Emergency furnace-stop system of bagasse slurry factory black liquor alkali-recovery furnace

A technology of bagasse pulp and black liquor alkali, which is applied in the direction of pulping waste liquid combustion, etc., can solve the problems of failure to complete in time, loss, etc., and achieve fast and strong implementation of emergency shutdown procedures, and shorten the implementation of emergency shutdown procedures the effect of time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

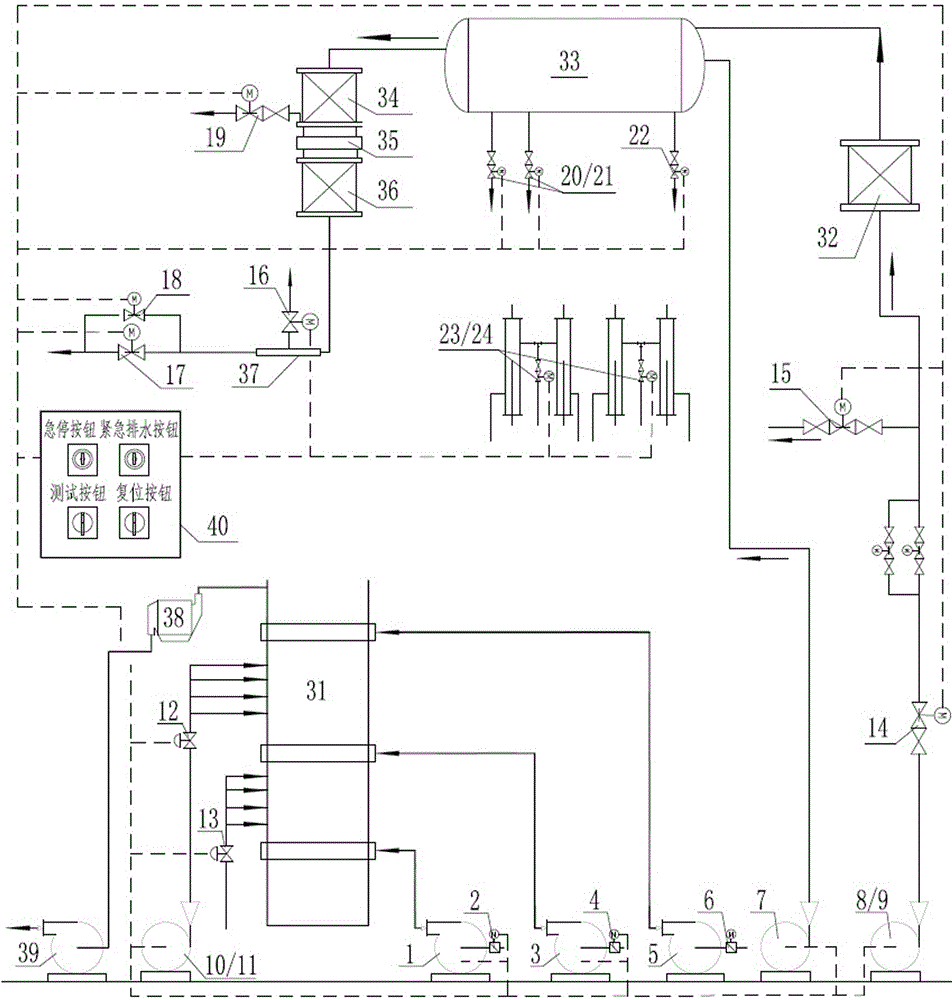

[0029] The present invention will be further described below in conjunction with the accompanying drawings.

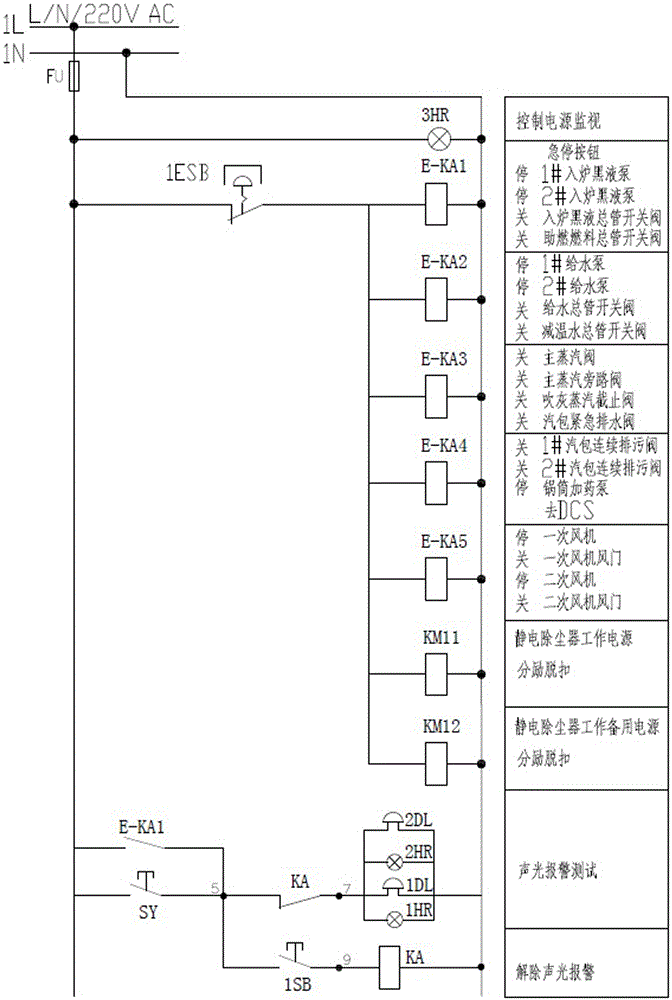

[0030] When the alkali recovery furnace is filled with water and the water cannot be stopped immediately, there is a danger of explosion or an explosion has occurred, break the glass shield and press the emergency stop button 1ESB and emergency drainage button 2ESB at the same time to start the emergency shutdown.

[0031] During emergency shutdown, press the emergency stop button 1ESB, the sound and light alarms 1HR, 1DL in the control room and the sound and light alarms 2HR, 2DL in the field are activated, warning irrelevant personnel to evacuate the scene immediately, and after the danger is eliminated, press Release the button SB to release the sound and light alarm. Usually use the test button SY to regularly test the reliability of the sound and light alarm system.

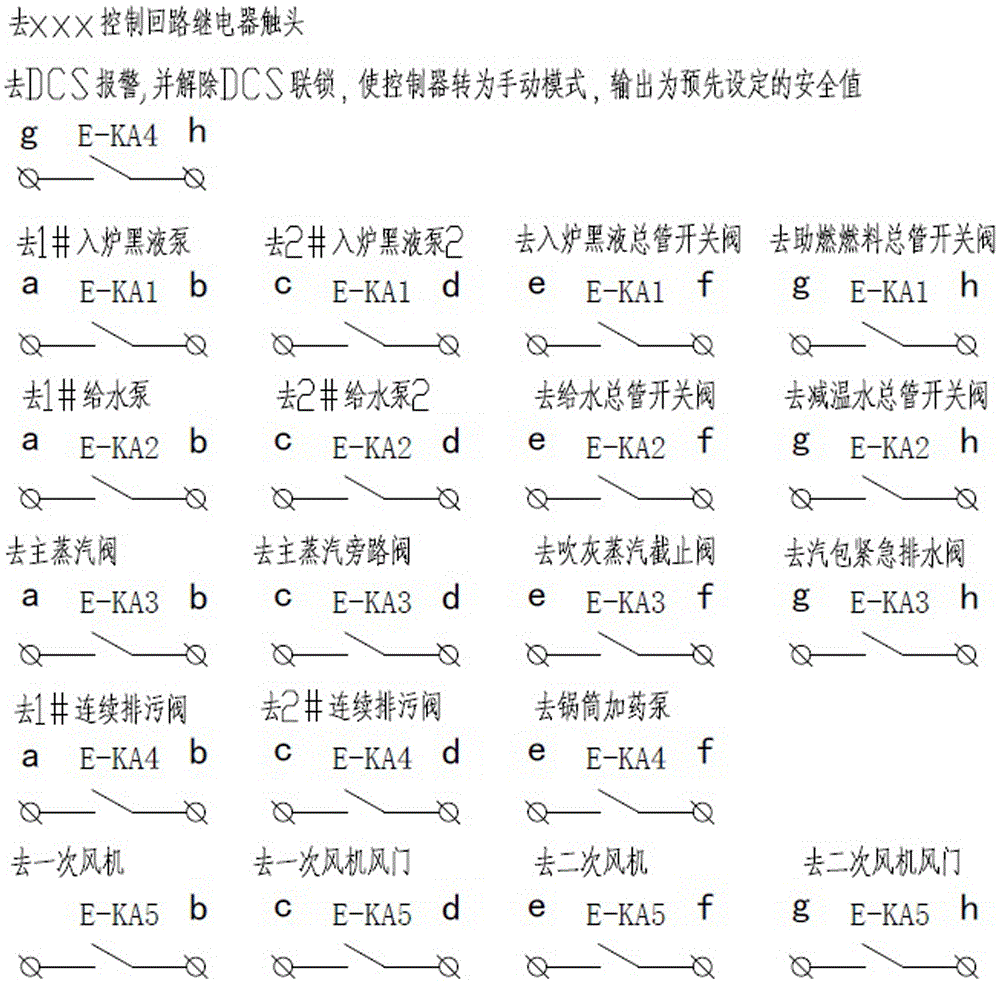

[0032] Press the emergency stop button 1ESB, the relay E-KA1 / E-KA2 / E-KA3 / E-KA4 / E-KA5 loses power...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com