Patents

Literature

74 results about "Whole food" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Whole foods are plant foods that are unprocessed and unrefined, or processed and refined as little as possible, before being consumed. Examples of whole foods include whole grains, tubers, legumes, fruits, vegetables.

High-quality human-grade ingredient dry pet food and method of producing same

InactiveUS20060251793A1Improve functionalityIncrease valueAnimal feeding stuffAccessory food factorsWhole foodAdditive ingredient

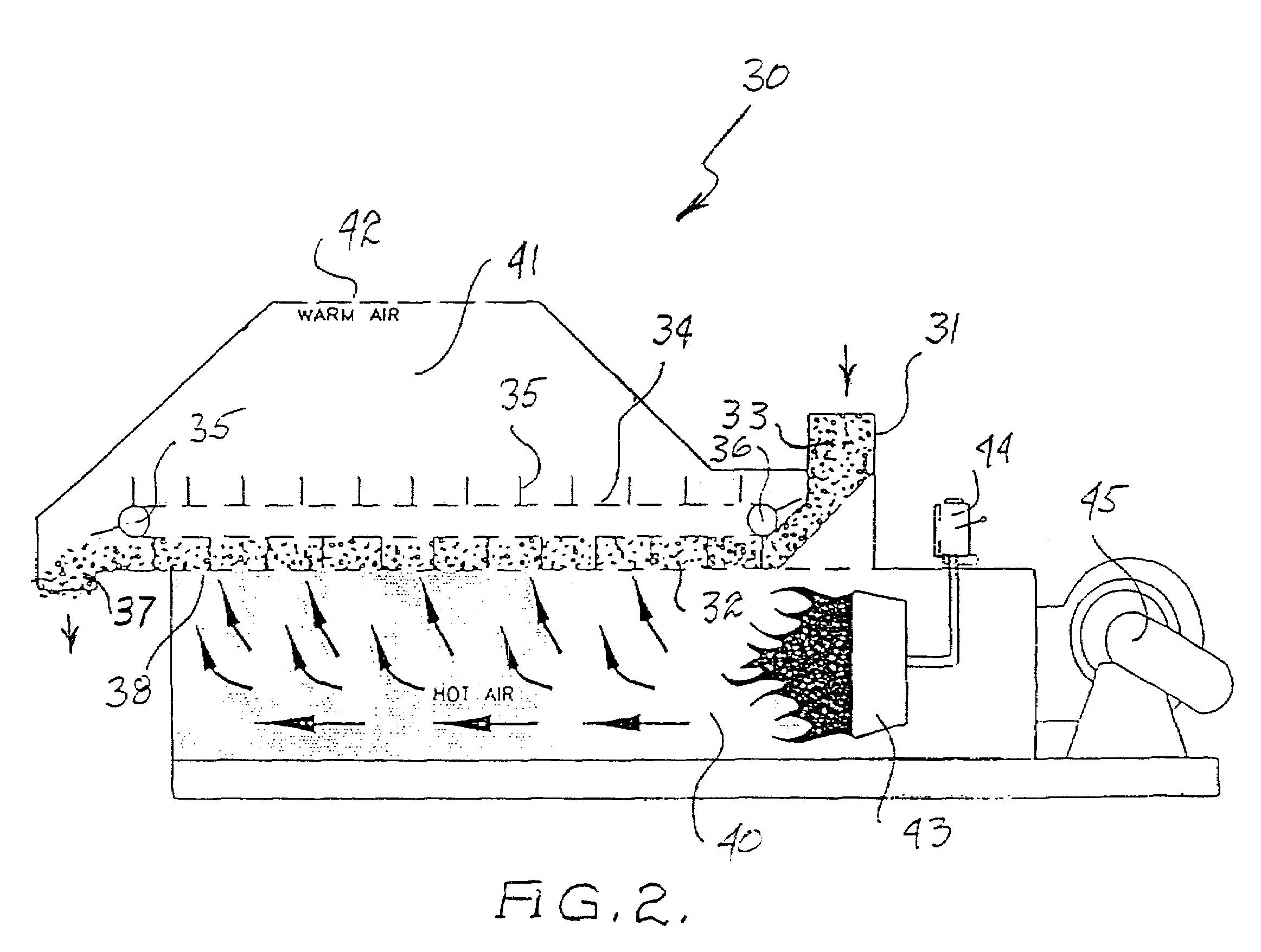

A method is described for producing safe, minimally processed, dry pet foods with high natural nutrient values. This is achieved by avoidance of potentially harmful artificial additives or supplements, removal of potential contaminations, and by utilizing unprocessed or minimally processed, high-quality, all human-grade, and mostly organic, whole food ingredients, as well as a low-heat temperature drying process. During the low-heat drying process, the product (dough) is never exposed to temperatures exceeding 38° C. (100.4° F.). Such low-heat drying is believed to preserve more of the naturally occurring nutrients of the ingredients in the end product than is possible with conventional high-heat processing.

Owner:JUNGER DR ADELHEID IRENE

Method of preparing nutritional legume product

InactiveUS7022369B1Prevent proliferationEasy to useAnimal feeding stuffMeat/fish preservation by freezing/coolingWhole foodDormancy

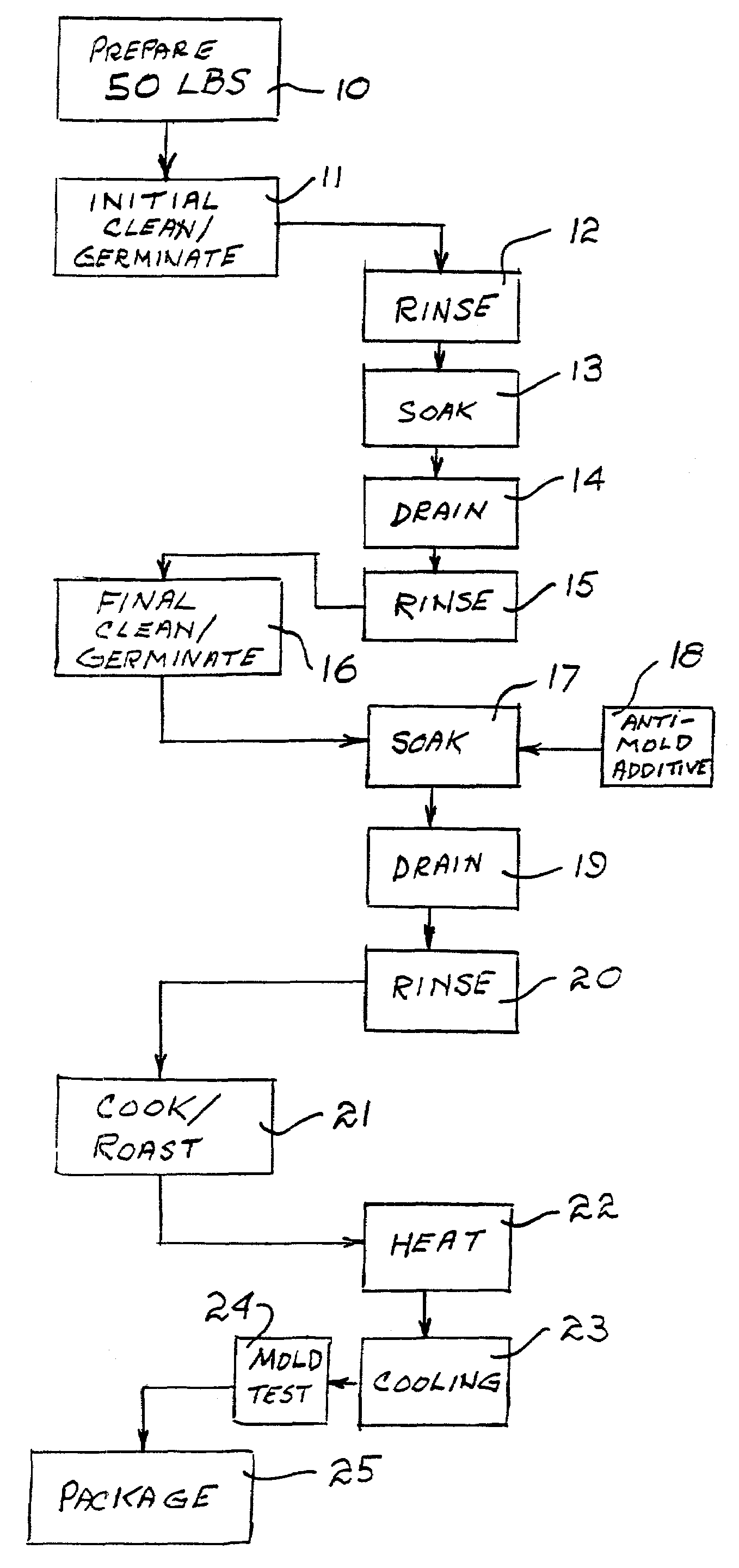

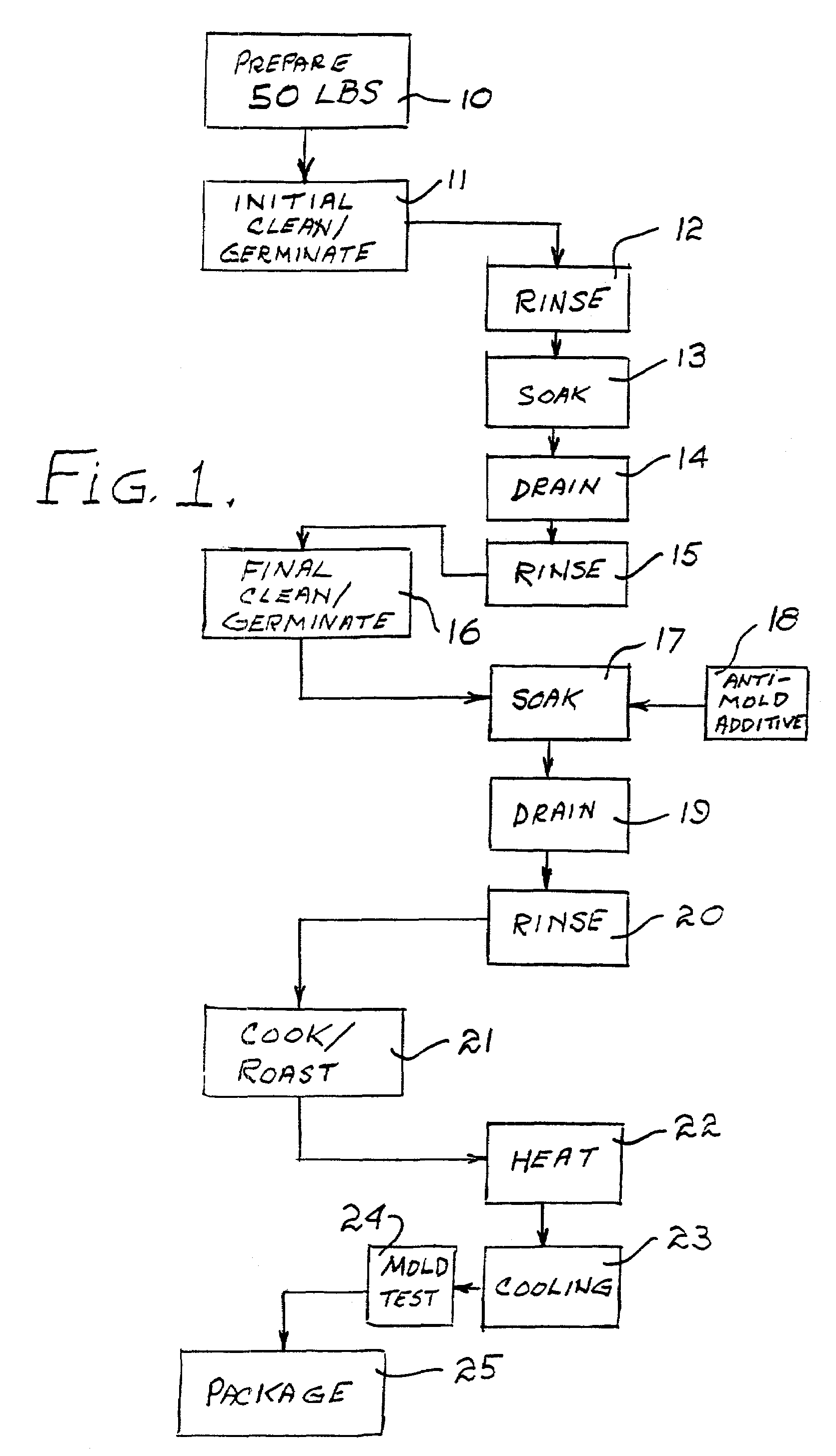

A nutritional convenient food product which enhances and defeats endogenous anti-nutritive factors in a whole food or base product by processing the whole food product by initially cleaning and breaking dormancy of the product, soaking and germinating, followed by a final cleaning and further germinating with subsequent soaking, draining and rinsing. Full cooking follows with subsequent heating, then cooling the whole food product to ambient temperature.

Owner:KLEINMAN JUDEE

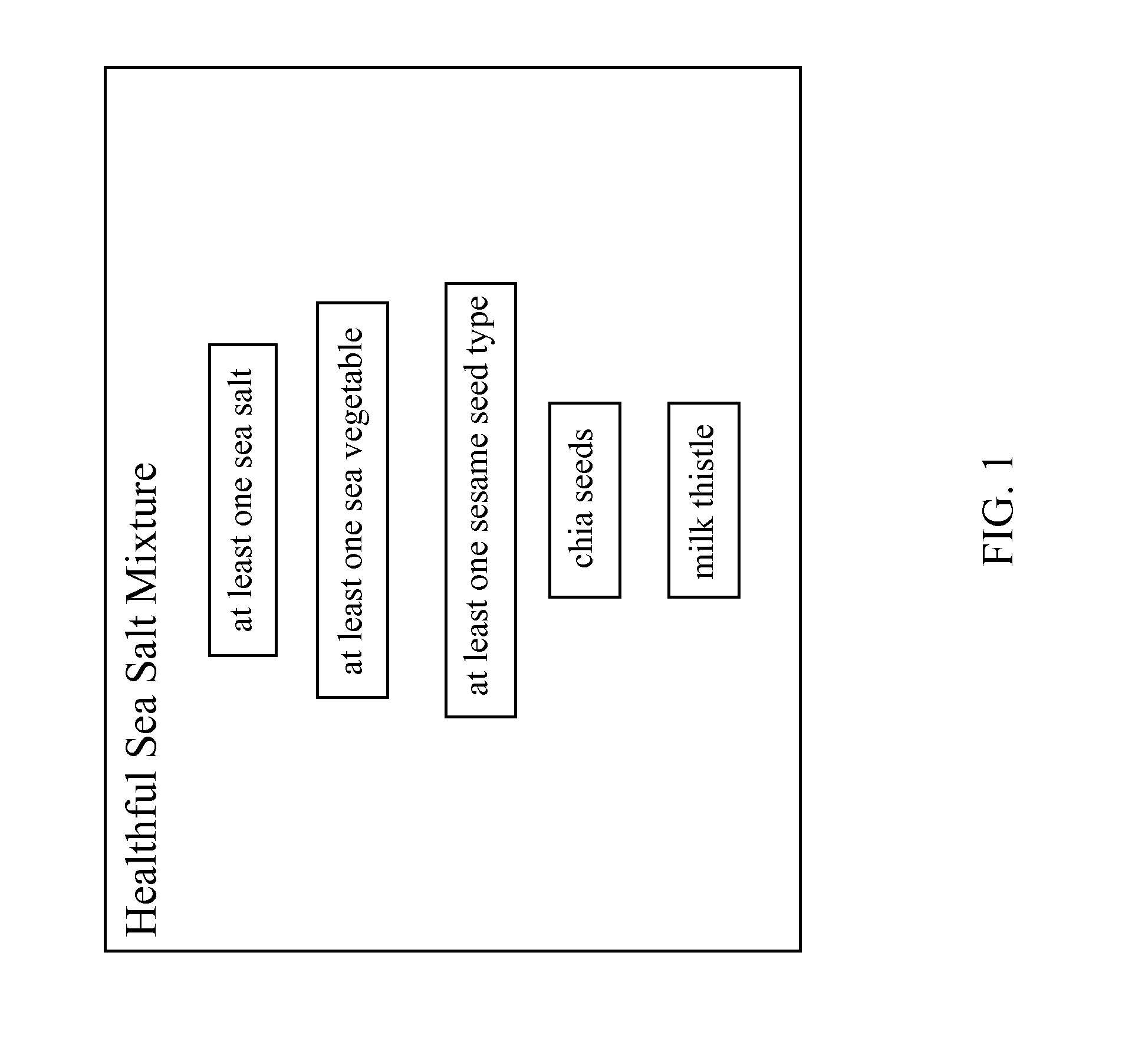

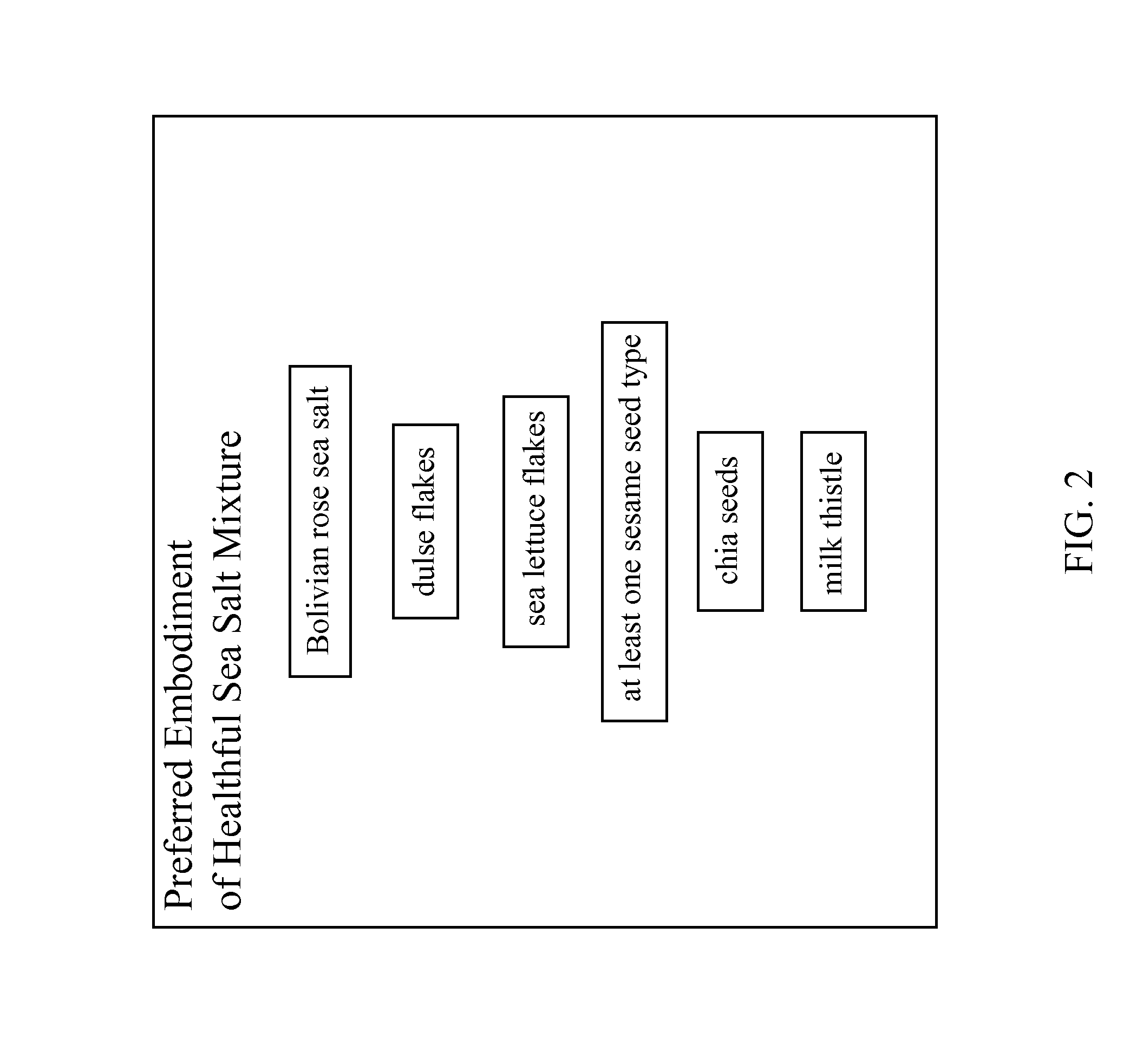

Healthful Sea Salt Mixture

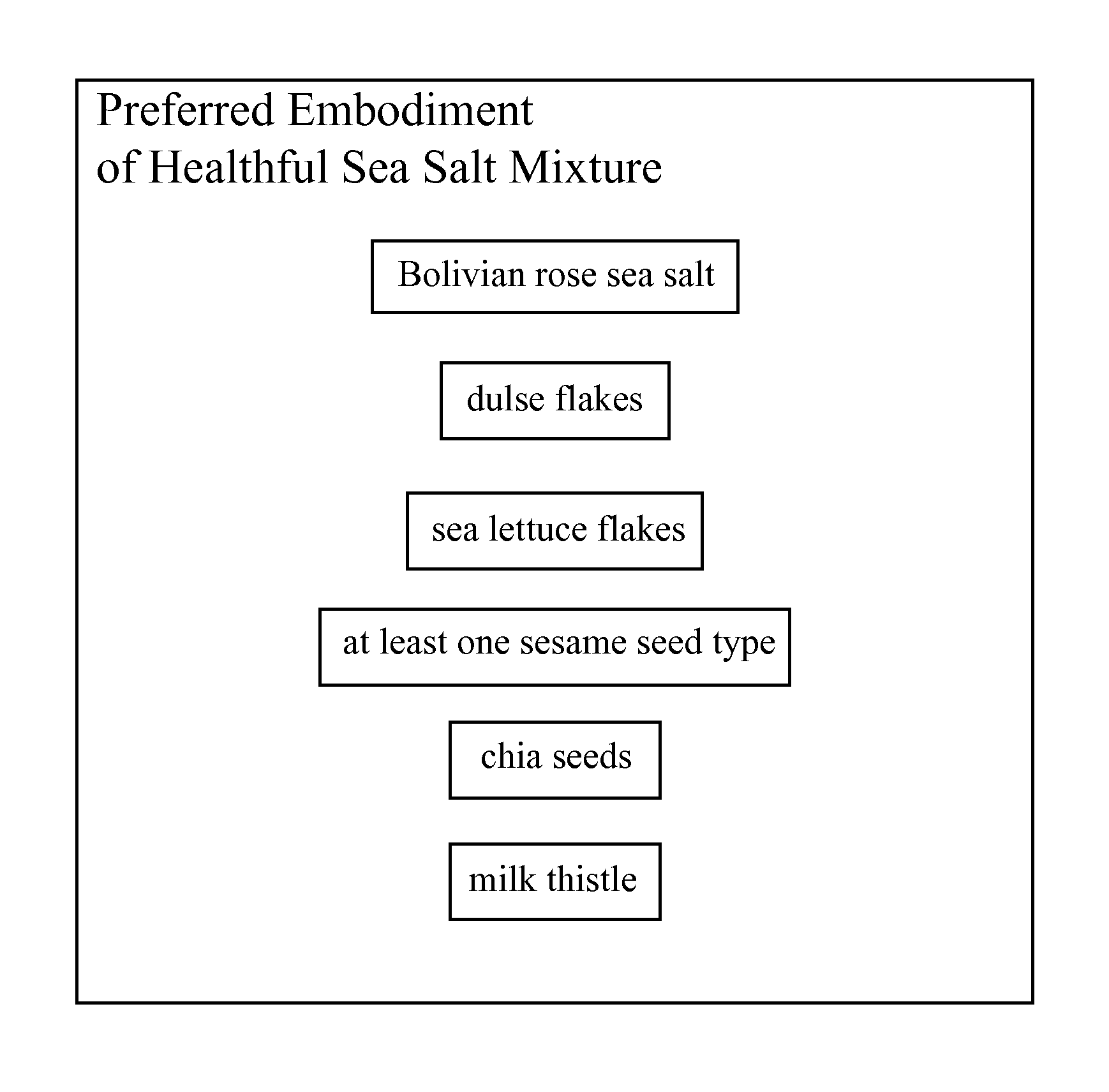

A healthful sea salt mixture composed of at least one whole sea salt, at least one organic whole sea vegetable, at least one whole raw sesame seed type, optional chia seeds and optional milk thistle. The at least one whole sea salt includes but is not limited to Celtic sea salt, pink Himalayan sea salt, and Bolivian rose sea salt. The at least one organic whole sea vegetable includes but is not limited to alaria, dulse, kelp, layer, and sea lettuce. The at least one whole raw sesame seed type includes various families of sesame seeds. The present invention provides a whole food source that has numerous minerals and nutrients. The present invention also serves as an iodine supplement for those with a thyroid-related condition. Furthermore, the present invention provides vitamin E, which aids in iodine absorption. The range of nutrients provided includes potassium, calcium, sodium, vitamins, and others.

Owner:ADDISON NANCY ALISA GIBBONS

Health supplement

The present invention relates to a health supplement that can include a number of ingredients that provide various health benefits. The supplement can be aloe vera based and include grape skin extract, grape seed extract, and / or citrus bioflavanoids. The supplement can also include a whole food component including ingredients such as spirulina, acelora berry, brown rice grain, and / or sunflower seed. The supplement can also include a cruciferous component, ginseng, metabolic coenzyme, and / or nopal cactus fiber. The supplement can also include a blend of amino acids, daily vitamins and minerals, and other beneficial ingredients. The supplement can also contain flavoring agents, preservatives, and a carrier, such as water.

Owner:SCHOCK JOEL FLOYD

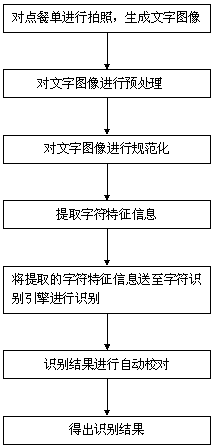

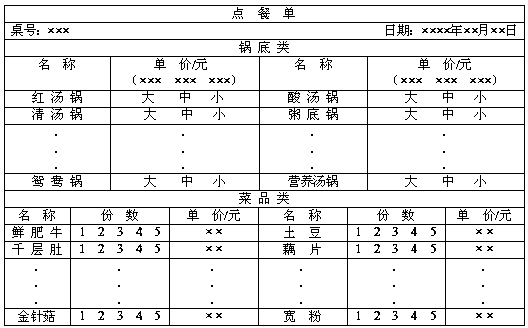

Food ordering method based on image identification technology

InactiveCN103646360AReduce workloadImprove work efficiencyData processing applicationsCharacter and pattern recognitionWhole foodImaging processing

The invention discloses a food ordering method based on an image identifying technology. The method includes the following steps: using a waiter handheld intelligent device to take a picture of a meal list of a customer so as to generate a character image; preprocessing the character image and normalizing the character image; extracting character feature information from the normalized character image; sending the extracted character feature information to a character recognition engine for recognition; and performing automatic proofreading on the recognition result according to character codes of menu information preset in the handheld intelligent terminal so that an accurate recognition result is obtained. In the food ordering method based on the image identification technology, the picture of the meal list is taken so that the character image is obtained and then the food ordering information is determined through an image processing and identification technology and then the meal list is transferred to a kitchen and a counter through the handheld intelligent device so that workload of waiters is reduced and the whole work efficiency of a dining hall is improved; and the whole food ordering process can be completed through only one paper meal-list sheet so that use of paper meal-list sheets is reduced and waste of resources is prevented.

Owner:CHENGDU BOYUE CHUANGXIN TECH

Equine whole food supplements

InactiveUS20090246314A1Improve the level ofMilk preparationMetabolism disorderBiotechnologyFood supplement

Whole food equine formulations provided by the invention include well balanced nutritional supplements providing nutrients and vitamins, among other benefits. The whole food formulations generally promote, for example, better cell utilization instead of cell saturation, which results in increased overall general physiological and psychological health of subject animals including horses.

Owner:MONTAGUE CYNTHIA

Method for achieving food process monitoring system

The invention discloses a method for achieving food process monitoring system. The method is that a food processing and sales all-industry-chain traceable system is built through an Internet of Things bar code and RFID, a wireless sensor and other technologies; the good production, supply and sales processes are subjected to information recording and accurately recognized; therefore, the safety control and quality safety tracking management of the whole food supply chain can be achieved.

Owner:SUZHOU YAAN INTELLIGENT TECH

Pourable Food Composition with High Natural Fiber Content and Methods of Production

The present invention relates to a pourable food composition, like a dressing, that has at least 2.5 grams of total dietary fiber per 32 gram serving. The fiber is derived from at least one whole fruit or vegetable that is partially or completely dehydrated and which is subjected only to minimal processing. The food composition has a viscosity of about 3,000 to about 12,500 centipoise. The fiber may be derived from whole vegetables that are high in fiber, such as beans, carrots, broccoli and the like. The fiber may also be derived from whole fruits that are high in fiber, such as avocados, mangos, and the like. The whole food is subject to only minimal processing, such as by physical means, enzymatic means, or by fermentative means.

Owner:KRAFT FOODS GLOBAL BRANDS LLC

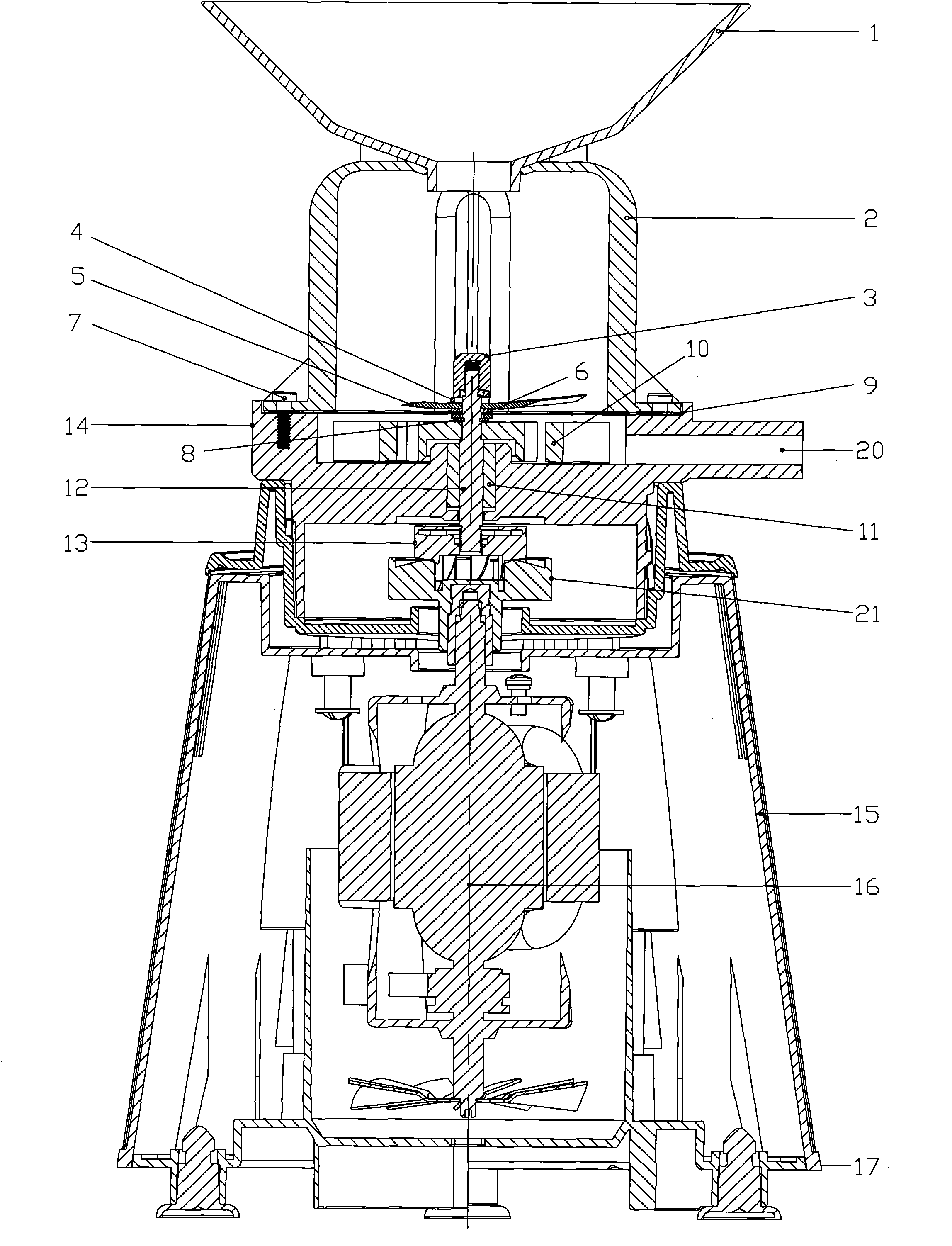

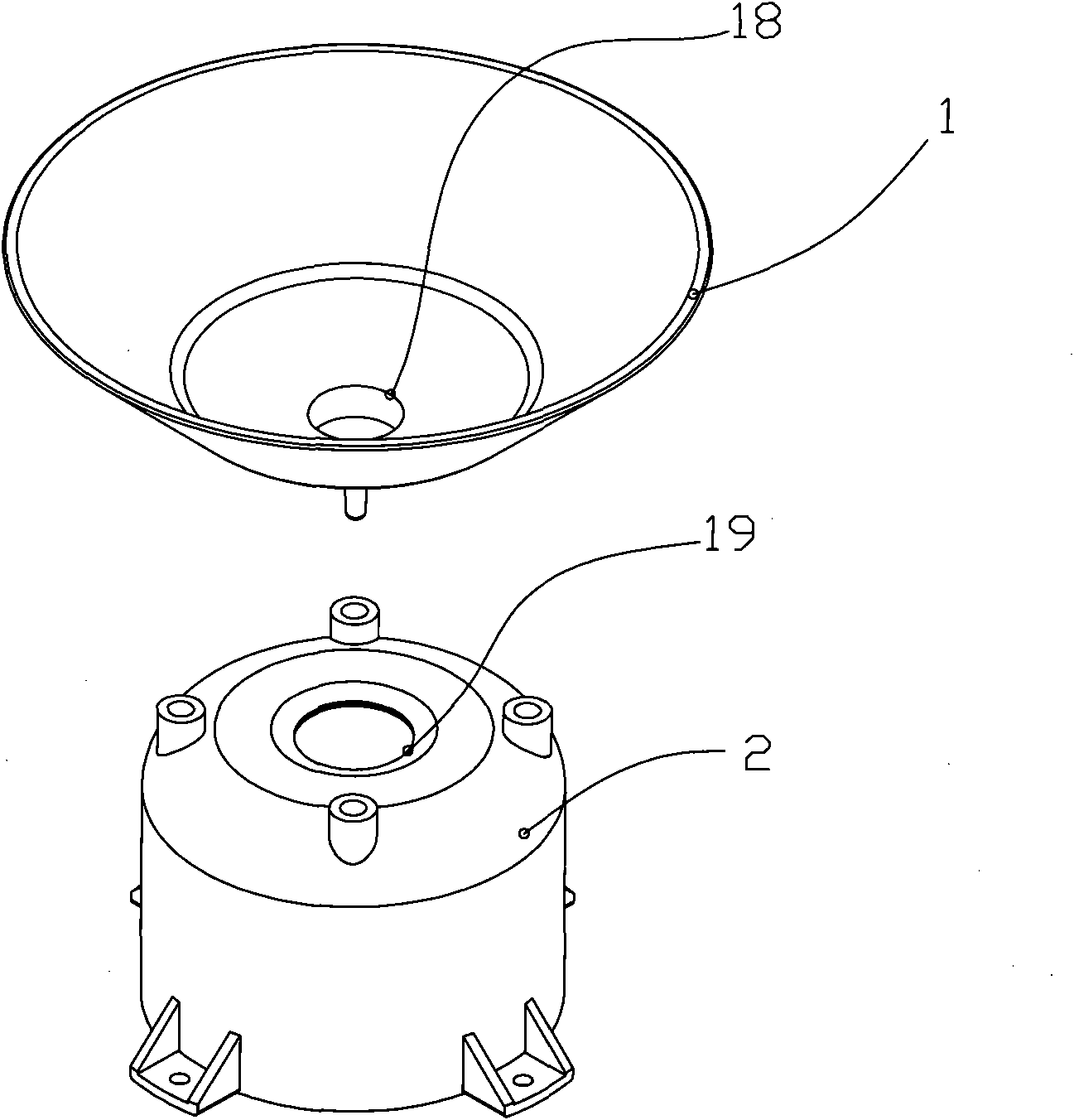

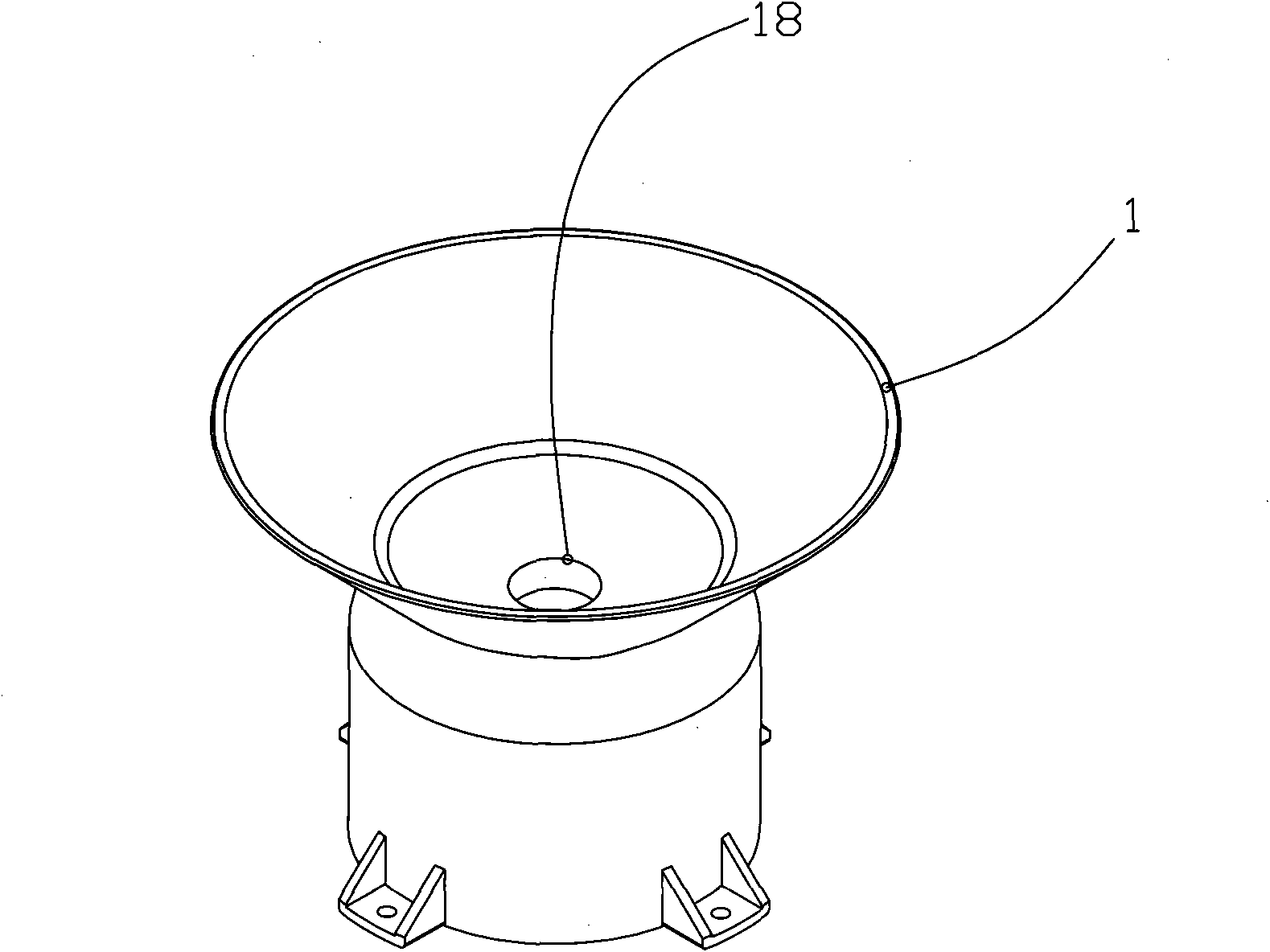

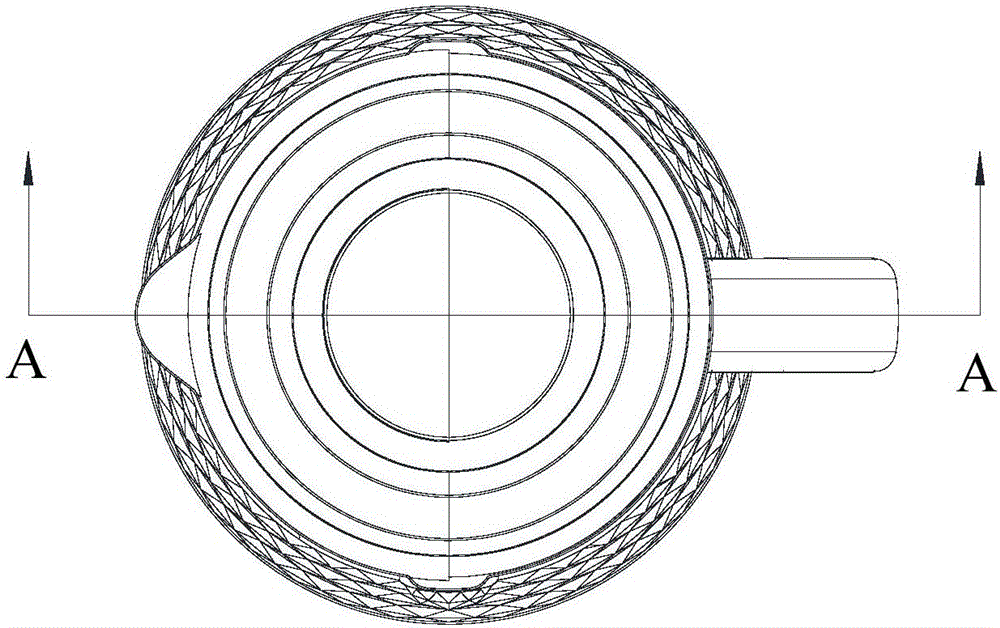

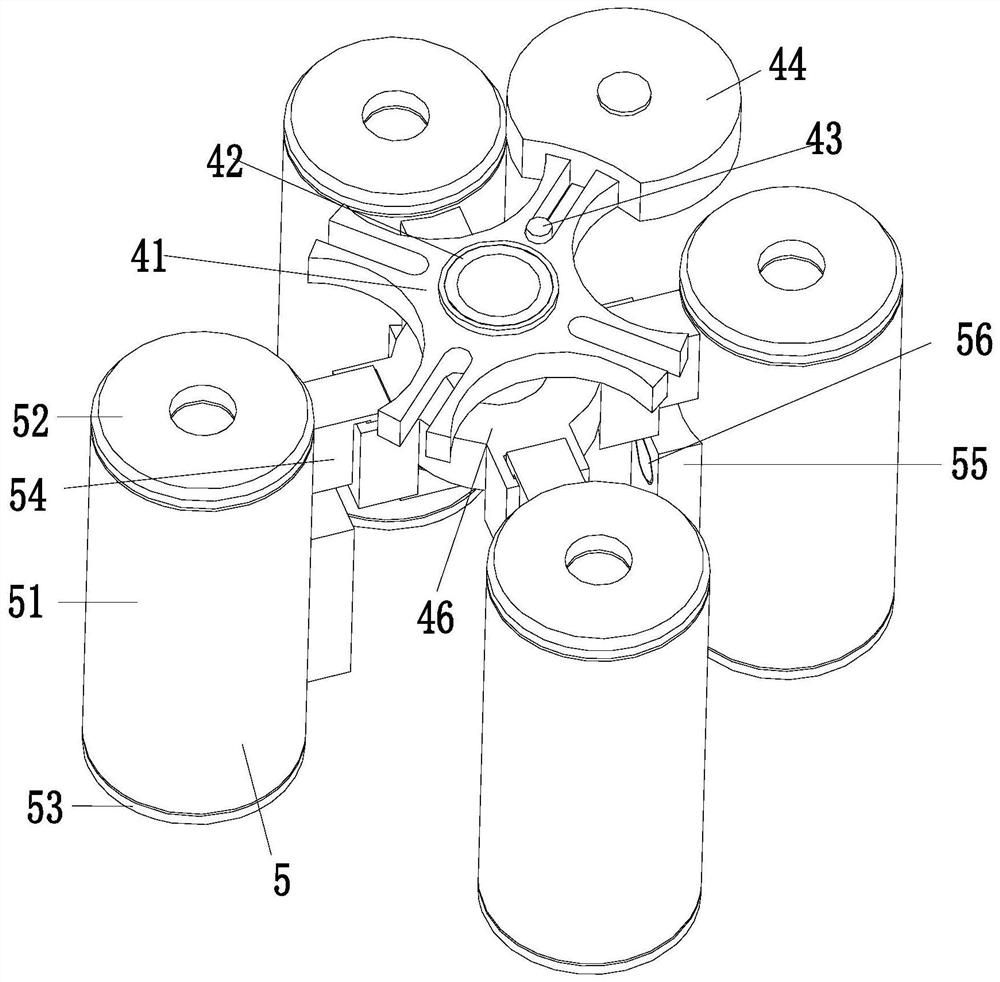

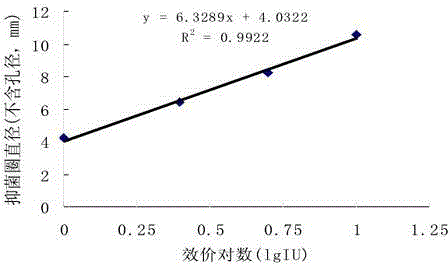

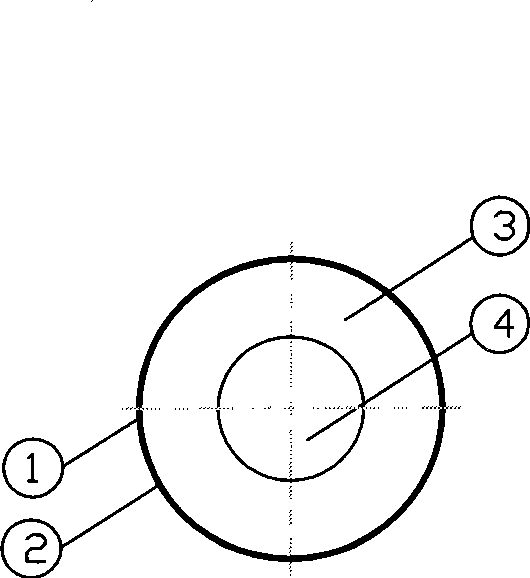

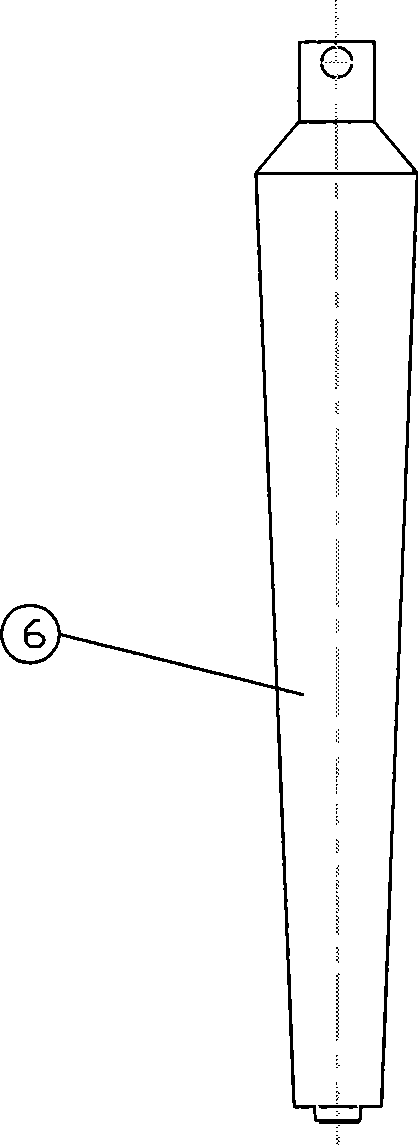

Food grinder

The invention discloses a food grinder. A cutter holder system of the grinder comprises a cutter holder and a cutter shaft, wherein the cutter holder is provided with a bearing; the lower end of the cutter shaft is arranged in the bearing, and the upper end of the cutter shaft is provided with a grinding component; a cup body is provided with a material inlet communicated with the outside; a filtering device is sleeved below the grinding component on the cutter shaft; a powder discharging / heat radiating device is sleeved below the filtering device; a powder discharging / heat radiating device is sleeved above the bearing on the cutter shaft; and a position on the side wall of the cutter holder, which corresponds to the powder discharging / heat radiating device, is provided with an outlet communicated with the outside. Food is delivered to the cup body from the material inlet and ground by the grinding component; the grinding degree is controlled by the filtering device; and the ground food is discharged from the food outlet by the powder discharging / heat radiating device. A convective air cooling system is formed on a passage in a whole food treating process so as to rapidly carry heat produced by high-speed friction between the cutter shaft and an oil-containing bearing out of the cup body and realize automatic food treatment started from feeding. The grinder can run continuously without causing thermal protection and powder burning and the service life of the grinder is prolonged.

Owner:MIDEA GRP CO LTD

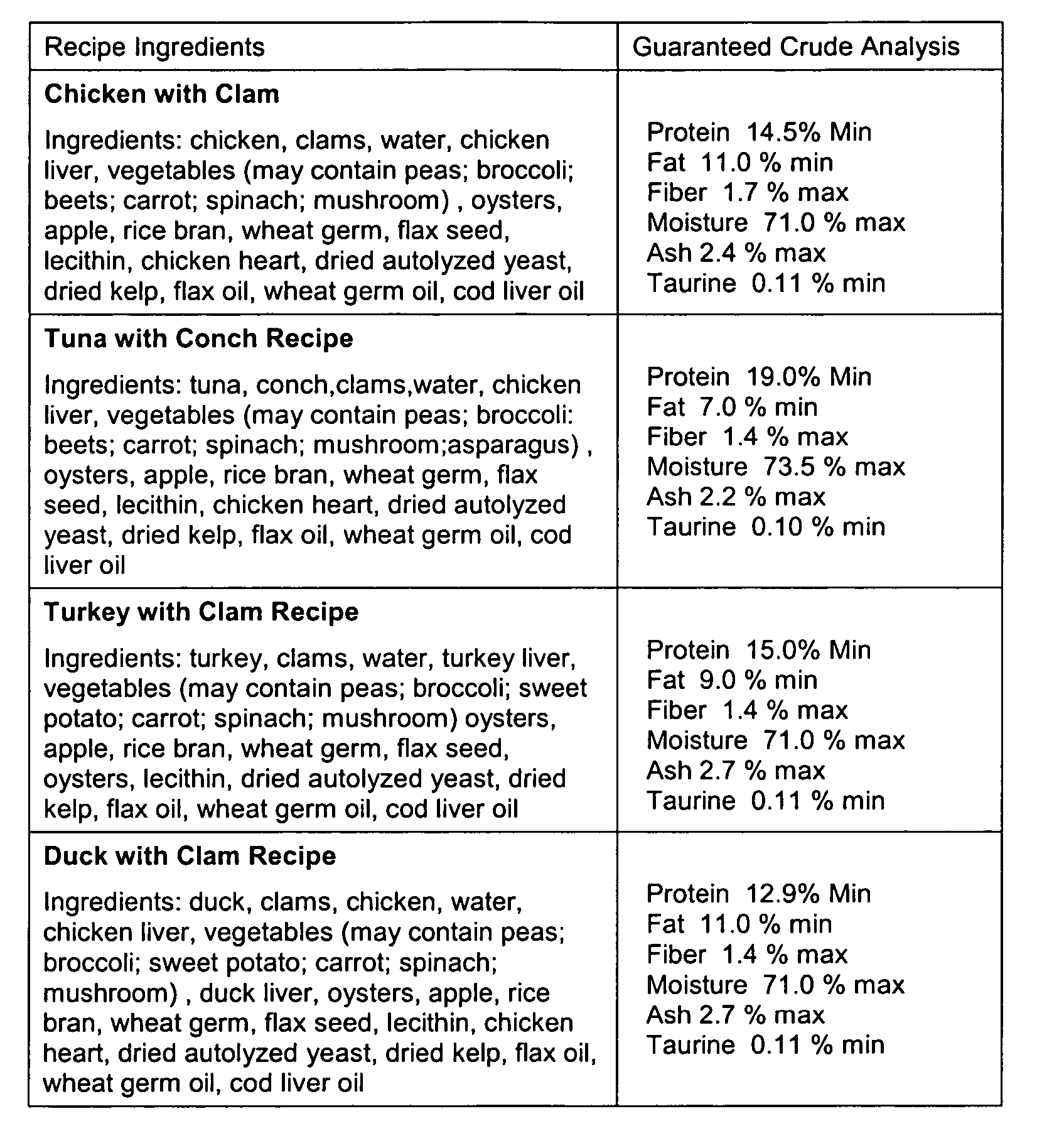

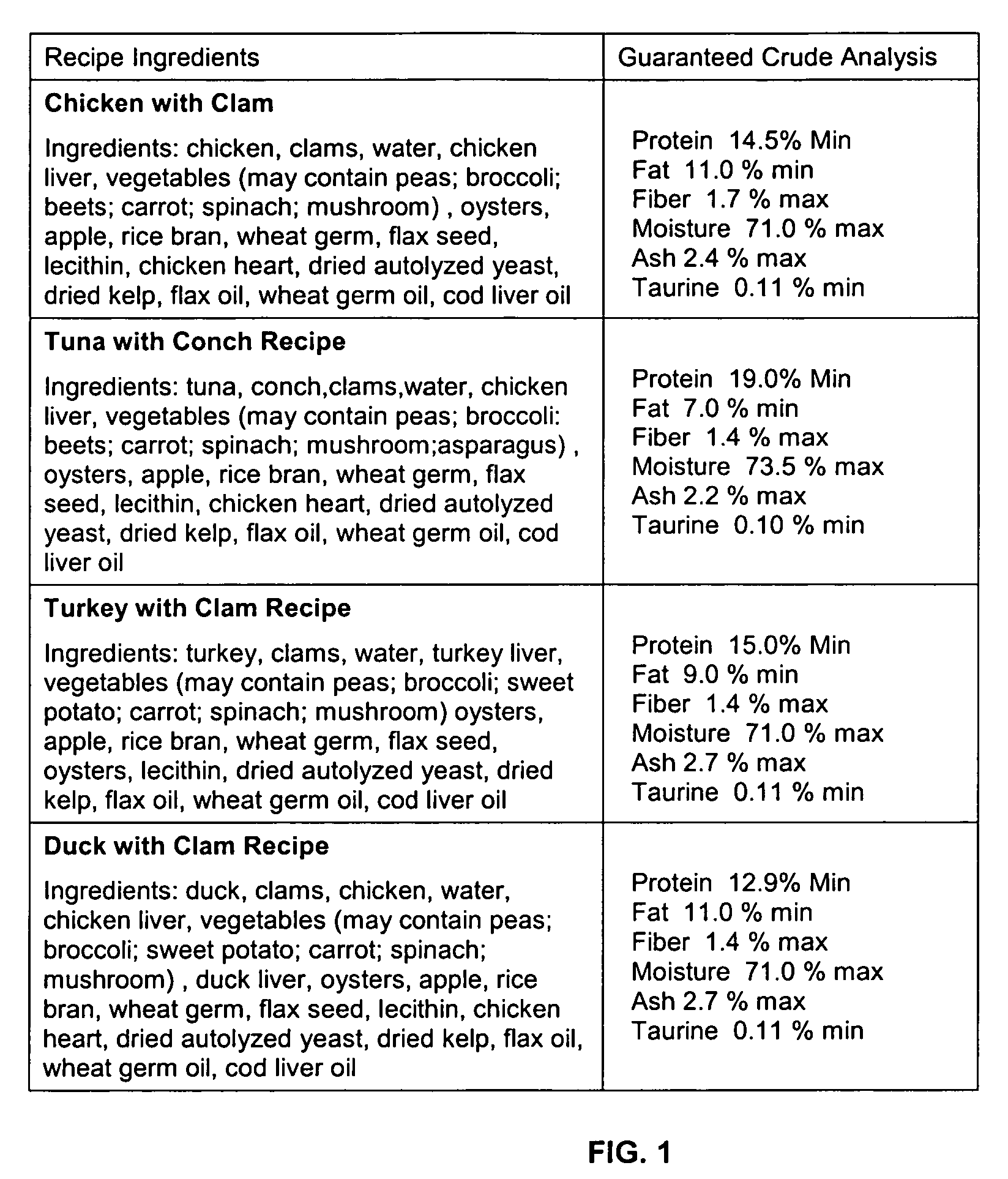

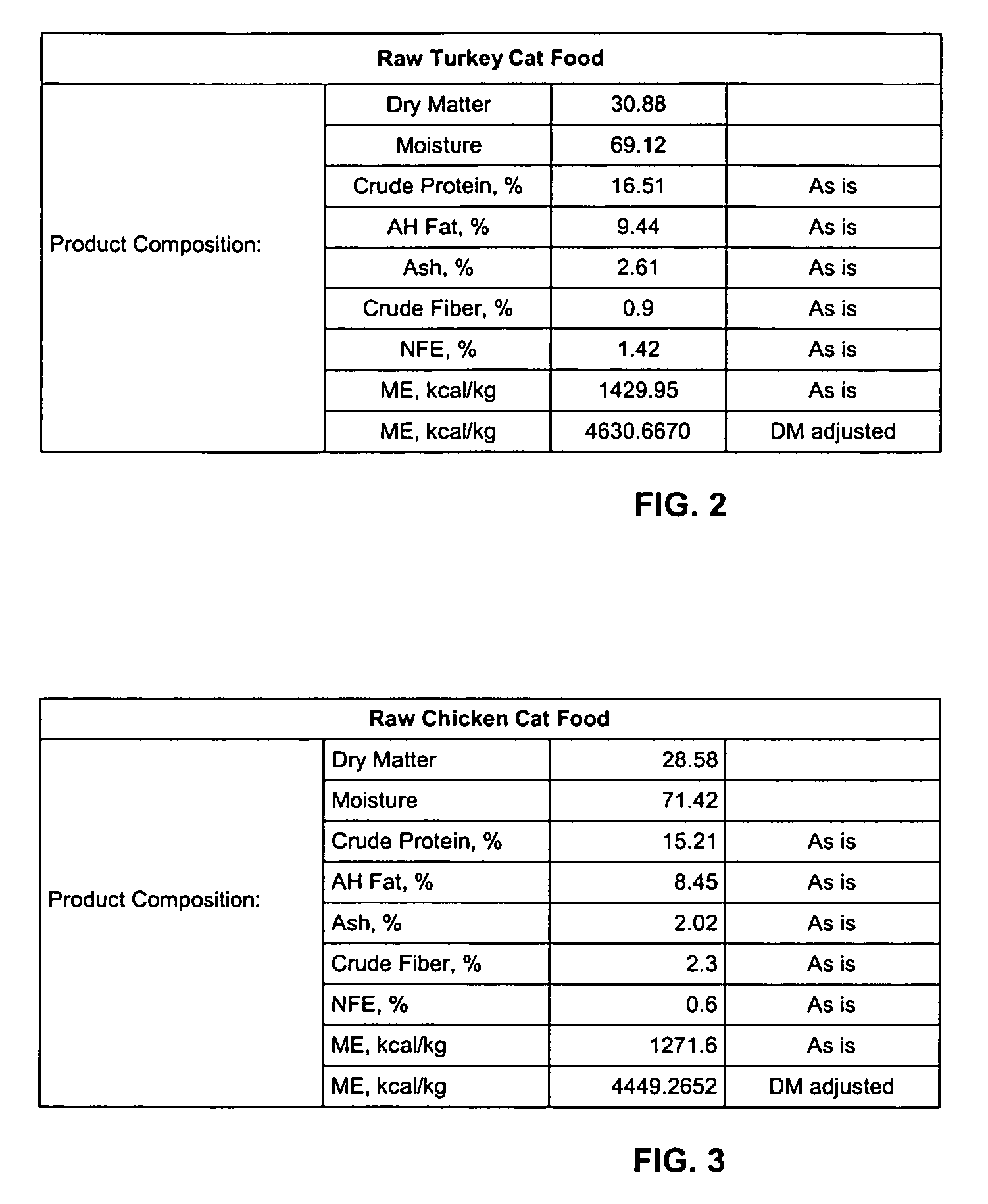

Frozen cat food

Frozen cat food that contains only whole food ingredients. The whole food ingredients include fresh human-grade meat and / or poultry food products, mollusk, vegetables and fruit, and additional ingredients such as wheat germ, wheat germ oil, lecithin, and rice bran. The food ingredients are raw, with the exception of mollusk, which may be cooked. The cat food is made of only human-grade food products and contains no non-food additives, such as amino acid, mineral or vitamin supplements. The raw frozen cat food provides a complete and balanced diet that meets or exceeds AAFCO standards.

Owner:NADEAU STEPHANIE

Protein-Rich Baked Food and Process for Producing the Same

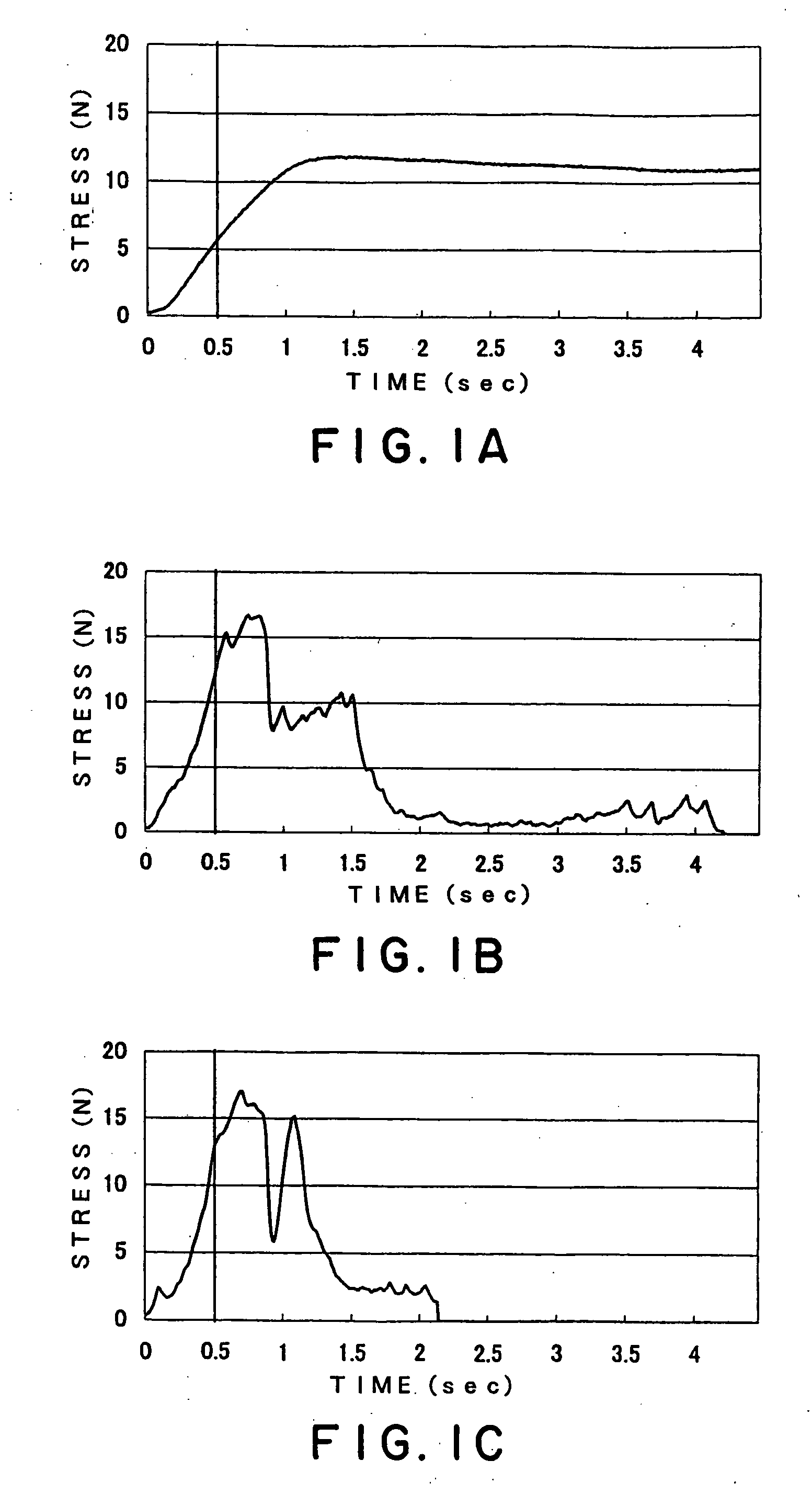

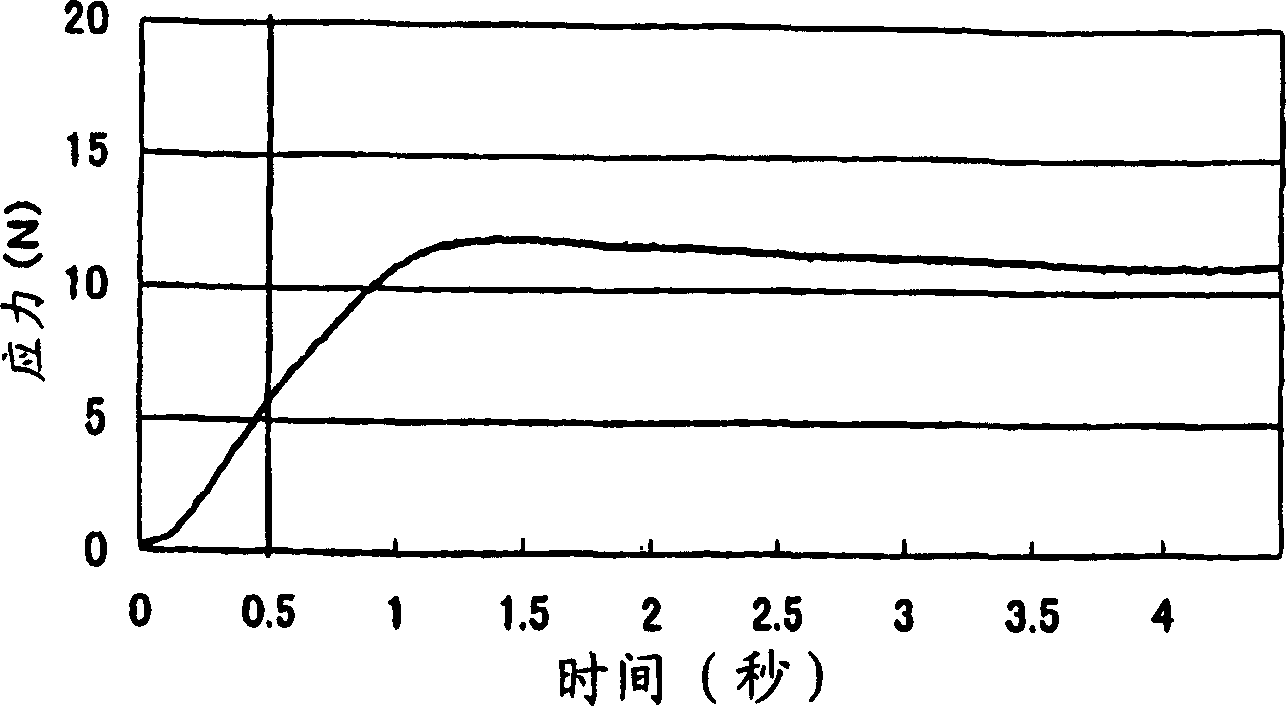

InactiveUS20070264392A1Excellent chewabilityExcellent dissolvabilityDough treatmentBaking mixturesHigh concentrationWhole food

This invention provides a high-protein baked food product, comprising at least: at least 15% by weight (on a dry weight basis), based on the whole food product, of a protein component; an oil and fat component and a saccharide component, wherein the high-protein baked food product is obtainable by finely grinding a first material mixture comprising a protein component, an oil and fat component, and a saccharide component, stirring the mixture to prepare a creamy primary product, mixing the primary product with a secondary material mixture provided separately from the primary product and comprising at least an oil and fat component and a saccharide component, and baking the mixture. This baked food product contains protein in a high concentration, is soft and has good chewability and dissolvability within the mouth.

Owner:BOURBON CORP

Protein-rich baked food and process for producing the same

InactiveCN1878472APromote digestion and absorptionEfficient intakeDough treatmentConfectioneryHigh concentrationWhole food

A protein-rich baked food containing at least 15% by weight (in terms of dry weight) of a protein component based on the whole food together with at least a fat component and a sugar component. This baked food is obtained by finely milling and stirring a first material mixture, which contains the protein component, the fat component and the sugar component, to give a creamy pre-product, and then mixing this pre-product with a second material mixture separately prepared, which contains at least a fat component and a sugar component, followed by baking. This baked product contains protein at a high concentration, has a soft texture and shows excellent crispness and meltability in the mouth.

Owner:BOURBON CORP

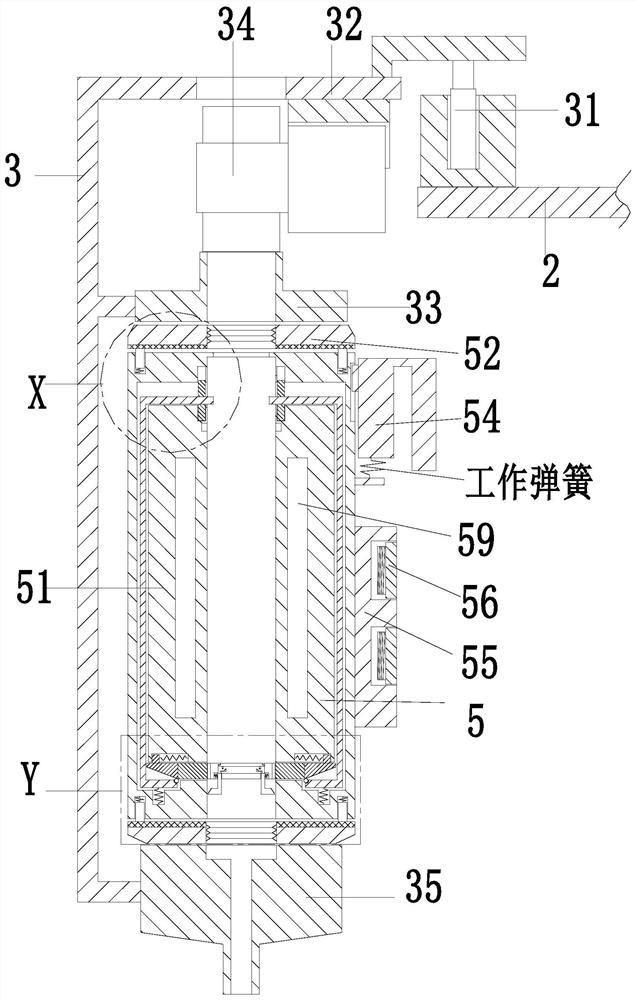

Food processor

ActiveCN107174143AAchieve coolingAffect user experienceFood processingKitchen equipmentWhole foodElectric machinery

The invention provides a food processor. The food processor includes a cup body, a base, a motor assembly and an air duct assembly. The bottom of the cup body is provided with a stirring knife assembly, the base is of a hollow structure and matched with the cup body, the motor assembly is arranged in the base, the motor assembly is connected with the stirring knife assembly, the motor assembly includes a motor and a fan which are connected, the air duct assembly is arranged at the bottom of the base, the air duct assembly includes an air duct, an air inlet and an air outlet, the air outlet is located at one end of the air duct, and the fan is located in the air duct; when the motor is started, the fan rotates, and air enters the base through the air inlet and is discharged through the air duct and the air outlet. According to the food processor, cooling of the motor assembly and related components in the base is achieved, and at the same time, a part of noise generated during operation of the motor and rotation of the fan is blocked, the noise generated when the whole food processor is in use is thus reduced, and the use experience of users is enhanced.

Owner:MIDEA GRP CO LTD

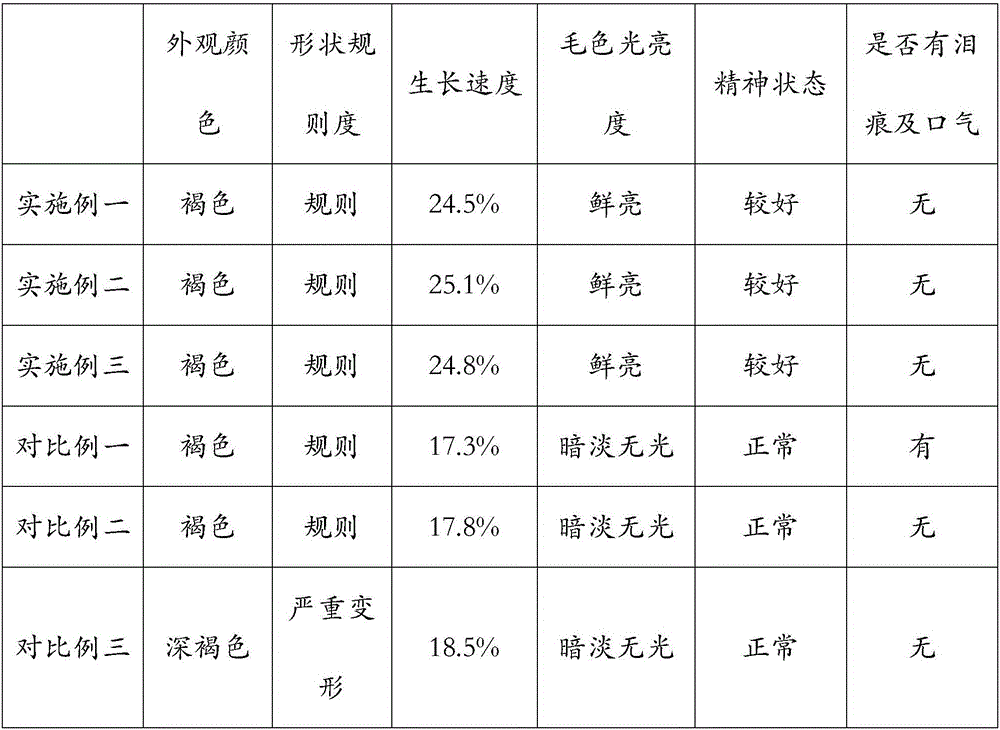

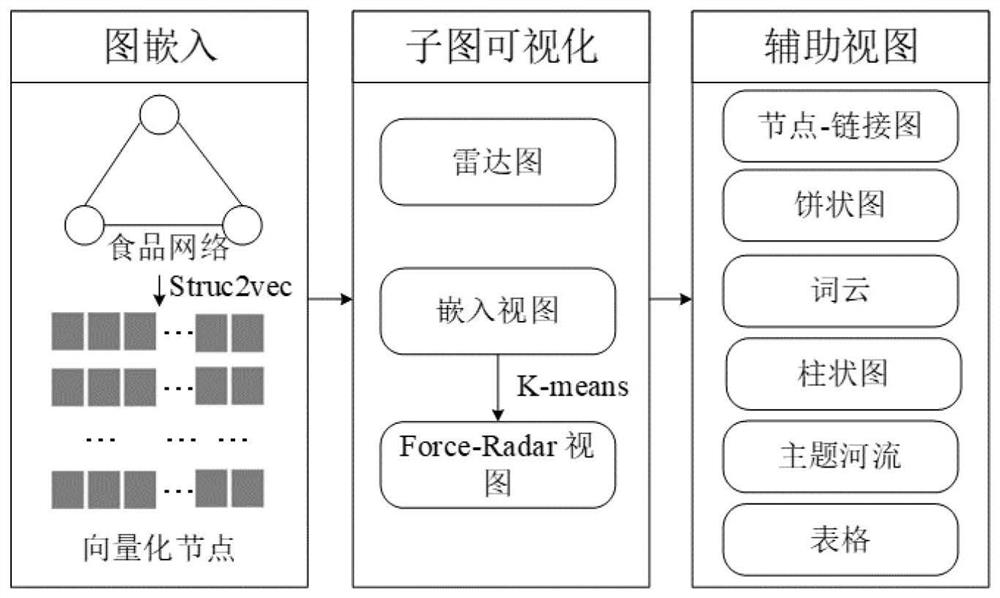

Pet food and preparation method thereof

InactiveCN106720958AGood for healthImprove the immunityAnimal feeding stuffAccessory food factorsCompanion animalIngested food

The invention discloses a pet food and a preparation method thereof. The pet food comprises a fish skin layer and a content matter, wherein the content matter is coated by the fish skin layer; the weight part ratio of the fish skin layer to the content matter is (2 to 3):(7 to 8); the content matter comprises livestock and poultry meat, salmon meat, corn starch, soy protein, sorbitol, potassium sorbate, glycerin, 95% edible alcohol, citric acid, dry flour, taurine, vitamin B3, vitamin C, green tea powder, fresh ginger powder, choline chloride, and phosphatidylserine. The pet food has the advantages that by combining the fish meat and the livestock and poultry meat, the meat content in the food is increased, the meat flavor is realized, the palatability is improved, the salt content of the whole food is decreased, the fishy smell is thinned, the functional food is favorable for the pet health, the resistance ability of the pet is enhanced, the bone is strong, the tear trace is reduced, and the wools are clean and bright; the phosphatidylserine is suitable for improving the brain nutrient, and promoting the brain development.

Owner:青岛麦健食品有限公司

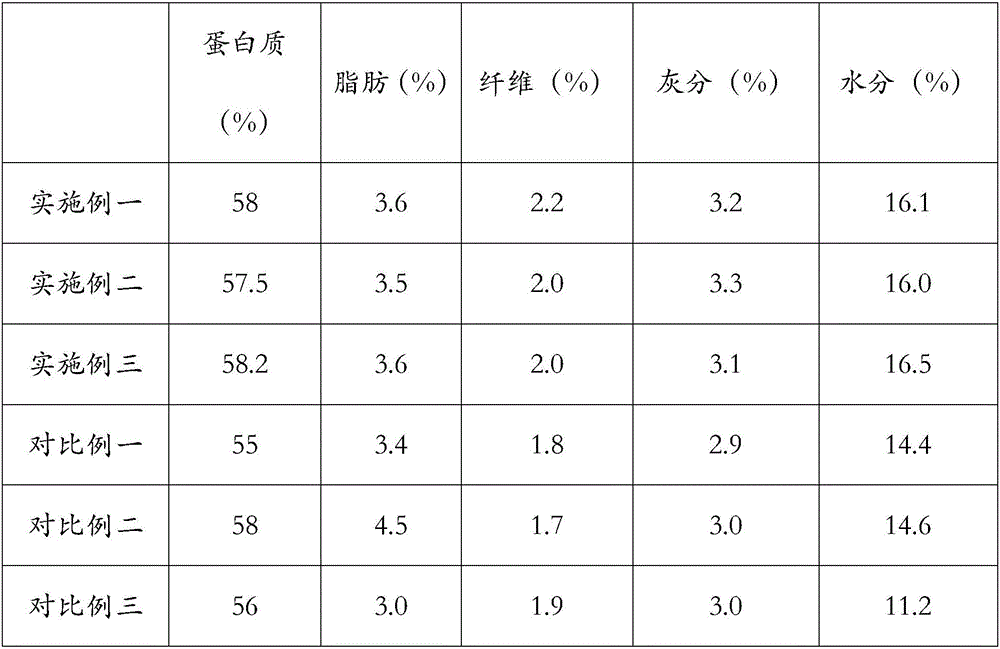

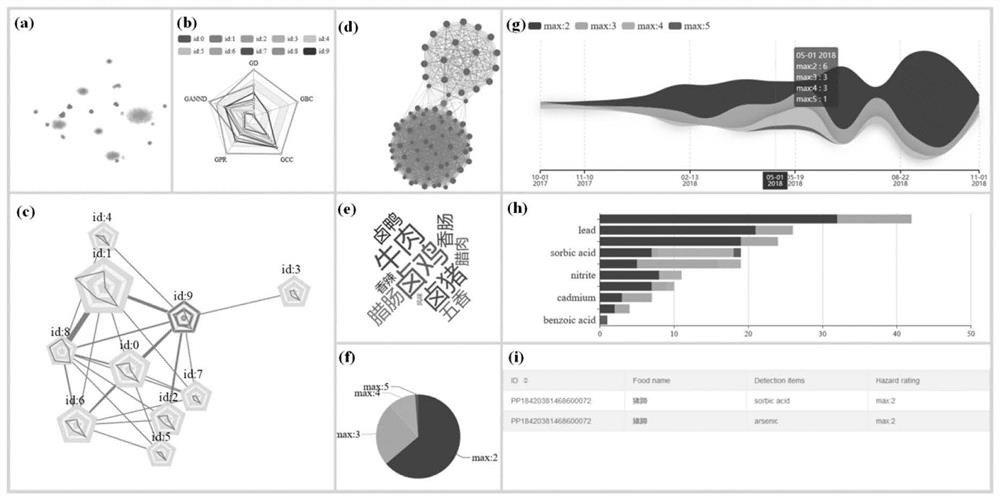

High-risk food and hazardous substance visual analysis method and system based on graph embedding

ActiveCN112148834AEfficient discoveryCharacter and pattern recognitionResourcesWhole foodFood safety

The invention discloses a high-risk food and hazardous substance visual analysis method and system based on graph embedding. The method comprises the following steps: building an edge through taking food as a node and whether a common hazardous substance is detected in the food or not, and constructing a food association network; vectorizing the nodes of the food association network; and clustering the vectorized nodes so as to divide the nodes with similar structural features into the same sub-graph. Force-Radar is visually designed to serve as a radar map for displaying characteristic indexes of sub-maps, correlation between the sub-maps serves as an edge, an overview map of the whole network is formed through force-oriented layout, and the relation among the overview of the whole food correlation network, the structural characteristics of the sub-maps and the sub-maps is effectively displayed. By adopting the method and the system, the food association network can be interactively analyzed and explored, high-risk food and harmful substances can be discovered, and support is provided for food safety supervision.

Owner:BEIJING TECHNOLOGY AND BUSINESS UNIVERSITY

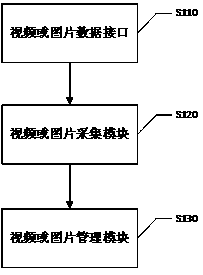

Method and device for obtaining food intake data, server, storage medium and system

InactiveCN110062183ASolve the inconvenience of calculating individual eating dataResolve inaccuraciesTelevision system detailsColor television detailsWhole foodFood intakes

The invention discloses a method and a device for obtaining food intake data, a server, a storage medium and a system. The method comprises the following steps: acquiring video or picture data of eachfood to be taken into the mouth in an individual feeding process, wherein the acquired video or picture data comprises fingers or tools of the individual food to be taken. According to the technicalscheme, the problems that in the prior art, through the whole food picture before eating and the remaining food picture after eating, a special object serves as a reference object, and calculation ofindividual feeding data is inconvenient and inaccurate are solved. Compared with the prior art, the video or picture data acquired by the method can be utilized to carry out more convenient and accurate food intake data analysis on individuals in a subsequent process.

Owner:王睿琪

Food processing workshop environment control method

InactiveCN112306127AMeet the production conditionsEnsure safetyLavatory sanitoryClosed circuit television systemsWhole foodProcess engineering

The invention provides a food processing workshop environment control method, and relates to the technical field of food processing. The environment control method comprises an overall environment control module, and the overall environment control module comprises a personnel access control module, a workshop internal control module, an equipment cleaning control module and an environment safetymonitoring module, and the workshop internal control module comprises a workshop cleanness control module and a workshop environment control module. Through setting of module control forms such as thepersonnel access control module, the workshop internal control module and the equipment cleaning control module, stable control work can be performed on the whole food processing workshop, it can beguaranteed that the interior of the workshop can meet the production conditions required by food processing, meanwhile, stable sterilization and disinfection control work can be performed, and throughthe arranged environment safety monitoring module, it can be guaranteed that the food production workshop has a stable safety monitoring system, and the personal safety and the property safety are guaranteed.

Owner:常德市源宏食品有限责任公司

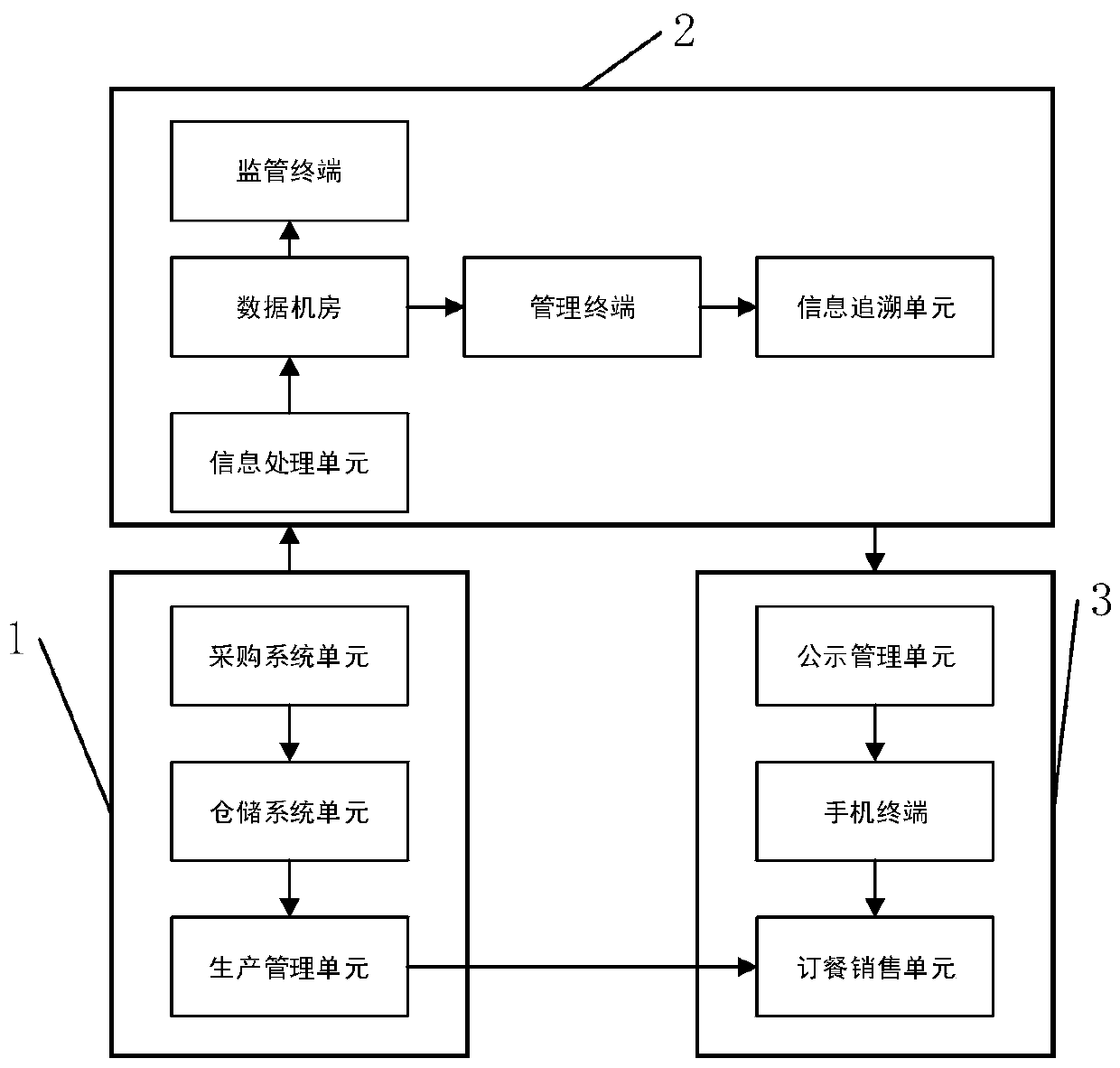

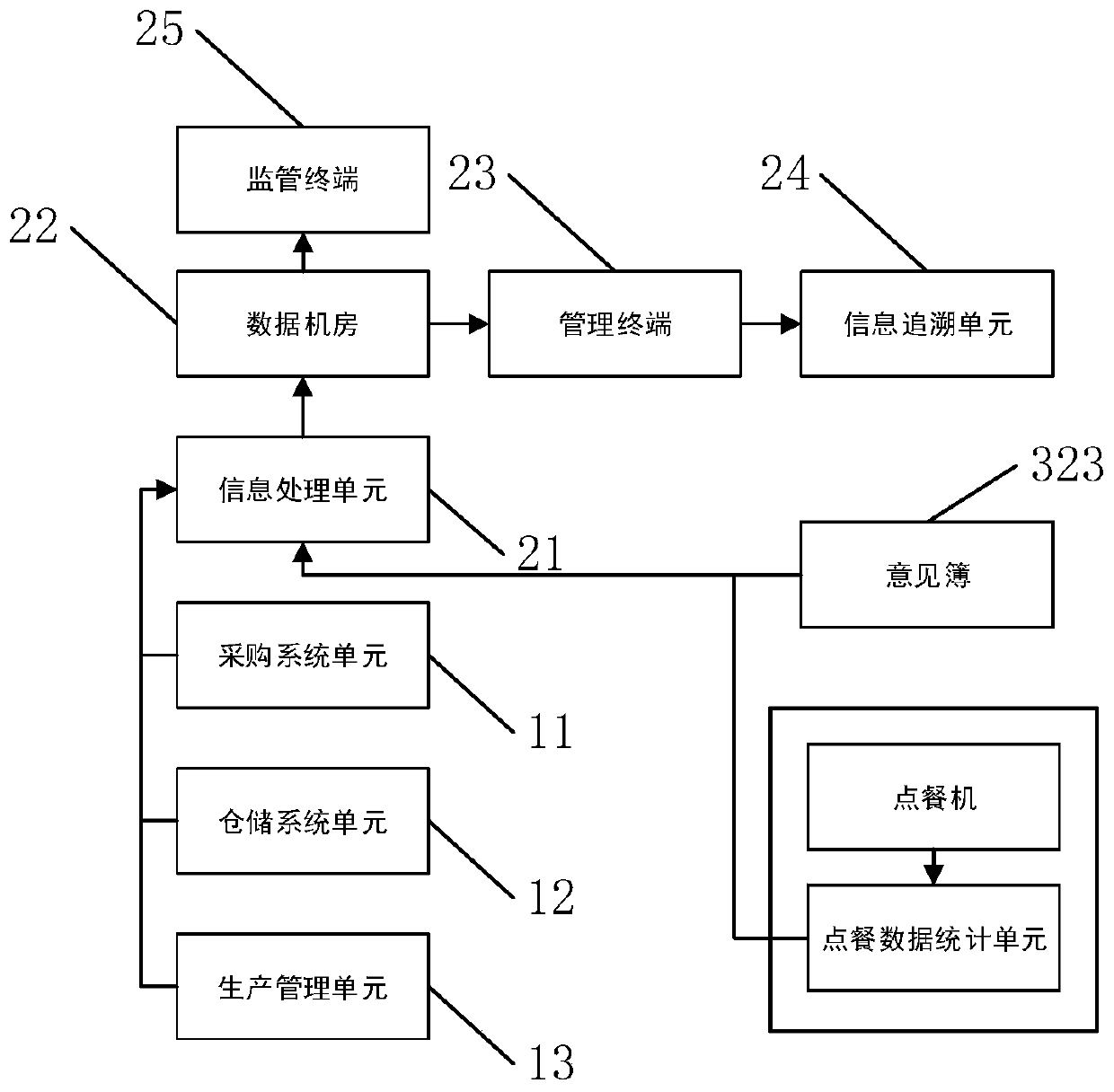

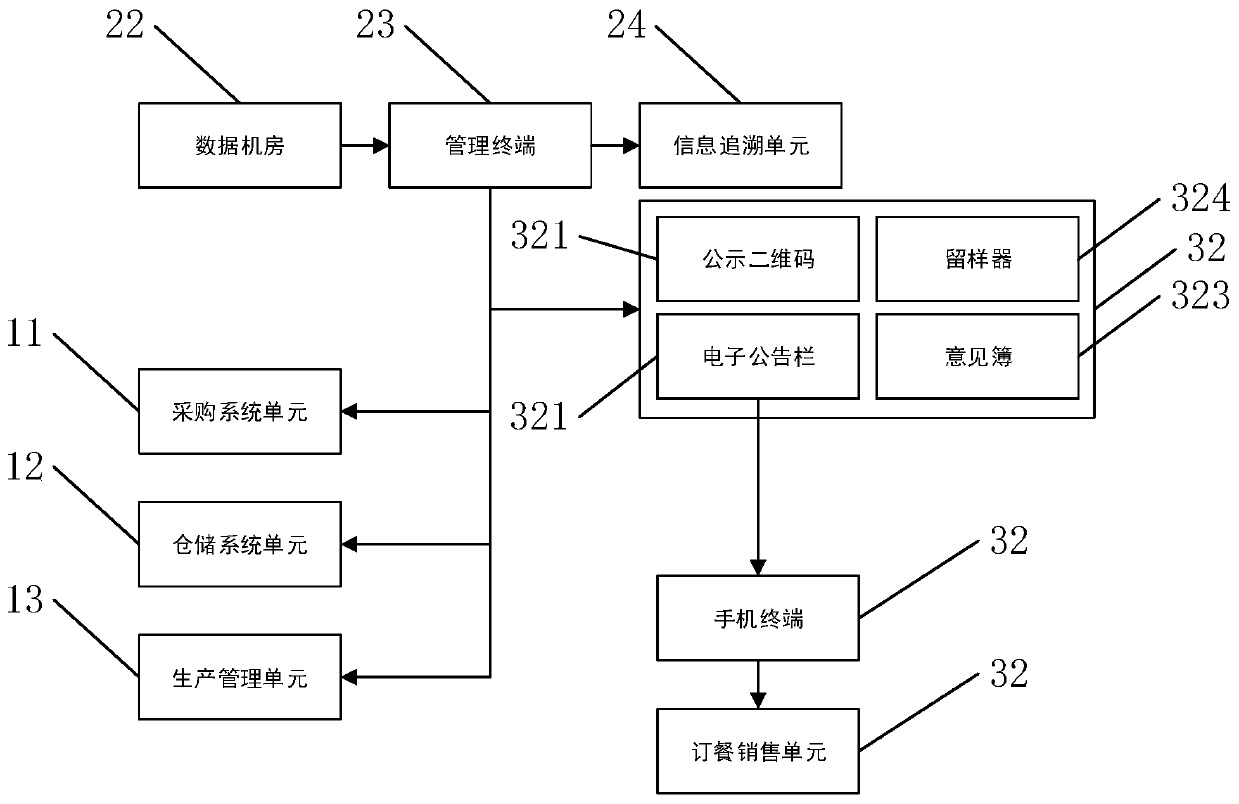

School canteen whole-course management system

PendingCN110533395AEasy to query dataImprove work efficiencyOffice automationCommerceWhole foodEngineering

The invention relates to the technical field of canteen food safety management, and discloses a school canteen whole-course management system. Compared with the prior art, the school canteen whole-course management system has the advantages and effects that the school canteen whole-course management system comprises the production part, the data part and the sales part, the production part is usedfor production, purchasing and manufacturing, the data part is used for data receiving, processing and accident tracing, and the sales part is used for publicizing announcements and selling meals. The video technology and the two-dimensional code technology are combined, on one hand, information can be accurately collected, decision making is assisted, and waste is reduced; on the other hand, tracking, traceability and improvement of the whole food making process are achieved, efficiency is improved, the root of a problem can be found in time after a food safety accident happens, other potential victims can be rapidly positioned, and harm of the problem is reduced; and a database can be established to perform early warning on food safety risks, so that the probability of occurrence of food safety problems is reduced, and the dining safety of teachers and students is powerfully guaranteed.

Owner:谷上科技(武汉)有限公司

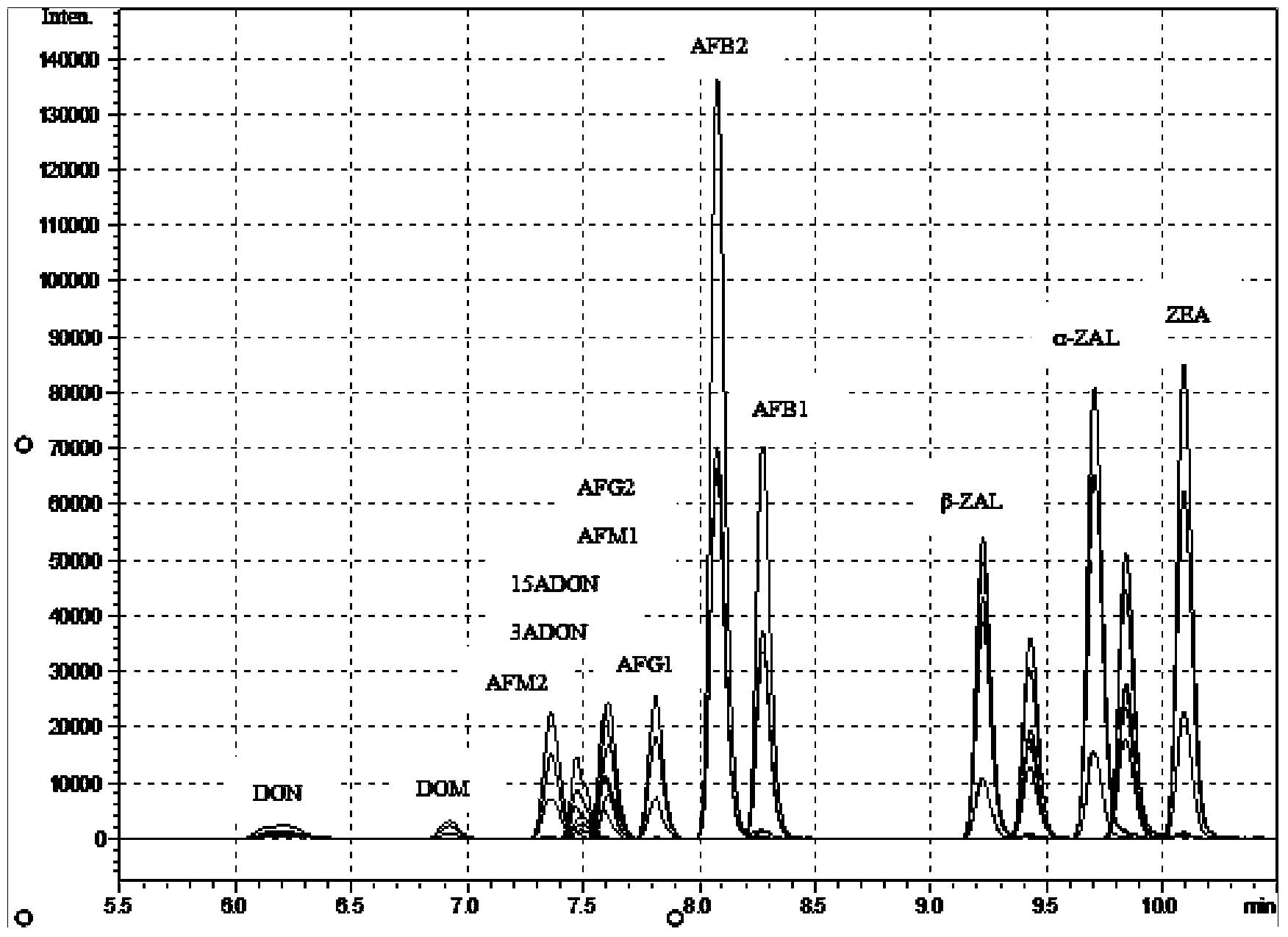

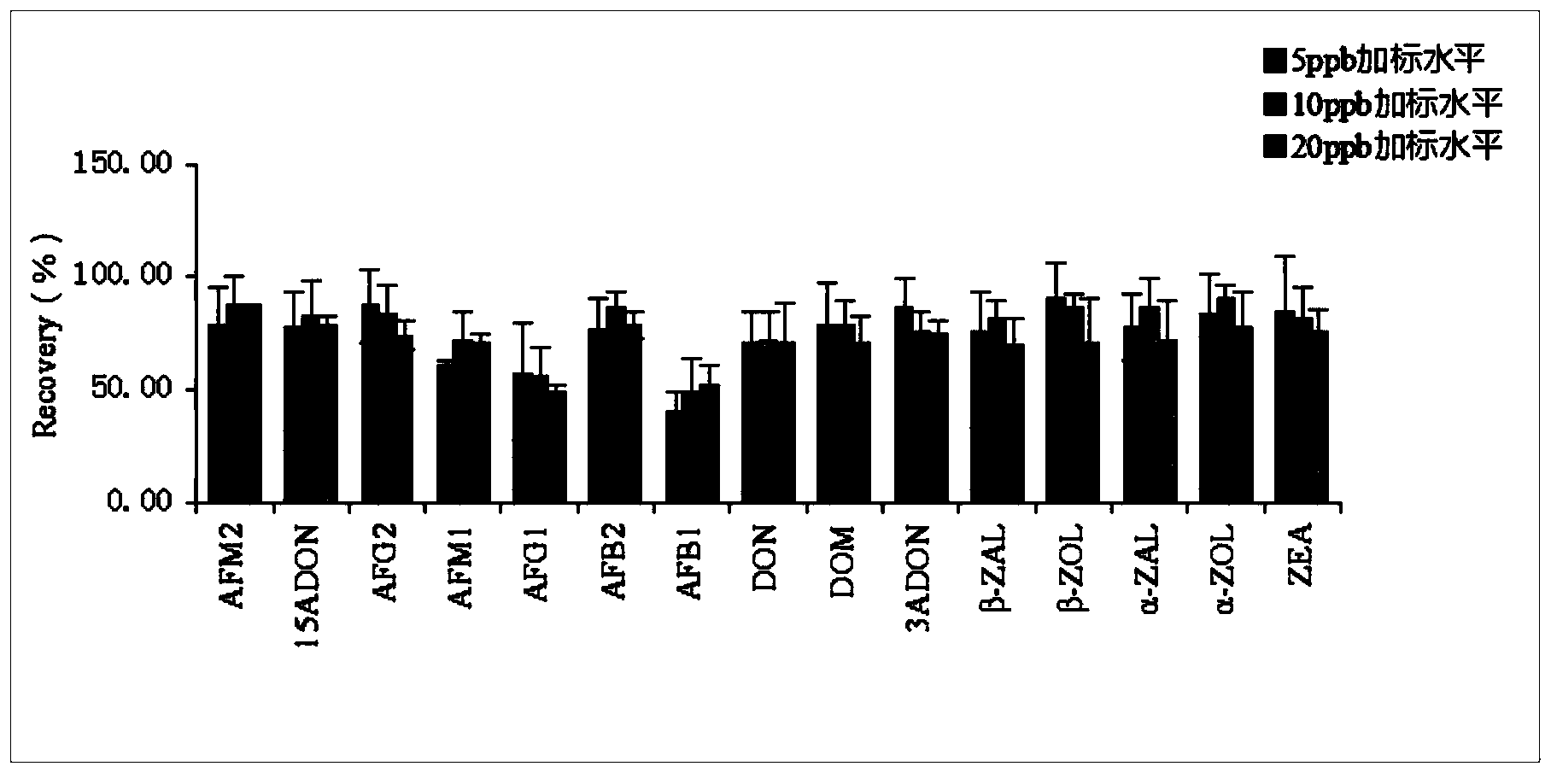

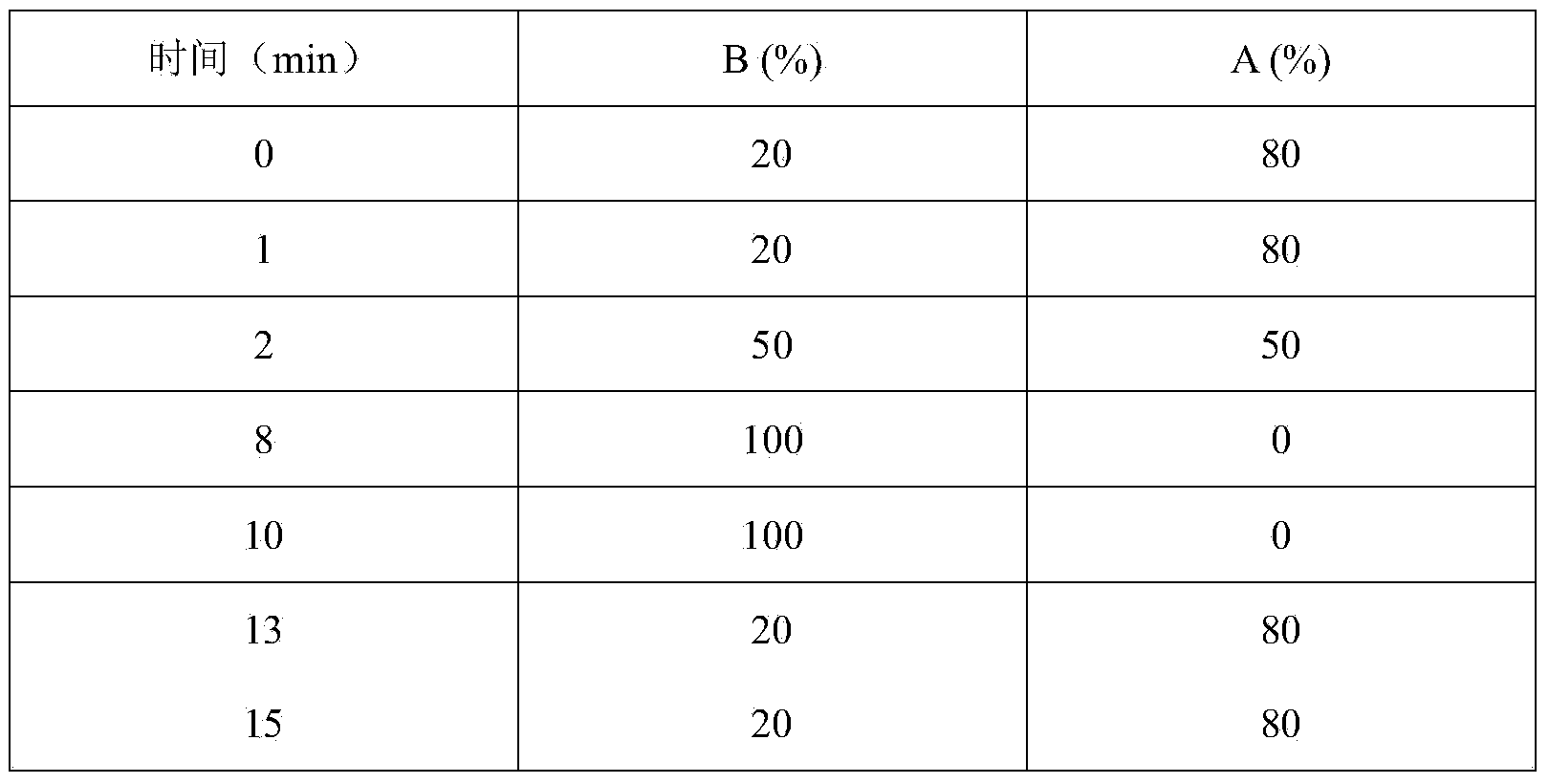

Method for detecting multiple fungal toxins in egg

The invention provides a method for detecting multiple fungal toxins in an egg. The method comprises the following steps: step 1, sequentially adding water and an organic extracting agent into a raw and fresh egg sample which is evenly stirred, whirling and then carrying out mechanical oscillation for certain time; step 2, adding a certain amount of salt into the egg sample after the oscillation extraction, whirling, centrifuging to obtain a supernatant, and drying the supernatant; and step 3, redissolving the dried sample with a mobile phase applied to liquid chromatography tandem mass spectrometry, then filtering and carrying out qualitative or quantitative detection on the fungal toxins by virtue of a liquid chromatograph / mass spectrometer. According to the method, few pretreatment steps are carried out on the sample, so that the time consumption of a sample pretreatment phase in a whole food analysis experiment is greatly reduced, the loss of a target compound in an operating process is lowered, system errors are greatly reduced and the extraction efficiency of the target compound is improved; and all adopted reagents are very cheap and are less in usage amount, so that the experiment cost is lowered and the environmental pollution is reduced.

Owner:UNIV OF SHANGHAI FOR SCI & TECH +1

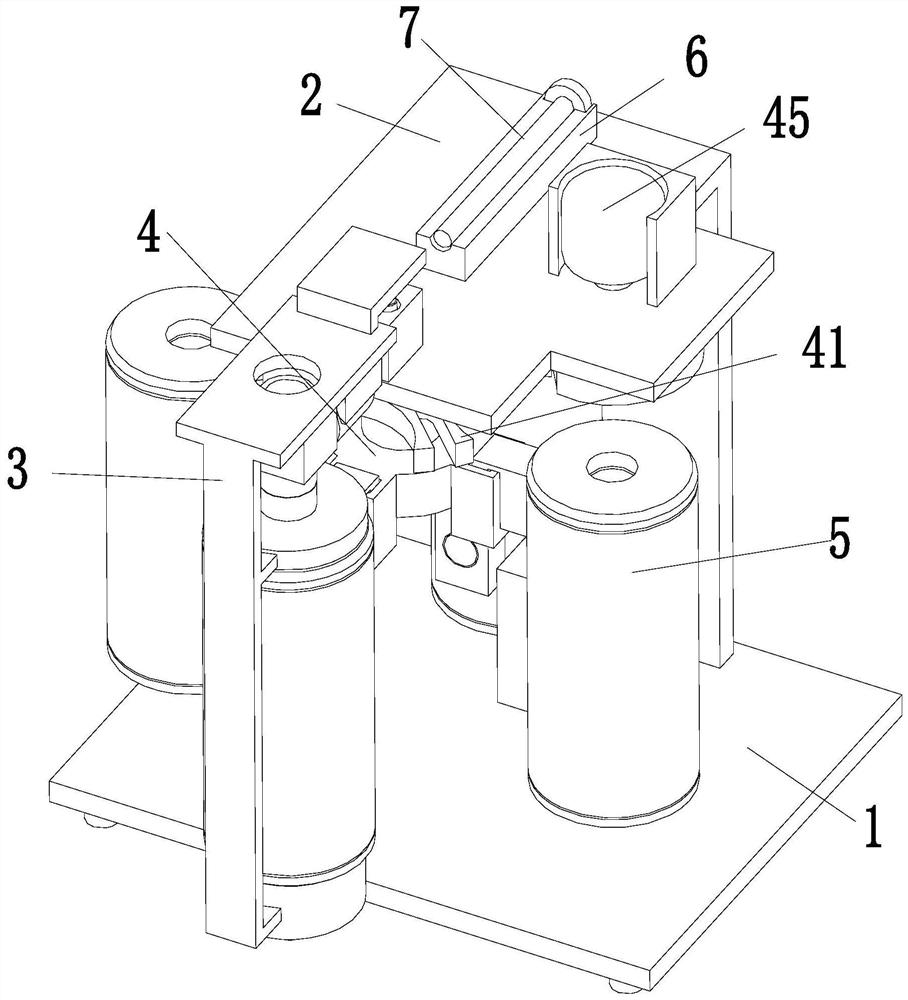

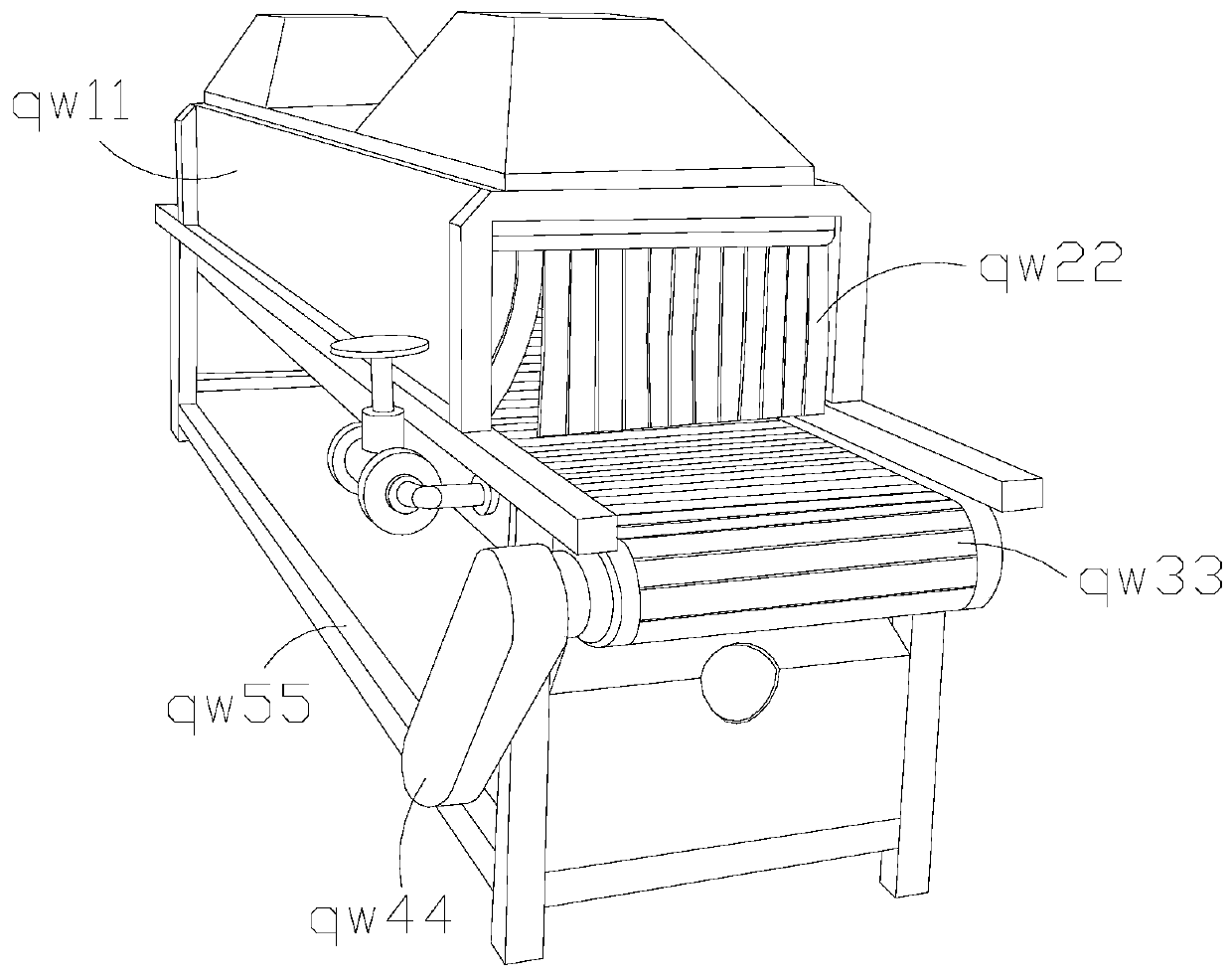

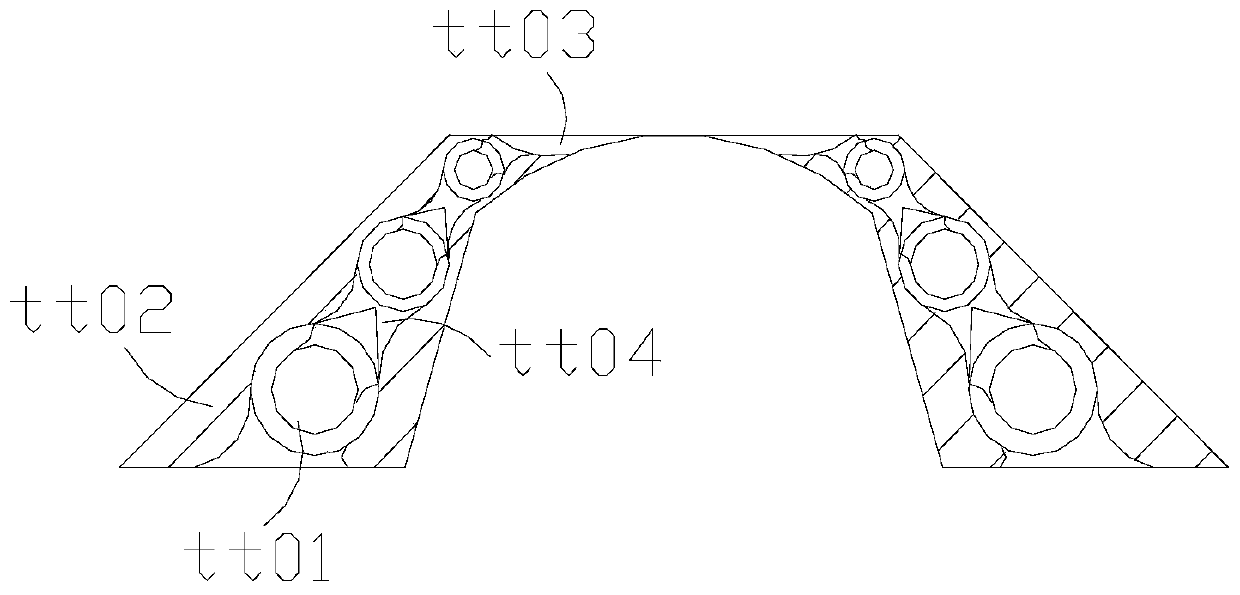

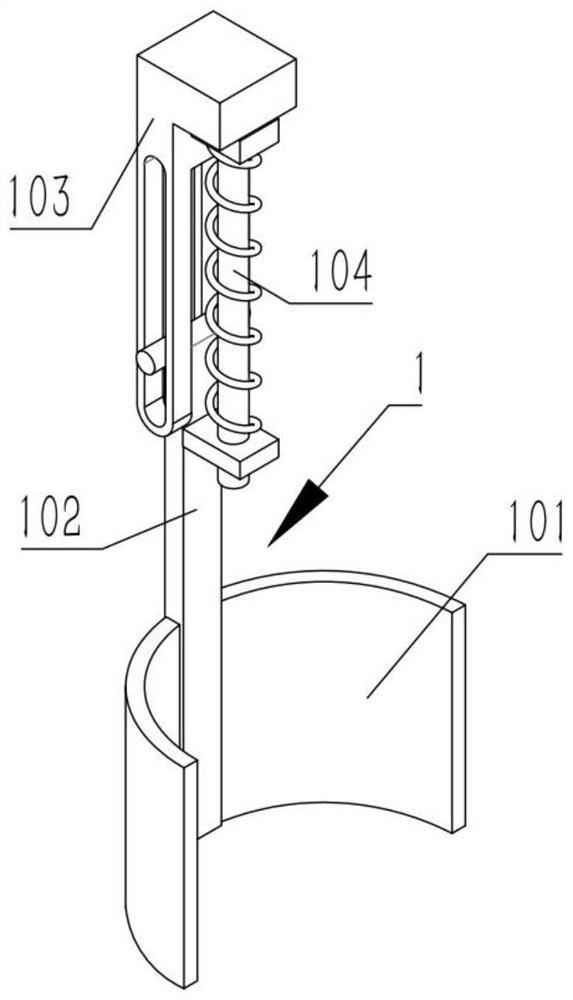

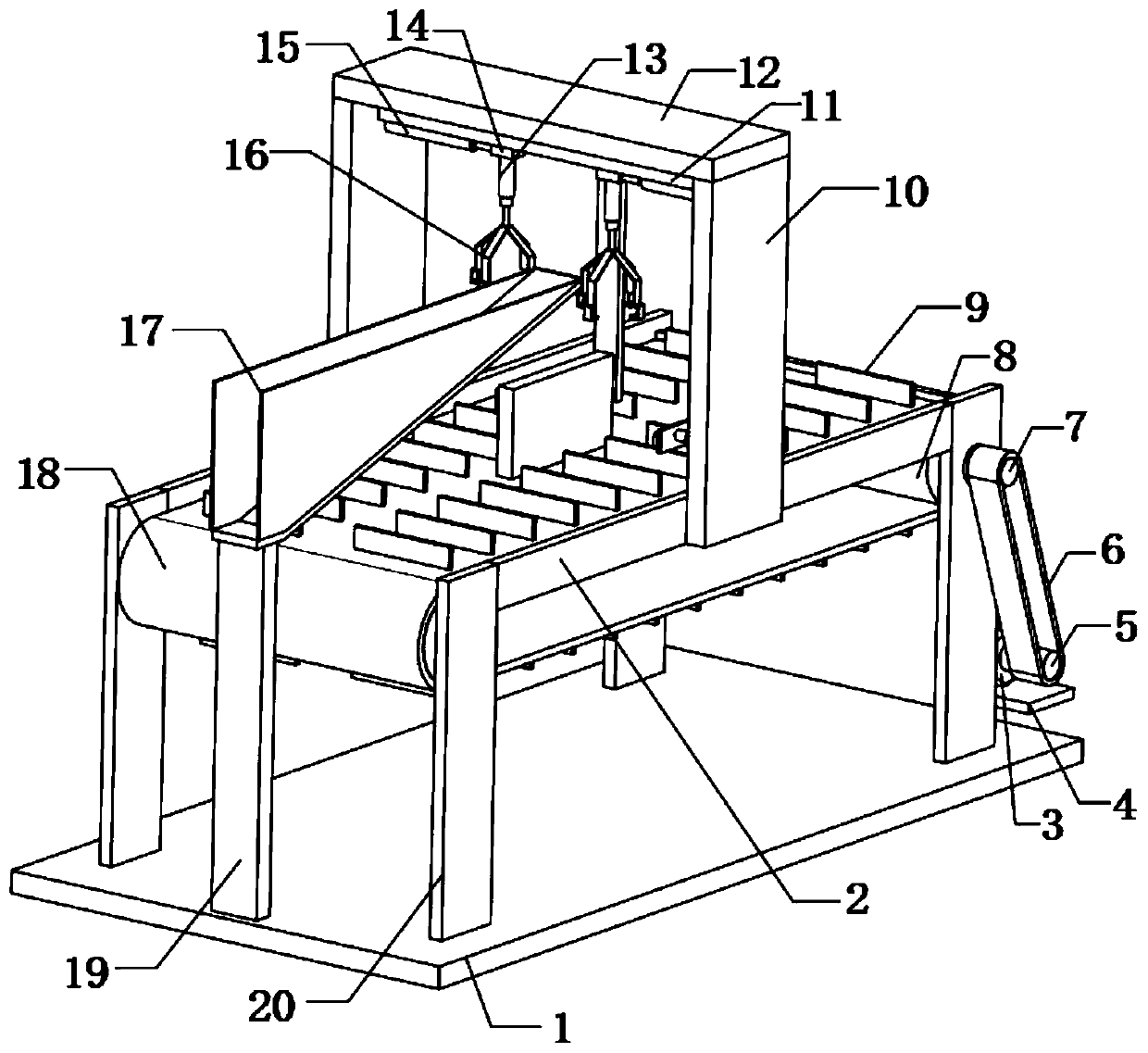

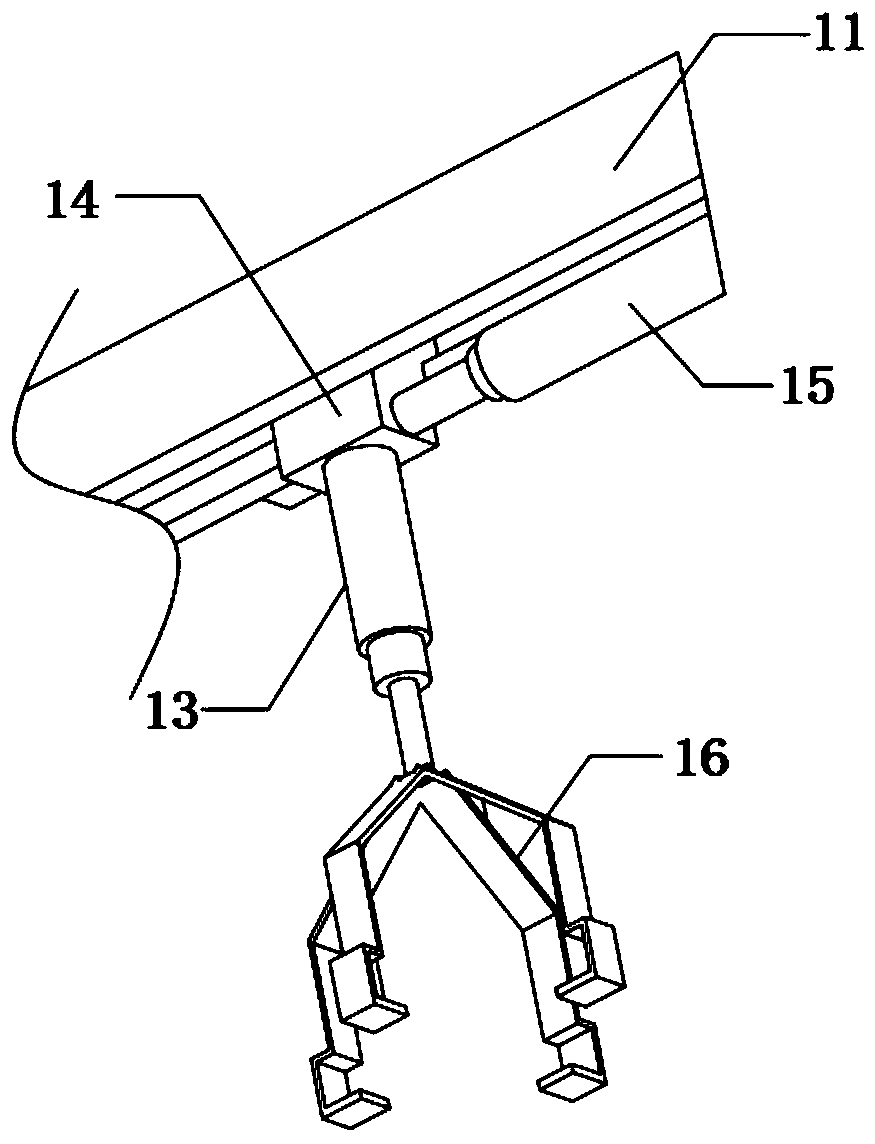

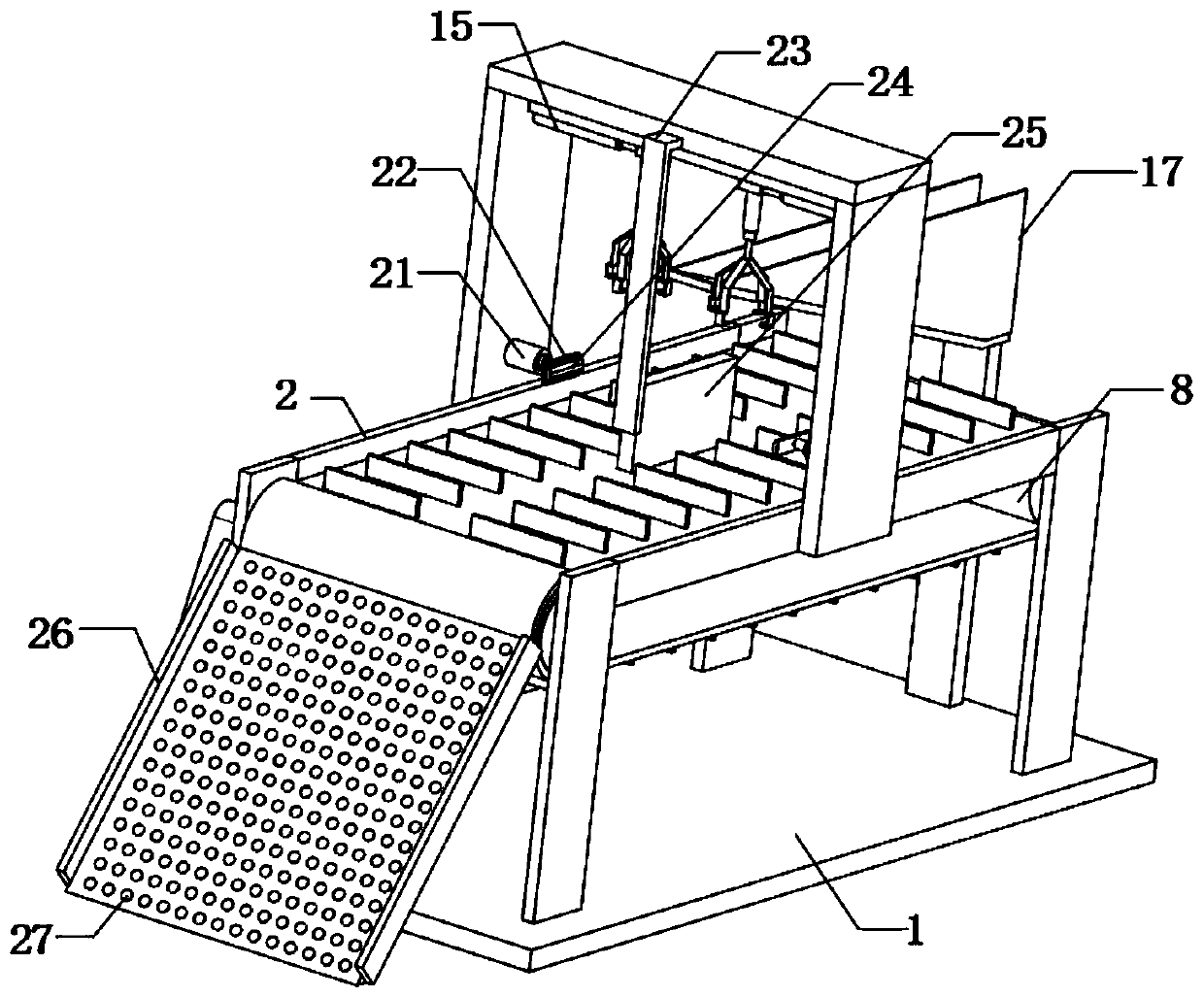

Sampling device for food detection

The invention relates to a food detection sampling device which comprises a base, a fixing frame, an air suction device, an intermittent driving device, sampling devices, a placing seat and an extrusion rod, the upper end of the base is provided with the fixing frame, the front end of the fixing frame is provided with the air suction device, the fixing frame is provided with the intermittent driving device, and the intermittent driving device is uniformly provided with the sampling devices; the placing seat is mounted at the upper end of the fixing frame, and the extrusion rod is inserted into the placing seat. The device can solve the problems that a small amount of liquid may leak due to blockage when a container opening is blocked after fluid food is extracted because the fluid food has certain fluidity, so that the sample amount is reduced, the efficiency of multi-group manual sampling is lower, the operation is more troublesome, quick sampling is difficult to carry out in a short time, thus the pause time of an assembly line is long during sampling each time, so that the whole food processing efficiency is influenced.

Owner:安徽国泰众信检测技术有限公司

Food processing plastic chain plate production line

The invention discloses a food processing plastic chain plate production line. The food processing plastic chain plate production line structurally comprises a food processing box, a blocking curtain,plastic chain plates and a side belt body. The blocking curtain is connected with the food processing box. An adhesion concave opening of each convex jacking head abuts against food, an internal jacking and scattering ball in each plastic chain plate jacks the whole food and keeps the highest point, the outer surface of the food is jacked, the food has a highest point, and the two sides graduallyslide down; connection between the constant force uniformizing balls is achieved through space supporting rubber, internal hard angle cores jack the overall form, the food is fixed through point positions, and heat of the food can be appropriately dissipated and prevented from gathering and softening the chain plates; return corners drag a protective layer to bear the overall bending force, whenthe return corners are forced apart and force is applied to the return corners, the return corners bear external force at a large area and make the external force to be evenly distributed, rubber pulling blocks of the return corners are bent along with the radian of curved openings, so that when the chain plate deforms and moves at a bending angle, the range of the chain plate can be limited, andthe chain plate can be pulled and reset in a following process.

Owner:王国义

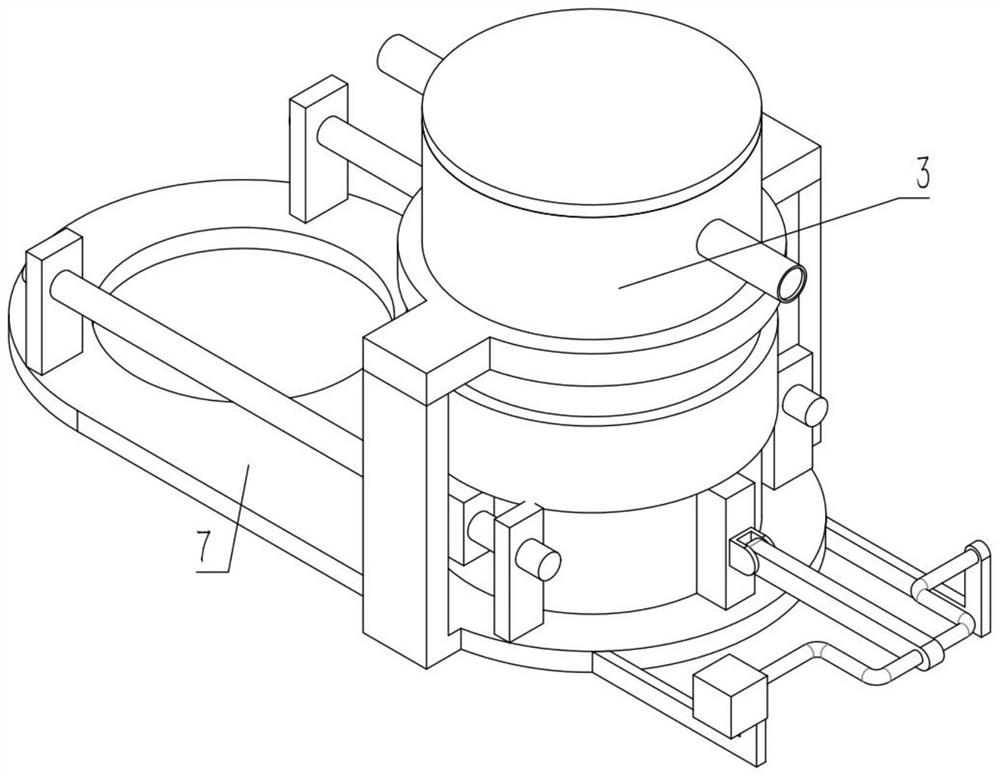

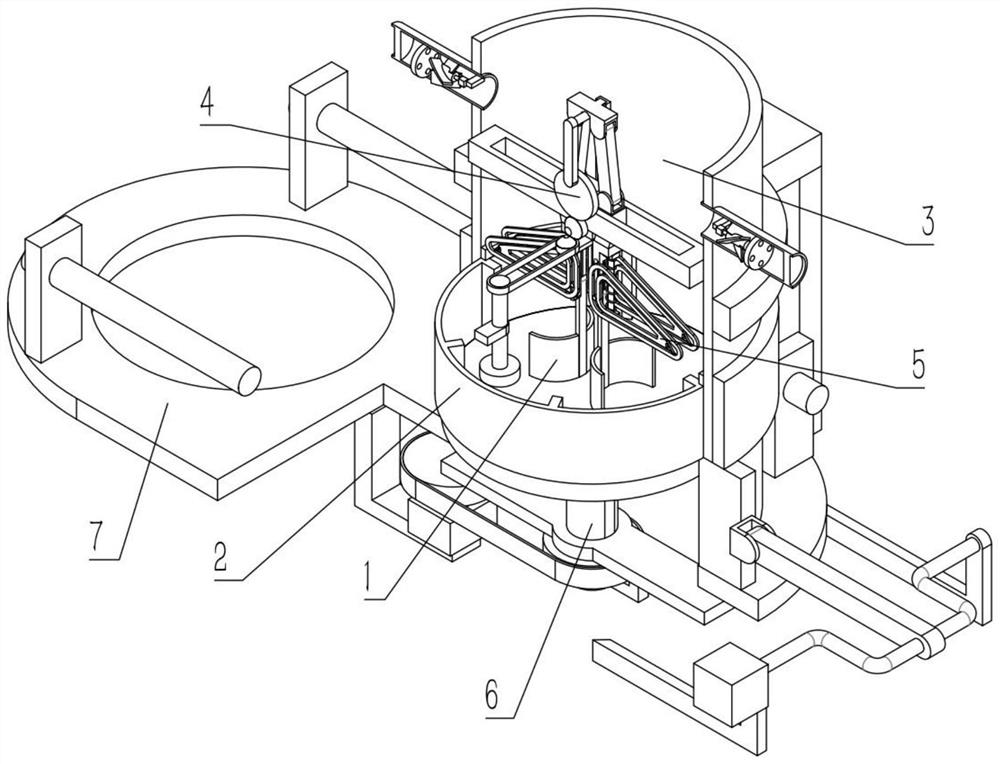

Food fermentation equipment and food fermentation method

InactiveCN112725156AEvenly heatedImprove qualityBioreactor/fermenter combinationsBiological substance pretreatmentsWhole foodProcess engineering

The invention relates to the technical field of food fermentation, in particular to food fermentation equipment and a food fermentation method, and a food fermentation method of the food fermentation equipment comprises the following steps: step 1, putting raw materials to be fermented into a fermentation box, step 2, adjusting the temperature and oxygen content in the fermentation box, step 3, moving a stirring plate and a circular ring to enable food to be in full contact with the inner wall of the fermentation box, and enabling the food to be heated uniformly, and step 4; enabling the transportation barrel to move to push the food on the base to move and fall into a containing container; and during food fermentation, the food at the middle is pushed to the outside and then the external food is driven to rotate, so that the external food flows into the interior, the whole food is heated more uniformly in the fermentation process, and the fermentation effect is better.

Owner:唐宪峰

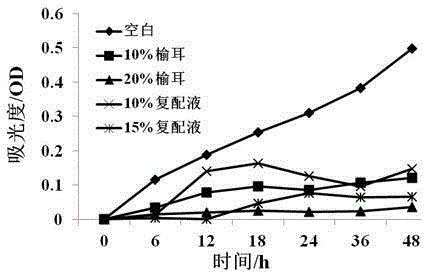

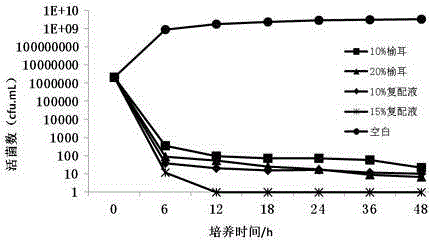

Fresh-keeping agent for fresh edible mushrooms and preparation method thereof

ActiveCN104351330AImproved preservation levelExtended shelf lifeFruit and vegetables preservationEscherichia coliStaphylococcus aureus

The invention discloses a fresh-keeping agent for fresh edible mushrooms, relates to a fresh-keeping agent for fresh edible mushrooms, prepared by compounding gloeostereum extract, auricularia auricula polysaccharide liquid and Nisin, and a preparation method thereof, belonging to the field of agricultural product processing, storage and fresh-keeping. The fresh-keeping agent comprises the following raw materials in percentage by mass of 6% of gloeostereum entity extract, 1.2% of auricularia auricula polysaccharide liquid, 1% of Nisin and 91.8% of distilled water by compounding. According to the invention, the fresh-keeping agent prepared by compounding several natural extracts has a good antibacterial effect, and inhibits escherichia coli and staphylococcus aureus and the like as the representatives of positive and negative spoilage microorganisms in food, so that the preservation period of edible mushrooms is prolonged, therefore, the fresh-keeping agent has a practical application value, and facilitates the improvement of the whole food preservation level.

Owner:冯磊

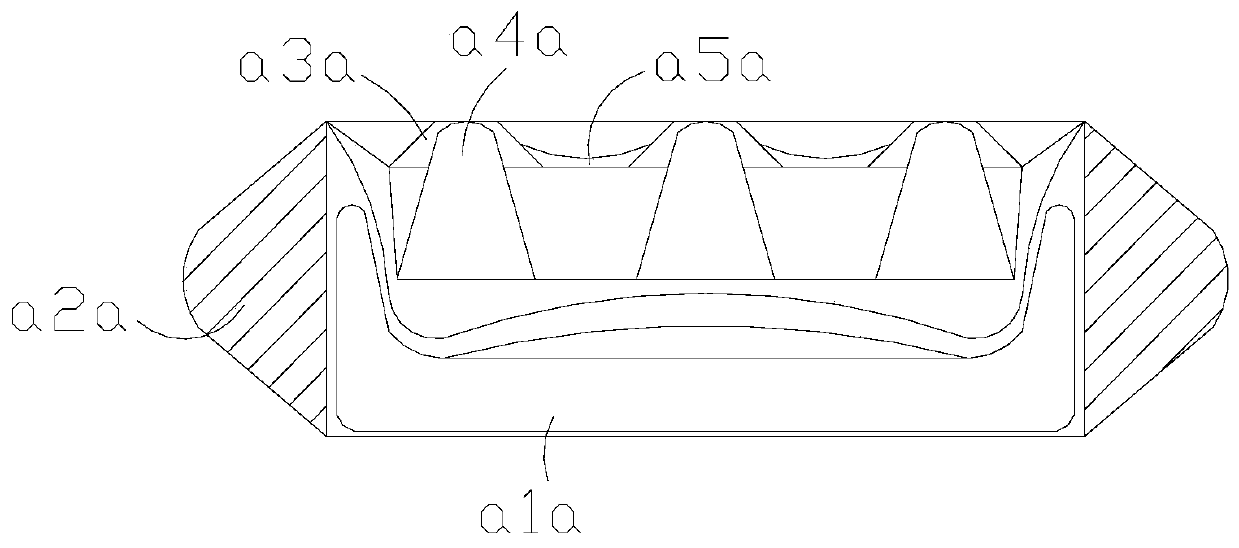

Hand-held edible rice type fast food and manufacturing method thereof

InactiveCN101530179AInhibit sheddingSolve the standardization problemFood coatingFood shapingFlavorInterior space

The invention relates to a fast food, in particularly a rice type fast food only depending on hand-held for completing food intaking process. The invention provides a rice type fast food which only depends on hand-held for completing the whole food intaking process, the rice and disc are integrated, easy processed and formed, the fast food can be eat by hand-held according with standard manufacturing. The invention also provides a method for manufacturing the fast food. The hand-held edible rice type fast food has characteristics that: a rice body (3) has an inner space, the inner space is filled with a disc flavor core (4), the bottom of the rice body (3) and the disc flavor core (4) are a base seat (5).

Owner:杨斌

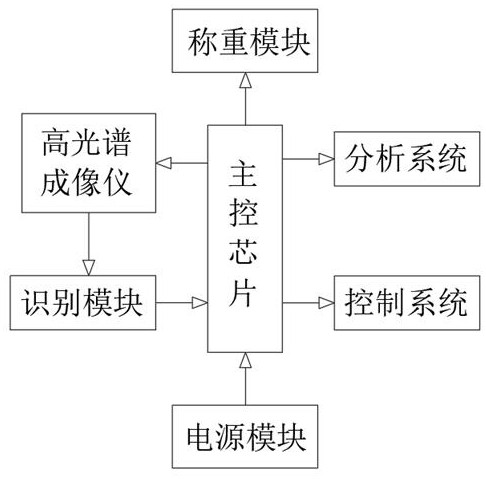

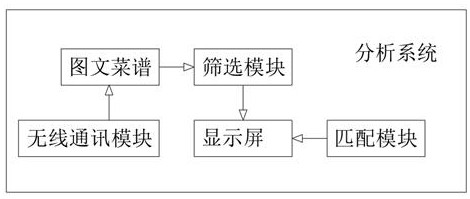

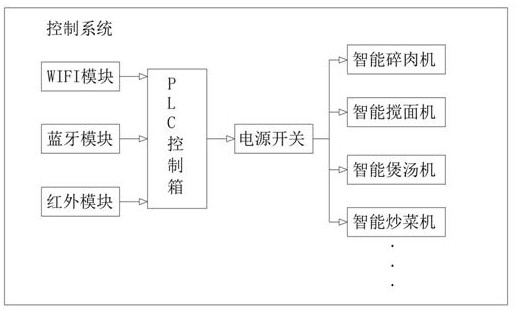

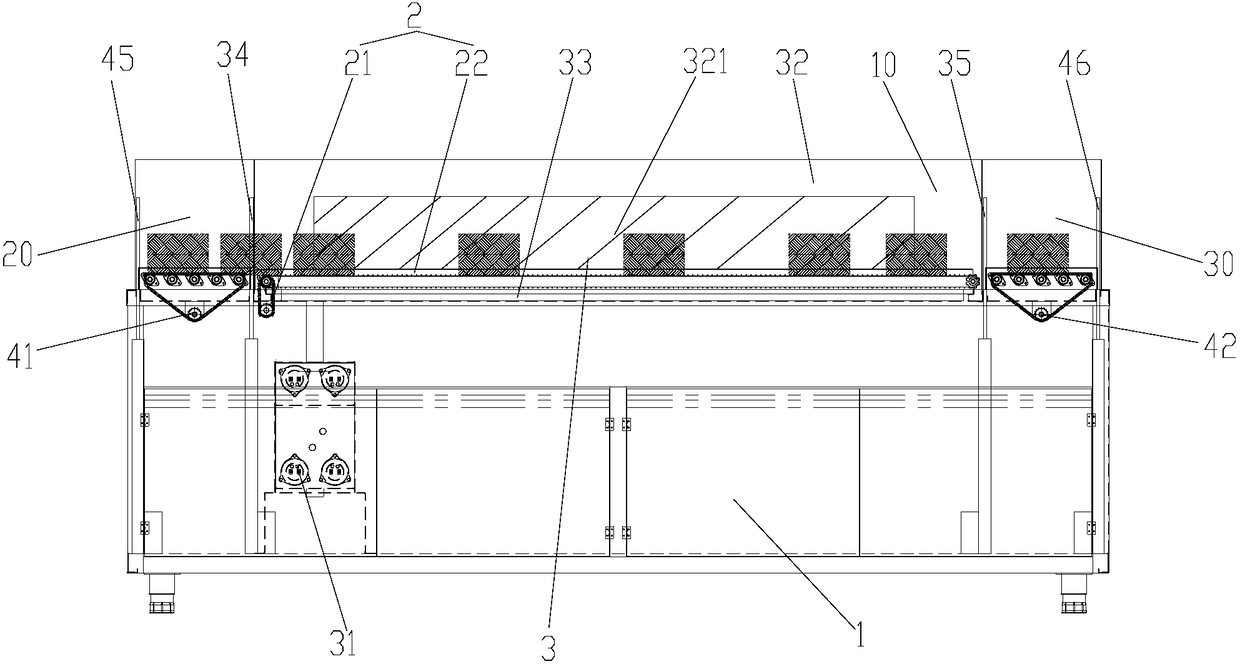

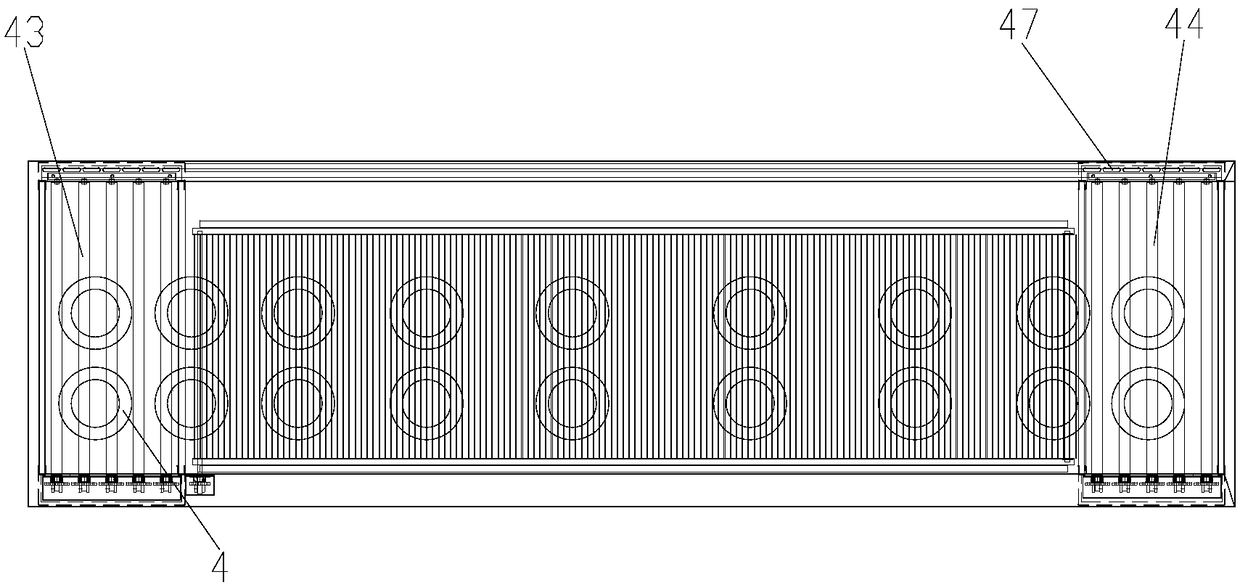

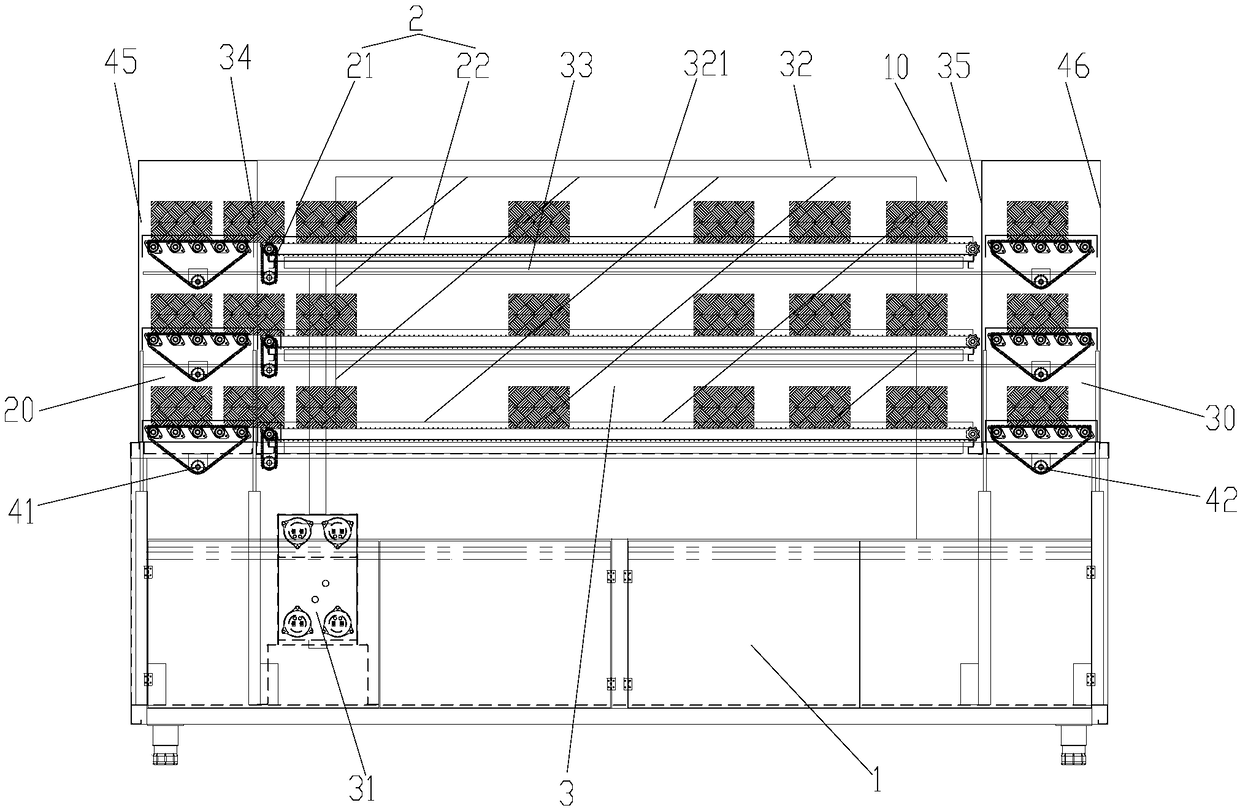

Automatic food material detecting, metering and processing auxiliary system

The invention discloses a food material automatic detection metering processing auxiliary system, and the system comprises a main control chip, a hyperspectral imager, an identification module, a power supply module, a weighing module, an analysis system and a control system; the main control chip is used for controlling and executing the work of the whole food material automatic detection metering processing auxiliary system, and the hyperspectral imager is used for shooting a food material image; the identification module is used for identifying the types of food materials, the power supplymodule is used for supplying power to the whole food material automatic detecting, metering and processing auxiliary system, and the weighing module is used for metering the weight of food. Accordingto the invention, the processing scheme of the food materials can be automatically obtained through the identified food material types and provided for a user, meanwhile, parameters such as the temperature, time and speed needed by processing can be matched according to the processing scheme selected by the user and the weighed food material weight, the practicability is higher, work of kitchen household appliances can be controlled, the functionality is higher, the convenience of daily use is improved, and the use is more facilitated.

Owner:深圳市澳特莱恩电器科技有限公司

Chain type steaming baking oven

The invention relates to a chain type steaming baking oven. The oven includes a frame; the frame is provided with a driving device, a steaming baking device and conveying devices; the driving device includes a first motor and a first transmission device driven by the first motor; the steaming baking device includes a steam generator, a steam hood and a steam outlet pipe covering the first transmission device, and a first air brake and a second air brake disposed at two ends of the first transmission device, and the steam hood and the first air brake and the second air brake form a first confined space; and the conveying devices are disposed on two ends of the steaming baking device. The steaming baking device is disposed on transmission devices, the steaming baking device is also providedwith a transparent glass cover or other transparent plate to display a whole food production process to customers, and also is provided with the air brakes and an air extracting device to make escaping steam pump out when food enters and leaves, at the same time, cold air does not enter the steaming baking device to affect the temperature in the steaming baking oven; and the whole device is simplein structure and easy to use, so that people can watch the food production process, and a flow process is transparent.

Owner:刘明

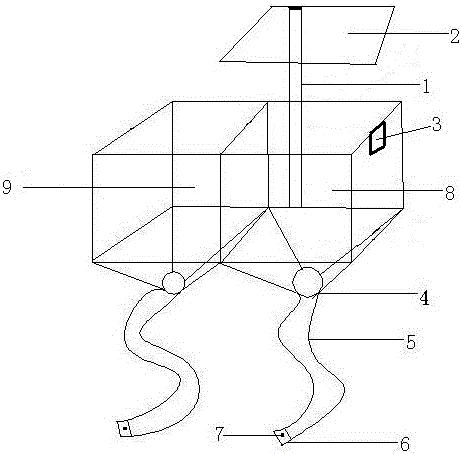

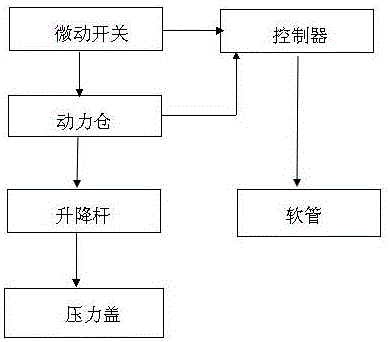

Tongue-control type food taking device

The invention relates to the field of daily articles, in particular to a tongue-control type food taking device. The tongue-control type food taking device comprises a lifting rod, a pressure cover, a power bin, a food outlet, a flexible pipe, a controller, a microswitch, a rice container, and a porridge container. The tongue-control type food taking device has the advantages that the microswitch is controlled by a tongue, and is used for controlling the food at the food outlet to flow out or stop, and the whole food taking process can be completed by the tongue; a person who loses the hand function can automatically take foods, the self-esteem is maintained, and the self-confidence is enhanced; the burden of family members is reduced; both hands of a normal person are liberated to do other things; the structure is simple, and the production is easy.

Owner:HENAN ZHIJIN NETWORK TECH CO LTD

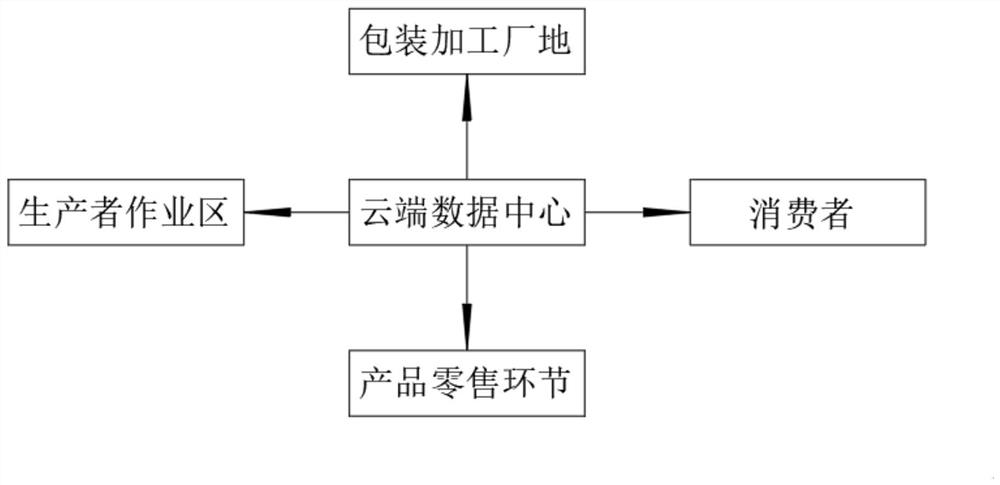

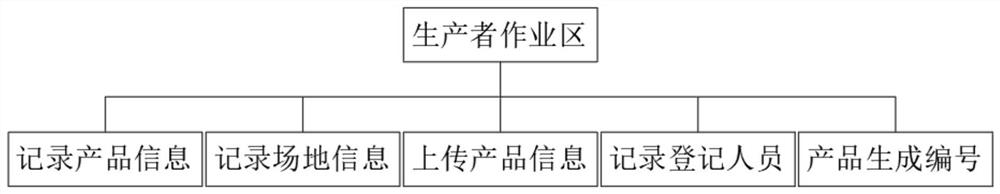

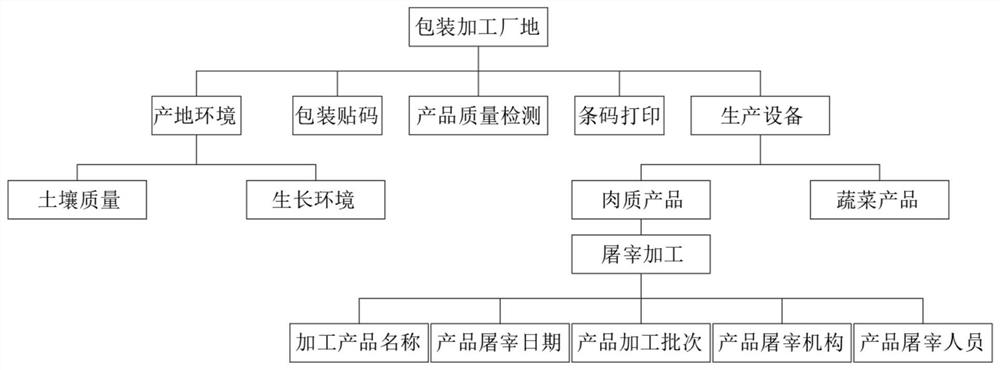

Intelligent agricultural product information tracing system based on agricultural internet of things

PendingCN111915319AGuaranteed food safetyRealize integrated dynamic real-time managementCo-operative working arrangementsCommerceAgricultural scienceTransit system

The invention relates to the technical field of smart agriculture, and discloses a smart agricultural product information tracing system based on agricultural Internet of Things, which comprises a cloud data center, a producer operation area system, a package processing field system, a consumer system and a product retail link system, products collected by the producer operation area system are transported to the packaging and processing site system through the transportation system to be processed, and then the processed products are transported to the product retail link system through the transportation system to be sold. The data information of the agricultural products is further detailed and accurate, so that in the tracing process of the agricultural products, the information of theagricultural products can be obtained at the first time, and consumers can trace back the agricultural products in the whole process at an intelligent terminal, including producing area environment,feed distribution, epidemic prevention quarantine, slaughter processing, logistics transportation and the like. In the whole food production, processing, circulation and sales process, the breadth ofproduct information and the length of traceable information are provided to the maximum extent.

Owner:陈琛

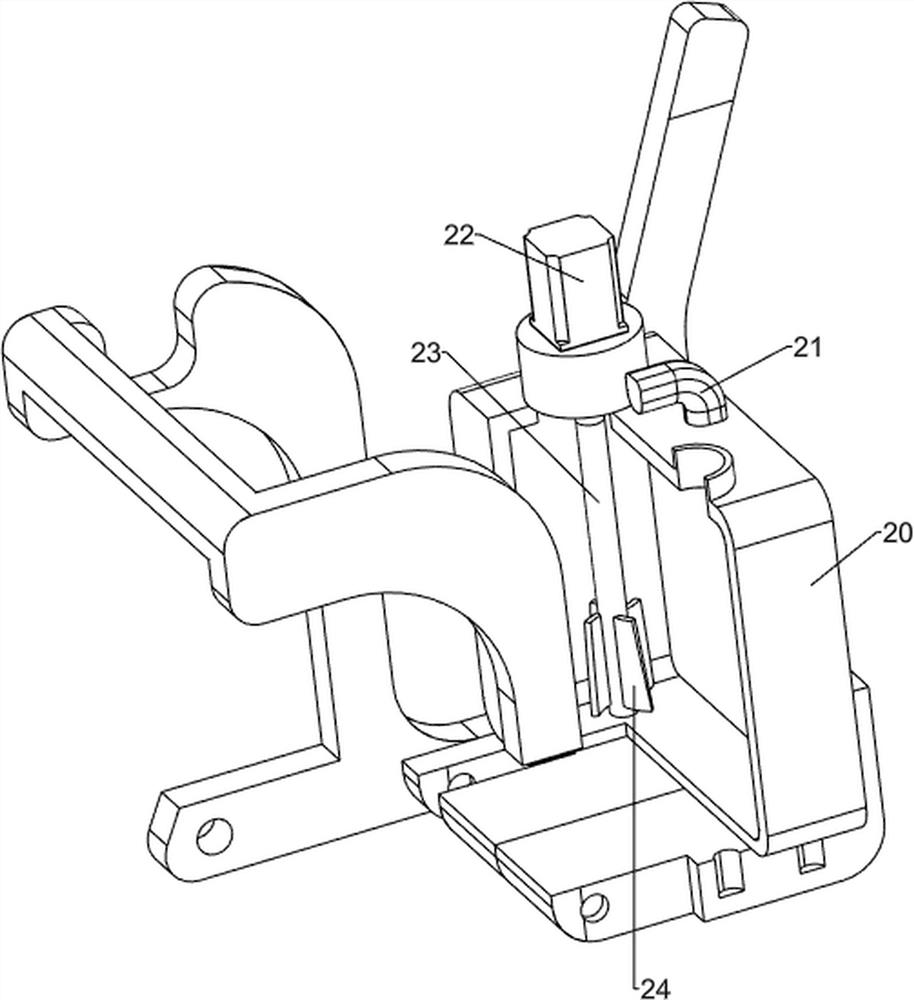

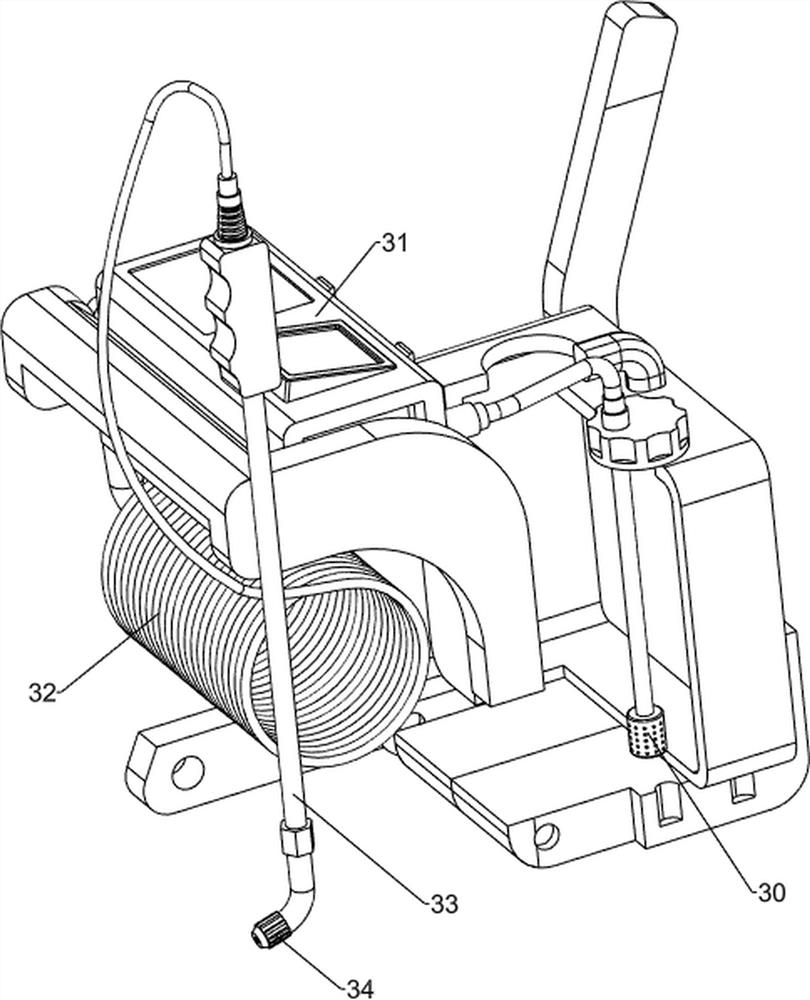

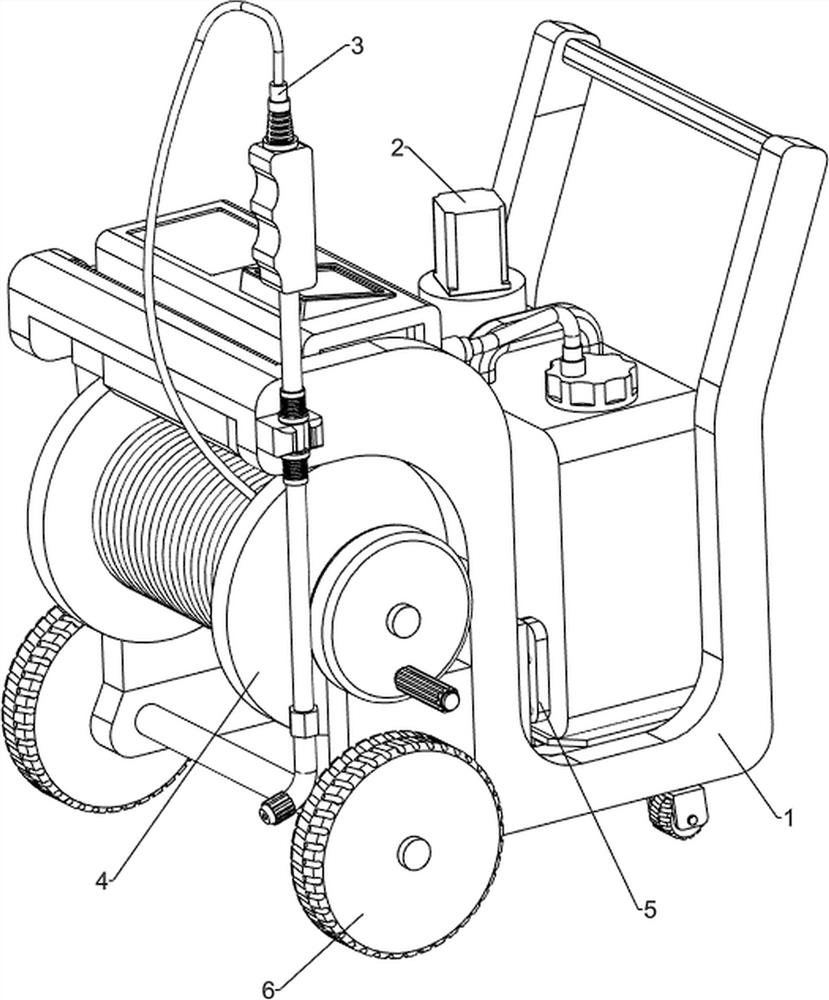

Intelligent microbial liquid spraying equipment for pond

InactiveCN112607870AAvoid taking it repeatedlyBiological water/sewage treatmentContaminated waterways/lakes/ponds/rivers treatmentBiotechnologyMicroorganism

The invention relates to intelligent spraying equipment, in particular to intelligent microbial liquid spraying equipment for a pond. The technical problem is to provide the intelligent microbial liquid spraying equipment for the pond, which can balance microbial colonies in the pond and supply biological nutrition to the pond. According to the technical scheme, the intelligent microbial liquid spraying equipment for the pond comprises a support, a stirring mechanism and a spraying mechanism, the stirring mechanism is arranged on the rear portion of the support, and the spraying mechanism is arranged on the front side of the stirring mechanism. According to the invention, the effect of supplying fine biological nutrition to balance the whole food chain in the pond is achieved, and enough microbial liquid can be contained in the storage box to be sprayed at one time, so that the microbial liquid is prevented from being taken repeatedly.

Owner:广州乔日贸易有限公司

Bagged food conveying and detecting device

InactiveCN110745470AImprove work efficiencyImprove practicalityConveyorsControl devices for conveyorsHydraulic cylinderWhole food

The invention discloses a bagged food conveying and detecting device, and relates to the technical field of food detection. The bagged food conveying and detecting device aims to solve the problems that according to an existing food conveying and detecting device, unqualified bagged food is inconvenient to discharge, manual discharging is needed, when multi-directional work is carried out, the discharging speed of workers is limited, and the whole food conveying and detecting progress is influenced. The bagged food conveying and detecting device specifically comprises a bottom plate, wherein fixing plates are arranged at the four corners of the outer wall of the top of the bottom plate. According to the bagged food conveying and detecting device, a sliding groove, a first hydraulic cylinder, a second hydraulic cylinder, a sliding block, a mechanical claw and a discharging groove are arranged, when the unqualified bagged food is discharged, the mechanical claw is driven by the first hydraulic cylinder to grab the unqualified bagged food, the second hydraulic cylinder drives the mechanical claw below the sliding block to move to the discharging groove, the mechanical claw loosens thefixation of the unqualified bagged food, the food slides down through the discharging groove, so that the discharging operation of the unqualified bagged food is completed, the working efficiency ofthe whole conveying and detecting is improved, and the practicability of the device is improved.

Owner:湖南省爱尚乐心食品有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com