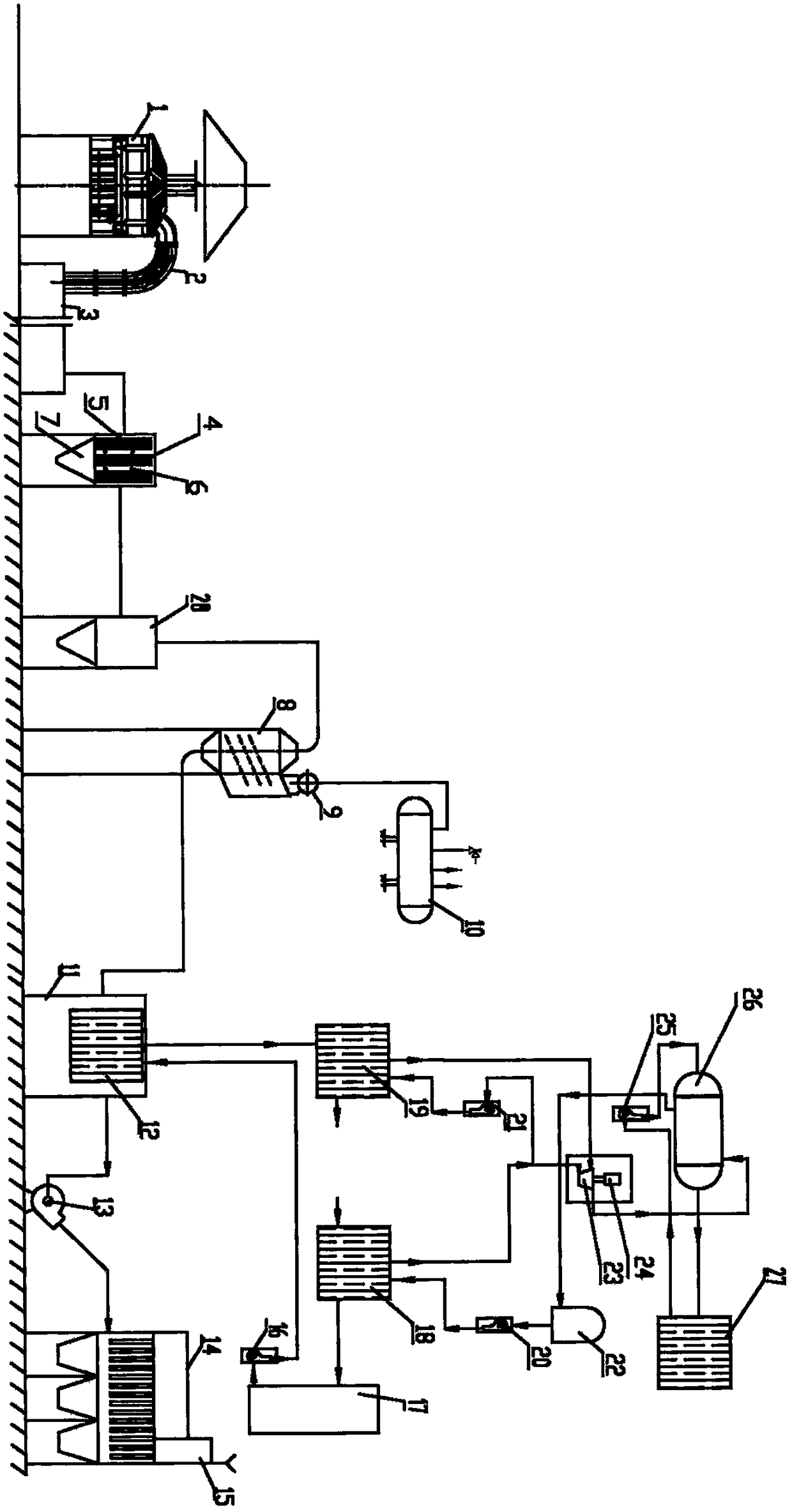

The invention relates to a Purified Terephthalic Acidproduction method with low energy consumption, low material consumption and low refuse discharge. The PTA production method comprises the following steps: tail gas of an oxidation reactor is outputted and passes through by-product steam of a first stage steam generator and is sent to an acetic acid regeneration tower for recycling acetic acid; a refined mother liquor is returned to the acetic acid regeneration tower, the original vacuum filtration filter is replaced by a pressure filter, and filter cakes are directly pulped and supplied to a refining section; through recovered acetic acid recovery extraction, an oxidized mother liquor is processed by extraction, and an acetic acid methyl ester removed tower top backflow liquid of the acetic acid regeneration tower is used for oxidizing, washing filter cakes of the refining section and blending slurries of the refining section. The method and system provided by the invention can effectively control acetic acid consumption in tail gas and waste water, recycle organic matters of the refined mother liquid, realize reuse of water, reduce consumption of steam and electric energy, reduce refuse discharge, and also can supply benzoic acid, mixed phthalic acids and other by-products. The invention has the advantages of short process flow, good operationality, low production cost and low apparatus investment.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

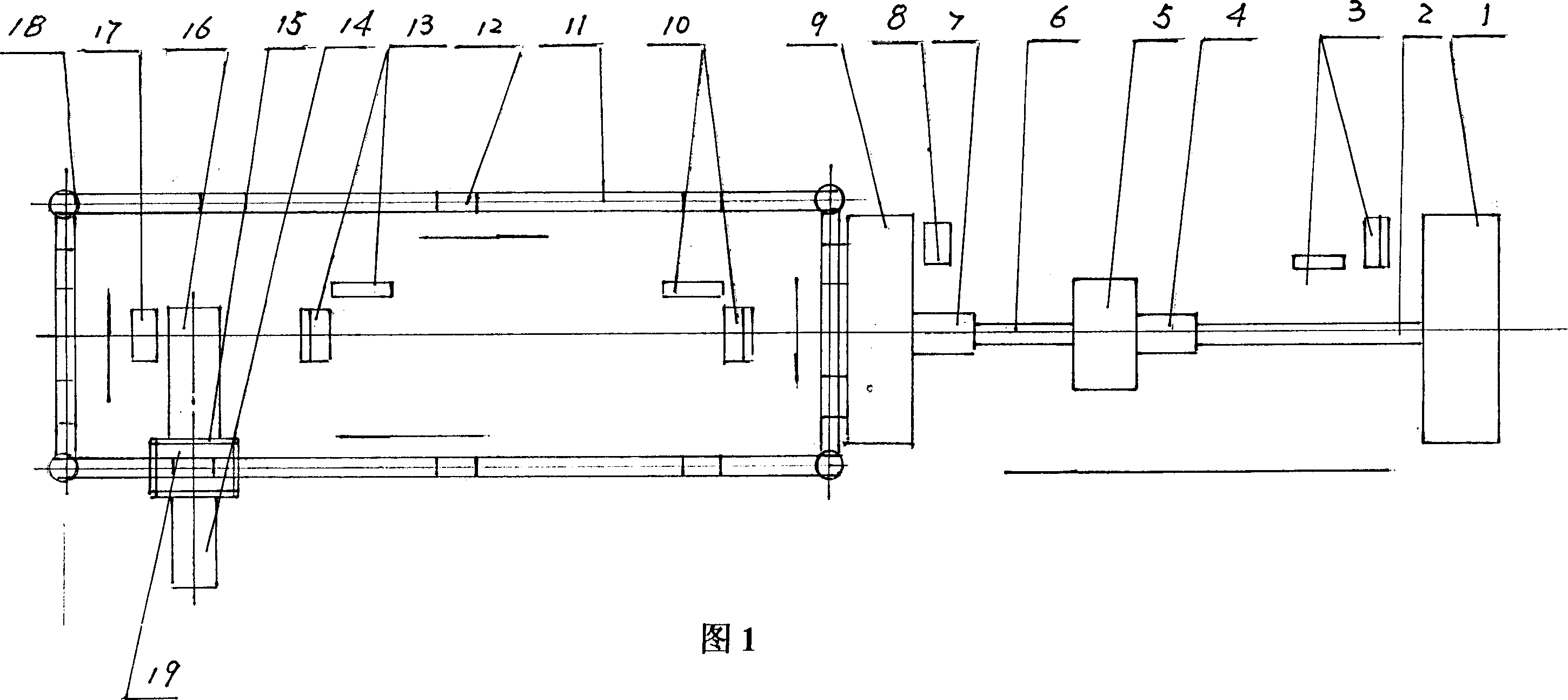

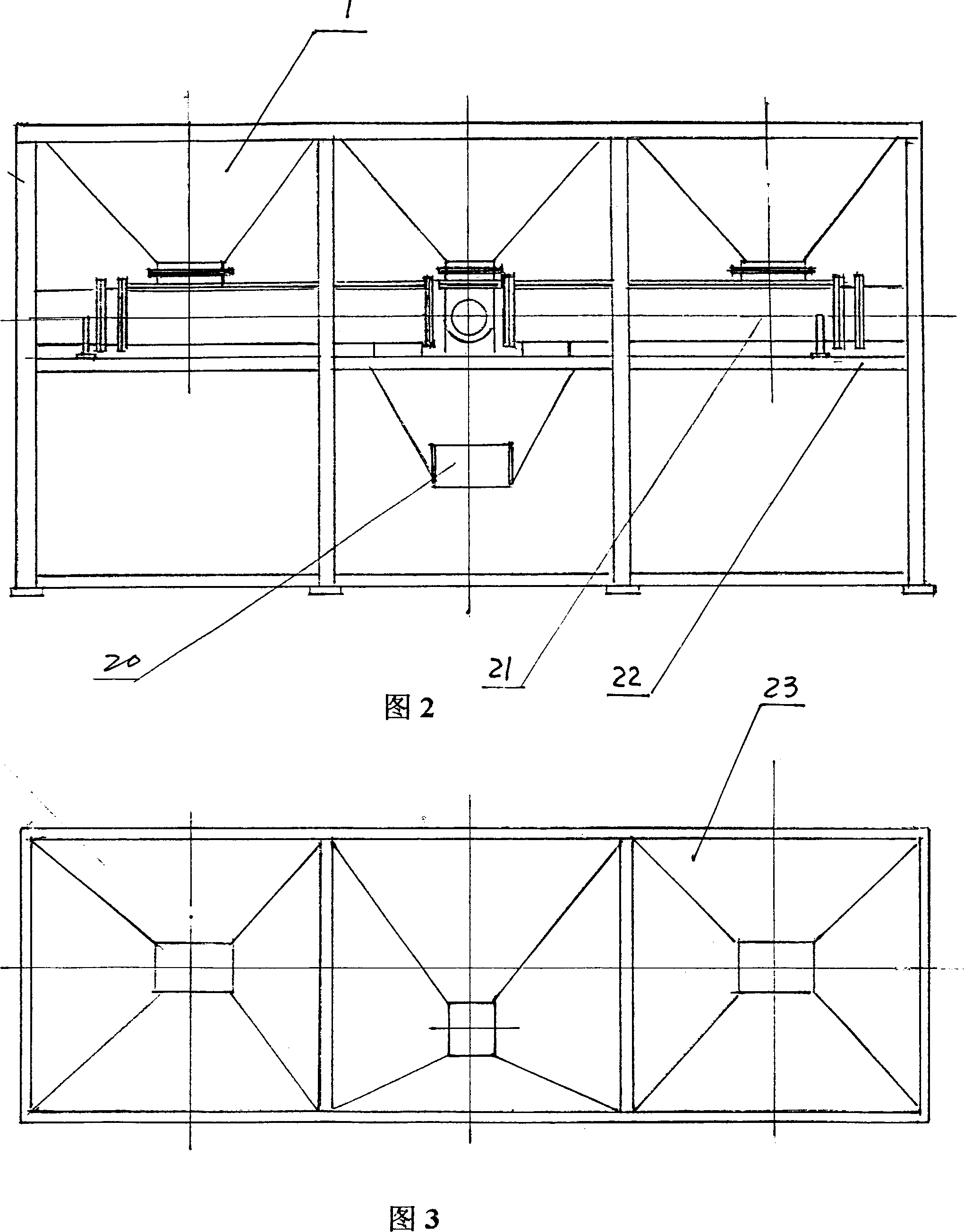

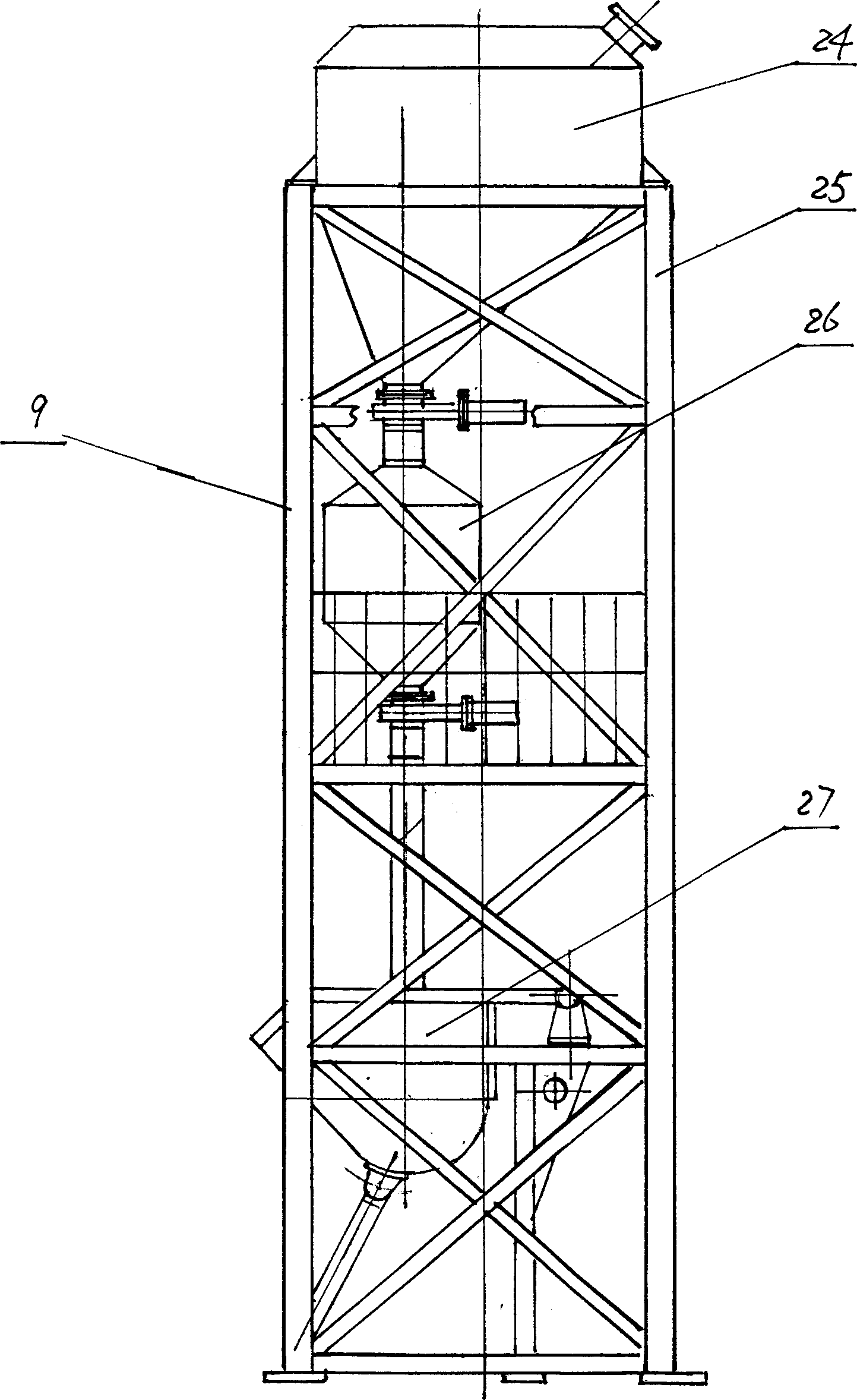

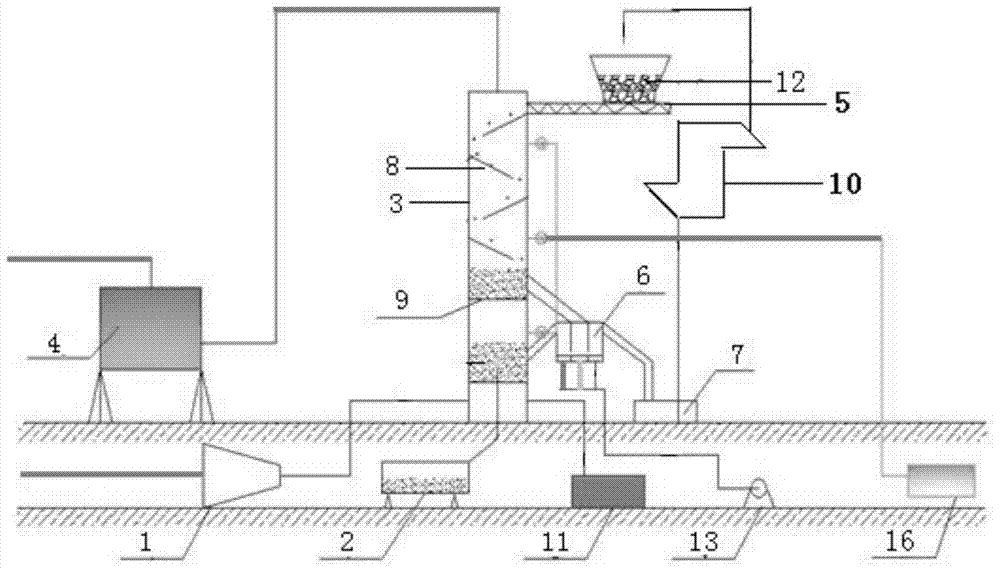

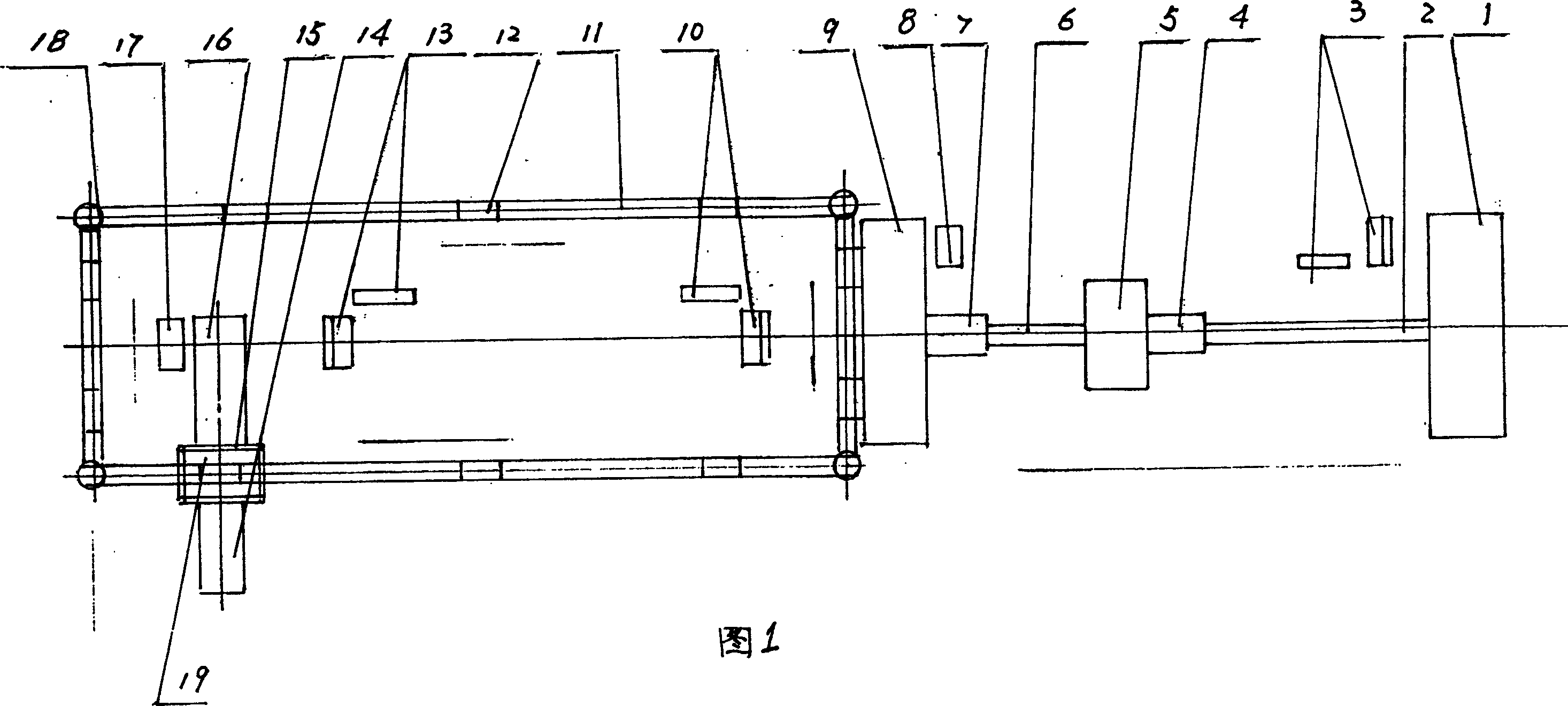

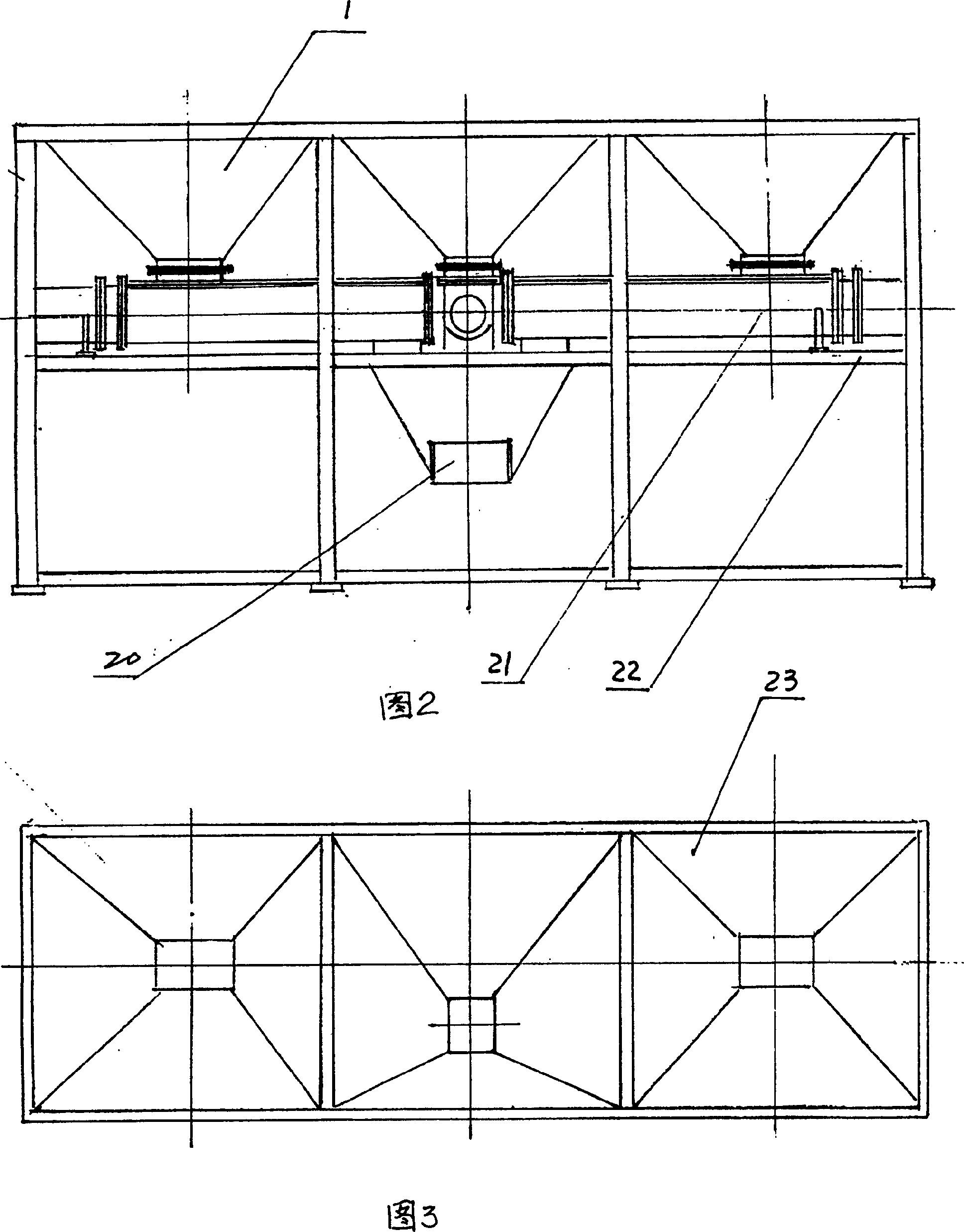

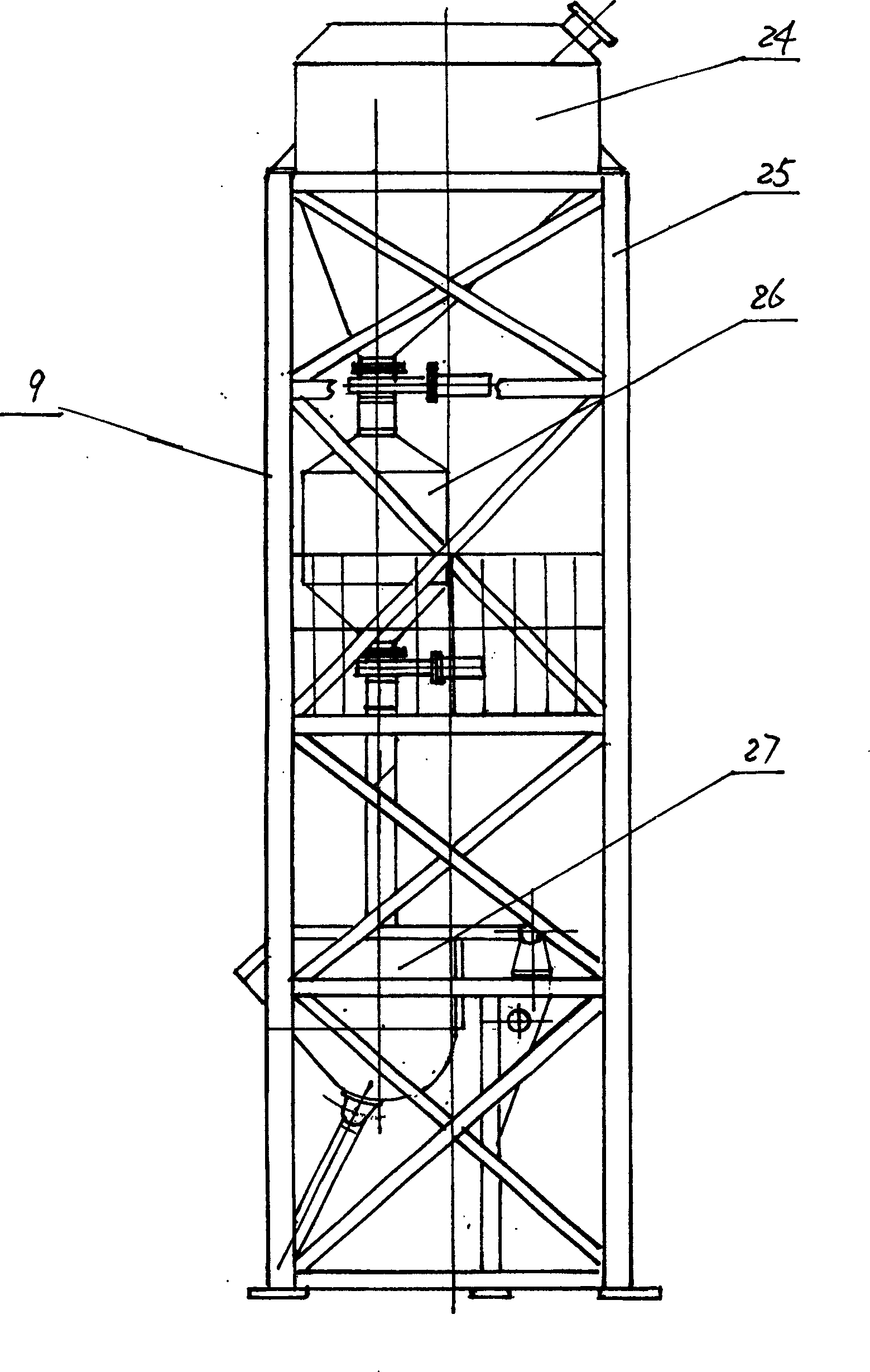

Full-automatic production line of building blocks made of industrial waste and gypsum

InactiveCN1386619AExpand production scaleImprove efficiencyMixing operation control apparatusCeramic shaping plantsIndustrial wasteScrew conveyor

A full-automatic production line for making the building gypsum blocks from industrial dregs is characterized by that between batching station and multi-station injection moulding system there are slope-type screw conveyor, hopper-type lifting unit, mixing system, horizontal screw conveyor, another hopper-type lifting unit, microcomputer control center, and control station for batching. Its full-automatic circulating system is composed of shaping moulds, diverter, hydraulic output unit, hydraulic demoulding unit, raise-fall unit and mould locking mechanism. Its advantage is high productivity.

Owner:崔达生

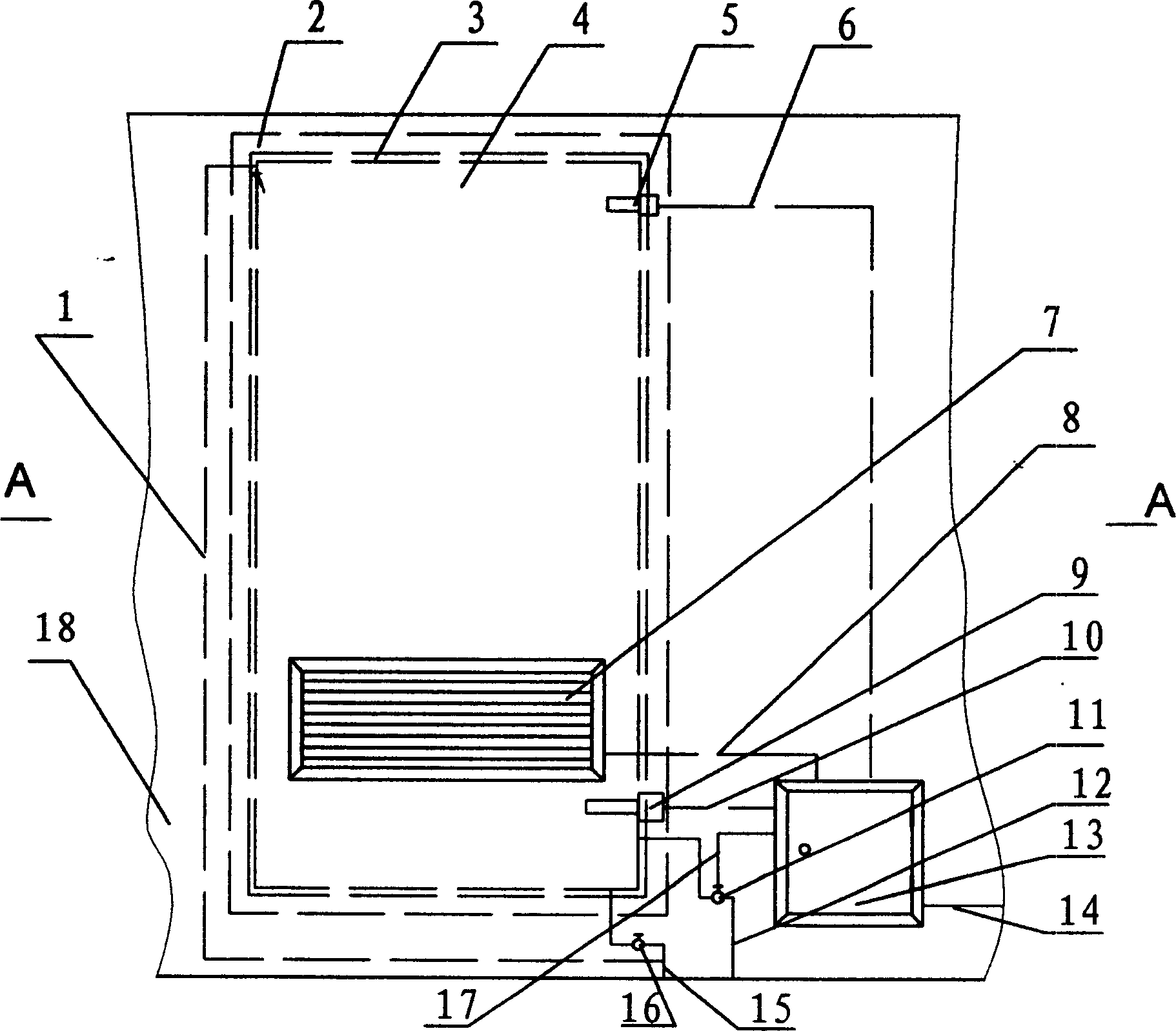

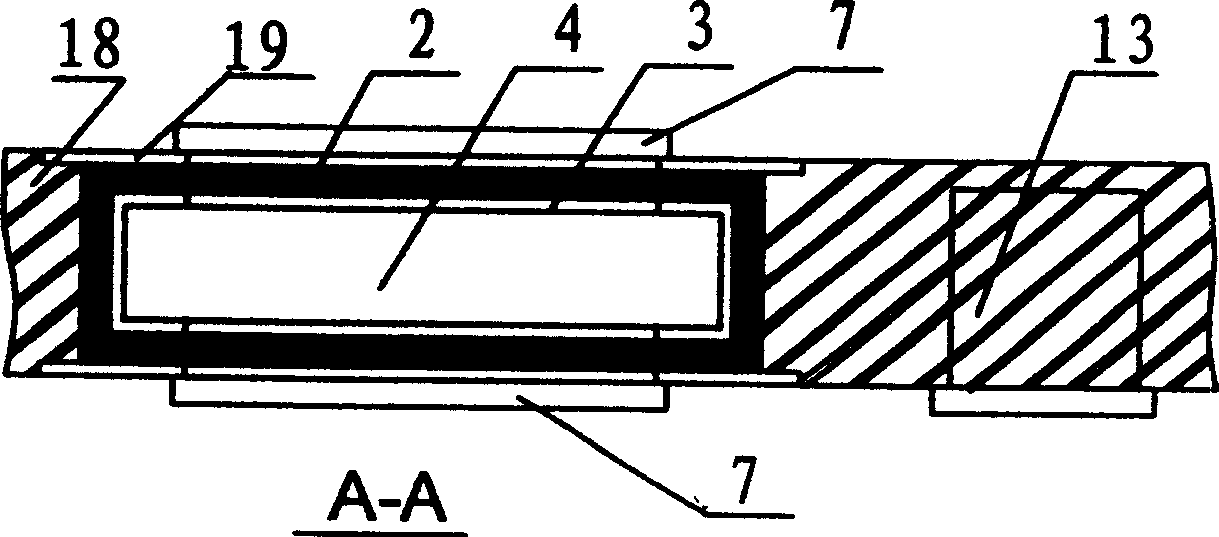

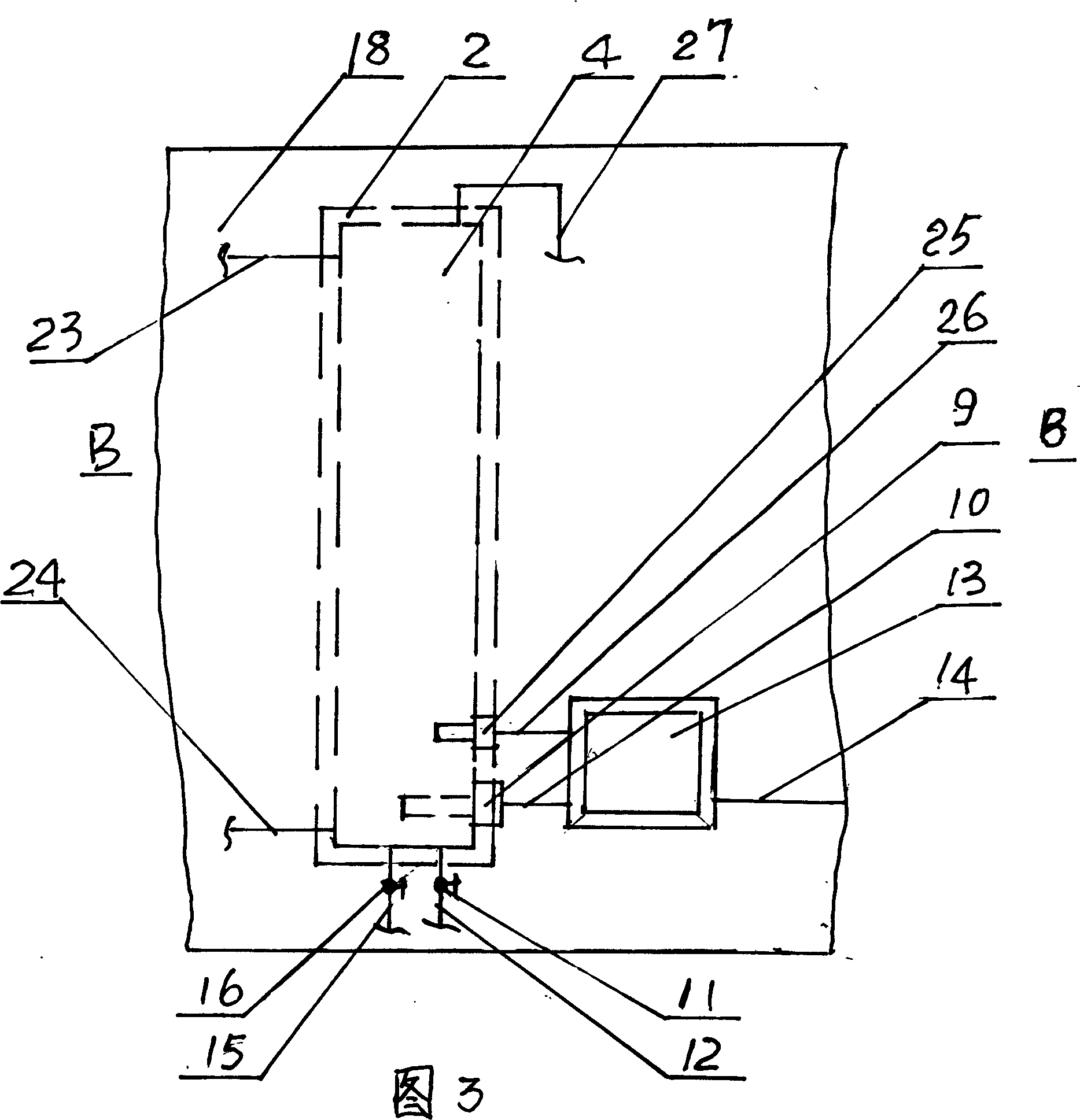

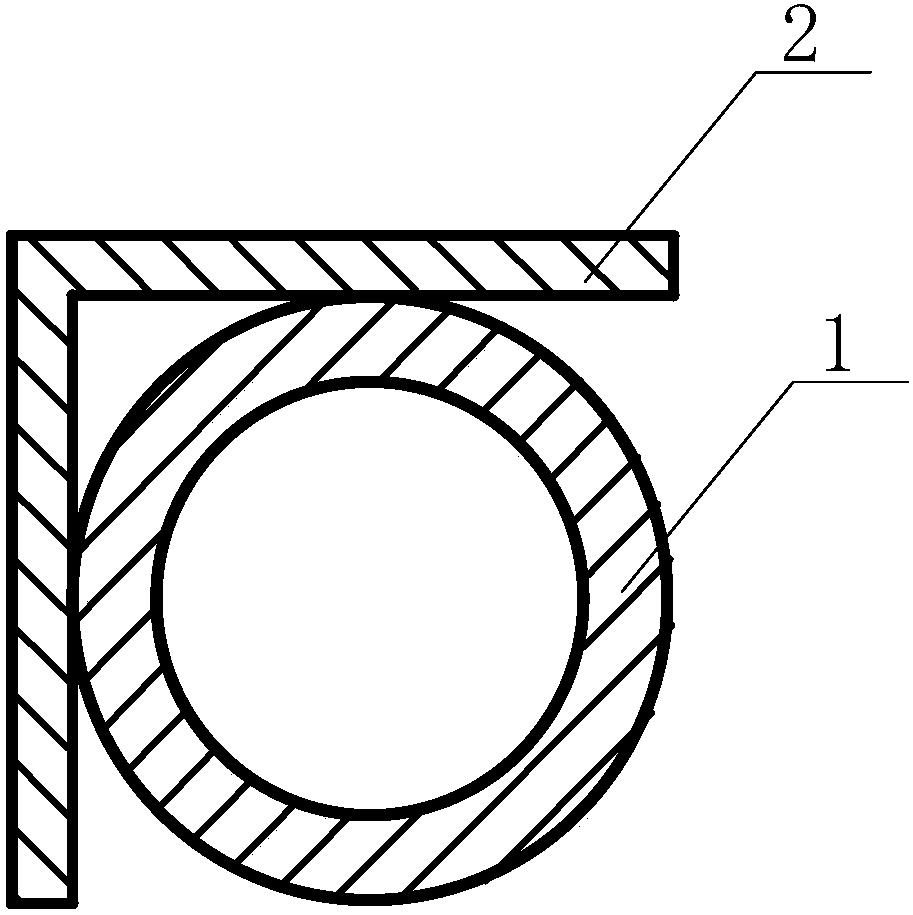

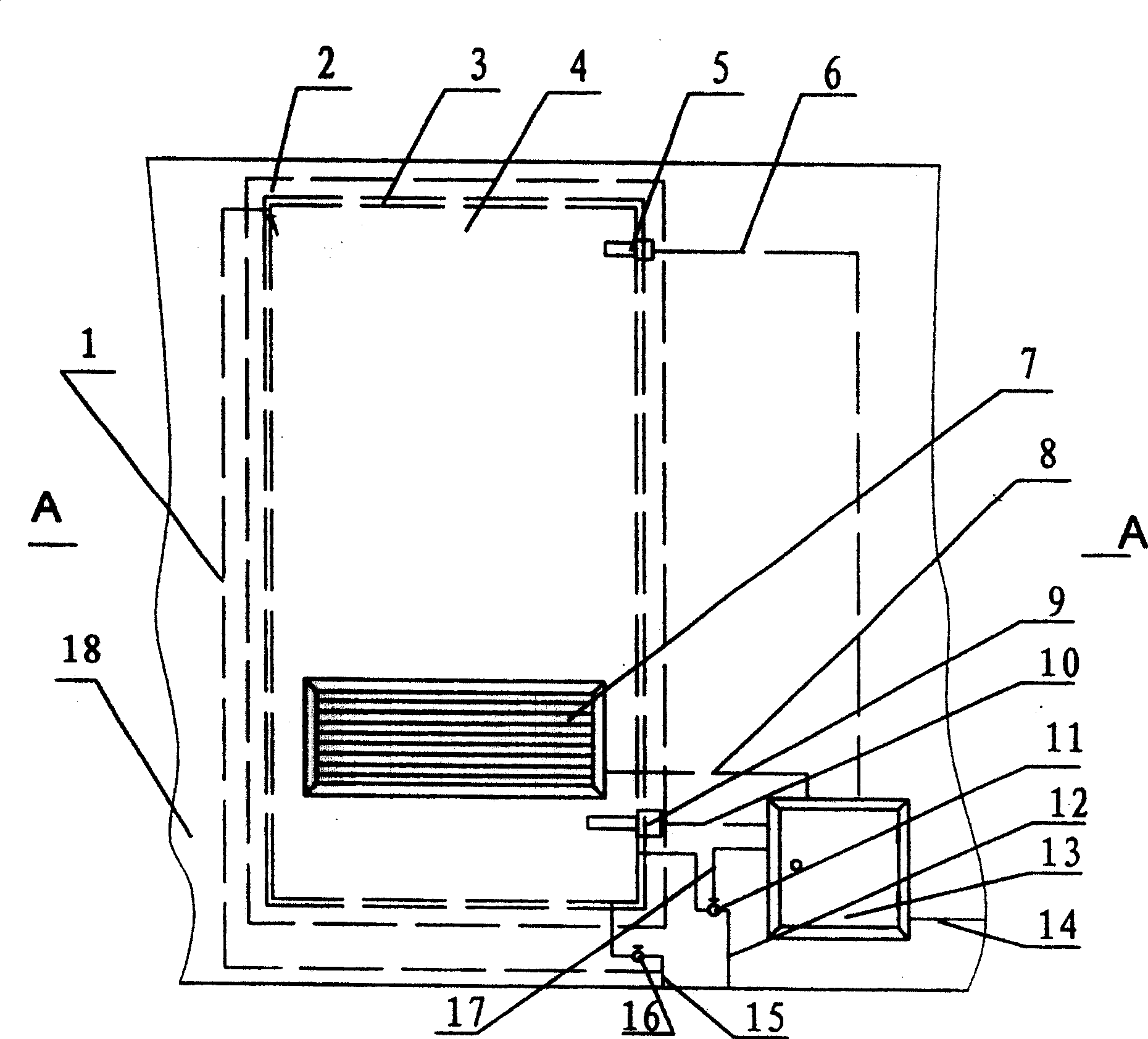

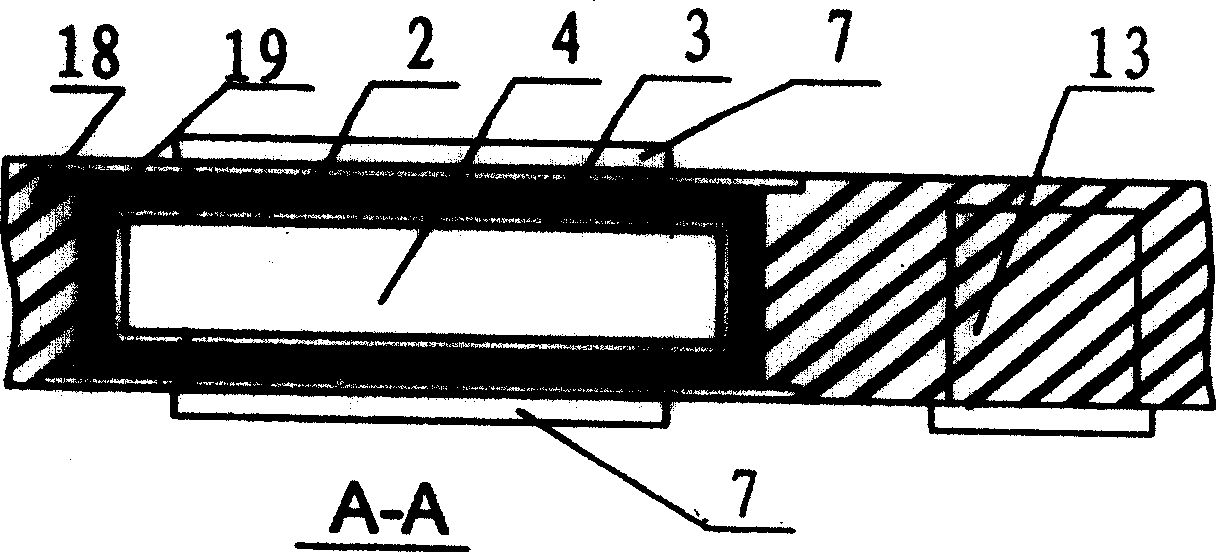

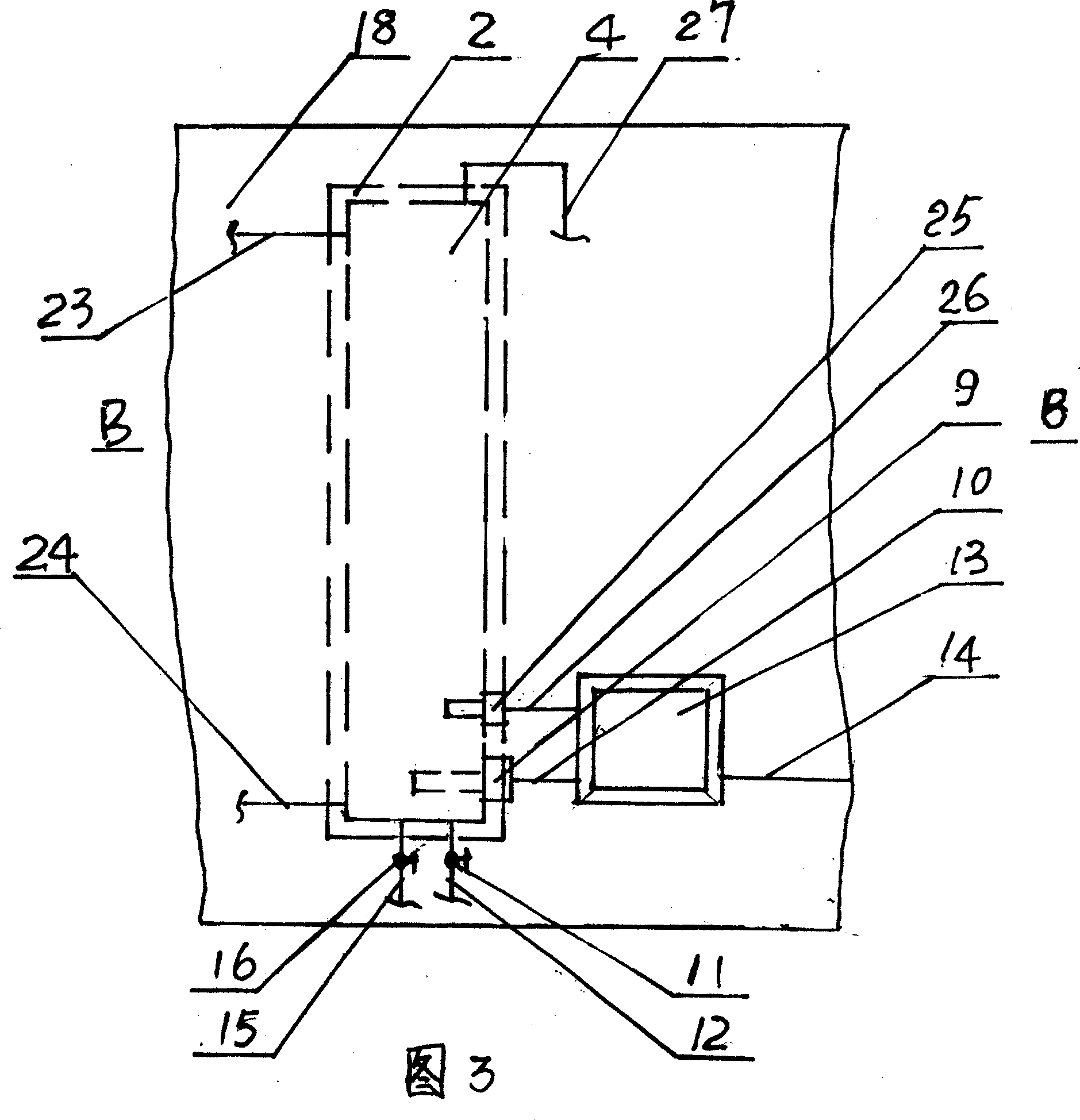

Energy storage wall and its use

The energy storing wall has energy storing apparatus installed inside the wall or near the wall, and the energy storing apparatus consists of energy storing box, energy storing unit comprising gap dn heat insulating layer, electric heating element, heat exchange coil pipe, electric controlling box, temperature controller, high water level controller, water pipe, heat exchange circulating pipe and cold and warm circulating pipe. The energy storing wall accumulates the cold or heat energy from the night valley electric energy, solar energy and air energy. It may be used in various kinds of building, especially energy saving building, and it is economic and environment friendly.

Owner:魏鸿申

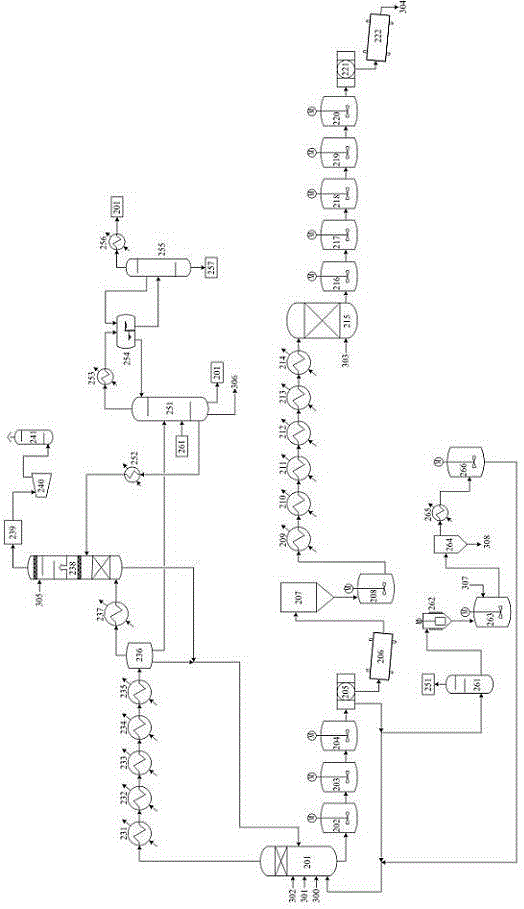

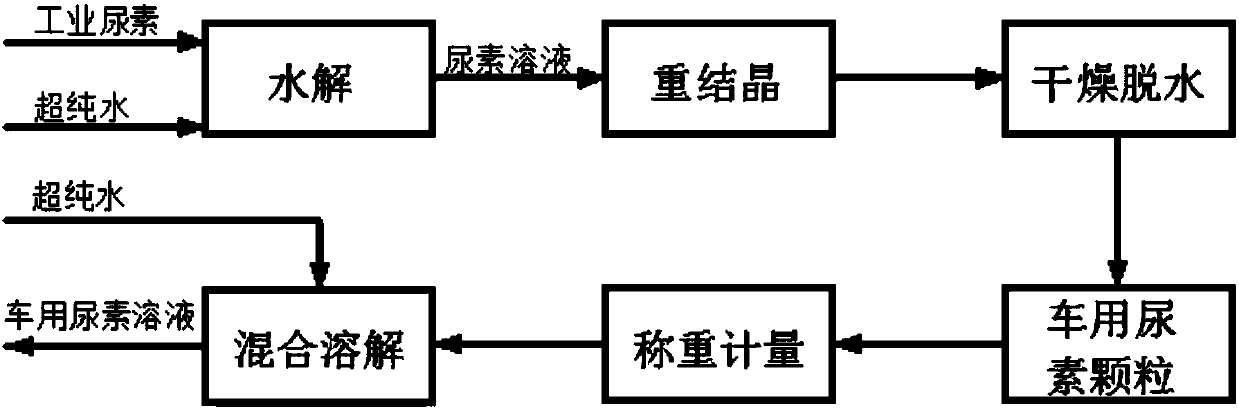

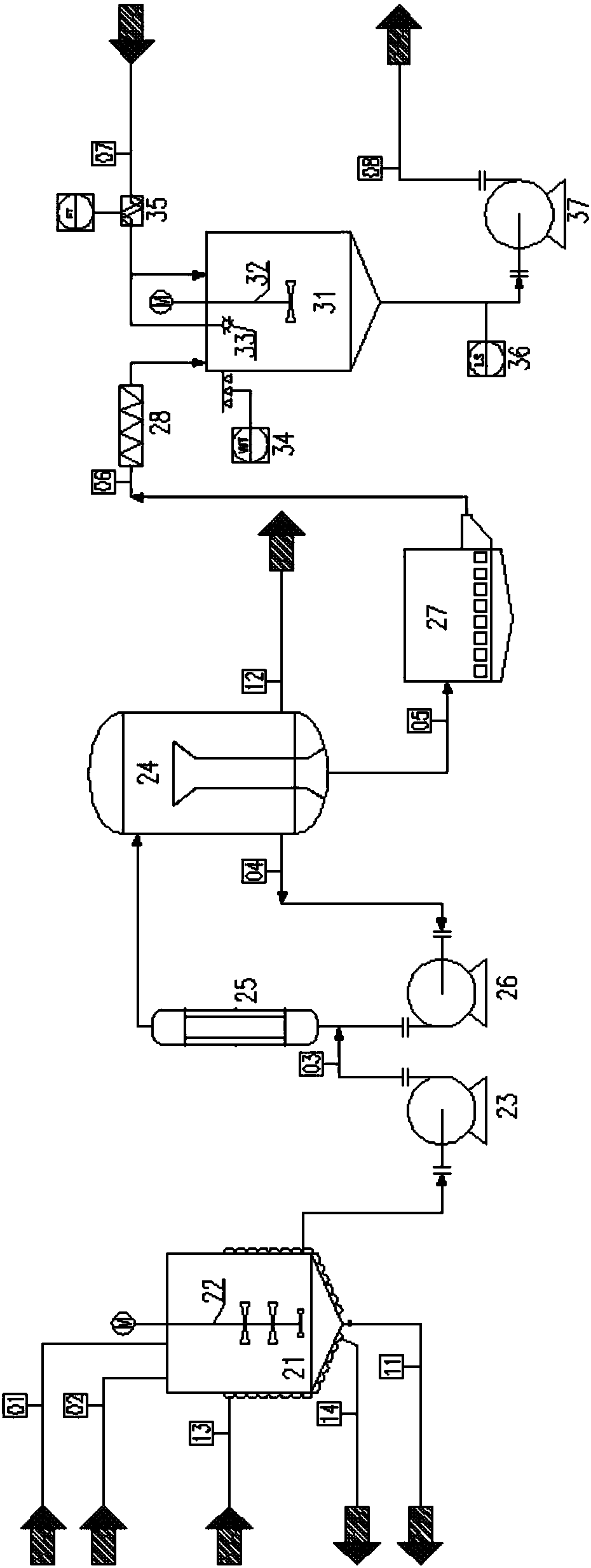

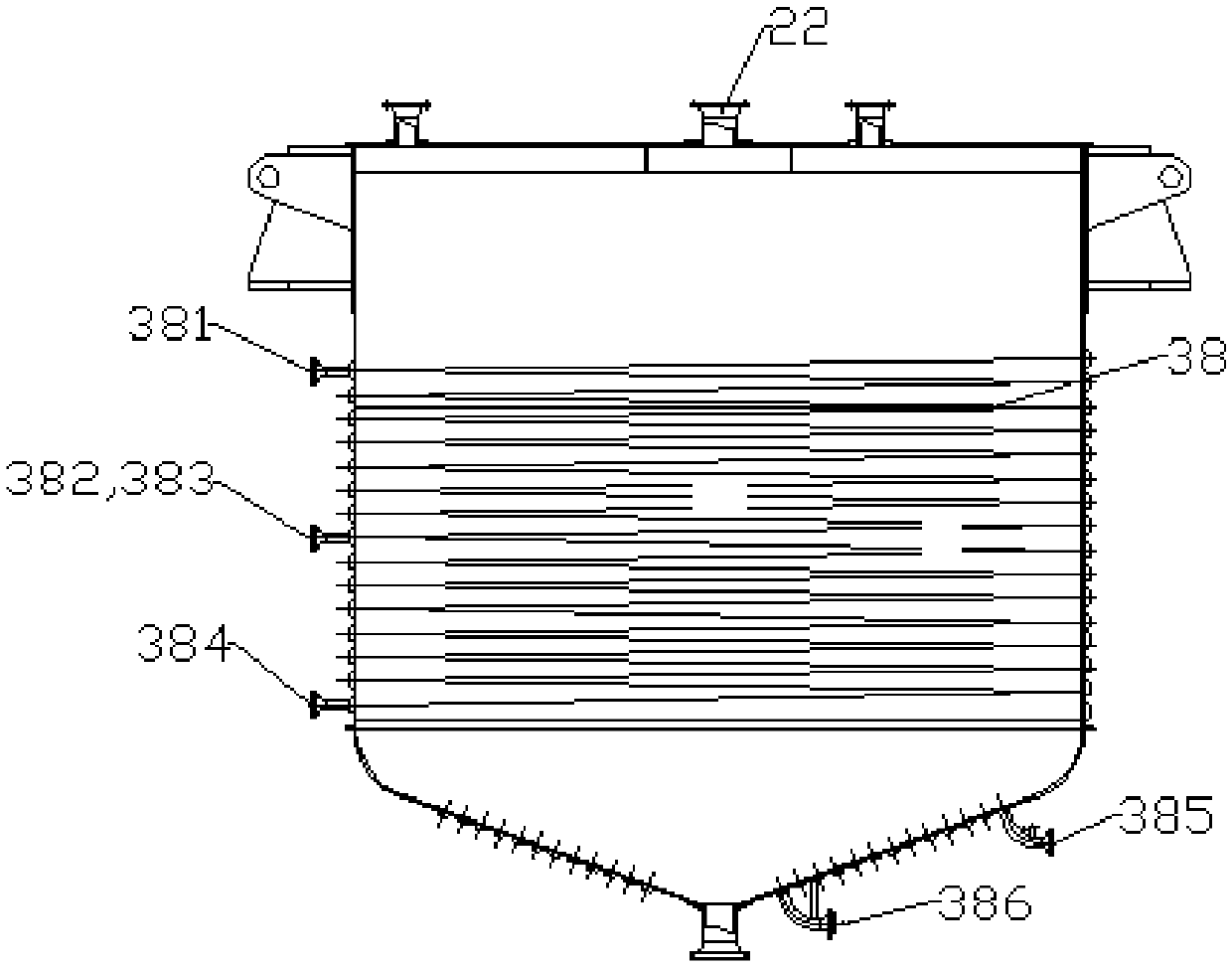

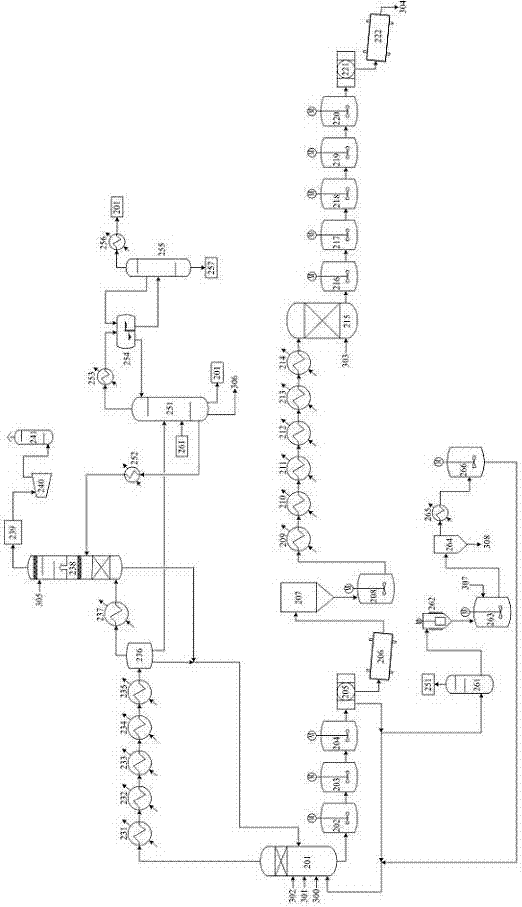

Production process and system for preparation of automobile urea solution from industrial urea

InactiveCN107930395AAdequate and stable market supplyLow costUrea derivatives preparationOrganic compound preparationUreaChemistry

The invention provides a production process and system for preparation of an automobile urea solution from industrial urea. The production process includes the steps of: S1, mixing the raw material industrial urea with ultrapure water to dissolve industrial urea completely in ultrapure water so as to obtain an industrial urea solution; S2, mixing the industrial urea solution with a crystallizer circulation liquid, then letting the mixture enter an external crystal cooler tube pass for cooling; S3, sending the cooled industrial urea solution and crystallizer circulation liquid mixed solution into a crystallizer; S4, subjecting the crystallizer bottom slurry to cooling crystallization, then drying the crystal in a continuous airflow dryer, thus obtaining qualified automobile urea particles;and S5, blending a certain amount of automobile urea particles with ultrapure water gradually to obtain an automobile urea solution. The production process for preparation of an automobile urea solution from industrial urea provided by the invention adopts cheap industrial urea as the raw material, has the advantages of short technological process, simple equipment, and convenient operation, and is suitable for mass production.

Owner:CHINA TIANCHEN ENG +1

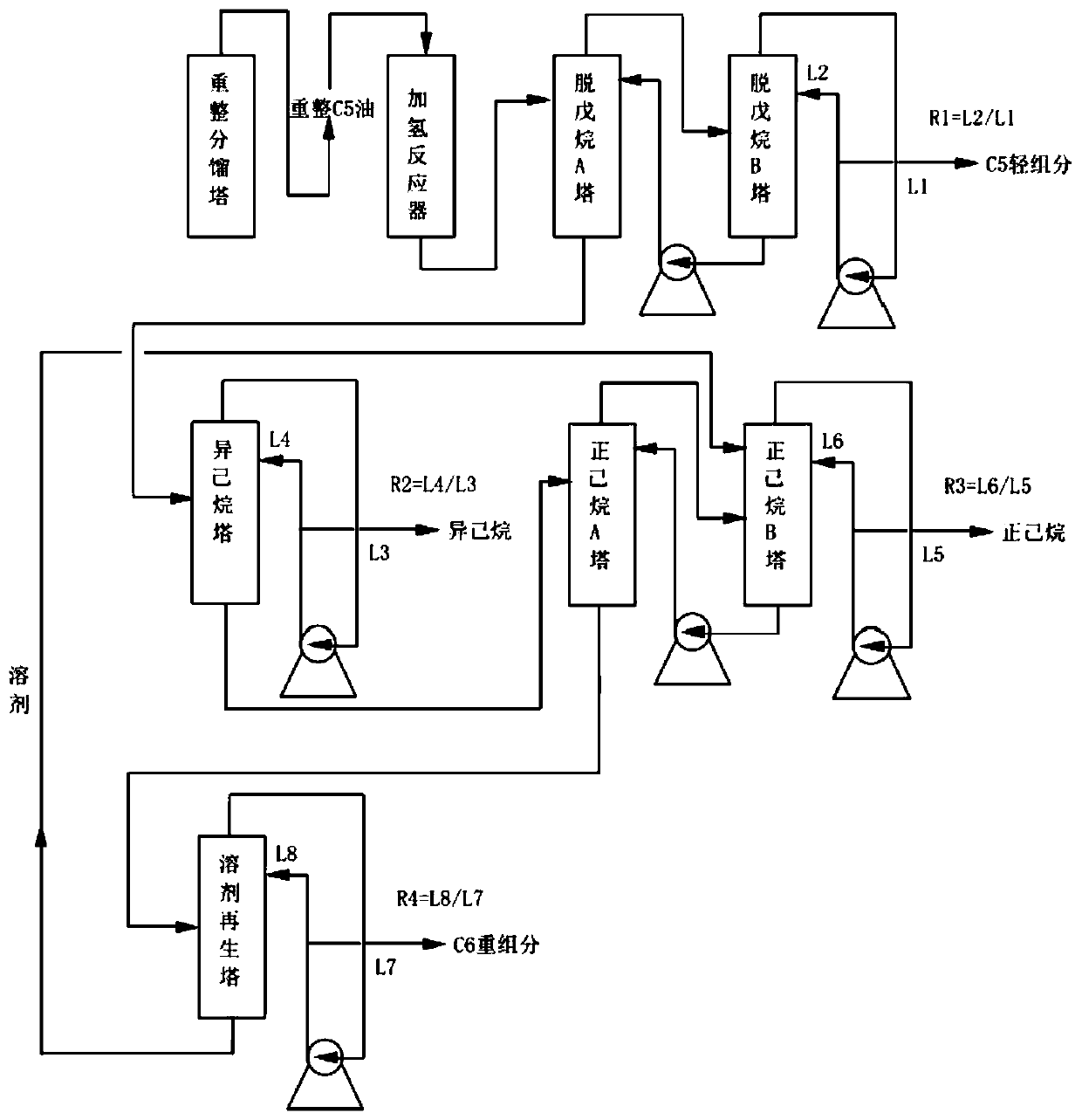

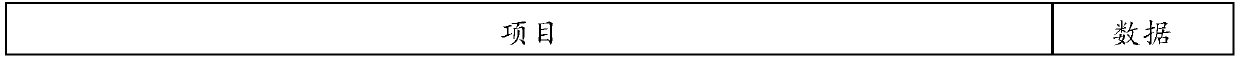

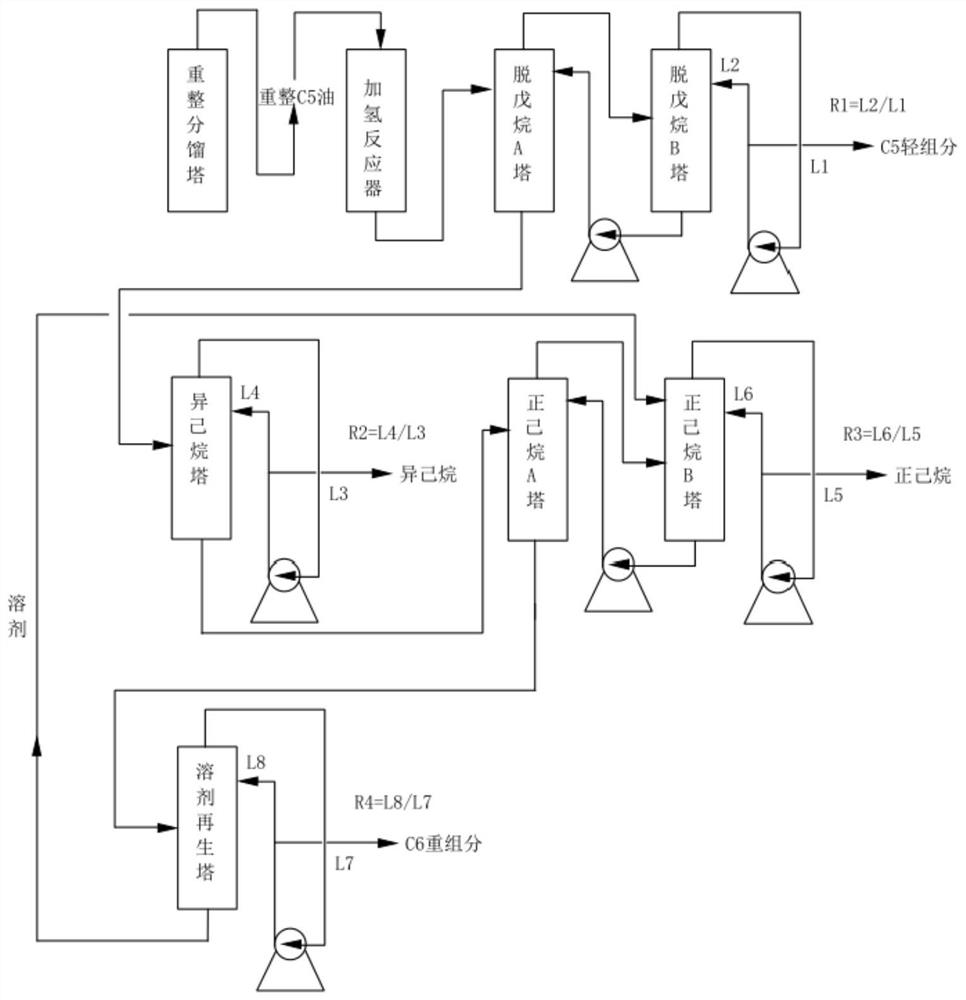

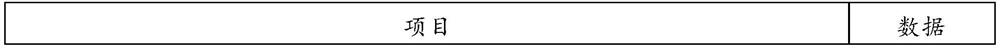

Preparation method of high purity n-hexane

ActiveCN110229042AEasy to prepareSimple processDistillation purification/separationHydrocarbonsLiquid productIsohexanes

The invention provides a preparation method of high purity n-hexane. The method includes the steps of: a) subjecting reformate C5 oil and hydrogen to hydrogenation reaction under the action of a hydrogenation catalyst, and conducting C5 light component separation on a reaction liquid product to obtain a remaining heavy component; b) subjecting the remaining heavy component to isohexane separationto obtain a isohexane removed heavy component; and c) conducting n-hexane separation on the isohexane removed heavy component obtained in step b), thus obtaining high purity n-hexane. Compared with the prior art, the preparation method provided by the invention takes reformate C5 oil as the raw material, and adopts a specific process to prepare the high purity n-hexane. The preparation method provided by the invention has the advantages of simple process, low cost, no pollution, and long-term stable operation. The prepared high purity n-hexane has purity of 99% or above, and the product quality is stable.

Owner:SHANDONG JINGBO PETROCHEM

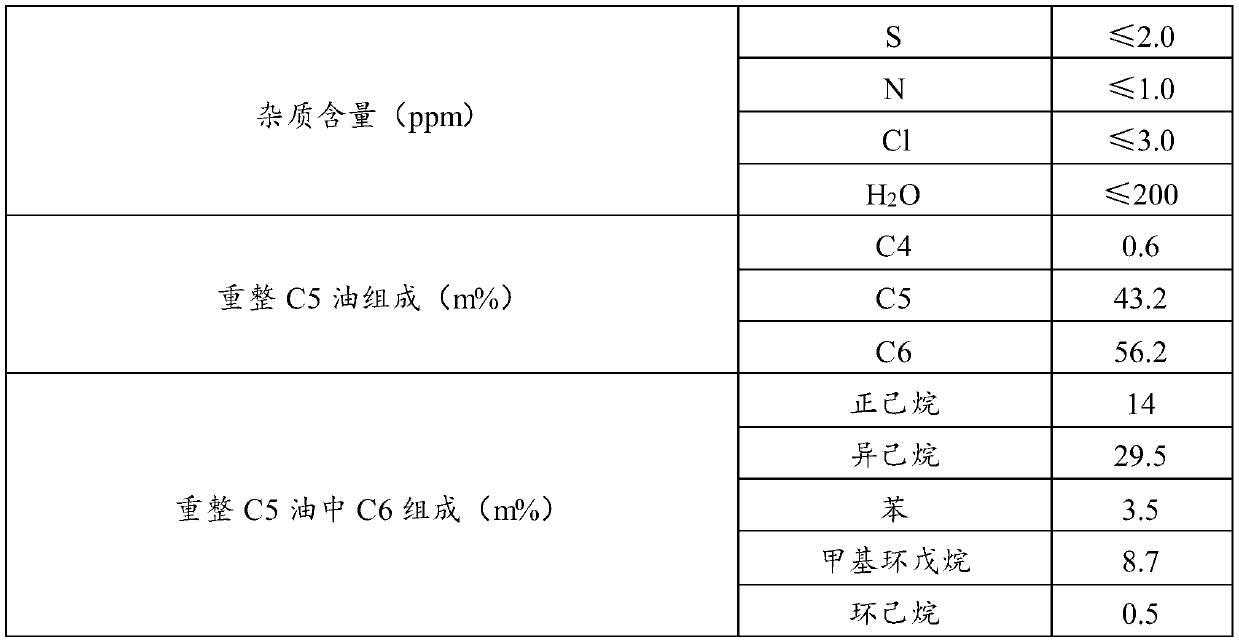

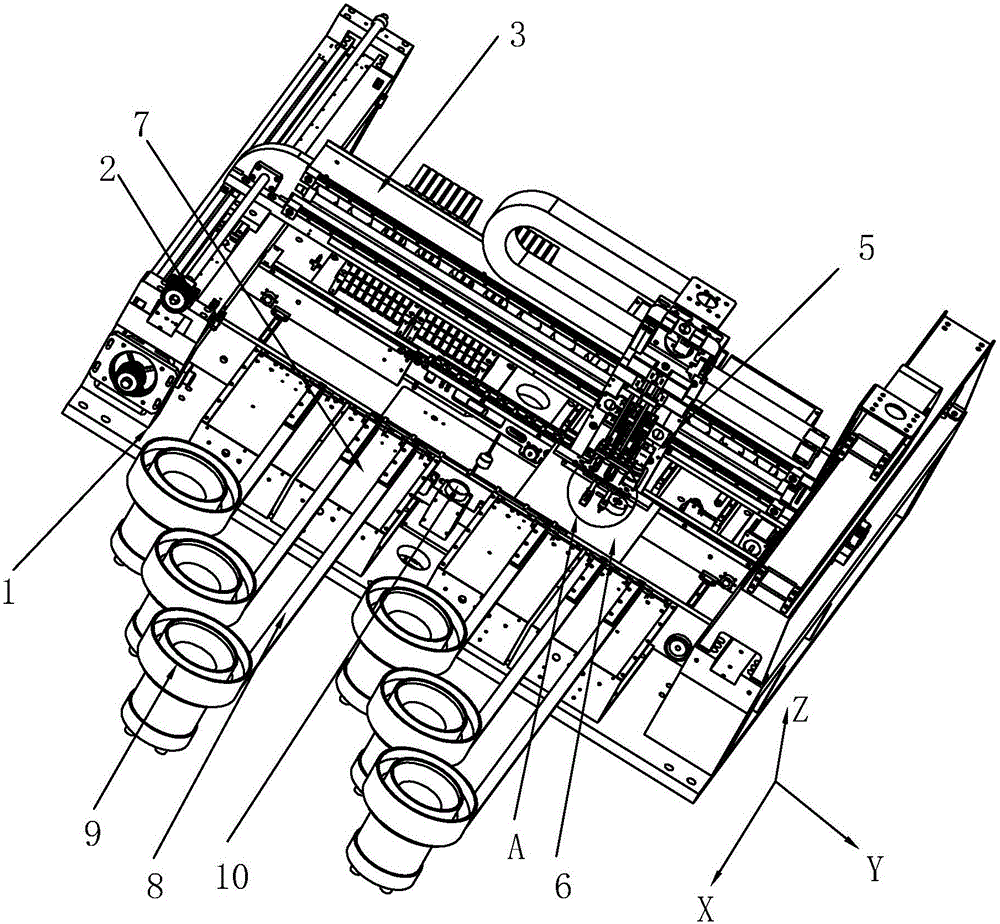

Workpiece attaching machine

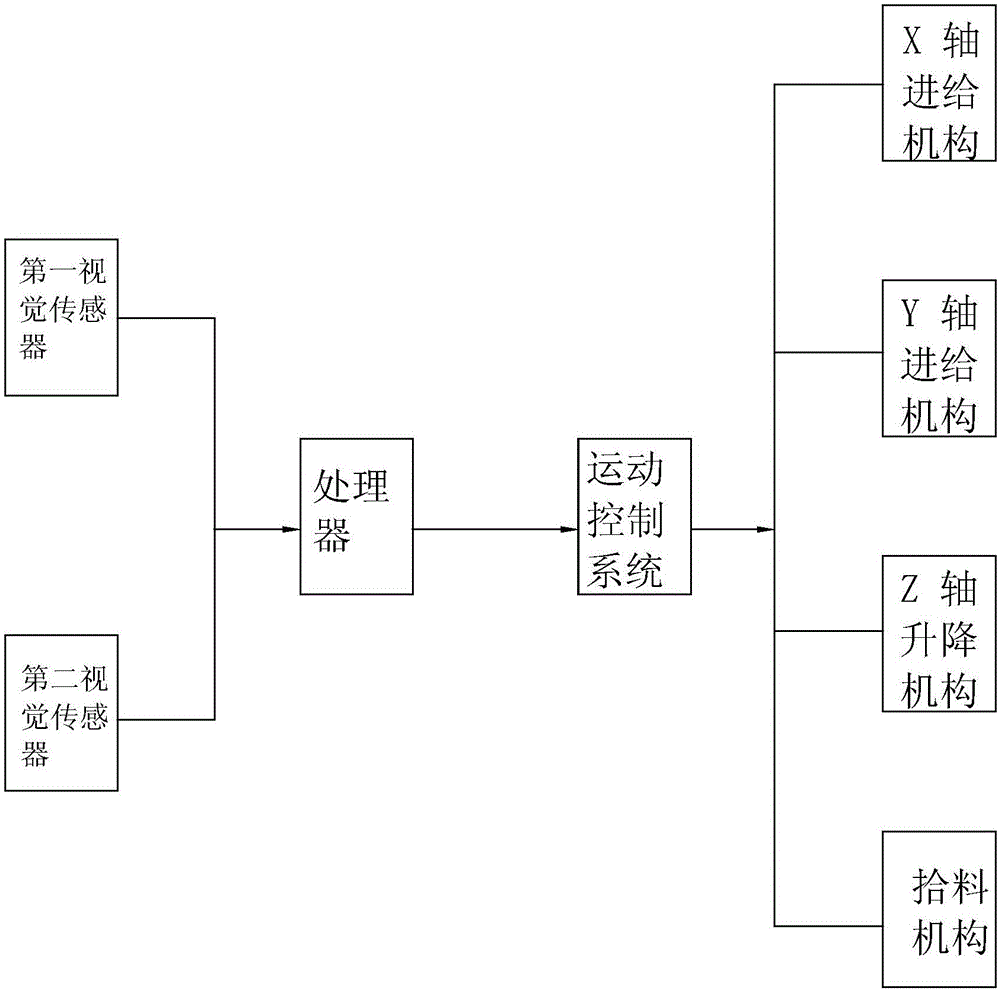

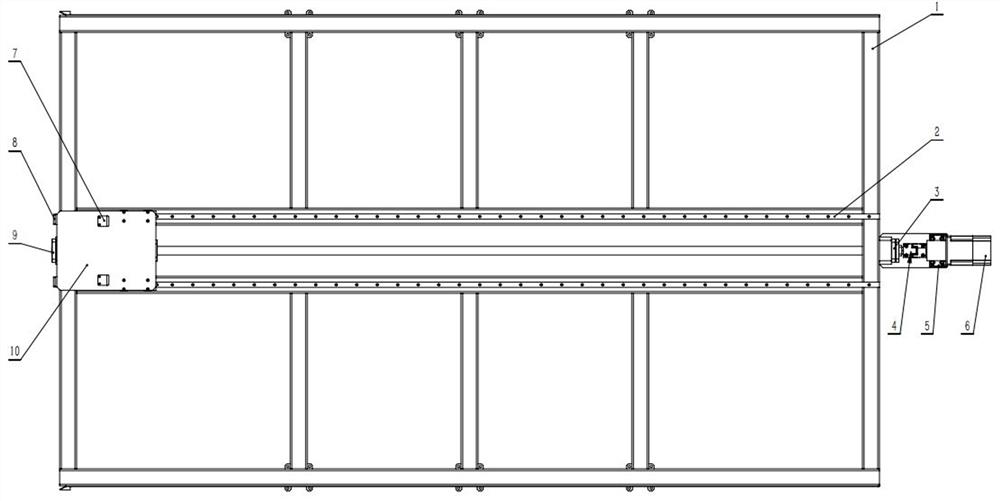

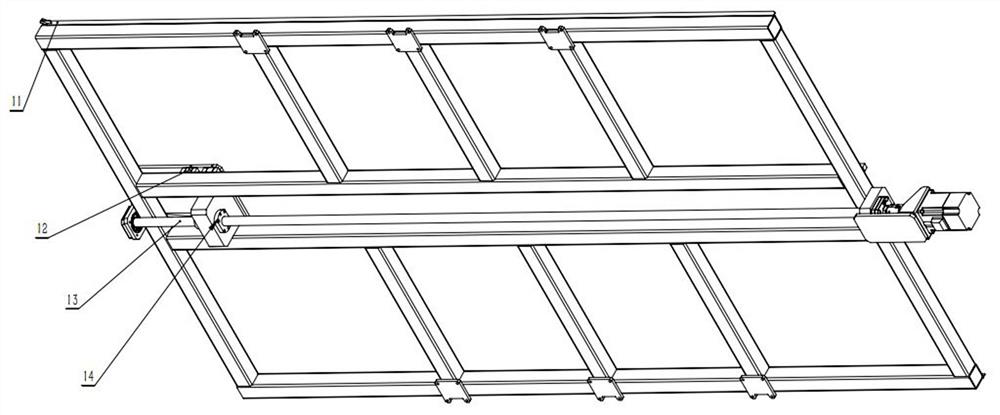

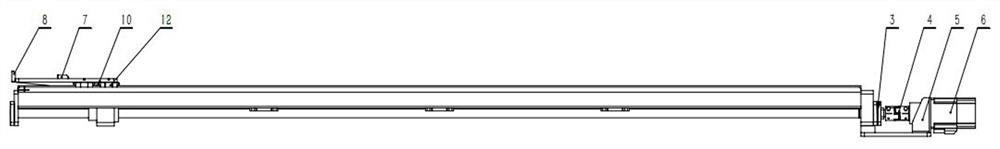

InactiveCN105149924AAssembly precisionThe assembly is accurate and the parts on the pick-up mechanism are accuratelyMetal working apparatusControl systemEngineering

The invention discloses a workpiece attaching machine which comprises a worktable, a movement control system, an X-axis feeding mechanism, a Y-axis feeding mechanism, a Z-axis lifting mechanism and a material picking mechanism. The material picking mechanism freely moves on the worktable in the three-dimensional direction through the joint action of the X-axis feeding mechanism, the Y-axis feeding mechanism and the Z-axis lifting mechanism. The movement control system is electrically connected with the X-axis feeding mechanism, the Y-axis feeding mechanism, the Z-axis lifting mechanism and the material picking mechanism. The worktable comprises an assembly area and a feeding area. A plurality of feeding rails used for conveying parts are distributed on the feeding area at intervals, and the end, outside the worktable, of each feeding rail is connected with one vibration plate. A first vision sensor is arranged on the feeding area, and a second vision sensor is arranged on the assembly area. The workpiece attaching machine further comprises a processor, and the first vision sensor and the second vision sensor are both electrically connected with the movement control system through the processor.

Owner:舒建文

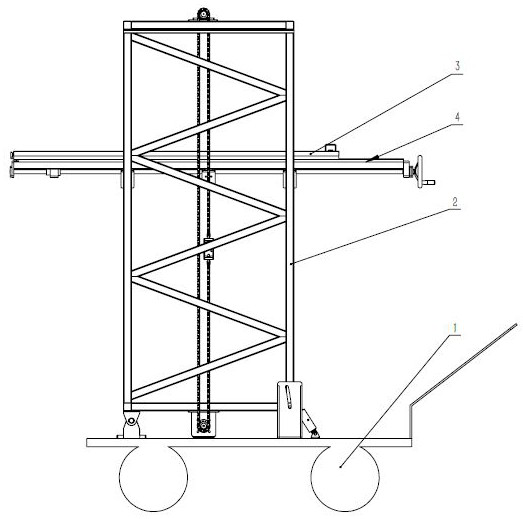

Equipment for dragging and pushing battery bracket in energy storage container

PendingCN111628125AEnsure safe entryReduce the risk of going off trackCell component detailsStructural engineeringMechanical engineering

The invention discloses equipment for dragging and pushing a battery bracket in an energy storage container. The equipment comprises a support frame, threaded holes are reserved in two support beams in the middle of the support frame, and two guide linear slide rails are mounted on the two support beams in the middle of the support frame through screws; and a sliding block is arranged on the guidelinear sliding rails, and a telescopic table is connected with the sliding block and slides forwards and backwards along the guide linear sliding rails. The equipment has the advantages that the costis low, the cost is reduced, the maintenance or replacement difficulty is reduced, and the working efficiency is improved.

Owner:蓝谷智慧(北京)能源科技有限公司

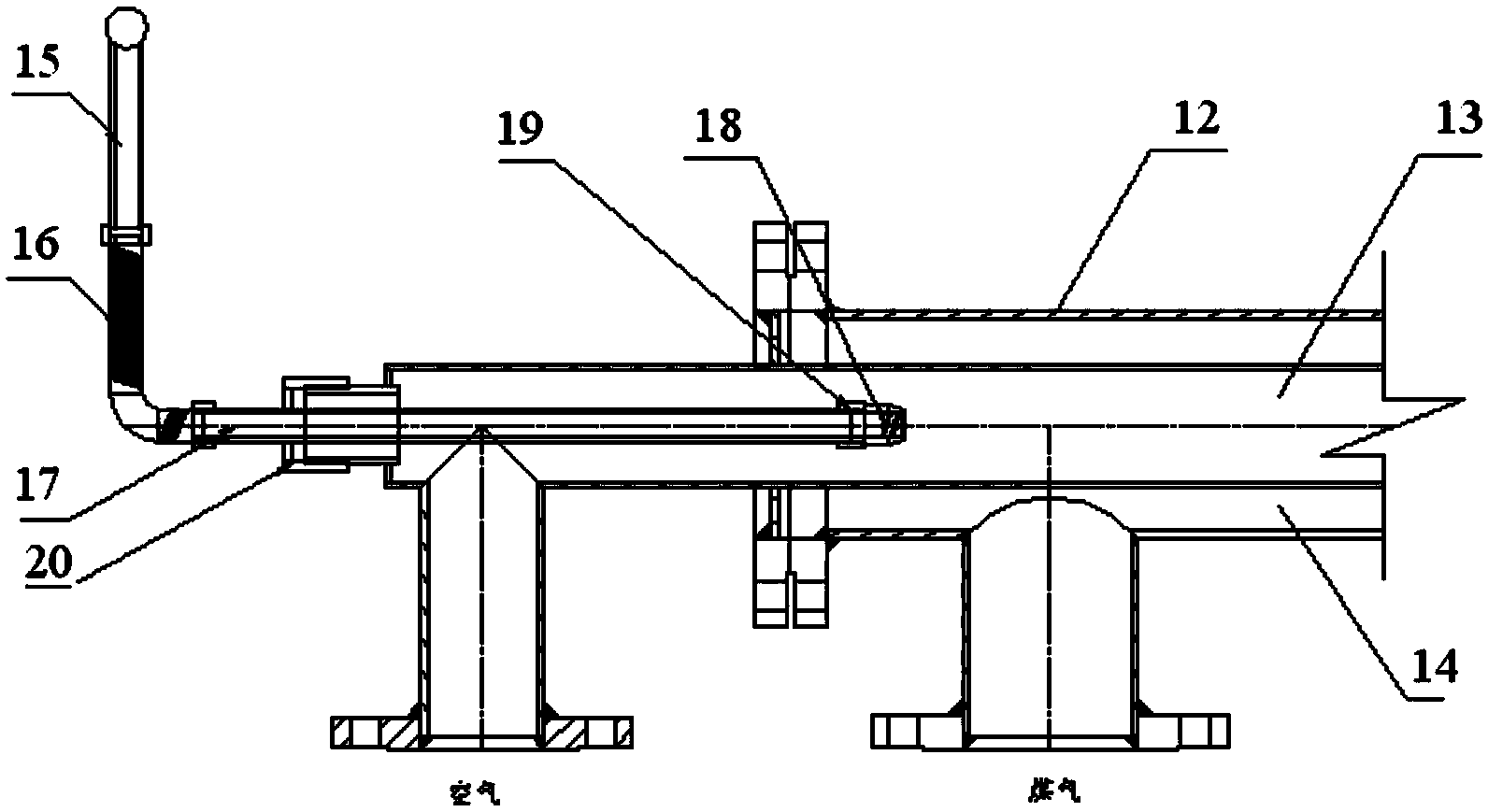

Flue gas residual heat utilizing method for copper smelting furnace through dust remover with exhaust funnel

InactiveCN108088265ADoes not affect stabilityDoes not affect continuityIncreasing energy efficiencyWaste heat treatmentShock waveLarge particle

The invention discloses a flue gas residual heat utilizing method for a copper smelting furnace through a dust remover with an exhaust funnel. The flue gas residual heat utilizing method is characterized in that flue gas of the copper smelting furnace is exhausted from the furnace, passes through a water cooling flue to be mixed with cold air and enters a burning settling chamber after carbon monoxide gas is combusted, the function of the burning settling chamber is that the flow speed of the flue gas is reduced to enable large-particle dust carried in the flue gas to be settled and cold air to be properly mixed, carbon monoxide gas is burnt out finally, flue gas exhausted from the burning settling chamber enters a heat storage temperature equaling device, and the heat storage temperatureequaling device comprises a carbon-silicon composite material heat storage body, a shock wave ash removing device and an ash bucket. The dust remover is provided with the exhaust funnel, clean gas isdirectly exhausted from a gas purifying bin of the dust remover, exhaust funnel steel consumption and civil engineering investment are reduced, the system occupied area is greatly reduced, the primaryinvestment cost of a dust removal system is reduced, the on-way resistance loss and local resistance loss of gas flow in redundant pipelines are reduced, finally, operation electricity consumption can be finally reduced, and the purpose of reducing the operation cost of the dust removal system is achieved.

Owner:无锡市东优环保科技有限公司

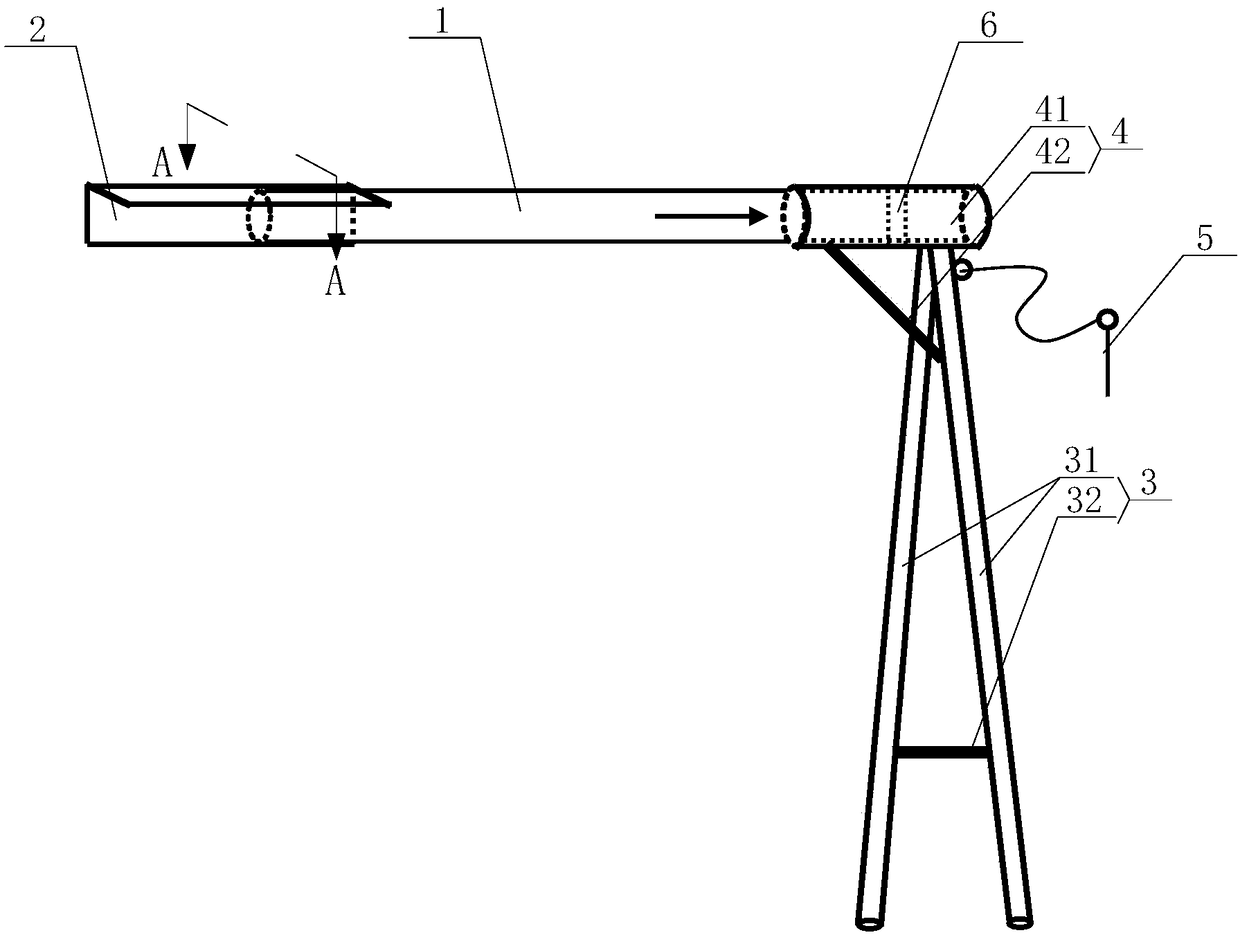

Mobile drip irrigation and micro-spray irrigation fertilization device

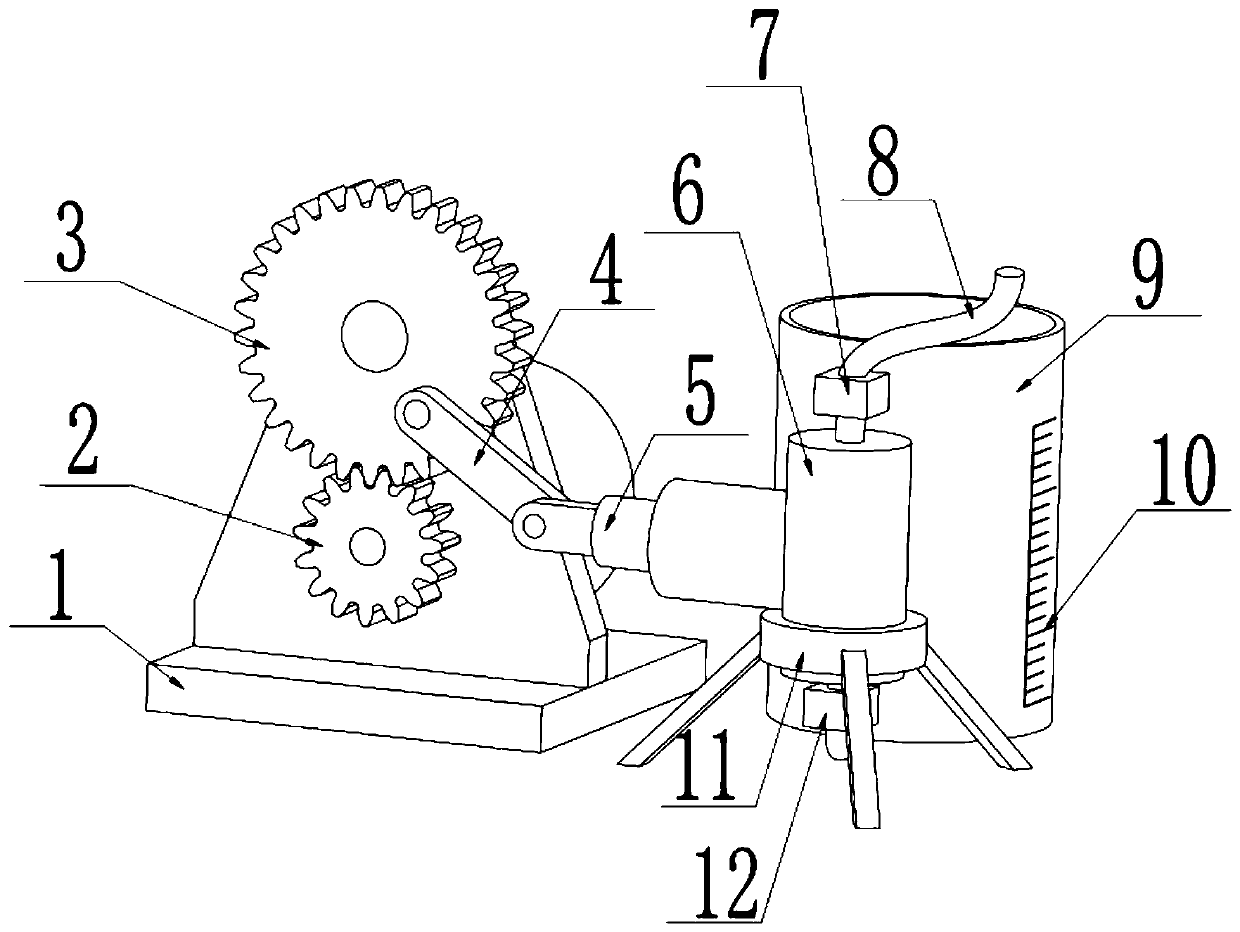

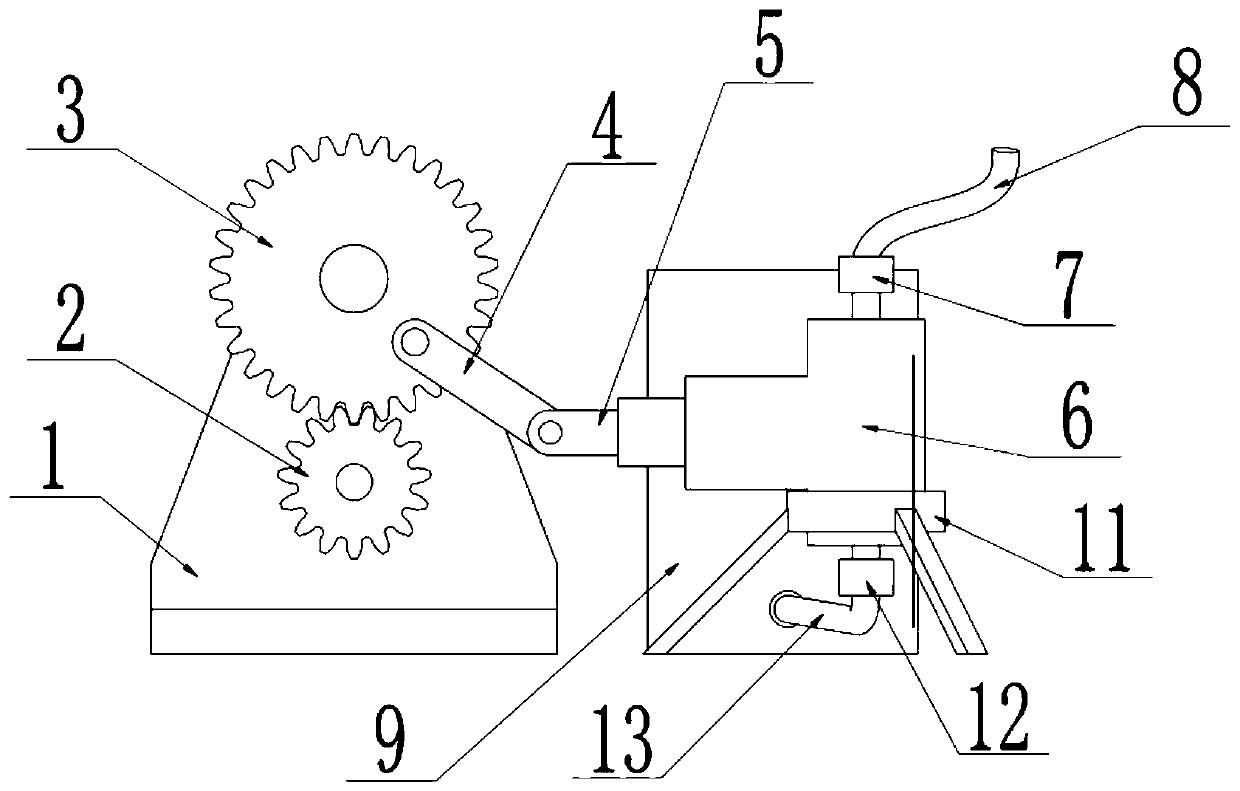

PendingCN110463575APrecision fertilizationPrecision irrigation and fertigationClimate change adaptationWatering devicesMotor speedGear wheel

The invention discloses a mobile drip irrigation and micro-spray irrigation fertilization device, and belongs to the technical field of drip irrigation and micro-spray.The device comprises a driving mechanism and a fertilization mechanism, wherein the driving mechanism comprises a rack, a pinion, a bull wheel, a connecting rod, a piston rod, a cylinder block, a motor, an output shaft, a coupling and a transmission shaft; the fertilization mechanism comprises a fertilizer box, a scale line, a one-way valve I, a water delivery pipe, a one-way valve II, a water absorption pipe, and a support frame.A fertilization method adopted by the device disclosed by the invention determines the use amount and proportion of fertilizer according to the law of fertilizer requirement in different growth periods of crops, and adjusts the appropriate range of motor speed according to the selection of the fertilization methods of drip irrigation and micro-spray irrigation and planting area, thereby realizing the conversion and use of drip irrigation and the micro-spray fertilization.According to the mobile drip irrigation and micro-spray irrigation fertilization device, the device is practical and convenient, the input cost is reduced, the fertilizer application amount and proportion are determined by considering the law of fertilizer requirement in different growth periods of the crops, and the specific use amount of water-fertilizer integrated fertilizer can be adjusted according to the concentration of liquid fertilizer and the rotation speed of the motor, so that the purpose of reasonable irrigation and fertilization is achieved.

Owner:GUANGXI UNIV

Production technology of dimethyl carbonate

InactiveCN106866417AIncrease productionReduce energy consumptionChemical industryPreparation from organic carbonatesChemistryDimethyl sulfite

Owner:SHANDONG DEPU CHEM IND SCI & TECH

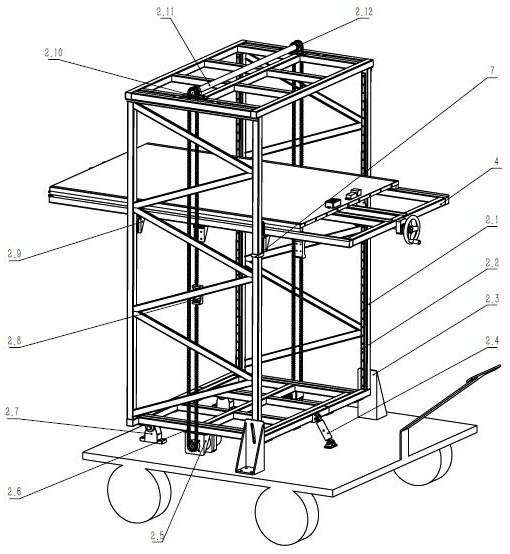

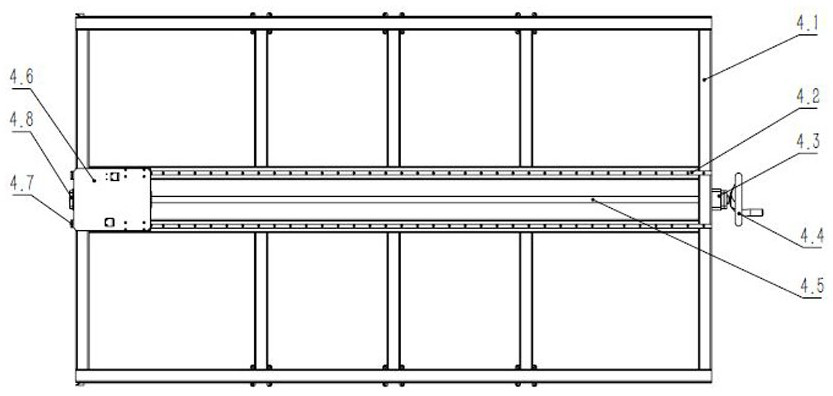

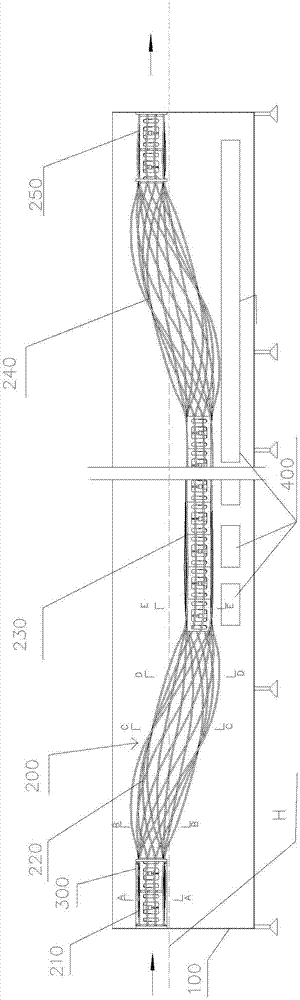

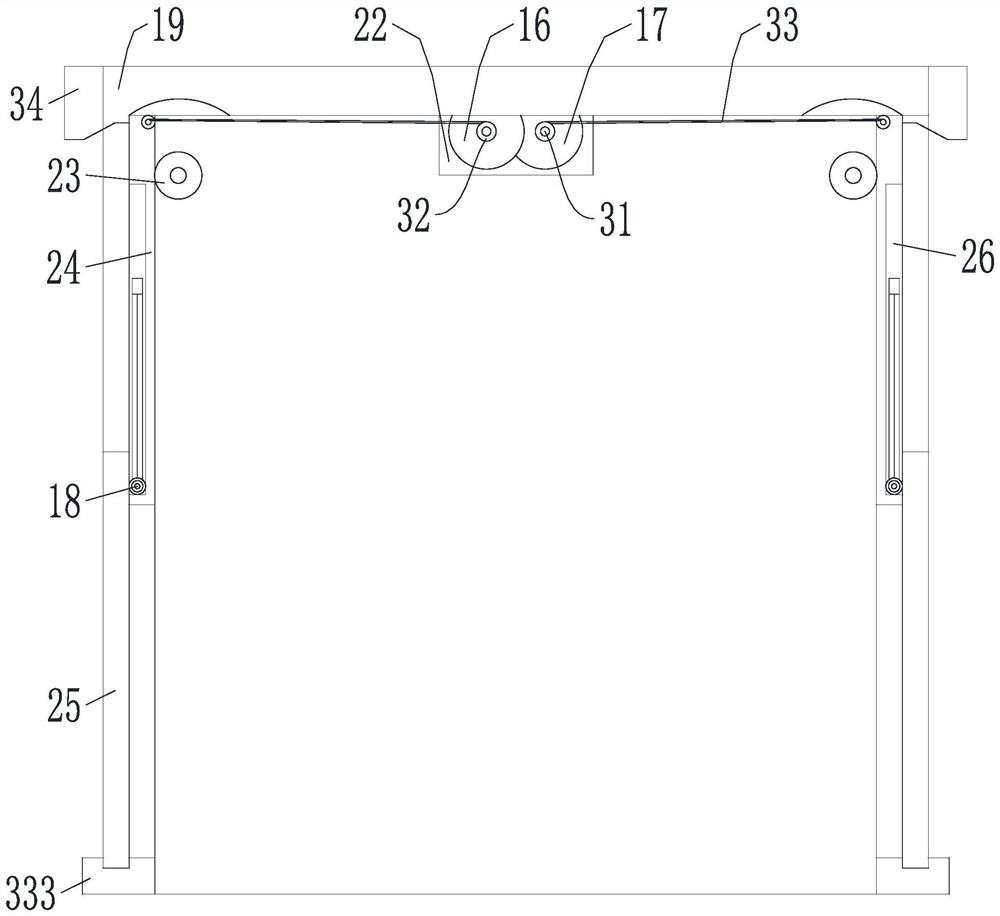

Equipment for replacing and maintaining battery of energy storage equipment

PendingCN111864133AReduce one-time investment costsLow investment costCell component detailsElectrical batteryStructural engineering

The invention discloses equipment for replacing and maintaining a battery of energy storage equipment, which comprises an electric flat car, wherein the electric flat car is provided with a lifting frame structure, a lifting platform structure is arranged on the lifting frame structure, the lifting frame structure drives the lifting platform structure to move up and down through a lifting chain, and after the lifting platform structure moves in place, the lifting platform structure drags out a battery bracket carrying a battery from a container for maintenance and replacement. The equipment has the advantages that the cost is low, the cost is saved, the maintenance or replacement difficulty is reduced, and the working efficiency is improved.

Owner:蓝谷智慧(北京)能源科技有限公司

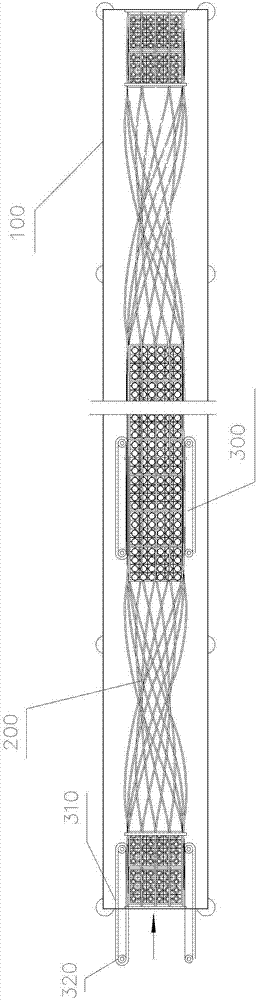

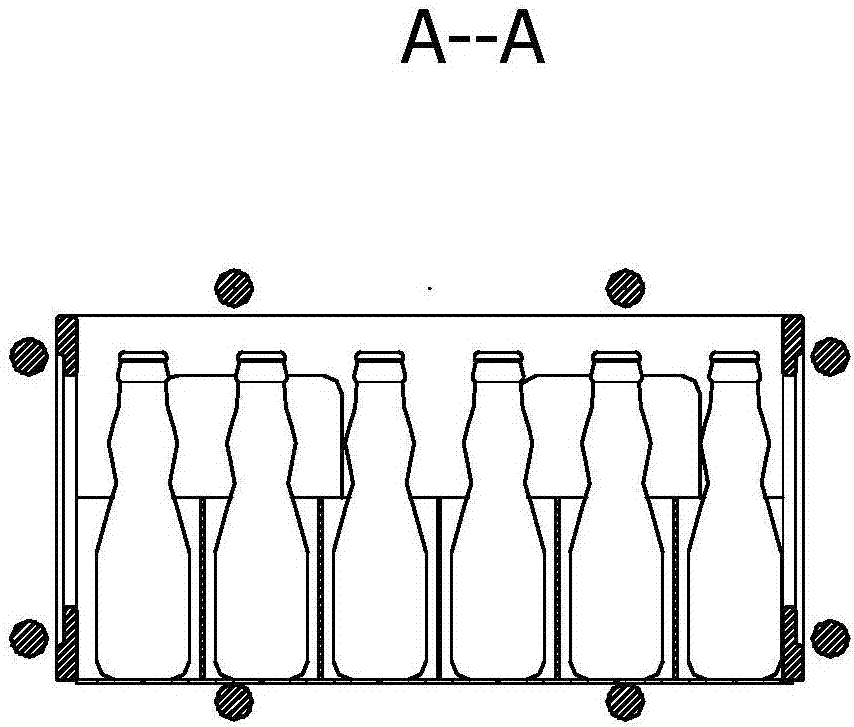

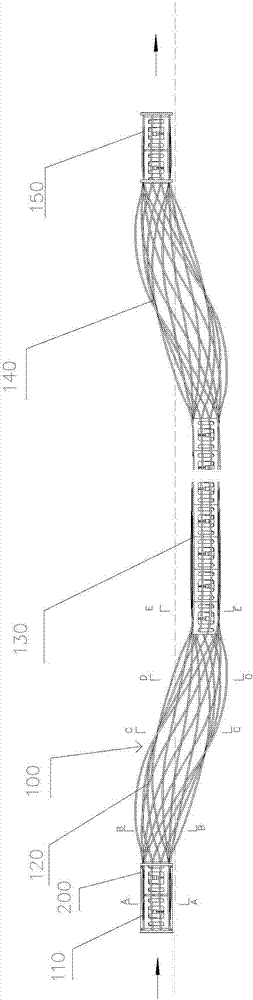

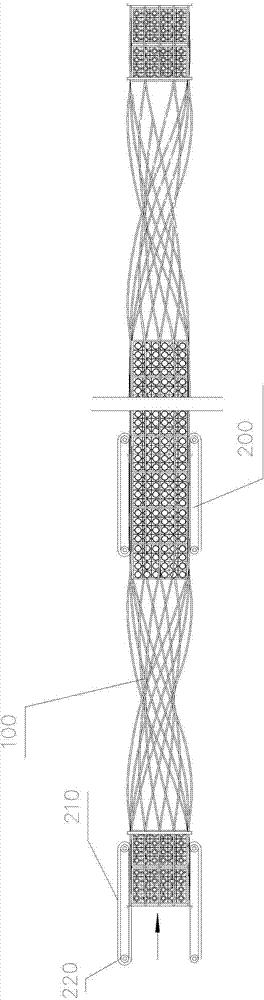

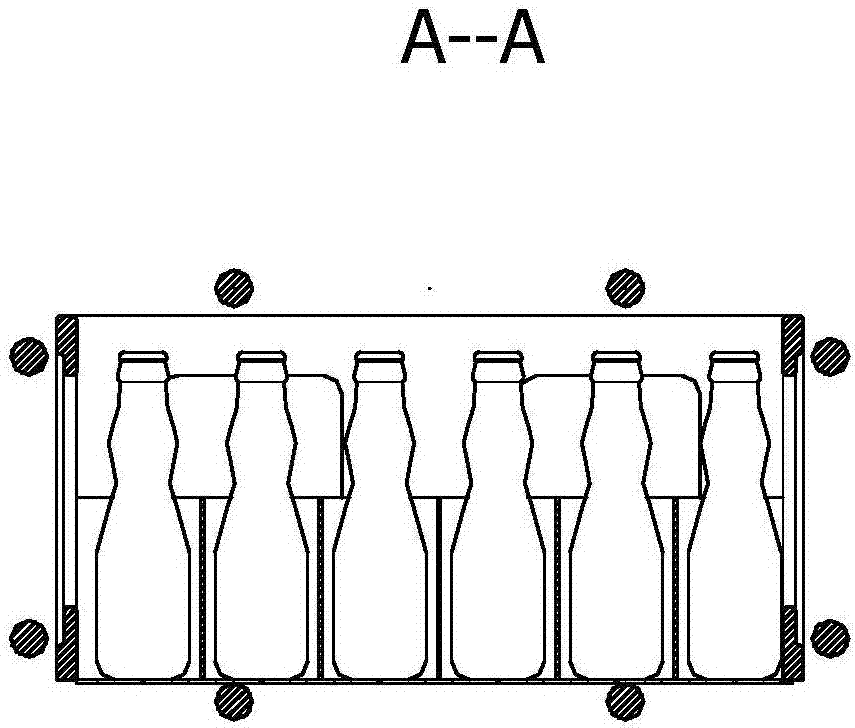

Spiral bottle box integral ultrasonic cleaning machine and method thereof

ActiveCN106944411APrevent falling outFall out surePlastic recyclingCleaning using liquidsProduction lineFailure rate

The invention relates to a spiral bottle box integral ultrasonic cleaning machine and a method thereof. The machine comprises a box body provided with cleaning liquid, and an ultrasonic generator arranged in the box body; a slide spiral cleaning channel for conveying boxes to be cleaned and a driving device are arranged in the box body; the slide spiral cleaning channel is positioned in the cleaning liquid of the box body, and two ends thereof are positioned on two sides of the box body; and two ends of the slide spiral cleaning channel are higher than the middle of the slide spiral cleaning channel. The slide spiral cleaning channel is put in the liquid in the box body for ultrasonic cleaning to greatly reduce needed transportation power; the box body slides on a slide spiral rail for operation, and is set as an overturning rotary structure for overturning repeated cleaning, so that the equipment volume is reduced; and meanwhile, the machine is low in once investment cost, convenient to install, less in occupied space, low in failure rate and free of after-scales repair troubles, and can be more liable to widely popularize and apply to a whole food beverage production line with glass bottles as containers.

Owner:蔡东宁

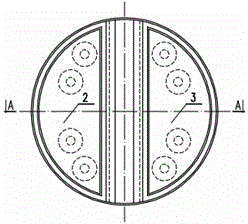

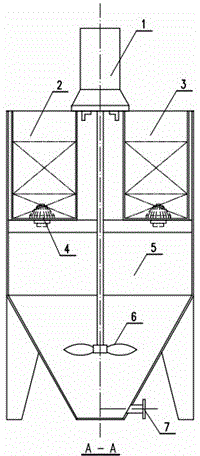

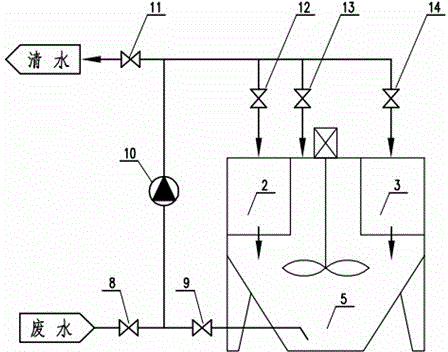

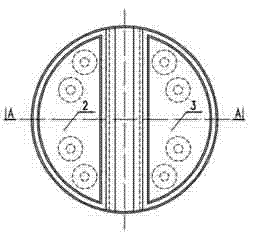

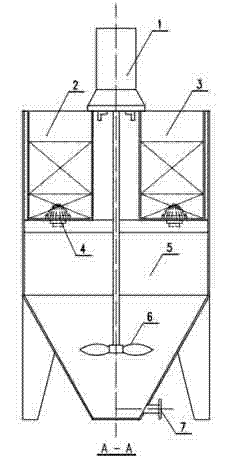

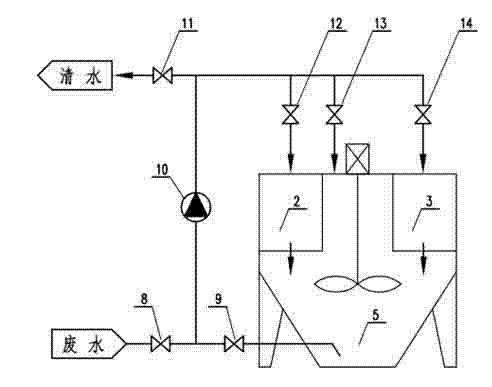

Sequencing batch wastewater processing device and its working method

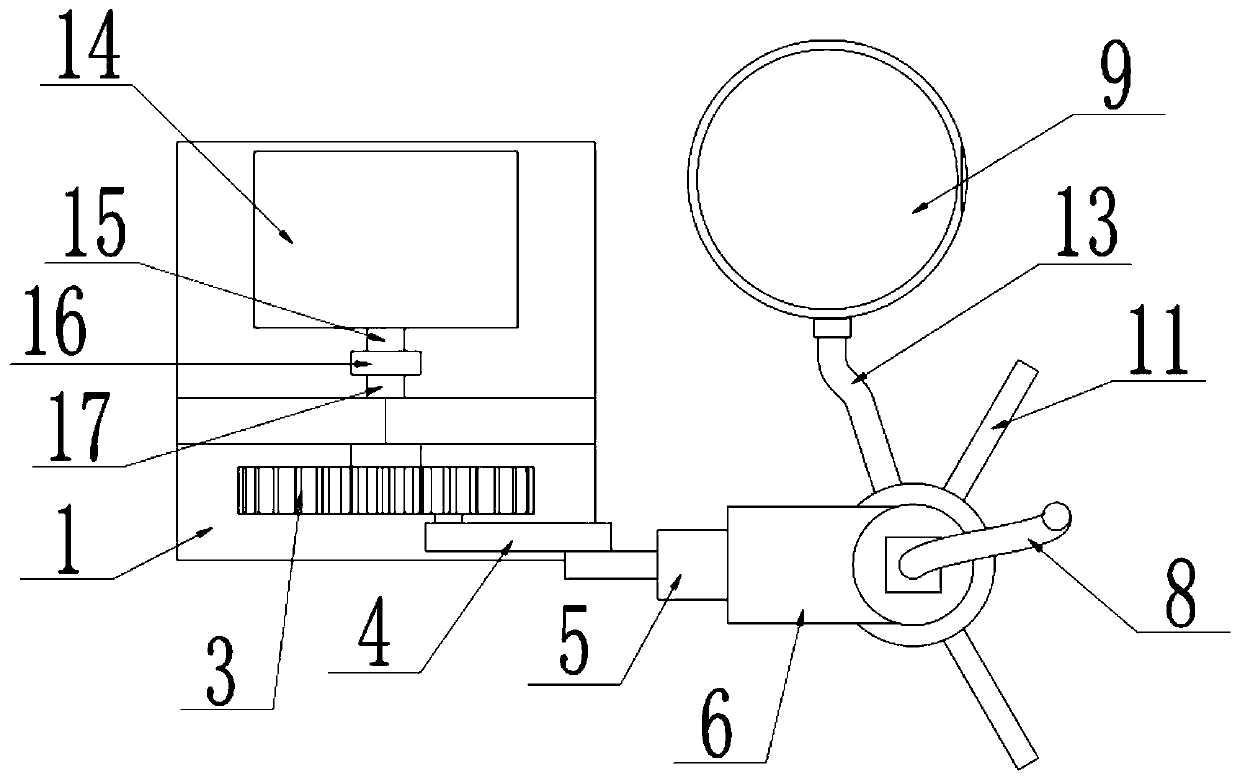

ActiveCN102295368BReduce one-time investment costsFlexible processMultistage water/sewage treatmentWater/sewage treatment by flocculation/precipitationMotor speedBatch processing

The invention discloses a sequencing batch wastewater processing device and its working method. The device provided by the invention comprises a housing and a motor speed reducer disposed on the top of the housing. An output shaft of the motor speed reducer extends downward to a main reaction zone inside the housing. The top of the output shaft is provided with stirring blades. A quartz sand filtering zone and an active carbon adsorption zone, which are separated from each other, are disposed inside the upper portion of the housing. The bottom of the quartz sand filtering zone and that of theactive carbon adsorption zone are both provided with a water filtering cap. According to the invention, the functions of dosing mixing reaction, flocculation reaction, gravity deposition, sand filtering, active carbon adsorption and the like are integrated into one device, thus reducing one-time investment cost; the sequencing batch processing technology is flexible so as to decrease maintenance links and personnel expenditure; and the waterpower gravity flow characteristic is fully utilized, thus greatly minimizing operation energy consumption

Owner:江苏倬誉环保科技有限公司

A kind of preparation method of high-purity n-hexane

ActiveCN110229042BEasy to prepareSimple processDistillation purification/separationHydrocarbonsIsohexanesPtru catalyst

The invention provides a method for preparing high-purity n-hexane, comprising the following steps: a) performing hydrogenation reaction on reformed C5 oil and hydrogen under the action of a hydrogenation catalyst, and separating C5 light components from the liquid phase product after the reaction , to obtain the remaining heavy components; b) separating the remaining heavy components obtained in step a) with isohexane to obtain heavy components after de-isohexane; c) separating the heavy components after de-isohexane obtained in step b) with n-hexane , to obtain high-purity n-hexane. Compared with the prior art, the preparation method provided by the present invention uses reformed C5 oil as raw material, and adopts a specific process to prepare high-purity n-hexane. The preparation method provided by the present invention has simple process, low cost, no pollution, and can run stably for a long time ; and the purity of the prepared high-purity n-hexane is above 99%, and the product quality is stable.

Owner:SHANDONG CHAMBROAD PETROCHEMICALS CO LTD

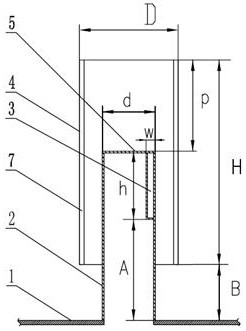

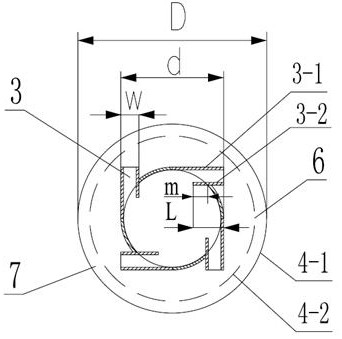

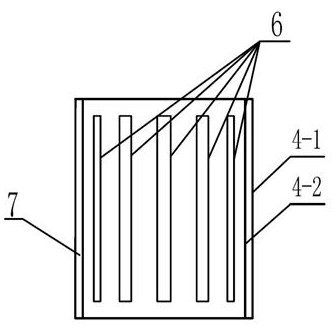

A cyclone demister

ActiveCN111298523BAvoid secondary entrainmentImprove removal efficiencyGas treatmentDispersed particle separationEngineeringMechanical engineering

The invention discloses a cyclone demister. The cyclone demister includes several defogging assemblies, each defogging assembly includes a riser pipe and an outer cylinder, the outer cylinder is arranged on the outside of the riser pipe, and is on the same axis as the riser pipe; the riser pipe is fixed on On the tray, a cover plate is set on the top of the gas riser, and a rectification channel is set on the circumference of the gas riser; the wall of the outer cylinder includes an inner wall and an outer wall, and the inner wall and the outer wall are hollow structures, and the hollow structure is closed at the top and open at the bottom . The demister of the present invention realizes the separation of liquid droplets and gases through the rectification, acceleration and scraping effect of the fluid in the flow process. The mist eliminator of the present invention has simple structure, high mist removal efficiency, single-layer arrangement can effectively realize gas-liquid separation, and satisfies the requirement of carrying amount of mist in gas.

Owner:CHINA PETROLEUM & CHEM CORP +1

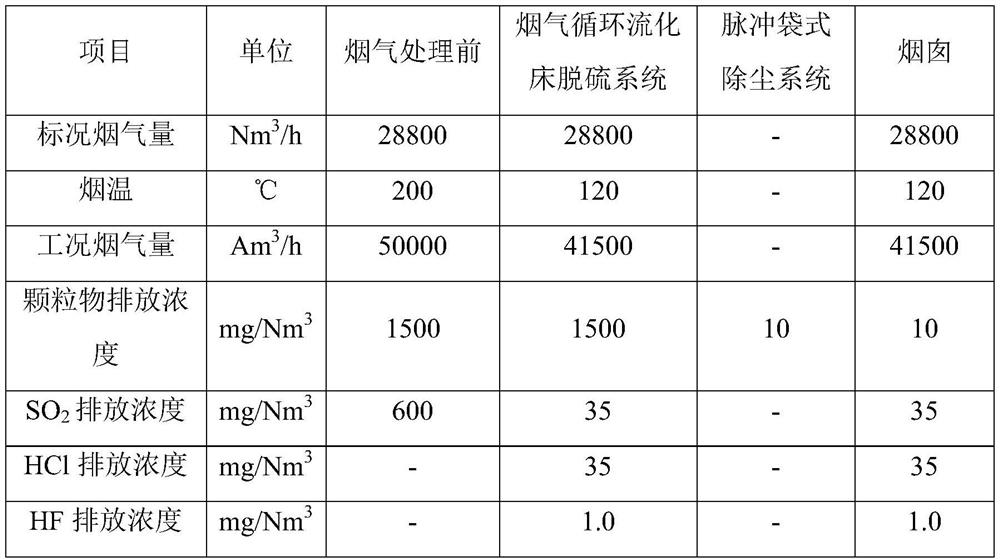

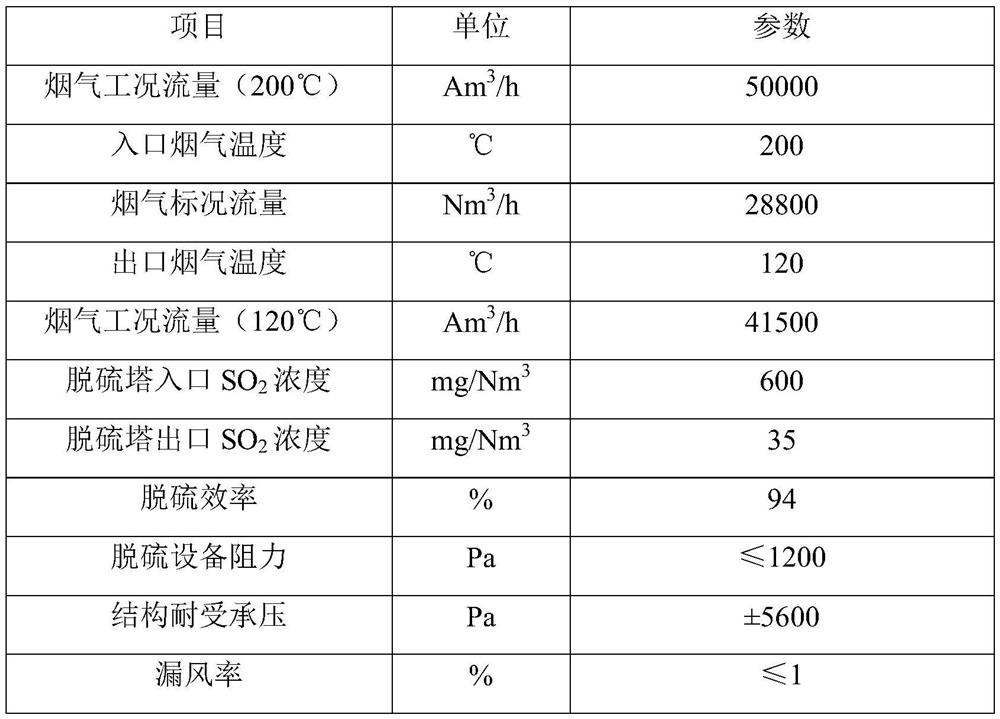

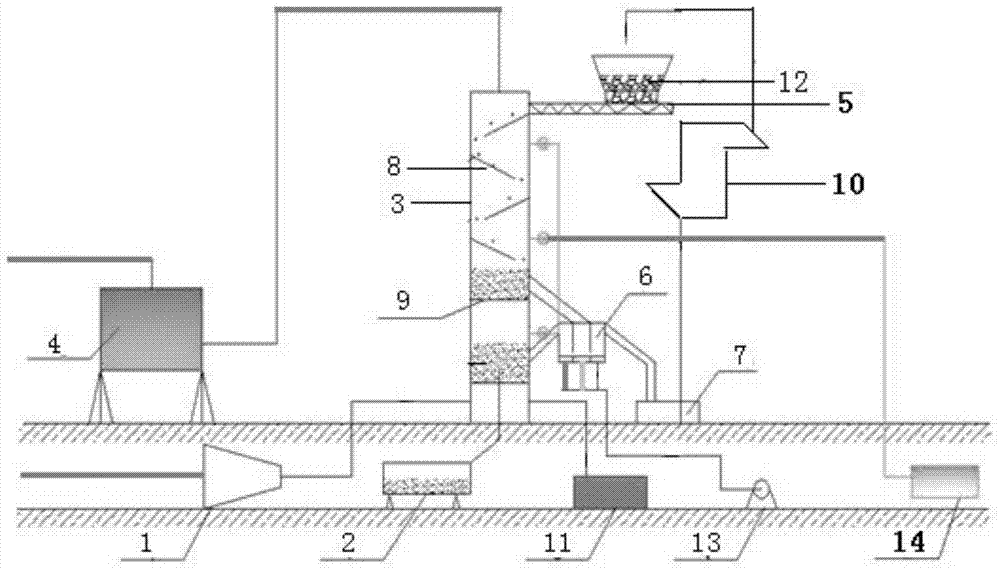

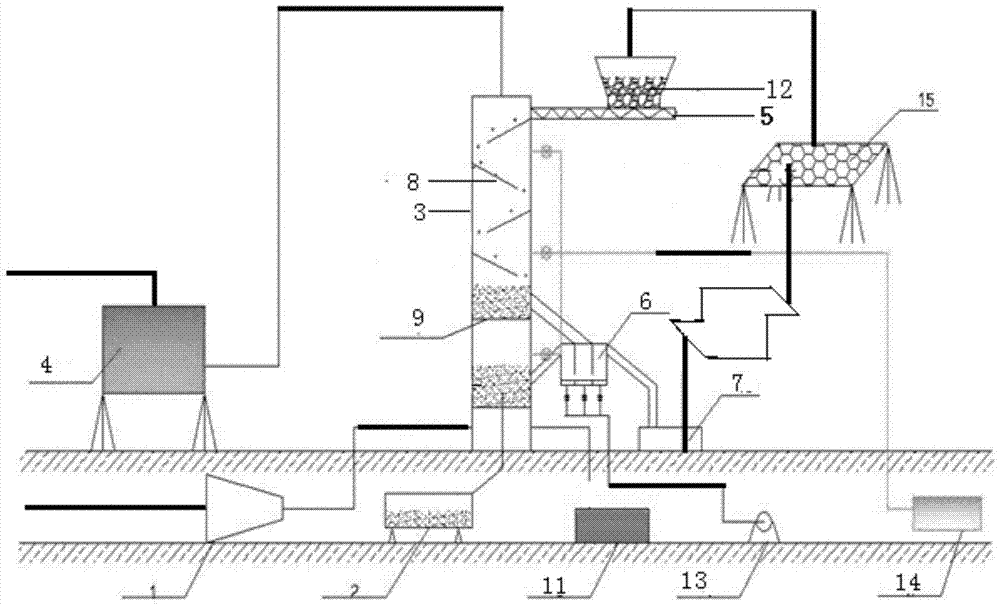

Semi-dry desulfurization and dust removal method for sludge sintering ceramic ceramsite waste gas

PendingCN113144877AMeet governance standardsMeet emission standardsCombination devicesGas treatmentTemperature controlSludge

The invention provides a semi-dry desulfurization and dust removal method for sludge sintering ceramic ceramsite waste gas, and relates to the technical field of environmental protection. A semi-dry desulfurization and dust removal system is adopted for waste gas treatment and comprises a desulfurization system, a lime system, a temperature control and humidification system, a dust removal system, an adsorption system and a discharge system. The waste gas treatment process comprises the following steps: desulfurization: introducing the sludge sintering ceramic ceramsite waste gas into a desulfurization tower, and reacting the waste gas with a desulfurization material in the desulfurization tower for desulfurization; dust removal: introducing the desulfurized waste gas into the dust removal system for dust removal; adsorption: introducing the waste gas into the adsorption system to adsorb volatile organic compounds; and discharging: introducing the desulfurized and dedusted waste gas into the discharge system, and discharging the qualified waste gas after detection. The method not only can meet the up-to-standard discharge requirement, but also can simplify the process route, reduce one-time investment and operation cost, reduce the occupied area, and can greatly reduce the generation of wastewater and wet smoke plume.

Owner:JIANGMEN TONGLI ENVIRONMENTAL PROTECTION TECH

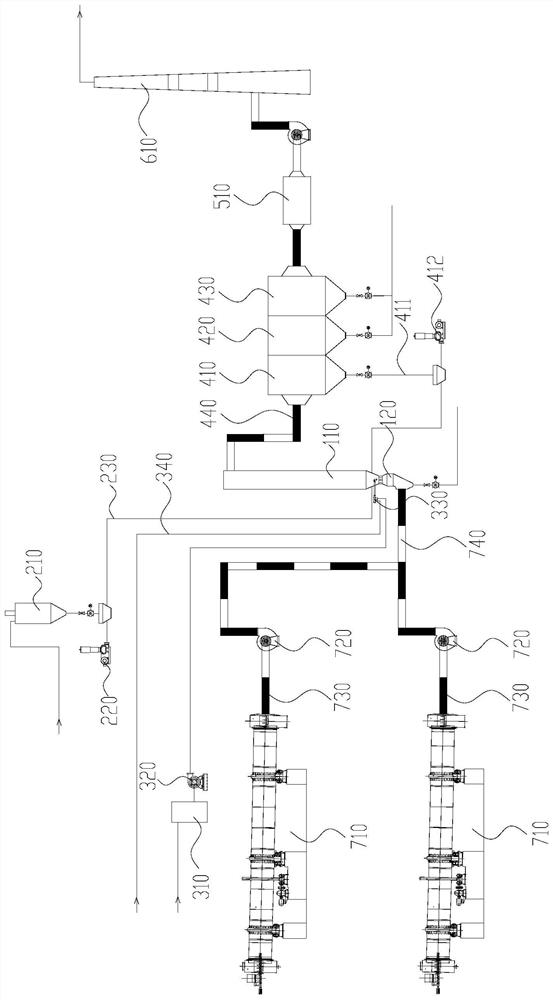

A multi-layer heterogeneous fluidized bed device for activated carbon desulfurization

ActiveCN105435577BRelieve pressureReduce energy consumptionDispersed particle filtrationHigh temperature storageActivated carbon

The present invention proposes a multi-layer heterogeneous fluidized bed device for activated carbon desulfurization, which is characterized in that it includes a booster fan, a cooling machine, an absorption tower, a dust collector, a feeder, a distribution valve, a storage device and a high-temperature hoist, The booster fan is connected to the lower side of the absorption tower, the cooling machine is connected to the bottom of the absorption tower, the top of the absorption tower is connected to the dust collector, the discharge port of the feeder is connected to the upper side wall of the absorption tower, and the distribution valve It is connected to one side of the absorption tower, and the storage equipment is connected to the distribution valve. There are n convection baffles installed on the upper part of the absorption tower, n≥2, and m layers of distribution plates are installed below, m≥2. The feed of the high-temperature elevator The outlet is connected to the outlet of the storage equipment, and the outlet of the high-temperature elevator is connected to the inlet of the feeder. The multi-layer heterogeneous fluidized bed device for activated carbon desulfurization of the present invention has the advantages of high desulfurization efficiency, low operation and maintenance costs, and the like.

Owner:BEIJING SPC ENVIRONMENT PROTECTION TECH

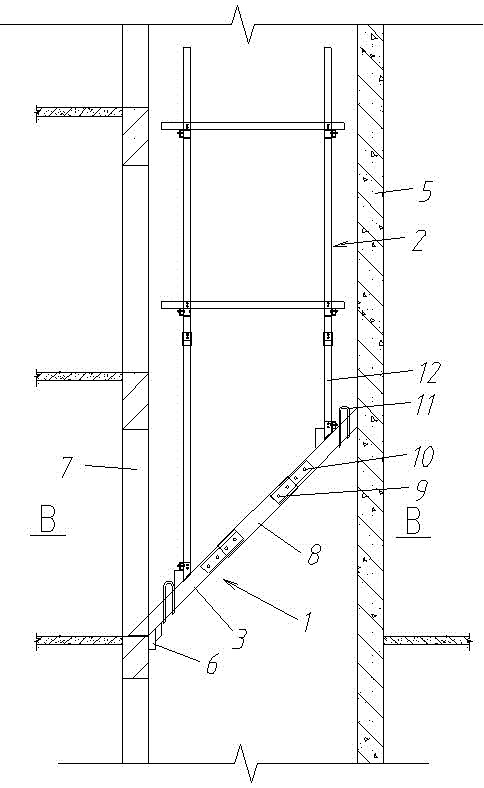

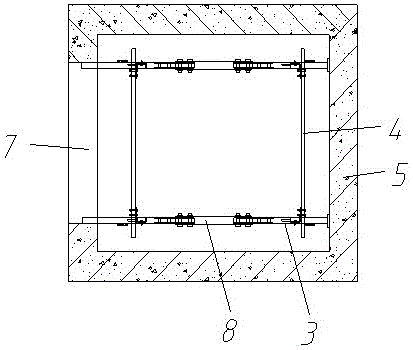

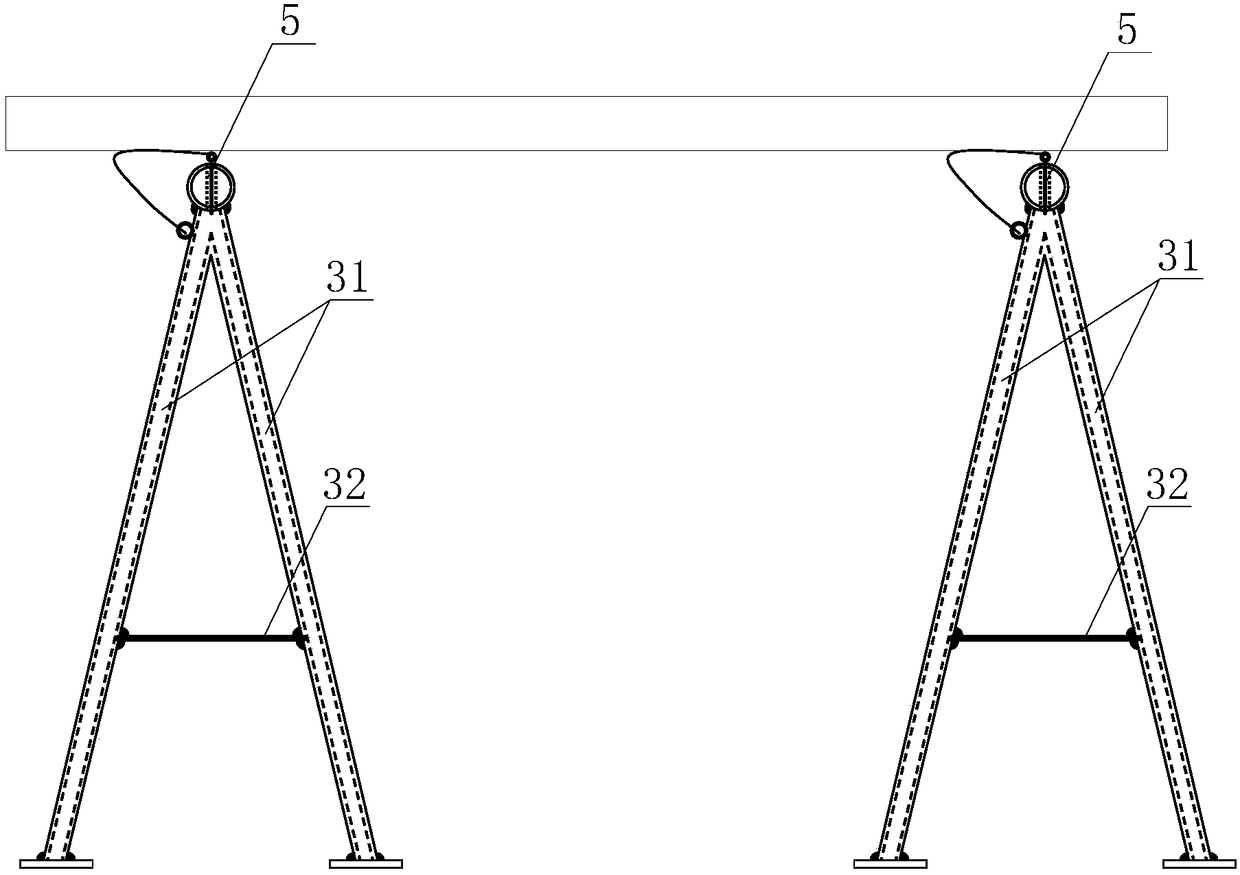

Elevator shaft section steel construction operation platform

InactiveCN103498551BEasy to useStressfulBuilding support scaffoldsEngineeringUltimate tensile strength

The invention discloses a lift shaft section steel construction operating platform which is mainly composed of a base and platform frames installed on the base. The base includes two pieces of parallel H-shaped oblique support section steel, and two section steel transverse linkage beams are arranged between the two pieces of oblique support section steel. The higher end of each piece of oblique support section steel is supported on one wall of a lift shaft, a corbel is additionally arranged at the lower end of each piece of oblique support section steel and supported on a lift shaft door opening external corner. The positions of flange upper surface, close to the two ends, of each piece of oblique support section steel are respectively provided with a platform frame locating column, the platform frames are constructed with fastener-style steel pipes, and platform frame locating columns are sleeved with steel pipes which form the four legs of the platform frames. Due to the fact that the lift shaft section steel construction operating platform is high in strength, the safety of operating personnel can be more guaranteed; besides, the lift shaft section steel construction operating platform is applicable to lift shafts with different inner space sizes, thereby being strong in universality.

Owner:重庆市南岸区建设工程施工安全监督站

Interior wall scaffold for masonry and using method thereof

The invention provides an interior wall scaffold for masonry and a using method thereof. The interior wall scaffold comprises a supporting member and a cross rod, one end of the cross rod is fixedly connected onto the supporting member while the other end of the same is fixedly connected with angle steel for being inserted into an interior wall vertical seam, and a length ratio of the cross rod tothe angle steel is 5-10:1. Assembly structures can all be made by welding short and old steel pipes, angle steel and rebars, so that waste is utilized, the interior wall scaffold is low in primary investment expense, simple in operation and convenient to mount and demount, cost is lowered, and production efficiency is improved. The angle steel is inserted into the interior wall vertical seam, sothat scaffold holes left on a wall are avoided, the process of blocking the scaffold holes after wall masonry is completed is omitted, and construction speed is accelerated.

Owner:内蒙古华立建设工程有限公司

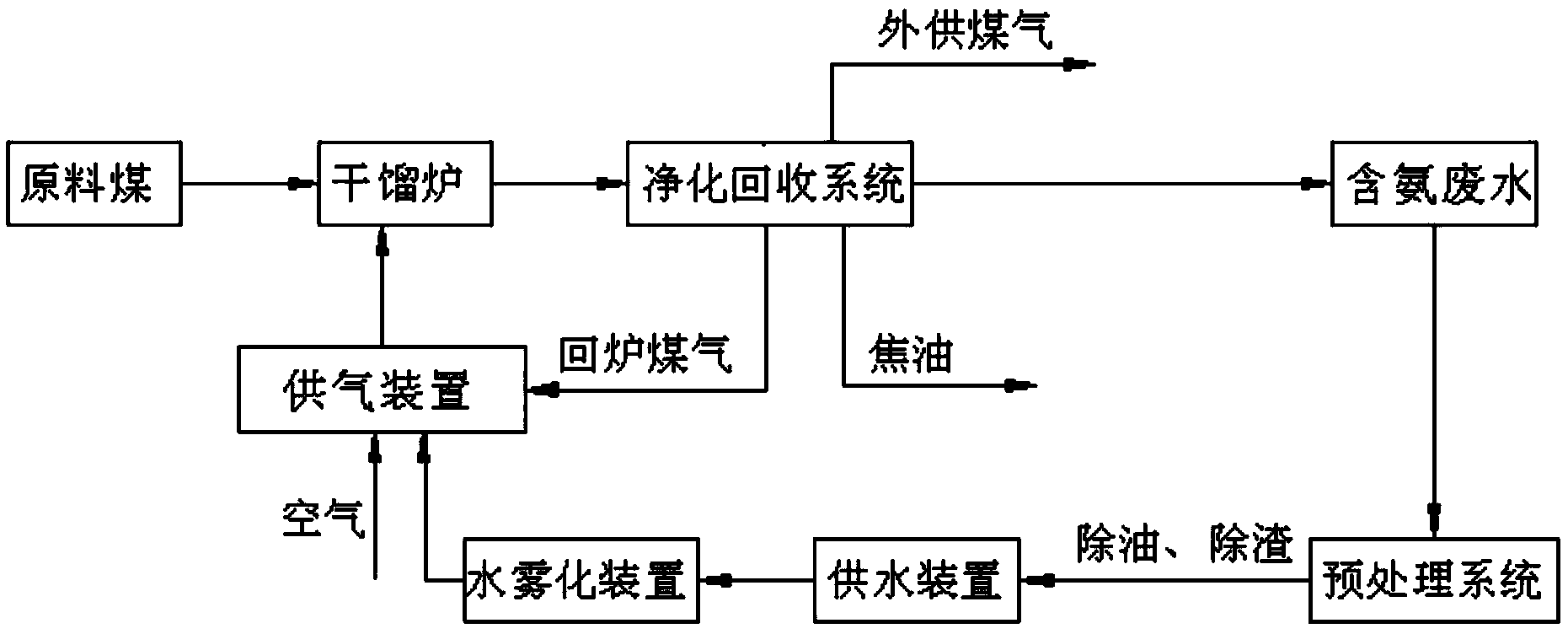

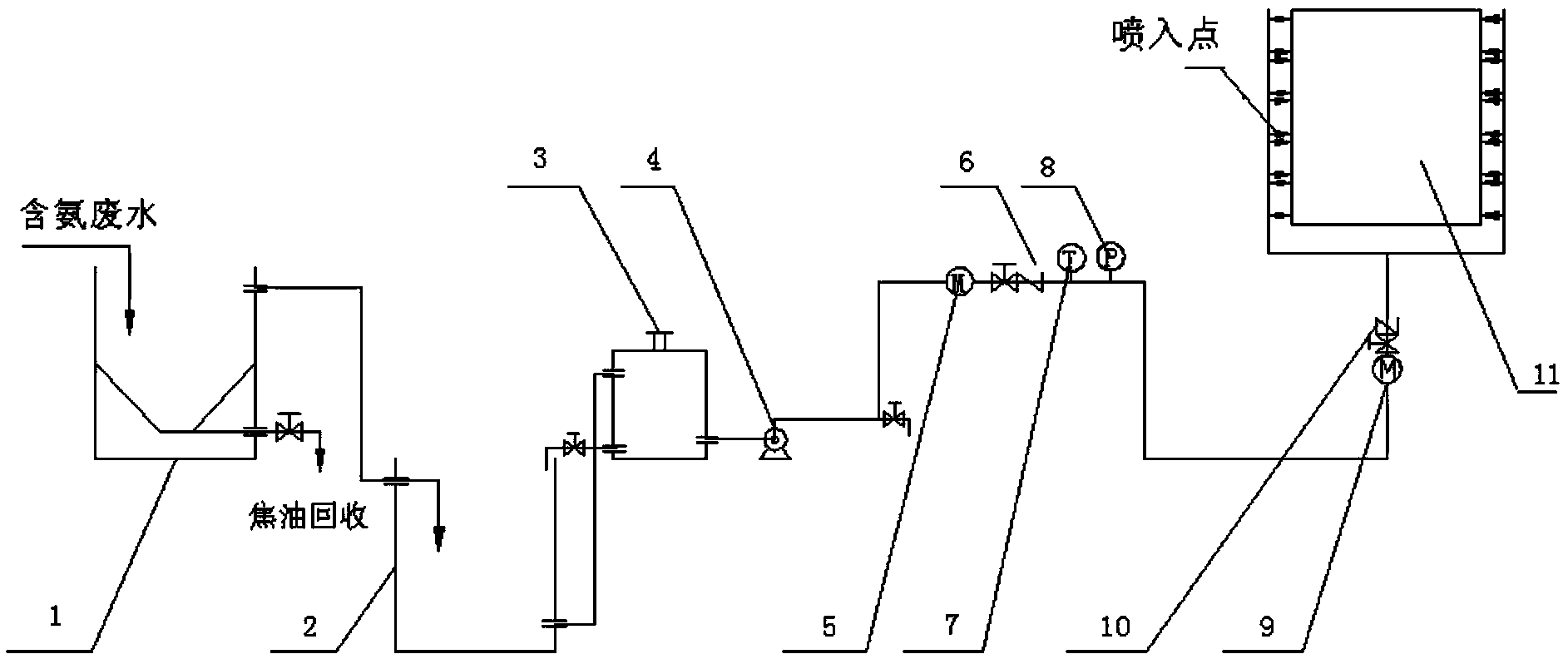

Ammonia-containing wastewater treatment method and system for blue carbon production

ActiveCN103693793BAchieve harmless treatmentImprove water qualityMultistage water/sewage treatmentWater vaporHazardous substance

The invention discloses a treatment method and a treatment system of an ammonia-containing wastewater in semi-coke production, belonging to the technical field of a coal chemical industry. The method comprises the following steps: firstly, filtering ammonia-containing wastewater produced in the semi-coke production process; removing greasy dirt and residues in the wastewater, and then conveying the ammonia-containing wastewater to an air supply device of a dry distillation furnace through a pipeline; spraying mixed and atomized ammonia-containing wastewater and air into the dry distillation furnace so as to decompose a hazardous substance in the ammonia-containing wastewater by high temperature inside the dry distillation furnace; carrying out water-gas reaction on water vapor and raw material coal in the dry distillation furnace, and completely processing the ammonia-containing wastewater, so as to achieve innocent treatment. Compared with the traditional treatment technologies such as a biochemical process and a burning method, the technique is simple and feasible to implement, and simple and convenient to operate, the existing equipment can be transformed under the production state, and the ammonia-containing wastewater is effectively processed.

Owner:SHAANXI SHENMU SAN JIANG COAL CHEM

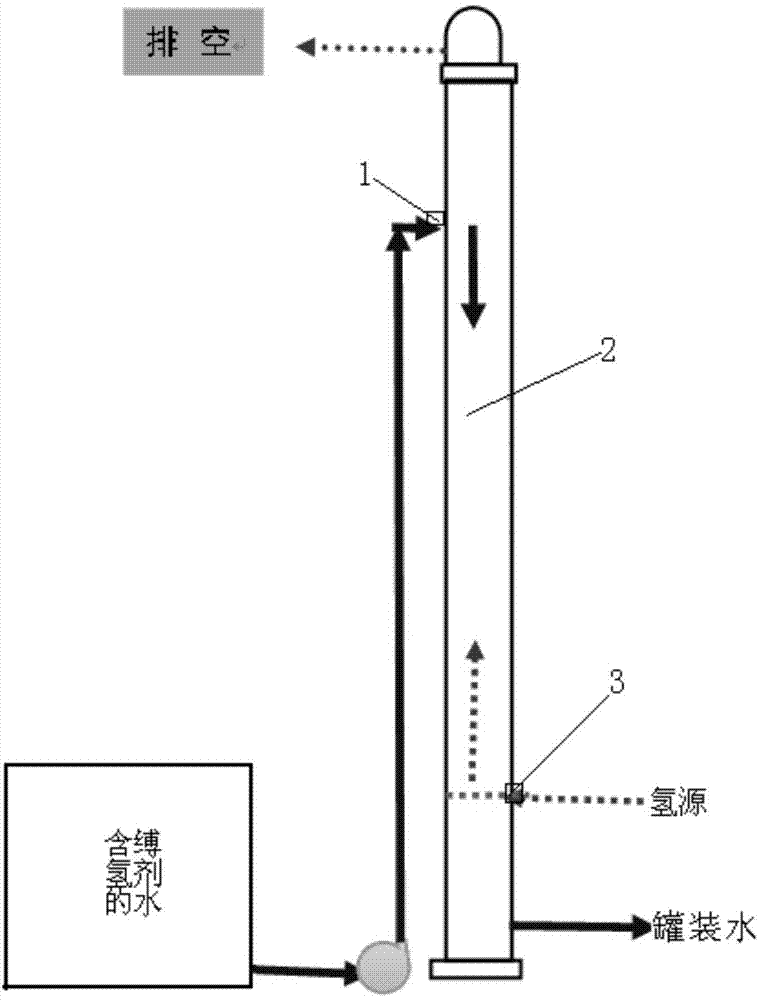

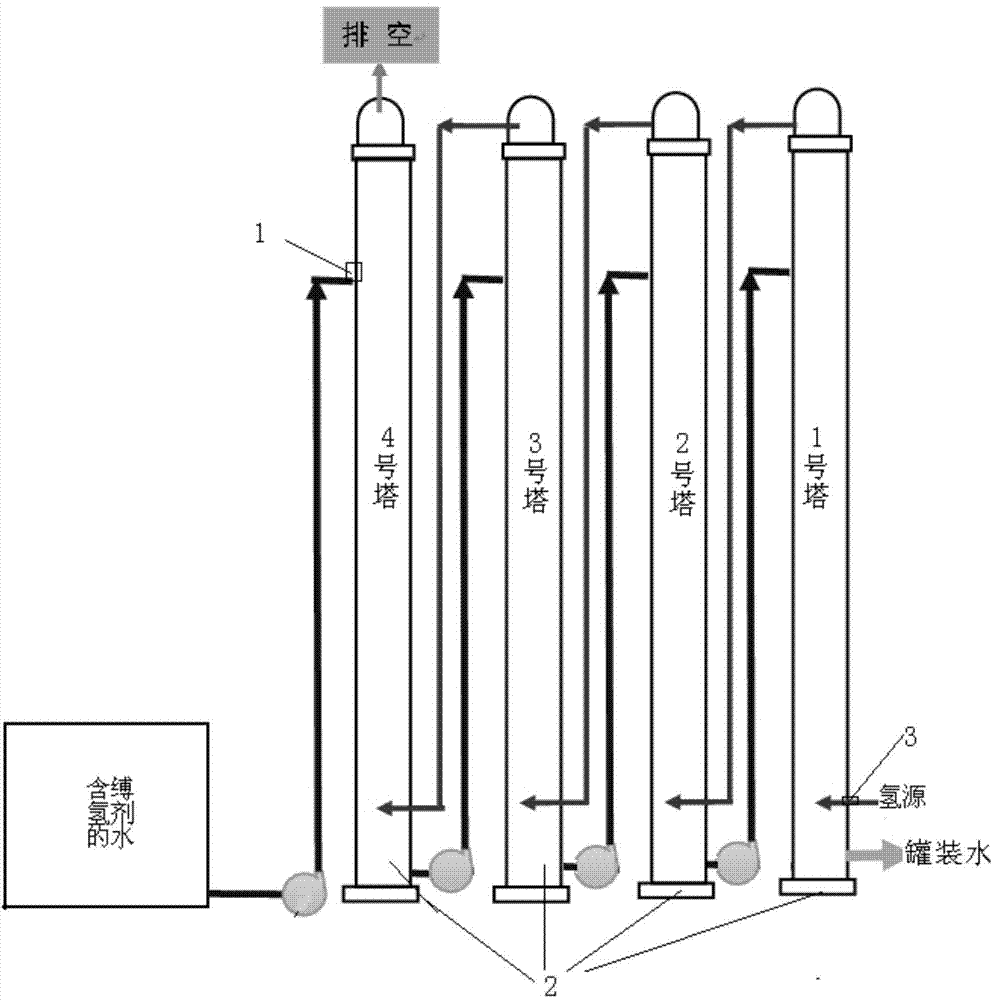

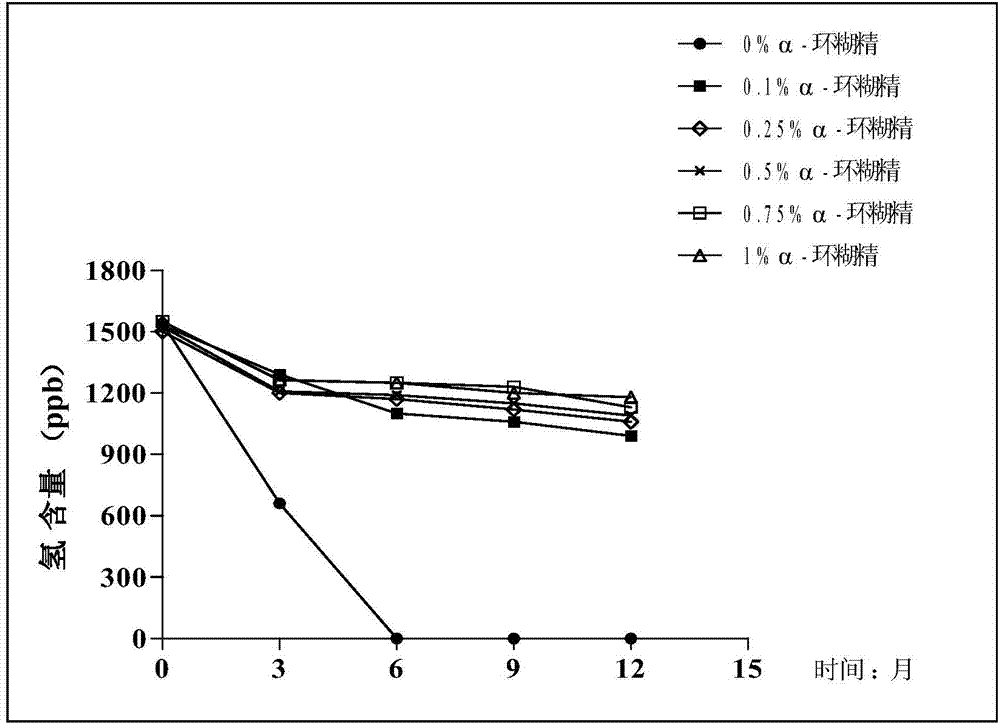

Method for cheaply preparing long-acting hydrogen-rich water

ActiveCN104016471BComposition is stableStable hydrogen concentrationWater/sewage treatment by substance additionProduction lineHydrogen concentration

A method for cheaply preparing long-acting hydrogen-rich water comprises the following steps: step 1, uniformly stirring a hydrogen-binding agent and drinking water to obtain a solution; step 2, transferring the solution obtained in the step 1 to an absorption tower via pipes, so as to cause counter-flow mixing of a gas phase and a liquid phase in the absorption tower because hydrogen at the lower part of the absorption tower runs from bottom to top, and fully contacting the gas phase and the liquid phase to reach absorption balance; and step 3, enabling superfluous hydrogen to flow out from the top of an absorption tower at the terminal of the production line, and enabling hydrogen-rich water saturated with dissolved hydrogen to flow out from the bottom of the absorption tower, and loading by using glass bottles so as to obtain long-acting hydrogen-rich water. According to the method, the hydrogen concentration of hydrogen-rich water at normal temperature under normal pressure reaches 1500 ppb, and the hydrogen concentration still is 1000 ppb or more after the hydrogen-rich water is stored for 12 month by adding a hydrogen-binding agent, and the requirements for industrialized production and commercialized operation are reached.

Owner:XI AN JIAOTONG UNIV

Submerged arc furnace smoke residual heat utilization method of dust remover with exhaust cylinder

InactiveCN108088268AContinuous and stable productionImprove cooling effectIncreasing energy efficiencySteam engine plantsElectric consumptionEngineering

The invention discloses a submerged arc furnace smoke residual heat utilization method of a dust remover with an exhaust cylinder. The method is characterized in that exhaust smoke in a submerged arcfurnace is exhausted out through a fourth hole, and cold air is mixed into the exhaust smoke through a water cooling sliding sleeve, carbon monoxide gas is combusted, obtained smoke enters a combustion settling chamber, and according to the action of the combustion settling chamber, the smoke flow speed is reduced, large-particle dust carried in smoke is subject to sedimentation, cold air is properly mixed in, finally, carbon monoxide gas is burnt off, the smoke passing through the combustion settling chamber enters a heat storage temperature uniformity device, the heat storage temperature uniformity device comprises a smoke inlet, a carbon iron composite material heat storage body, a sound wave ash clearing device, a smoke outlet and an ash bucket; the carbon iron composite material heatstorage body is arranged between the smoke inlet and the smoke outlet, the sound wave ash clearing device is arranged in the carbon iron composite material heat storage body in a segmented manner. The dust remover is provided with the exhaust cylinder, steel consumption amount of the exhaust cylinder and civil engineering investment are reduced, running electric consumption is reduced, and the running cost of a dust removal system can be reduced.

Owner:无锡市东优环保科技有限公司

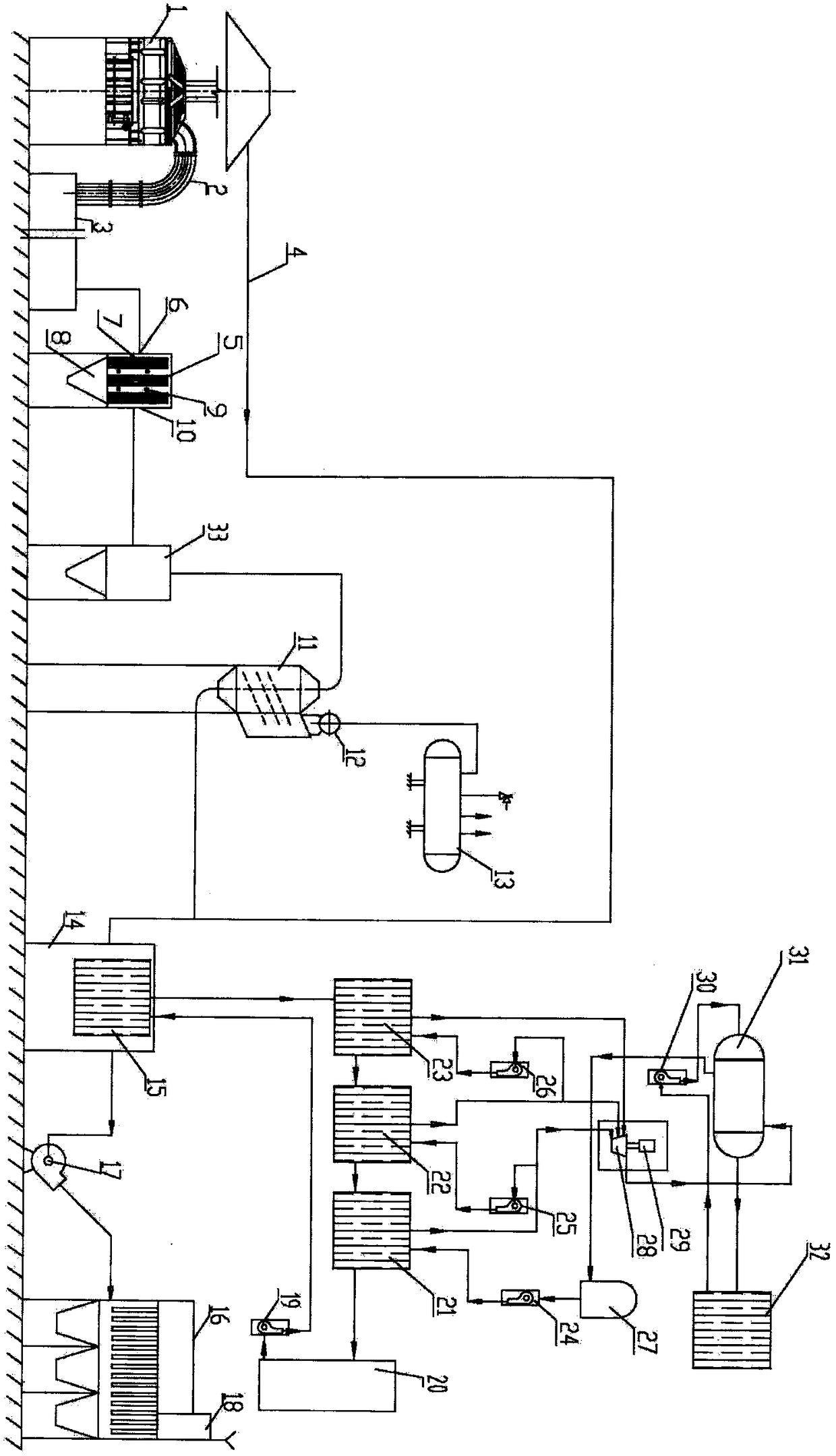

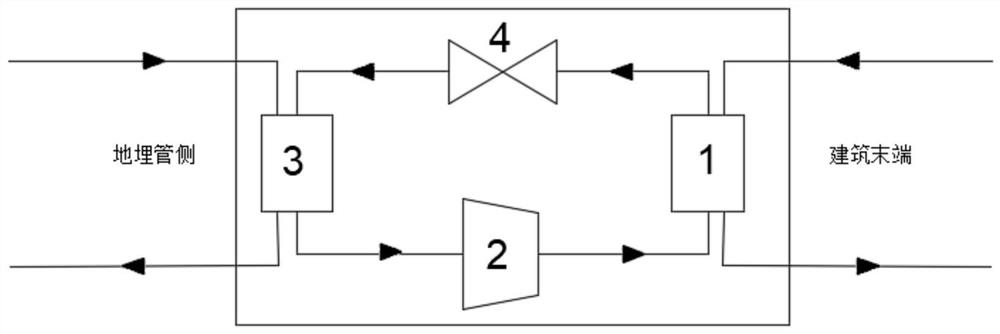

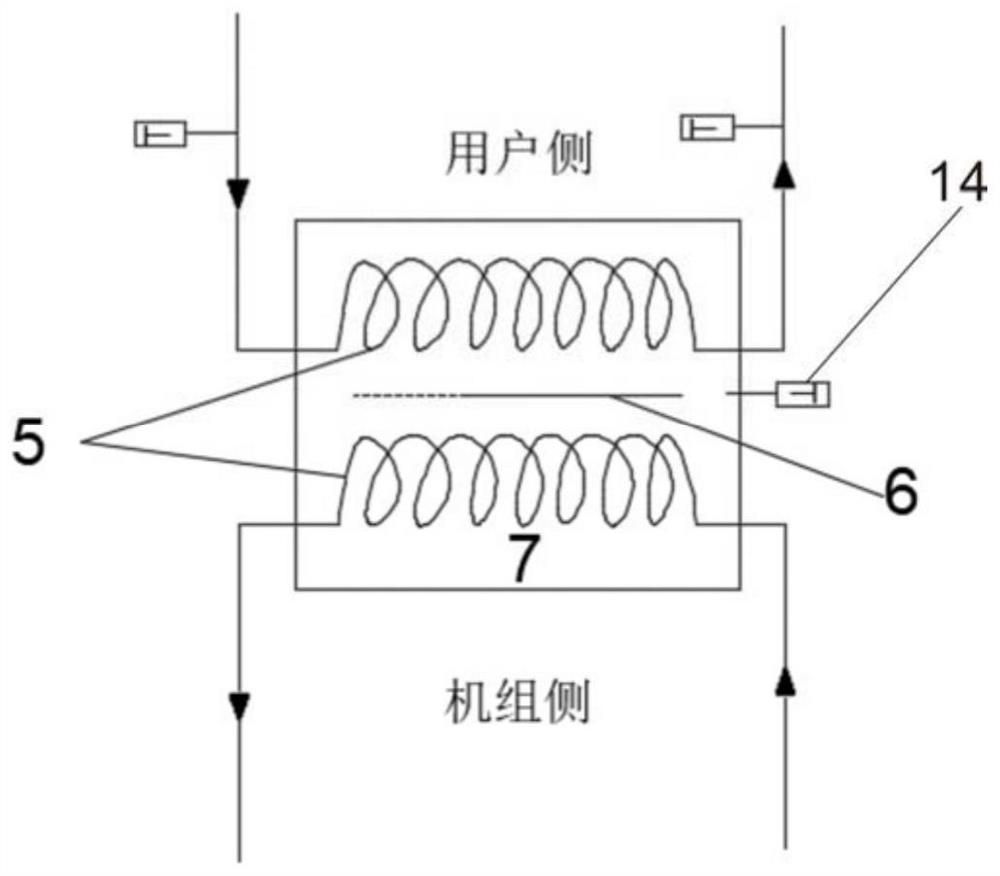

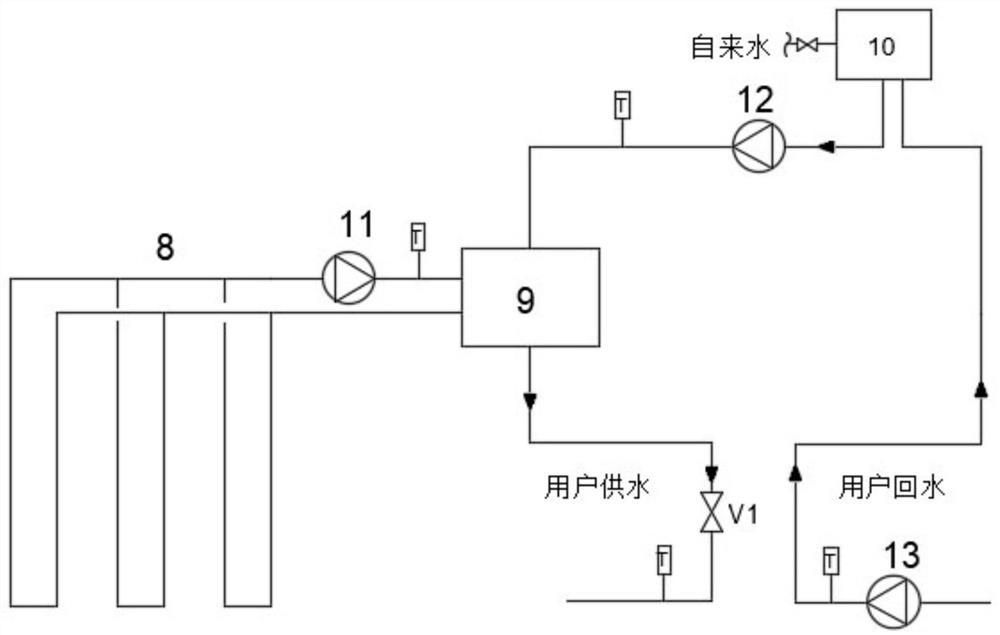

Ground source heat pump integrated with phase change energy storage module and heating system

PendingCN114087643AReduce peak loadReduce capacityCentral heating with accumulated heatHeat storage plantsHeating systemEvaporator

The invention relates to a ground source heat pump integrated with a phase change energy storage module and a heating system. The ground source heat pump comprises a unit body, an evaporator, an expansion valve, a compressor and a phase change condenser, wherein the evaporator, the expansion valve, the compressor and the phase change condenser are arranged in the unit body, and the phase change condenser comprises a condenser body, two heat exchange coils arranged in the condenser body and a phase change material filled in the condenser body. A traditional ground source heat pump device and the phase change energy storage module are integrated, a part of building load is borne, and therefore the peak load of the system is reduced, the host capacity of the system is reduced, the number of buried pipes is reduced, and the one-time investment cost is reduced; meanwhile, the phase change material is added into the condenser body, the phase change process of the phase change material is fully utilized, the sensitivity of the unit to the indoor tail end load change is reduced, the time for the return water temperature to reach the unit operation stopping temperature is prolonged, the start-stop period of the unit is prolonged, the start-stop frequency of the unit is reduced, and long-term stable operation of the unit is facilitated.

Owner:TIANJIN UNIV

Energy storage wall and its use

The energy storing wall has energy storing apparatus installed inside the wall or near the wall, and the energy storing apparatus consists of energy storing box, energy storing unit comprising gap dn heat insulating layer, electric heating element, heat exchange coil pipe, electric controlling box, temperature controller, high water level controller, water pipe, heat exchange circulating pipe and cold and warm circulating pipe. The energy storing wall accumulates the cold or heat energy from the night valley electric energy, solar energy and air energy. It may be used in various kinds of building, especially energy saving building, and it is economic and environment friendly.

Owner:魏鸿申

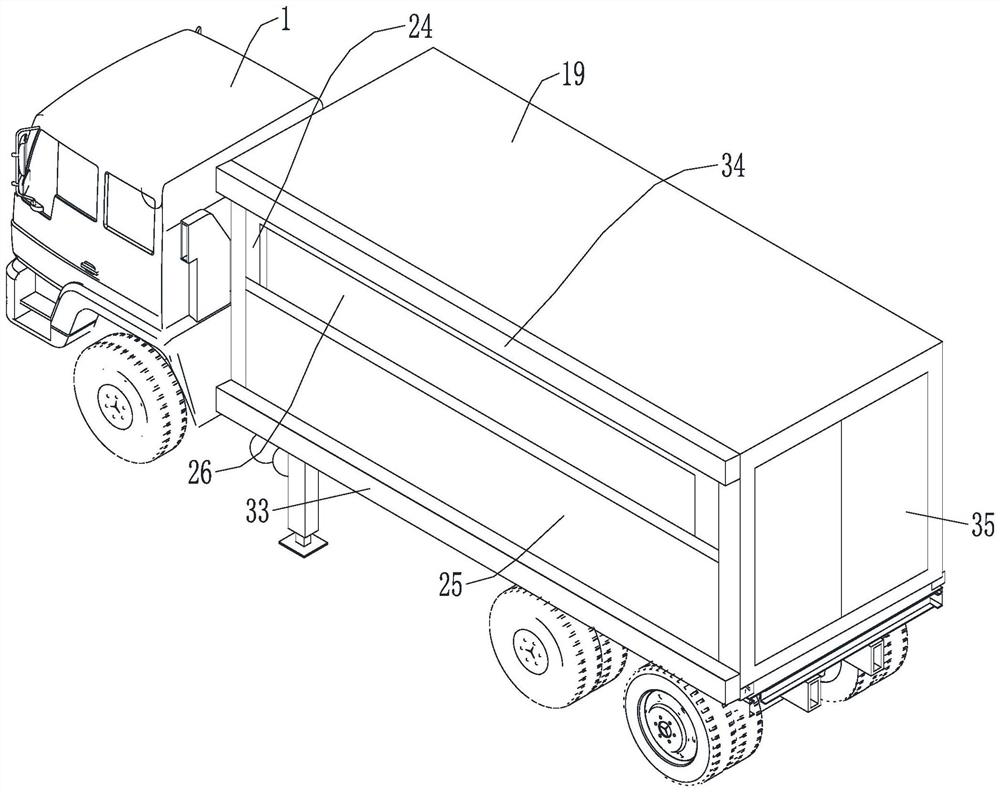

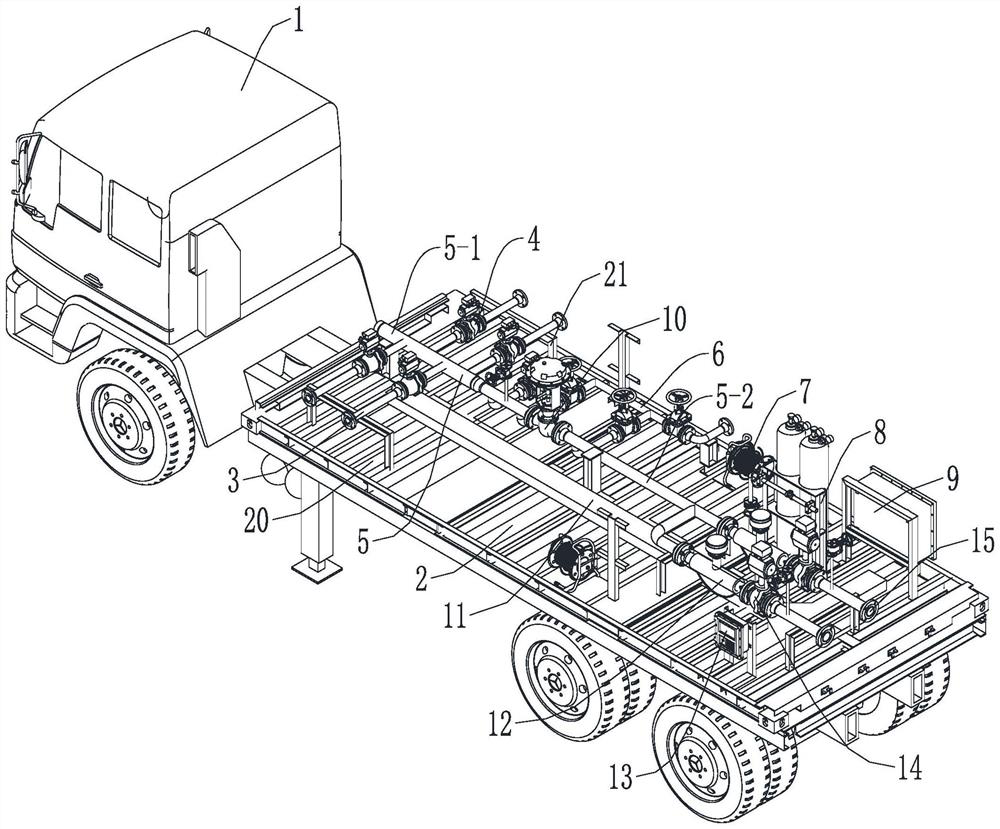

Movable kerosene fuel filling sledge

PendingCN113895663ALow investment costGood mobilityCosmonautic ground equipmentsLiquid transferring devicesTruckIn vehicle

The invention relates to the technical field of rocket kerosene filling, in particular to a movable kerosene fuel filling sledge which comprises a container tank car and a 20-inch container type chassis. According to the movable kerosene fuel filling sledge, a plurality of rented kerosene tank cars with pumps are used for replacing conventional kerosene cars and on-site pump trucks, and a vehicle-mounted quantitative filling skid is used for replacing on-site filling pipelines, so that the one-time investment cost is reduced; the filling sledge comprises a flow regulating valve, an emergency cut-off valve, a mass flow meter, a pressure transmitter and other valve instrument assemblies, and the filling task can be safely and quantitatively completed; the quantitative filling skid chassis is designed according to the mounting form of a 20-inch container and can be conveniently mounted on a container trailer, the maneuverability of the pump truck and the quantitative filling truck is good, a launching site is saved, and transition is facilitated; compared with outdoor arrangement, the vehicle-mounted filling skid is good in storage condition, easy to maintain and longer in service life.

Owner:JIANGSU CHANGLONG PETROCHEM EQUIP

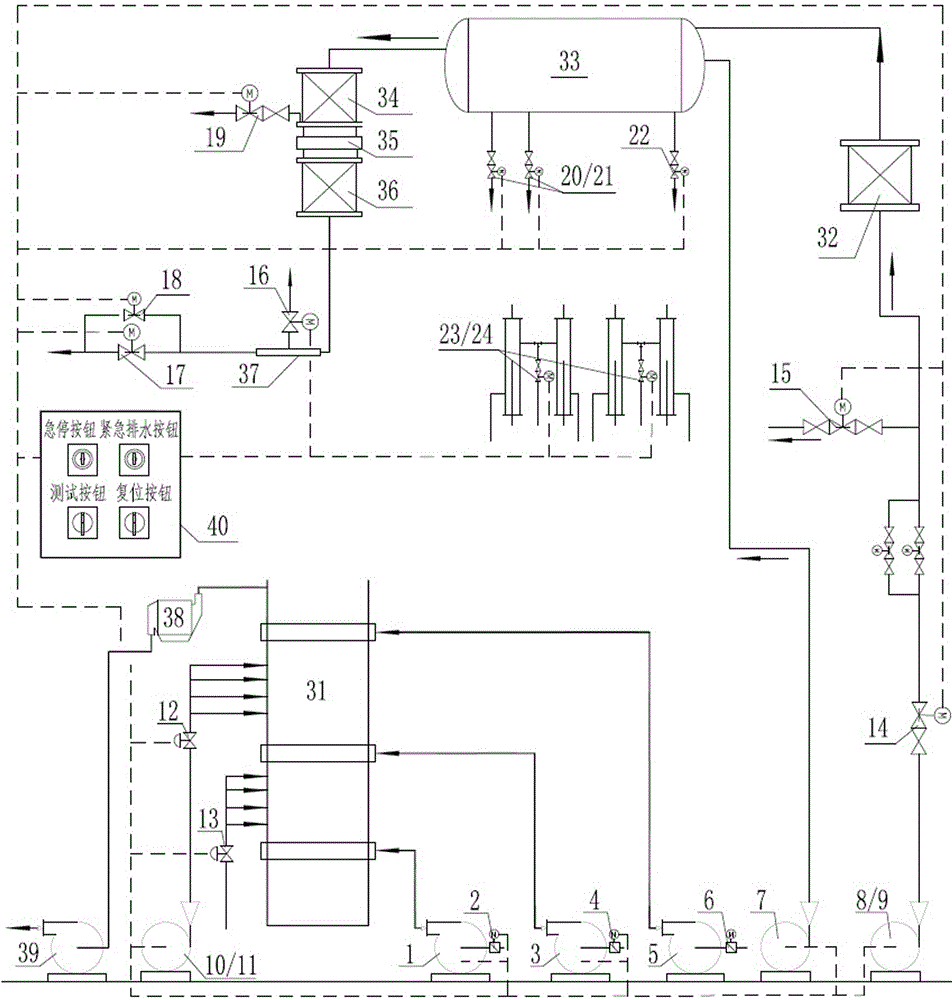

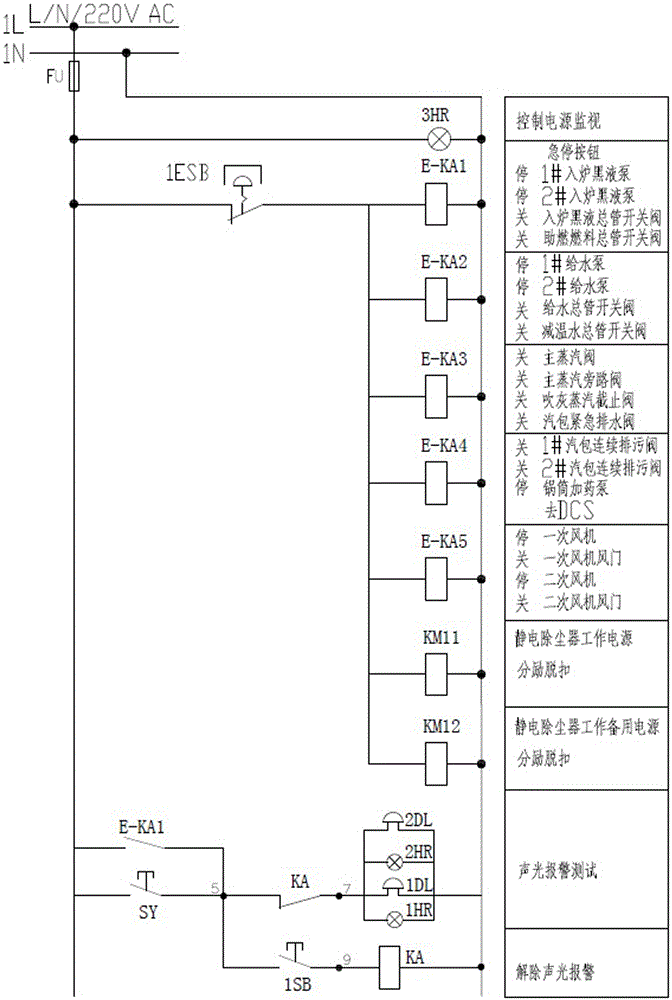

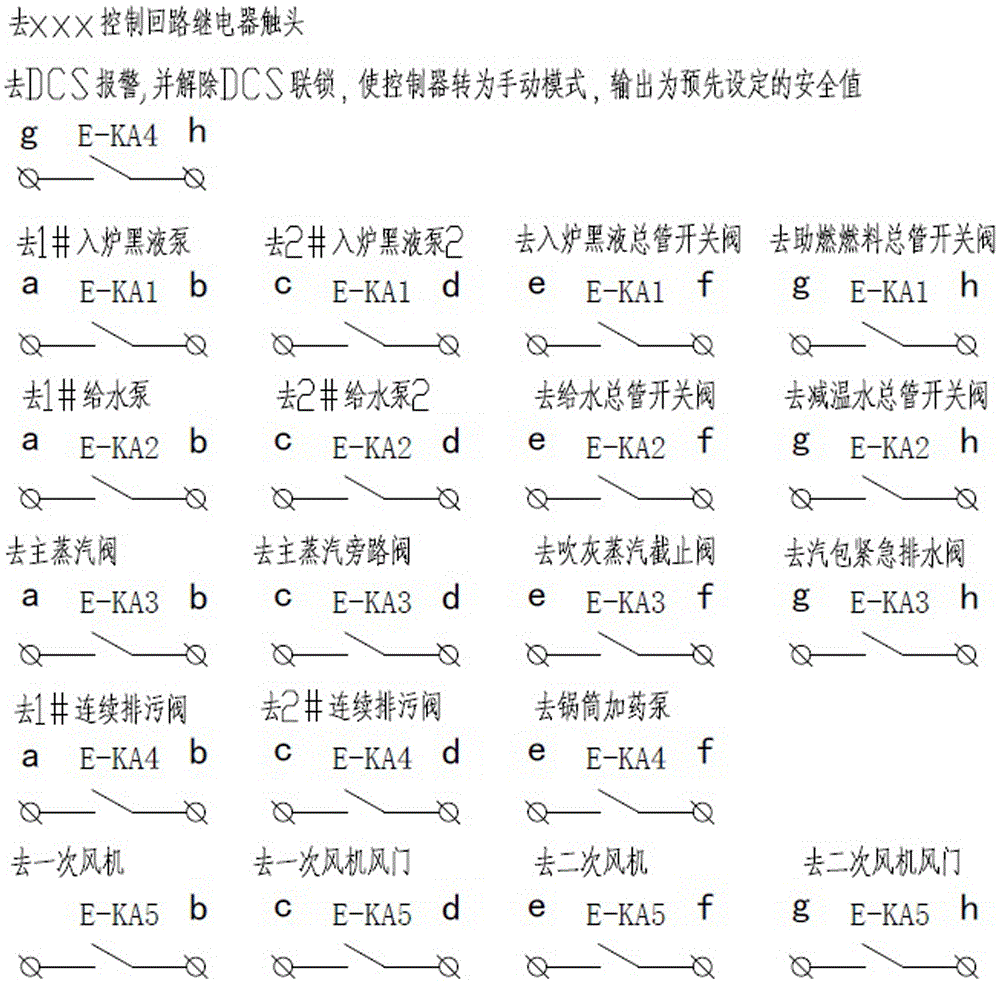

Emergency furnace-stop system of bagasse slurry factory black liquor alkali-recovery furnace

InactiveCN105484087AHighlight substantiveSignificant progressPulp liquors combustionBlack liquorSlurry

An emergency furnace-stop system of a bagasse slurry factory black liquor alkali-recovery furnace includes an emergency stop control panel, an emergency furnace-stop button, an emergency water drain button, a test button, a mute button, a set of emergency furnace-stop control circuit and a set of emergency water drain control circuit, the emergency furnace-stop button, the emergency water drain button, the test button and the mute button are arranged on the emergency stop control panel, by an emergency furnace-stop control button and an emergency water drain control button, a relay control circuit is used to switch a control valve and other equipment which affect operation safety to a safe mode for emergency water drain, at the same time a sound-light alarm system is started to alert personnel within a production area to evacuate. An emergency furnace-stop procedure can be executed independently, accurately, completely and rapidly in a short time, accidents or worsen situations can be prevented, the safety of operating personnel and equipment can be protected, and loss can be minimized.

Owner:CHINA LIGHT IND NANNING DESIGN ENG

Efficient spiral sliding cleaning orbit for bottle boxes

The invention relates to an efficient spiral sliding cleaning orbit for bottle boxes. The efficient spiral sliding cleaning orbit comprises spiral bottle box guide rails for stopping other four sides except for the motion directions of the bottle boxes; the spiral bottle box guide rails for stopping the other four sides form a spiral sliding cleaning channel for rotatably cleaning the bottle boxes; two sides of the spiral bottle box guide rails located on the open surfaces of the bottle boxes are also provided with a plurality of anti-drop guide rails; and each of the distance between every two adjacent anti-drop guide rails and the distance between each anti-drop guide rail and the spiral bottle box guide rail located on the open surfaces of the bottle boxes is smaller than the external diameter of a bottleneck of each of glass bottles. By using the efficient spiral sliding cleaning orbit, power required by transportation is greatly reduced, and each of box bodies operates by sliding along the spiral sliding cleaning orbit and is arranged to be of an overturning and rotating structure to ensure that the box bodies are overturned and cleaned repeatedly, so that the equipment volume is reduced, meanwhile, the disposable equipment investment expense is low, and the efficient spiral sliding cleaning orbit is convenient to mount, small in space occupation, low in equipment fault rate and free of after-sales repair troubles and can be relatively easily and widely popularized and used in food and beverage production lines taking the glass bottles as vessels.

Owner:蔡东宁

A batch type wastewater treatment equipment and its working method

ActiveCN102295368AReduce one-time investment costsFlexible processMultistage water/sewage treatmentWater/sewage treatment by flocculation/precipitationMotor speedWater filter

The invention discloses a sequencing batch wastewater processing device and its working method. The device provided by the invention comprises a housing and a motor speed reducer disposed on the top of the housing. An output shaft of the motor speed reducer extends downward to a main reaction zone inside the housing. The top of the output shaft is provided with stirring blades. A quartz sand filtering zone and an active carbon adsorption zone, which are separated from each other, are disposed inside the upper portion of the housing. The bottom of the quartz sand filtering zone and that of theactive carbon adsorption zone are both provided with a water filtering cap. According to the invention, the functions of dosing mixing reaction, flocculation reaction, gravity deposition, sand filtering, active carbon adsorption and the like are integrated into one device, thus reducing one-time investment cost; the sequencing batch processing technology is flexible so as to decrease maintenance links and personnel expenditure; and the waterpower gravity flow characteristic is fully utilized, thus greatly minimizing operation energy consumption

Owner:江苏倬誉环保科技有限公司

Full-automatic production line of building blocks made of industrial waste and gypsum

InactiveCN1189296CHigh precisionExpand production scaleMixing operation control apparatusCeramic shaping plantsProduction lineLocking mechanism

A full-automatic production line for making the building gypsum blocks from industrial dregs is characterized by that between batching station and multi-station injection moulding system there are slope-type screw conveyor, hopper-type lifting unit, mixing system, horizontal screw conveyor, another hopper-type lifting unit, microcomputer control center, and control station for batching. Its full-automatic circulating system is composed of shaping moulds, diverter, hydraulic output unit, hydraulic demoulding unit, raise-fall unit and mould locking mechanism. Its advantage is high productivity.

Owner:崔达生

PTA production method and system with low energy consumption, material consumption and less waste discharge

ActiveCN105001073BEfficient recyclingEmission reductionOrganic compound preparationCarboxylic compound separation/purificationBenzoic acidSlurry

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com