Gradient permeable concrete product and preparation method thereof

A permeable concrete and gradient-type technology, applied in the field of concrete, can solve problems such as prominent engineering quality warranty problems, large product performance differences, and difficult compaction by vibration, achieving significant economic and environmental benefits, low cost, and effective treatment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

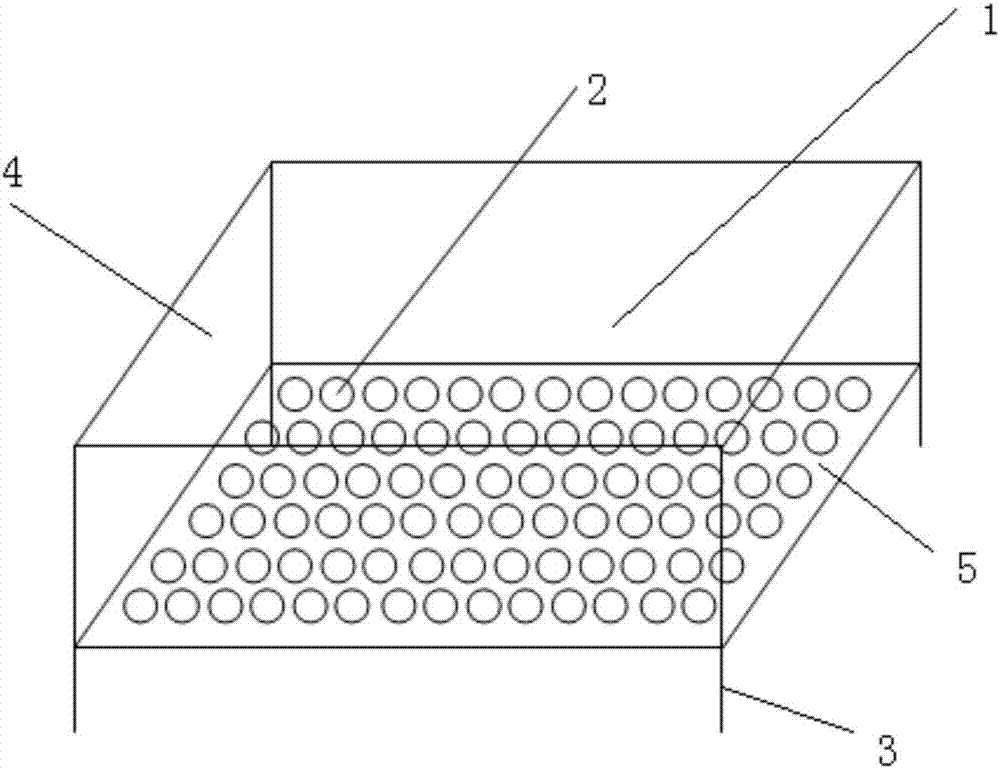

Image

Examples

Embodiment 1

[0043] The embodiment of the present invention provides a kind of preparation method of gradient type permeable concrete product, and preparation method comprises the following steps:

[0044] 1) Weigh 750kg of recycled aggregate, 500kg of lightweight aggregate, 300kg of Portland cement, 60kg of fly ash, 60kg of mineral powder, 12kg of composite admixture, and 110kg of water, and add them to the mixer, stir at high speed evenly, and mix compound;

[0045] Among them, the composite aggregate is composed of recycled aggregate and lightweight aggregate, and the recycled aggregate and lightweight aggregate are mixed at a volume ratio of 1:1 to form a composite aggregate. Recycled aggregate is a single-grain recycled aggregate with a particle size of 5 mm to 10 mm obtained from construction waste concrete; light aggregate is artificial ceramsite with a particle size of 3 to 5 mm. Recycled aggregates and lightweight aggregates are aggregates in a saturated surface-dry state.

[00...

Embodiment 2

[0052] The embodiment of the present invention provides a kind of preparation method of gradient type permeable concrete product, and preparation method comprises the following steps:

[0053] 1) Weigh 750kg of recycled aggregate, 500kg of lightweight aggregate, 300kg of Portland cement, 60kg of fly ash, 60kg of mineral powder, 8.5kg of composite admixture, and 125kg of water, and add them to the mixer, and stir evenly at high speed to obtain admixture;

[0054] Among them, the composite aggregate is composed of recycled aggregate and lightweight aggregate, and the recycled aggregate and lightweight aggregate are mixed at a volume ratio of 1:1 to form a composite aggregate. Recycled aggregate is a single-grain recycled aggregate with a particle size of 5 mm to 10 mm obtained from construction waste concrete; light aggregate is artificial ceramsite with a particle size of 3 to 5 mm. Recycled aggregates and lightweight aggregates are aggregates in a saturated surface-dry state....

Embodiment 3

[0061] The embodiment of the present invention provides a kind of preparation method of gradient type permeable concrete product, and preparation method comprises the following steps:

[0062] 1) Weigh 750kg of recycled aggregate, 500kg of lightweight aggregate, 290kg of Portland cement, 45kg of fly ash, 75kg of mineral powder, 7.5kg of composite admixture, and 130kg of water, and add them to the mixer, and stir evenly at high speed to obtain admixture;

[0063] Among them, the composite aggregate is composed of recycled aggregate and lightweight aggregate, and the recycled aggregate and lightweight aggregate are mixed at a volume ratio of 1:1 to form a composite aggregate. Recycled aggregate is a single-grain recycled aggregate with a particle size of 5 mm to 10 mm obtained from construction waste concrete; light aggregate is artificial ceramsite with a particle size of 3 to 5 mm. Recycled aggregates and lightweight aggregates are aggregates in a saturated surface-dry state....

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com