Food grinder

A processor and food technology, applied in beverage preparation devices, home appliances, applications, etc., can solve problems such as inconvenient operation, peculiar smell, uncontrollable and unselectable food crushing effect, and achieve the effect of improving the life of the whole machine and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

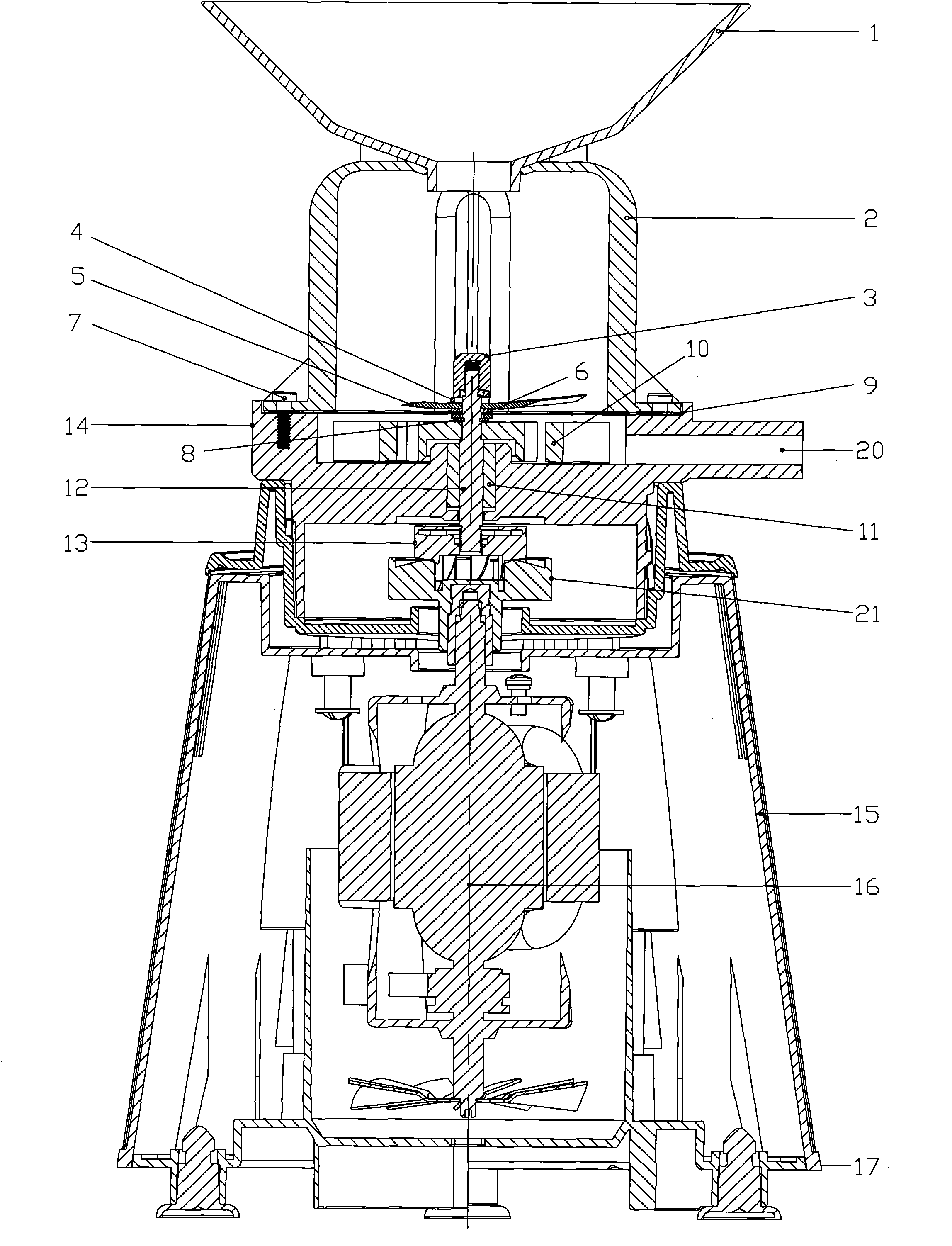

[0030] figure 1 It is a schematic structural diagram of an embodiment of the food crushing processor of the present invention. As shown in the figure, the food crushing processor can be divided into according to functions: feeding system, knife seat system, crushing system, filtering device, powder discharge system, cooling system and power system Composition, the components of these systems are interrelated or coincident.

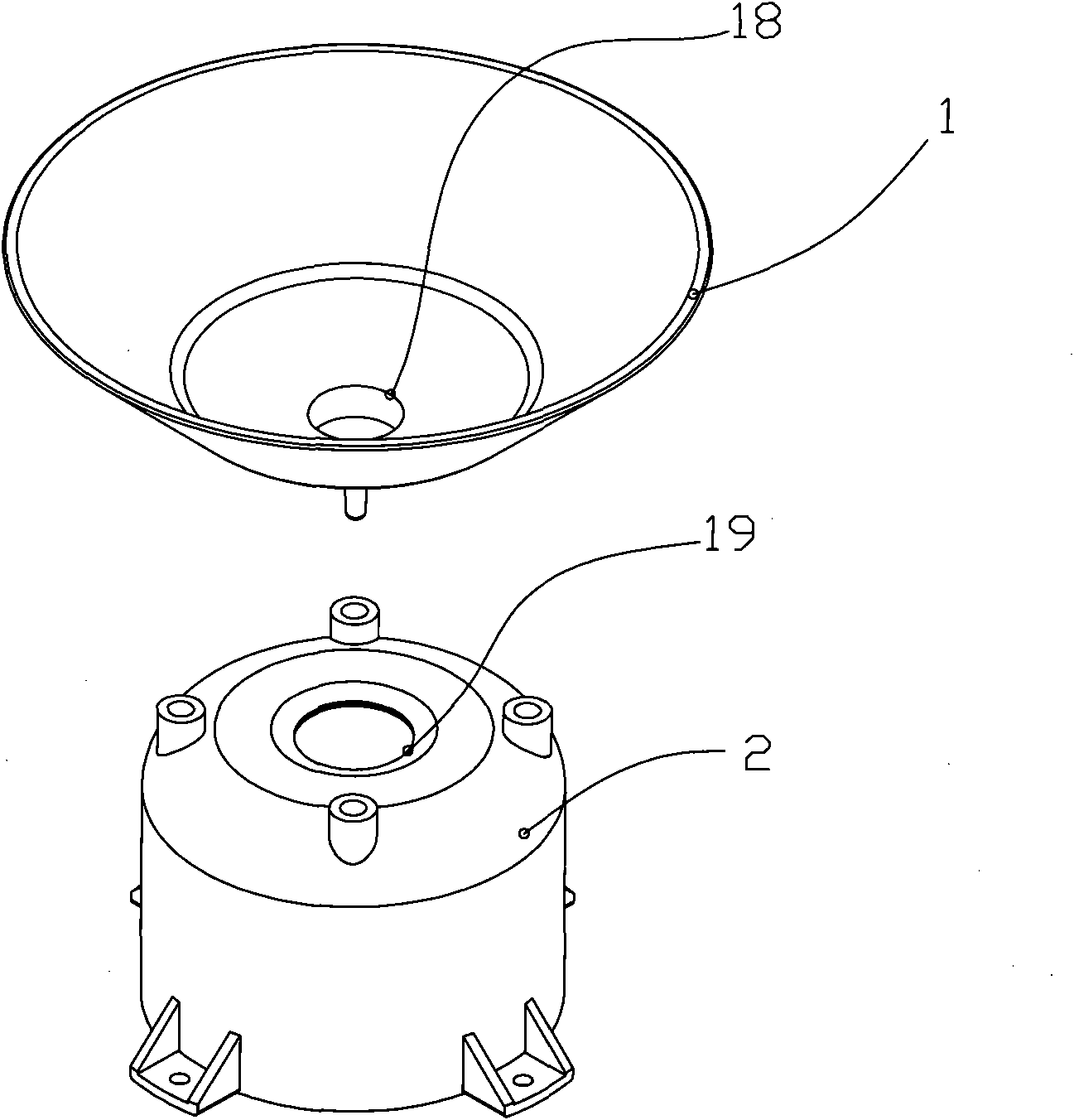

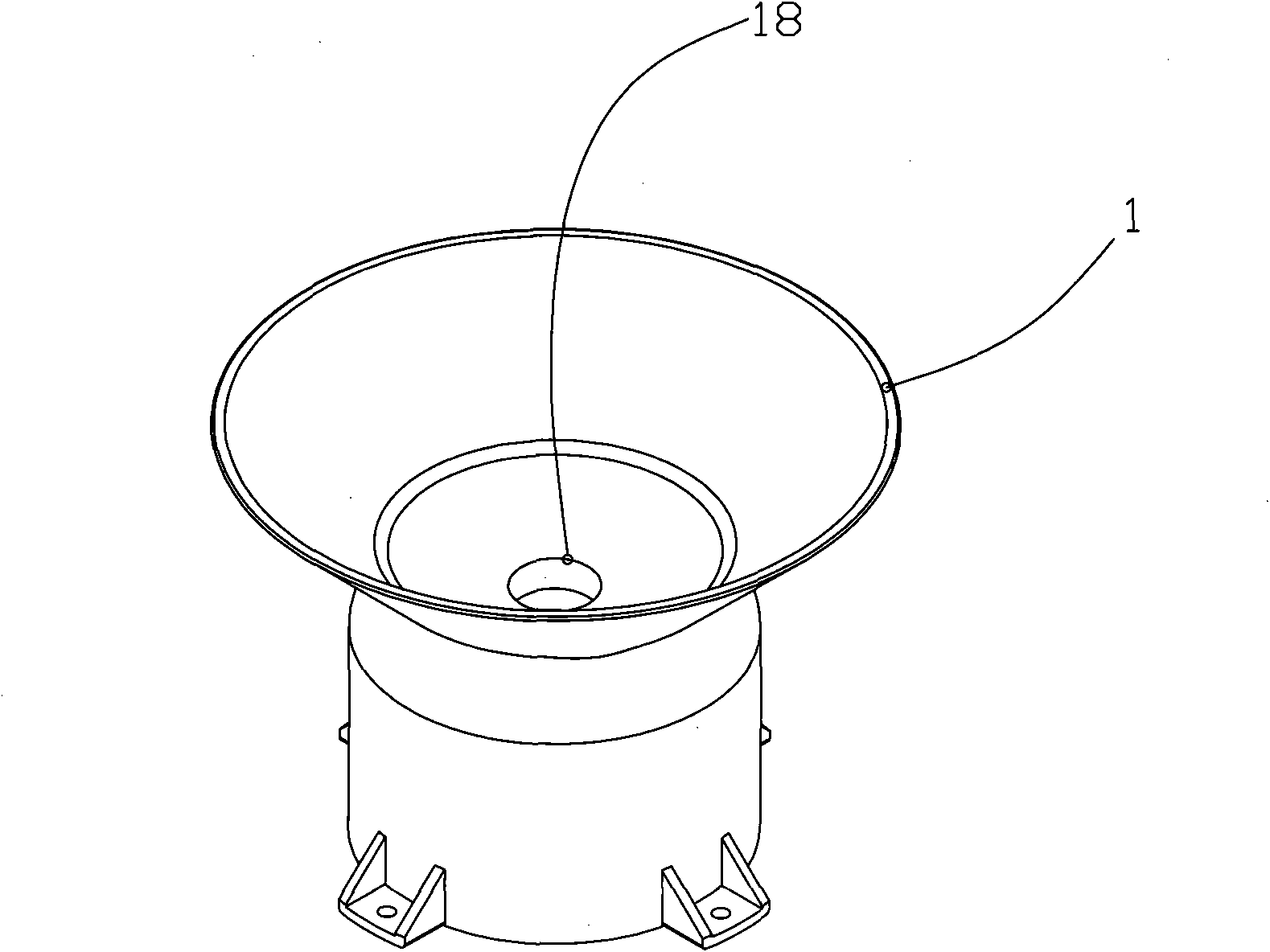

[0031] According to attached Figure 2-8 , the composition of these systems will be introduced respectively according to their functions: figure 2 As shown, the feed system includes a feed hopper 1 and a cup body 2, and a feed inlet 18 is opened on the feed hopper 1 to communicate with the feed inlet 19 of the cup body 2. in figure 2 The shown feed hopper 1 is separate from the cup body 2 . image 3 The shown feed hopper is integrated with the cup body 1 and is provided with a feed inlet 18 .

[0032] as attached Figure 4 As shown, the tool seat s...

Embodiment 2

[0039] Figure 9 is another embodiment of the food pulverizer of the present invention, which is the same as figure 1 The difference of the embodiment lies in the cutter shaft 12, which is shared with the motor output shaft 28, so that the upper pusher 13 and the lower pusher 15 can be eliminated. The other components are consistent with the connection relationship.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com