Food fermentation equipment and food fermentation method

A food fermentation and equipment technology, which is applied in biochemical equipment and methods, sterilization methods, and methods of supporting/immobilizing microorganisms, etc., can solve problems such as inability to turn food inside and outside, save manpower and material resources, reduce contact, even heating effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

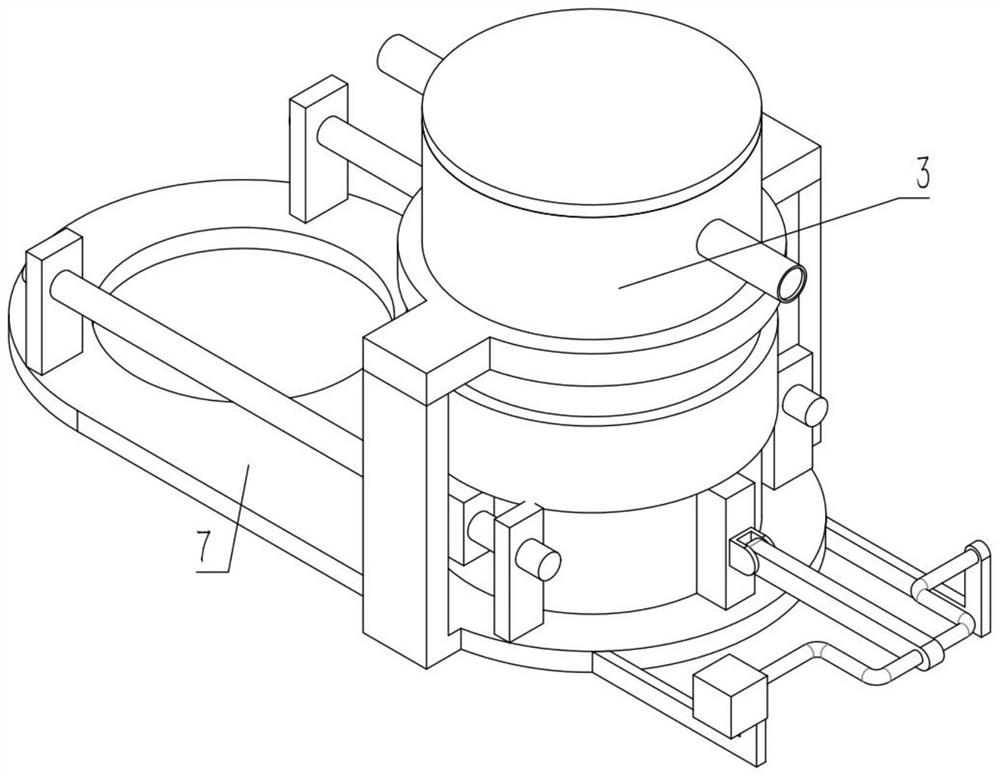

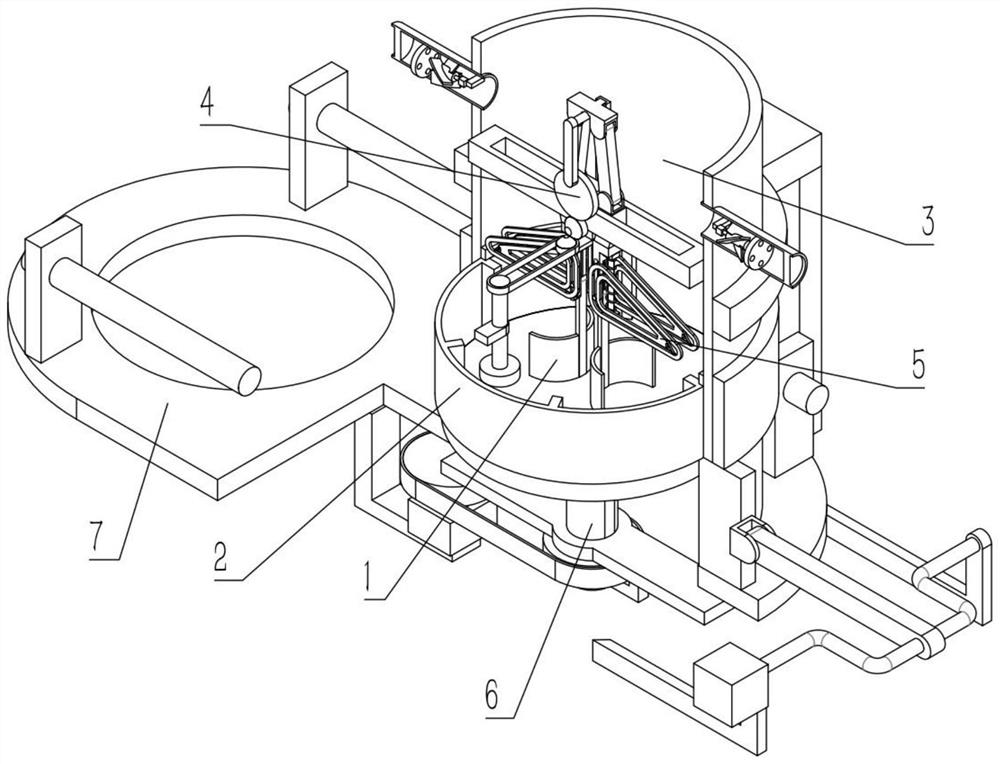

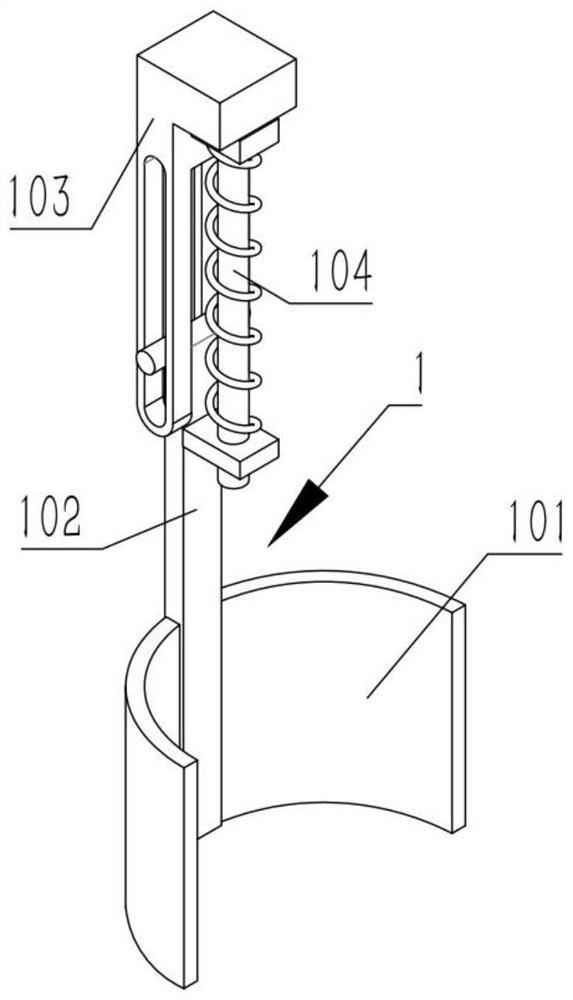

[0035] Combine below Figure 1-9 Description of this embodiment, a food fermentation equipment and a food fermentation method, including a stirring mechanism 1 and a rotating mechanism 2, the stirring mechanism 1 includes a stirring plate 101, a stirring rod 102, a stirring slide bar 103 and a stirring connecting rod 104, the stirring plate 101 Fixedly connected to the stirring rod 102, the stirring rod 102 is slidingly connected in the stirring rod 103, the stirring rod 102 is slidingly connected to the stirring connecting rod 104, the stirring rod 102 and the stirring rod 103 are connected by a spring, and the stirring connecting rod 104 is fixedly connected On the stirring slide bar 103, the rotating mechanism 2 includes a rotating ring 201, and the inner wall of the rotating ring 201 is provided with a plurality of fixed plates;

[0036]During normal food fermentation, it is easy to cause the external temperature to be higher than the internal temperature, resulting in une...

specific Embodiment approach 2

[0038] Combine below Figure 1-9 Describe this embodiment, this embodiment will further explain the first embodiment, the rotating mechanism 2 also includes a gear ring 202, a gear shaft 203, a bevel gear set 204 and a bevel gear set II 205, and the gear ring 202 is fixedly connected to the ring 201 , gear ring 202 and gear shaft 203 mesh transmission, gear shaft 203 and bevel gear set 204 belt transmission, bevel gear set 204 and bevel gear set II 205 mesh transmission;

[0039] The bevel gear set II 205 rotates to drive the bevel gear set 204 to rotate, the bevel gear set 204 rotates to drive the gear shaft 203 to rotate, the gear shaft 203 rotates to drive the gear ring 202 to rotate, and the gear ring 202 rotates to drive the ring 201 to rotate.

specific Embodiment approach 3

[0041] Combine below Figure 1-9 Describe this embodiment mode, this embodiment mode will further illustrate embodiment 2, described a kind of food fermentation equipment also comprises fermentation mechanism 3, and fermentation mechanism 3 comprises fermentation box 301, fermentation temperature control device 302, fermentation ventilation pipe 303, ventilation filter Net 304, ventilation fan 305 and ventilation motor 306, fermentation temperature control device 302 are fixedly connected on the fermentation box 301, two fermentation ventilation pipes 303 are all fixedly connected on the fermentation box 301, and valves are all arranged on the two fermentation ventilation pipes 303 , two ventilation filter screens 304 are respectively fixedly connected to two fermentation ventilation pipes 303, two ventilation fans 305 are respectively fixedly connected to the output shafts of two ventilation motors 306, and two ventilation motors 306 are fixedly connected to two fermentation v...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com