Food processing plastic chain plate production line

A food processing and assembly line technology, applied in the direction of transportation and packaging, conveyors, etc., can solve problems such as softening and deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

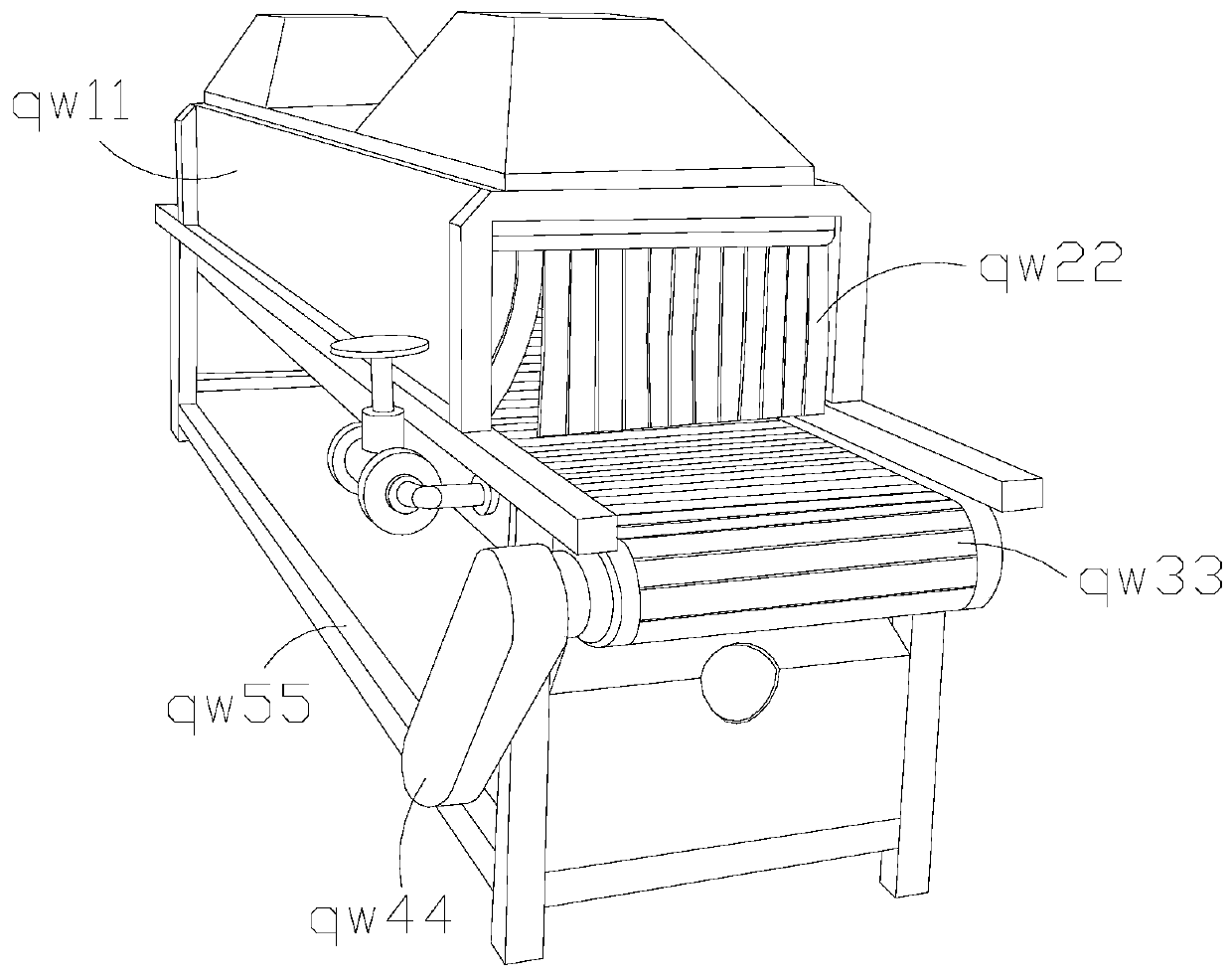

[0032] as attached figure 1 to attach Figure 5 Shown:

[0033] The invention provides a food processing plastic chain plate assembly line, the structure of which includes a food processing box qw11, a curtain qw22, a plastic chain plate qw33, a side belt body qw44, and a support rod qw55.

[0034] The curtain qw22 is connected to the food processing box qw11, the bottom of the food processing box qw11 is welded to the upper surface of the support rod qw55, and the side belt body qw44 is connected to the plastic chain plate qw33.

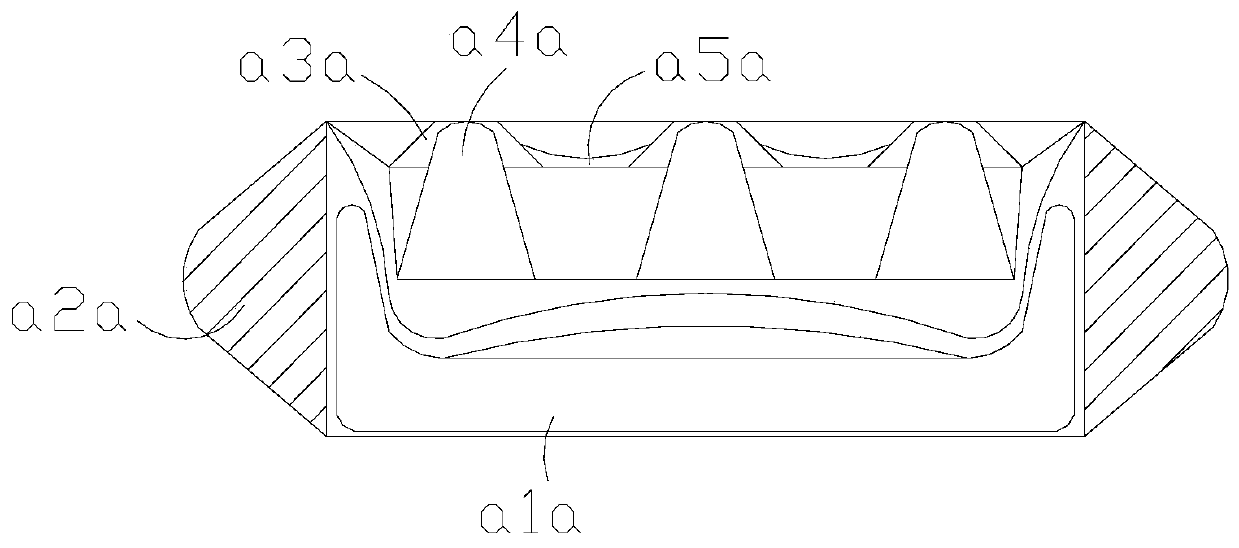

[0035] Wherein, the plastic chain plate qw33 includes a bottom hard core a1a, a side connecting block a2a, a convex head a3a, an inner core a4a, and a concave arc a5a. The bottom hard core a1a is arranged below the inner core a4a, and the inner The abutment core a4a is connected with the convex head a3a, the outer surface of the convex head a3a is equipped with a concave arc a5a, the bottom hard core a1a is embedded in the side joint block a2a, an...

Embodiment 2

[0042] as attached Image 6 to attach Figure 8 Shown:

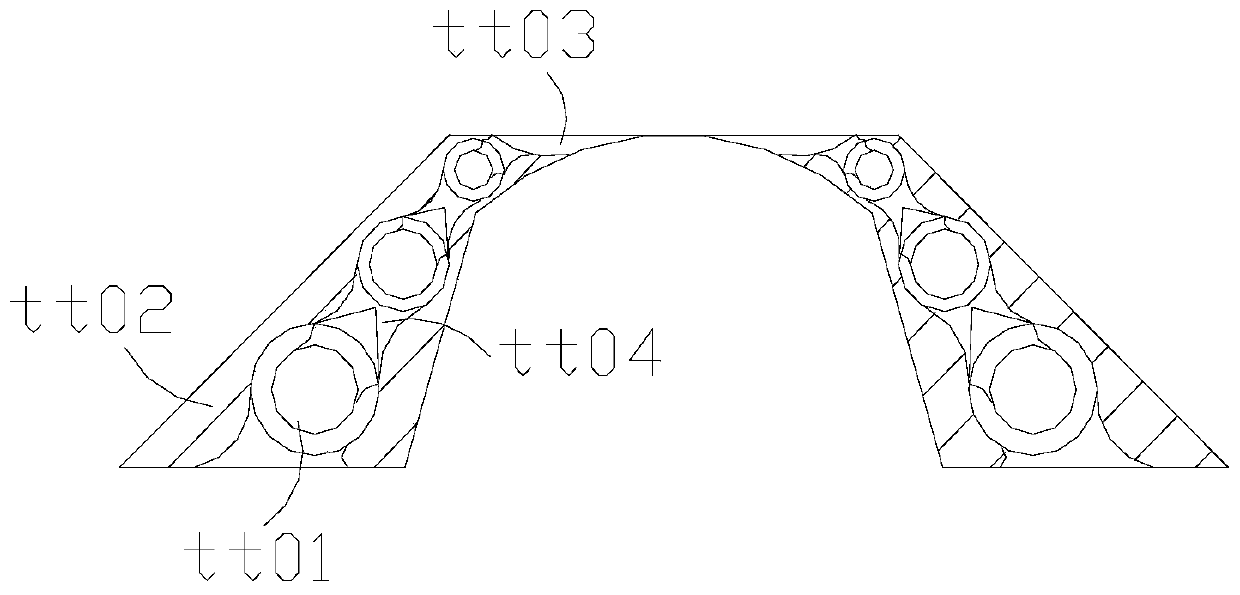

[0043] Wherein, the bottom hard core a1a includes a pullback angle ss01, a support block ss02, a protective layer ss03, and a slow force pulling core ss04, the slow force pull core ss04 is connected with the pull back angle ss01, and the support block ss02 is attached to the protective On the outer surface of the layer ss03, the support block ss02 has a semi-arc structure, and the return angle ss01 has a triangular structure, and the return force angle ss01 bears external forces in a large area and is evenly distributed. The force is in the state of stretching and pulling, and it acts as a pulling back. The supporting block ss02 supports the general range of the whole.

[0044] Wherein, the return force angle ss01 includes an elliptical ball www1, an arc extension www2, a rubber pull block www3, and a bend www4. The ellipse ball www1 is embedded inside the arc extension www2. Blocks www3 are connected, the outer surfa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com