Full-automatic production line of building blocks made of industrial waste and gypsum

A technology of gypsum block and industrial waste residue, which is applied in the field of fully automatic industrial waste gypsum block production line, achieving the effect of multiple quality grades, low investment cost and high block precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

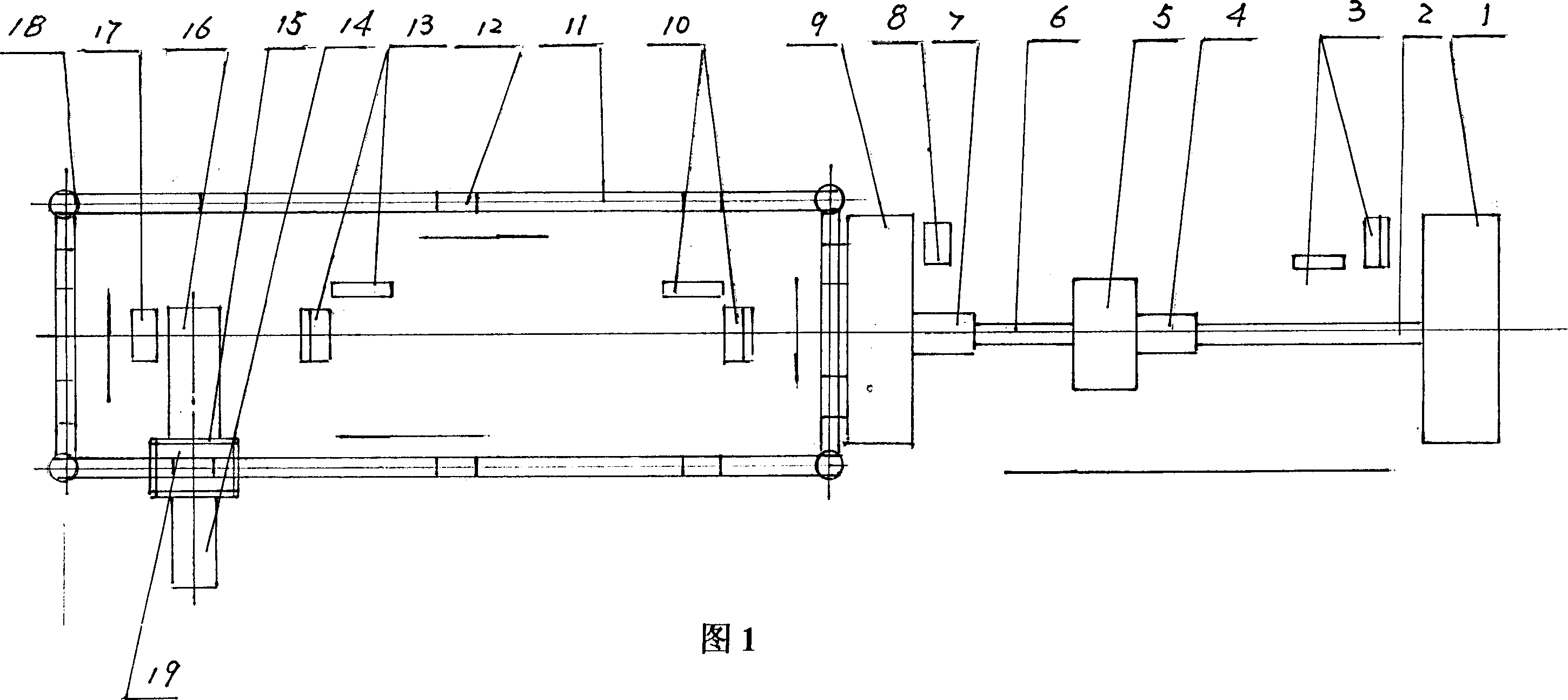

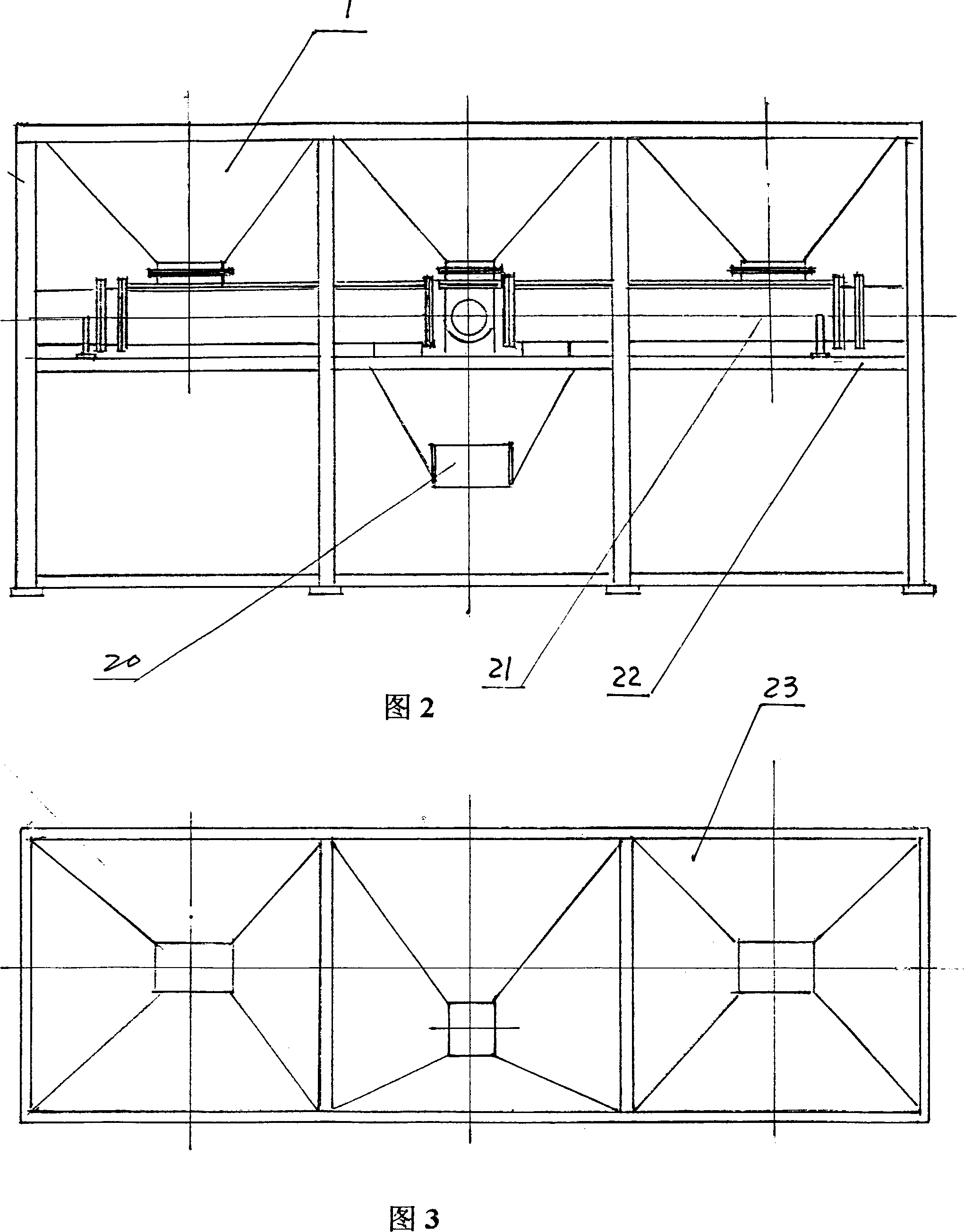

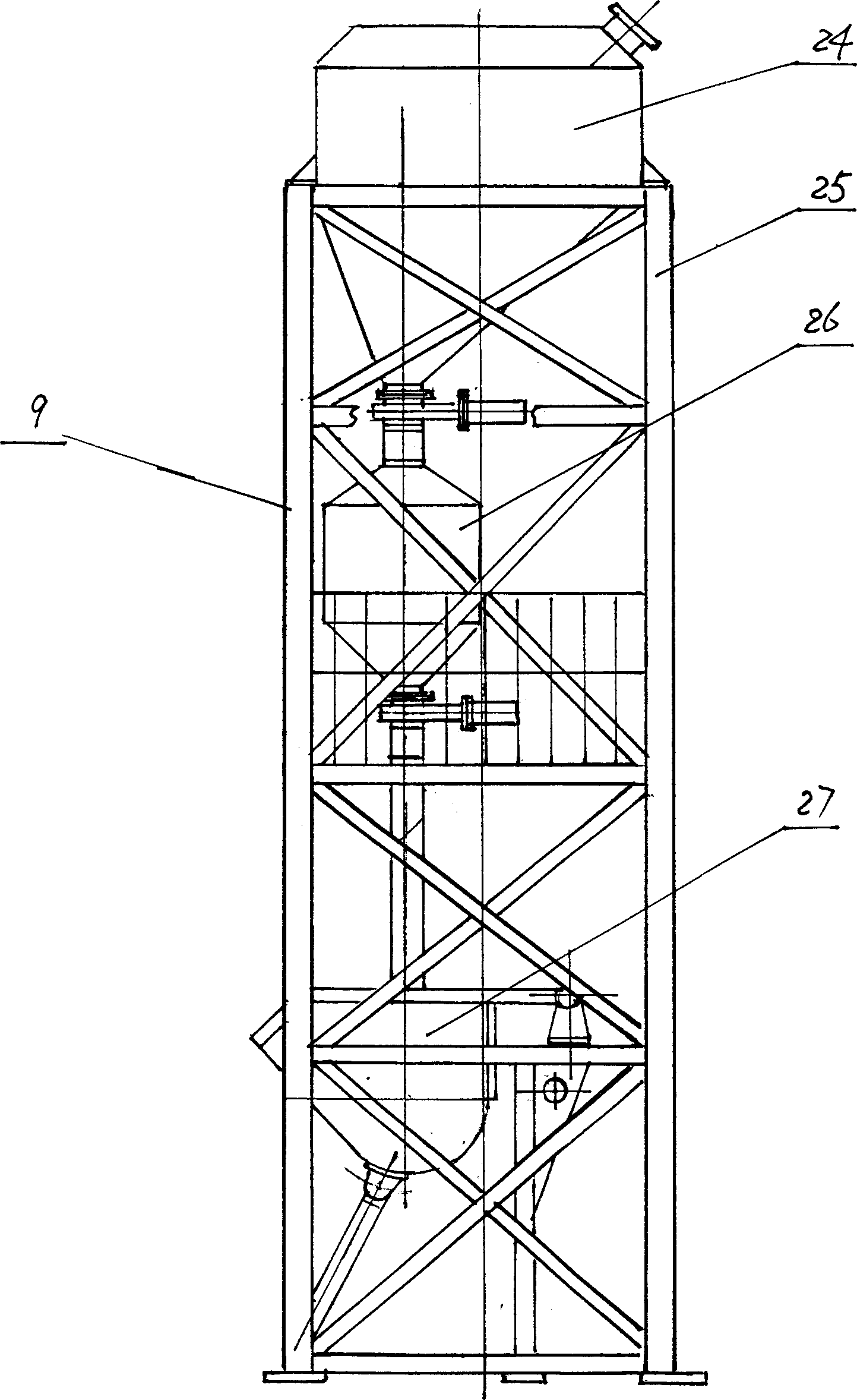

[0037] This embodiment takes the gypsum block with an annual output of 350,000-500,000 square meters and a thickness specification of 80 / 90 / 100 / 110 mm as an example. The fully automatic industrial waste gypsum block production line consists of a batching system and a molding system. The hydraulic system and electric control system of the system can be realized by general engineers and technicians according to the functional requirements and usage requirements of each equipment. The batching system consists of batching station 1, TD160 bucket elevator 4, φ250 screw conveyor, and computer control center , hydraulic transmission system, φ250 slope screw conveyor 2, bucket elevator 4, JS500 dry mixing system 5, φ250 horizontal screw conveyor are arranged in sequence between the batching station 1 of the batching system and the multi-station injection molding system 9 Machine 6, TD160 bucket elevator 7, microcomputer control center 3 controls batching station 1, hydraulic station 8 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com