All-water-blown high-dispersion silicon dioxide in-situ reinforced polyurethane grouting lifting material and preparation method thereof

A silica, all-water foaming technology, applied in the field of polyurethane grouting lifting material and its preparation, to achieve the effects of good dispersion, good storage stability and high filling.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

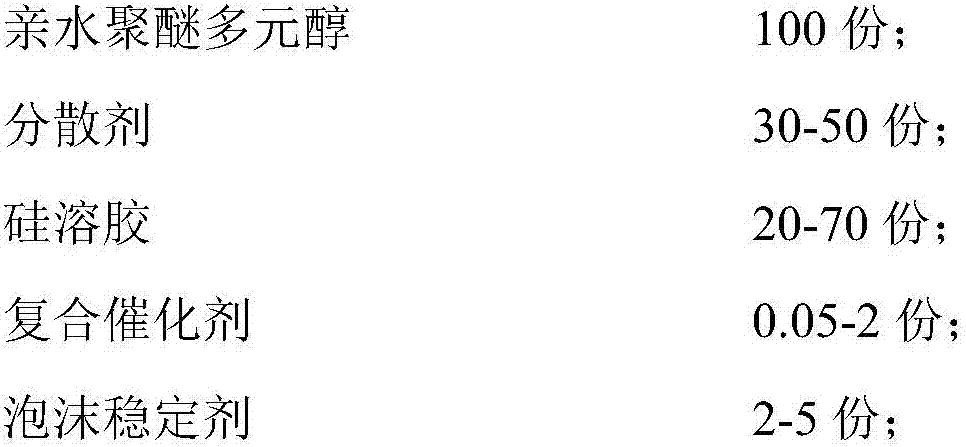

Method used

Image

Examples

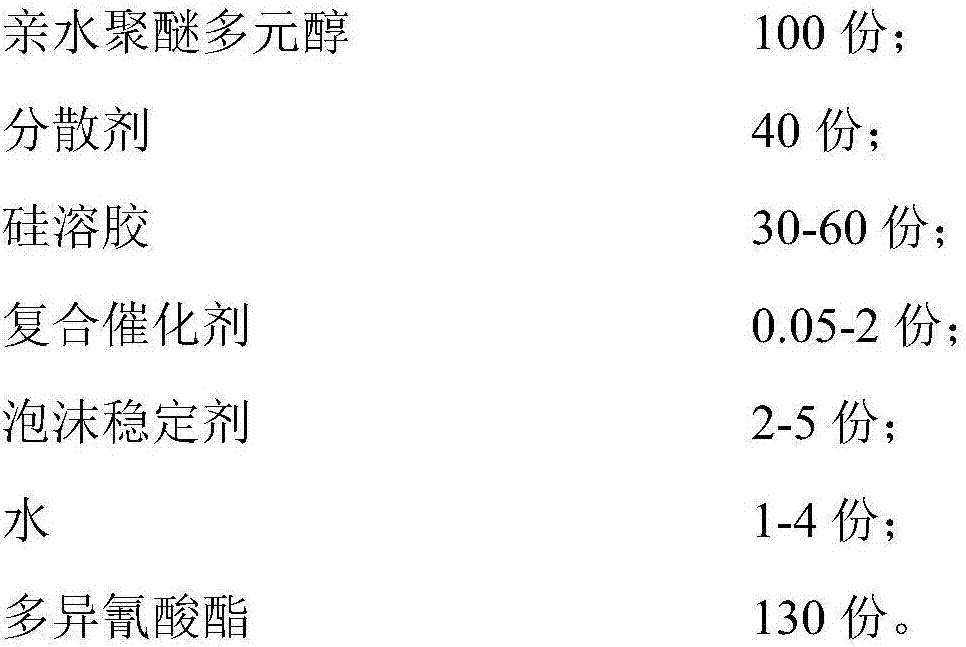

Embodiment 1

[0054] The polyurethane grouting lifting material of the present embodiment is prepared as follows:

[0055] 1. At room temperature, weigh 60 parts of silica sol (pH=6-8, silicon dioxide content 30%, particle size 10-20nm) and 40 parts of dispersant 1, pour them into a reaction kettle, and vacuum remove at 70°C. Water was raised to 110°C for 1 hour to remove water under vacuum for 1 hour to obtain SiO 2 Dispersions.

[0056] 2. Add 100 parts of polyether polyol 2 (functionality 3.2, number average molecular weight 550, viscosity 250-450mPa·s), 1.2 parts of composite catalyst, 3 parts of foam stabilizer and 1.2 parts of deionized water into the reactor, Stir and disperse evenly to obtain component A (viscosity 812mPa·s).

[0057] 3. Weigh 130 parts of polyisocyanate PAPI as component B (viscosity 272 mPa·s).

[0058] 4. Mix component A and component B at a volume ratio of 1:1.3, then foam freely at room temperature, and perform relevant performance tests after standing for thr...

Embodiment 2

[0062] The polyurethane grouting lifting material of the present embodiment is prepared as follows:

[0063] 1. At room temperature, weigh 60 parts of silica sol (pH=6-8, silicon dioxide content 30%, particle size 10-20nm), and 40 parts of dispersant 2, pour them into the reaction kettle, and vacuum remove at 70°C. Water was raised to 110°C for 1 hour to remove water under vacuum for 1 hour to obtain SiO 2 Dispersions.

[0064] 2. Add 100 parts of polyether polyol 2 (functionality 3.2, number average molecular weight 550, viscosity 250-450mPa·s), 0.1 part of composite catalyst, 3 parts of foam stabilizer, 1.2 parts of deionized water into the reactor, Stir and disperse evenly to obtain component A (viscosity 721mPa·s).

[0065] 3. Weigh 130 parts of polyisocyanate PAPI as component B (viscosity 272 mPa·s).

[0066] 4. Mix component A and component B at a volume ratio of 1:1.3, then foam freely at room temperature, and perform relevant performance tests after standing for th...

Embodiment 3

[0070] The polyurethane grouting lifting material of the present embodiment is prepared as follows:

[0071] 1. At room temperature, weigh 60 parts of silica sol (pH=6-8, silicon dioxide content 30%, particle size 10-20nm), 20 parts of dispersant 1, 20 parts of dispersant 2, and pour them into the reaction kettle , vacuum dewatering at 70°C for 1h and then raised to 110°C for 1h to obtain SiO 2 Dispersions.

[0072] 2. Add 100 parts of polyether polyol 2 (functionality 3.2, number average molecular weight 550, viscosity 250-450mPa·s), 0.5 parts of composite catalyst, 3 parts of foam stabilizer, 1.2 parts of deionized water into the reactor, Stir and disperse evenly to obtain component A (viscosity 761mPa·s).

[0073] 3. Weigh 130 parts of polyisocyanate PAPI as component B (viscosity 272 mPa·s).

[0074] 4. Mix component A and component B at a volume ratio of 1:1.3, then foam freely at room temperature, and perform relevant performance tests after standing for three days. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com