Bagged food conveying and detecting device

A detection device and food transportation technology, which is applied in the direction of conveyor control devices, conveyors, conveyor objects, etc., can solve problems that affect the progress of food transportation detection, unsuitable feeding methods, and limited feeding speed, etc., to achieve Protects against wear, reduces friction, and improves accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

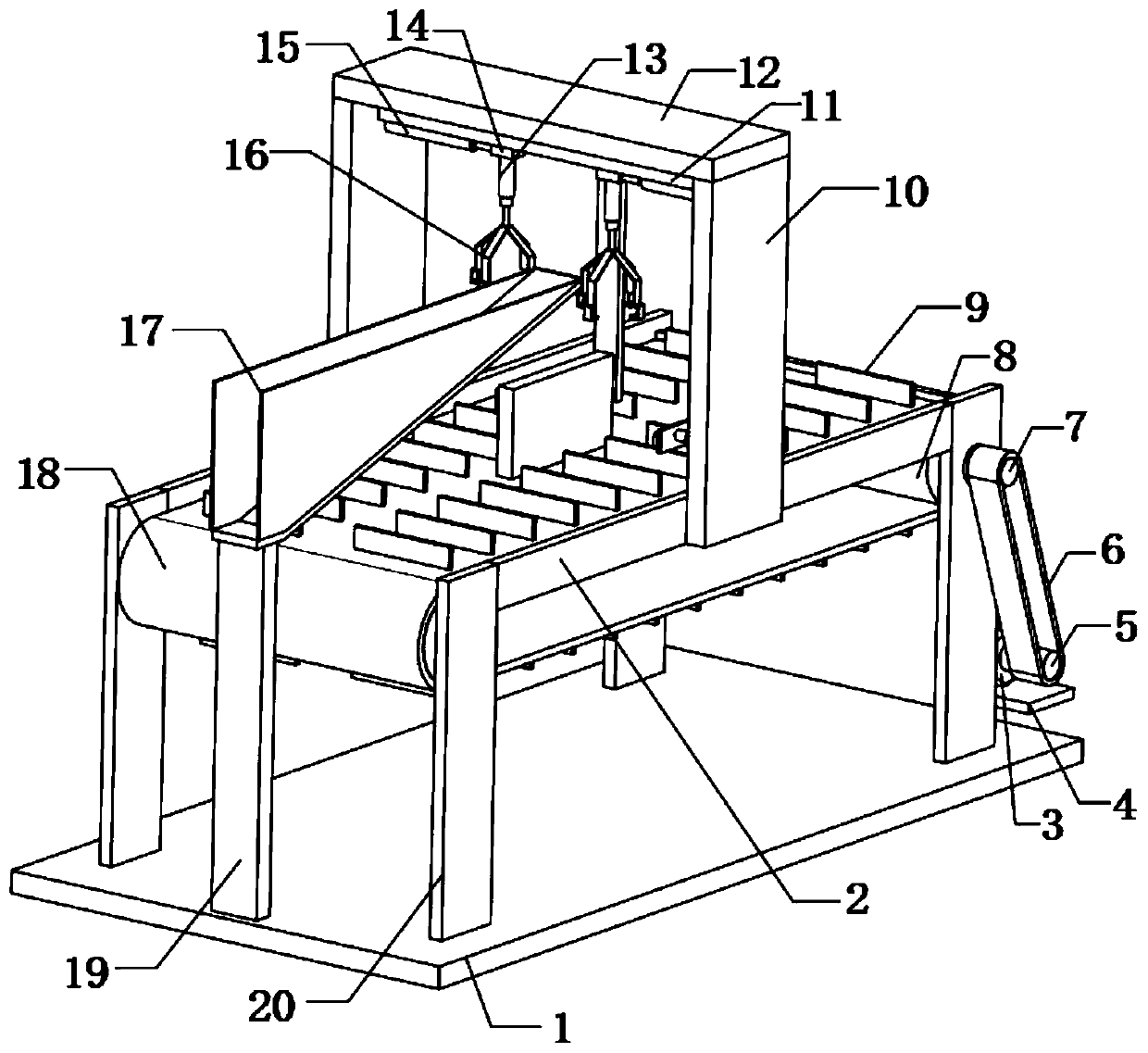

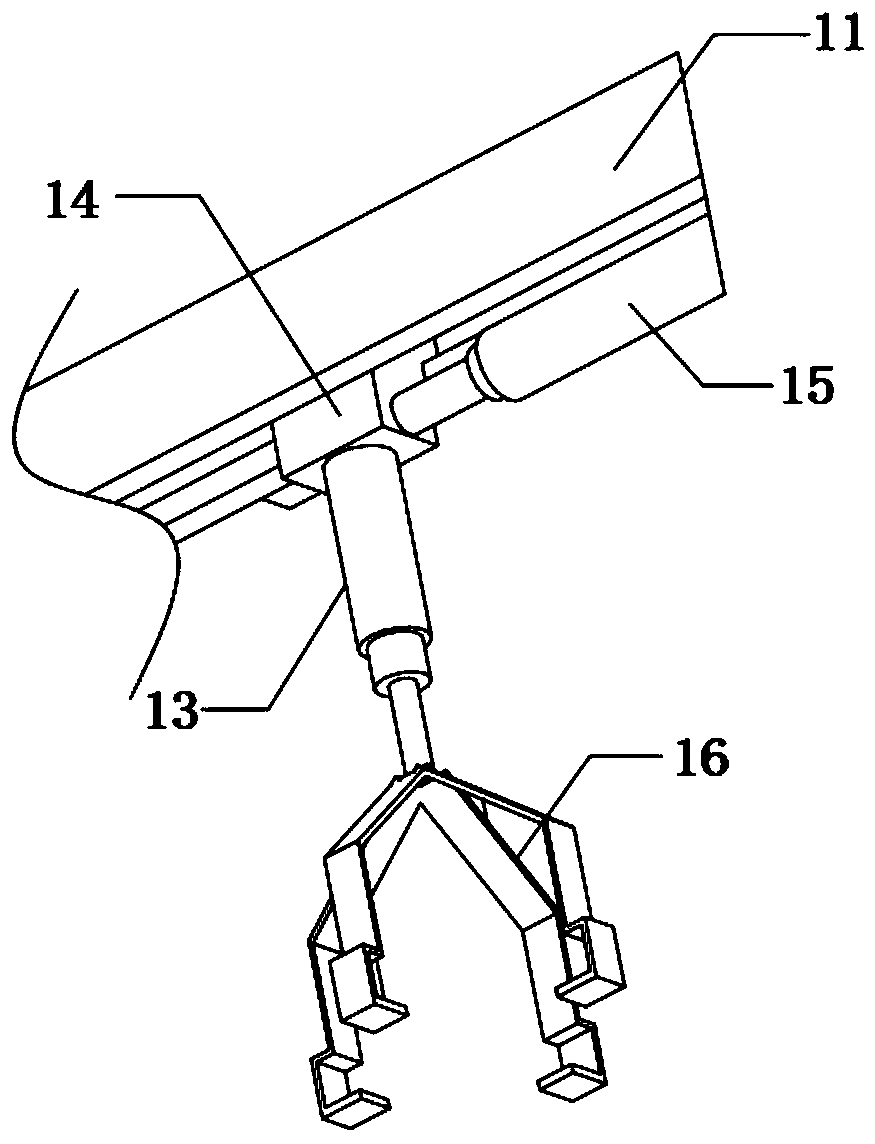

[0030] A bagged food delivery detection device, such as Figure 1-2 As shown, including the base plate 1, the four corners of the top outer wall of the base plate 1 are fixed with fixing plates 20 by screws, and the outer walls on the opposite side of every two fixing plates 20 are fixed with the same baffle plate 2 by screws, and the two baffle plates 2 The outer walls on the opposite side of the two support plates 10 are fixed with support plates 10 by screws, and the top outer walls of the two support plates 10 are fixed with the same top plate 12 by screws, and the bottom outer walls of the top plates 12 are fixed with chute 11 by screws, and the chute 11 The inner wall is slidably connected with two sliders 14, and the outer walls on the opposite side of the two support plates 10 are fixed with the No. 2 hydraulic cylinder 15 by screws, and the other ends of the two No. 2 hydraulic cylinders 15 are fixed on the slider 14 by screws. The outer walls of the bottom of the two...

Embodiment 2

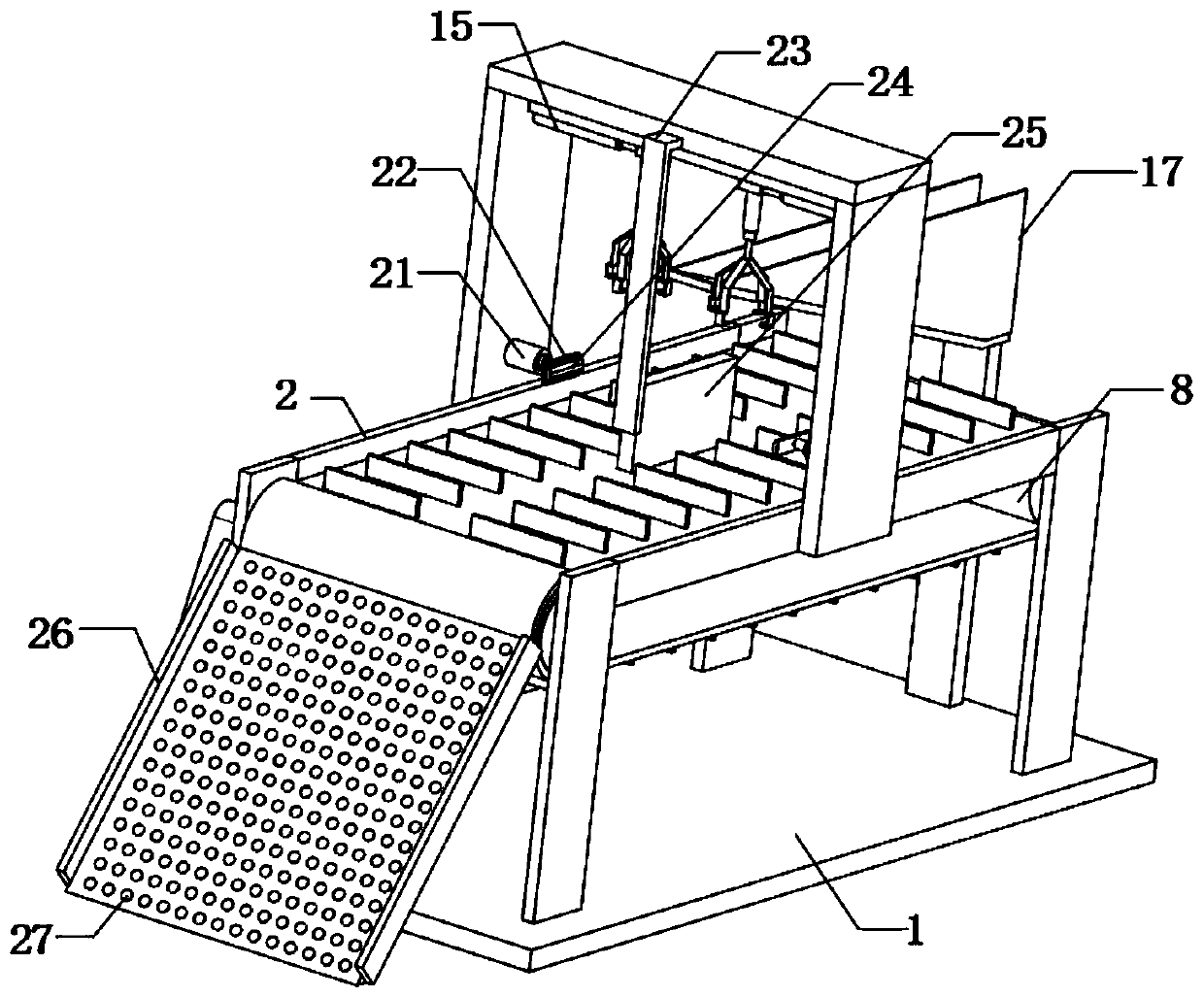

[0036] A bagged food delivery detection device, such as Figure 2-5 As shown, in order to solve the problem of unloading of qualified bagged food after food testing; this embodiment makes the following improvements on the basis of embodiment 1: the top outer wall of the base plate 1 is fixed with a connecting column 29 by screws, and the connecting column 29 The top outer wall is fixed with a blanking plate 26 by screws, and the top outer wall of the blanking plate 26 is equidistantly fixedly connected with a protrusion 27, and the protrusion 27 is a semicircular structure. The installation of 26 reduces the input of labor force and does not need manual cutting. At the same time, the work efficiency of blanking is improved. A protrusion 27 is installed on the cutting plate 26. The protrusion 27 is a semicircular structure, which reduces the bagged food and the cutting plate. The friction force between 26 can protect the bagged food from being worn out, further improving the pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com