Method for commissioning adsorbent bed in acetone recycling process

An adsorption bed and acetone technology, which is applied in separation methods, chemical instruments and methods, separation/purification of carbonyl compounds, etc., can solve the problems of affecting the adsorption capacity of activated carbon, large economic losses, and slow water velocity, so as to improve the ability to adsorb acetone , Reduce acetone emission, reduce the effect of water content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

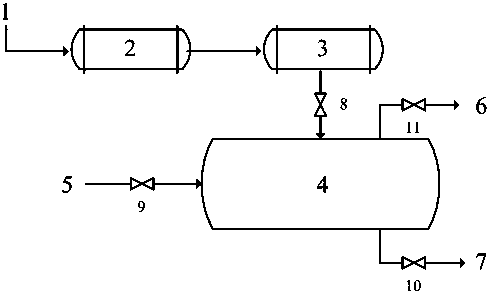

Image

Examples

Embodiment 1

[0016] When the adsorption bed is maintained or the activated carbon of the adsorption bed is replaced, the adsorption bed is withdrawn, and the activated carbon is soaked with water. After the maintenance operation is completed, the adsorption bed is put into operation. When the adsorption bed is a region, proceed as follows:

[0017] 1. The adsorption bed is put into operation for analysis, and the steam is introduced at a flow rate of 7 tons / hour for 1.5 hours (at this time, close the VLA inlet valve of the adsorption bed, close the tail gas valve, and open the analysis steam valve and steam valve);

[0018] 2. After the analysis of the operation is completed, the acetone-air mixture enters the secondary cooler through the primary cooler, and the temperature of the acetone-air mixture at the outlet of the secondary cooler is controlled to be 43°C, and then the acetone-air mixture enters the adsorption bed for activated carbon adsorption 56 minutes;

[0019] 3. After the ads...

Embodiment 2

[0021] In the case of multiple adsorption beds (about 10), it can be divided into two areas, and the operation of the adsorption beds is carried out as follows:

[0022] 1. Analysis of the operation of the adsorption bed in the area containing the newly put into operation adsorption bed. The steam is introduced at a flow rate of 9 tons / hour for 1 hour (at this time, close the VLA inlet valve of the adsorption bed, close the tail gas valve, and open Analyzing steam valves and steam valves);

[0023] 2. After the operation analysis is completed, the acetone-air mixture enters the secondary cooler through the primary cooler, and the temperature of the acetone-air mixture at the outlet of the secondary cooler is controlled at 44°C, and the acetone-air mixture of the secondary cooler in another area The gas outlet temperature is 41°C, and then the acetone-air mixture enters the adsorption bed for activated carbon adsorption for 60 minutes;

[0024] 3. The steps are the same as in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com