A battery acid addition and chemical formation system

A battery and battery technology, applied in lead-acid batteries, lead-acid battery construction, secondary batteries, etc., can solve the problems of inability to be formed by vacuum, unable to add acid to form consistency, etc., and achieve the consistency of batteries. , Avoid corrosion problems, keep dry effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

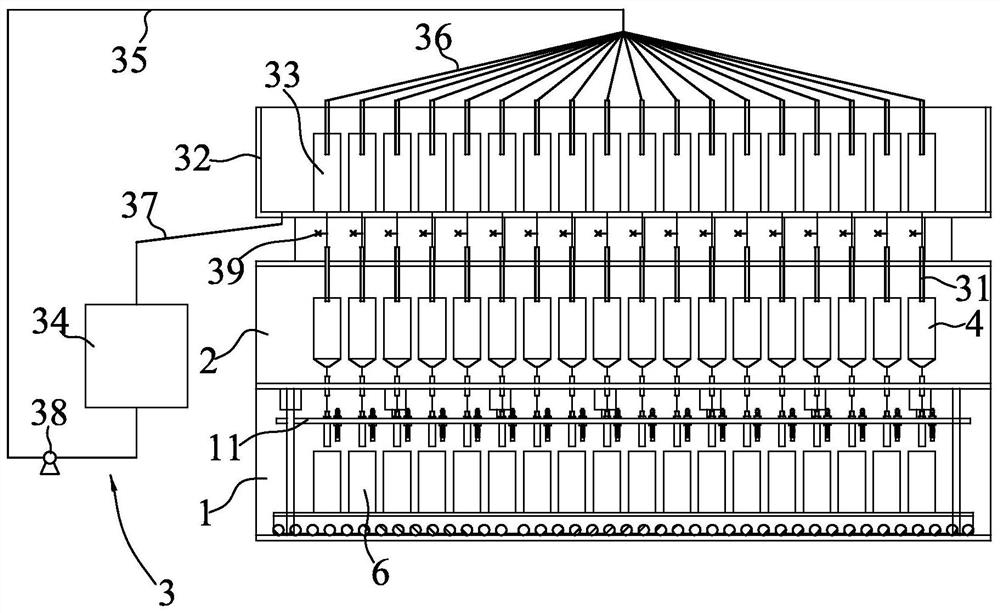

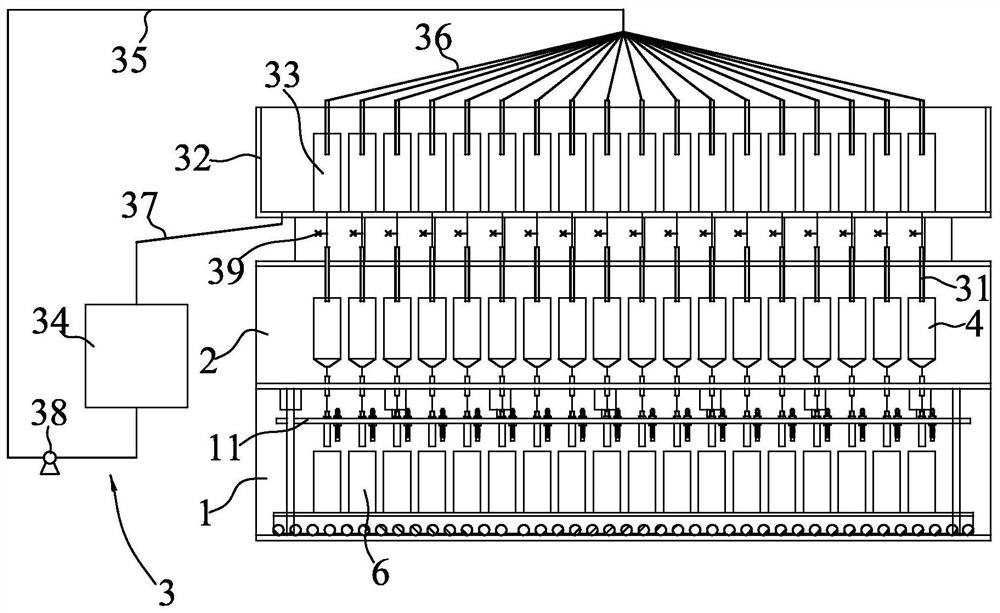

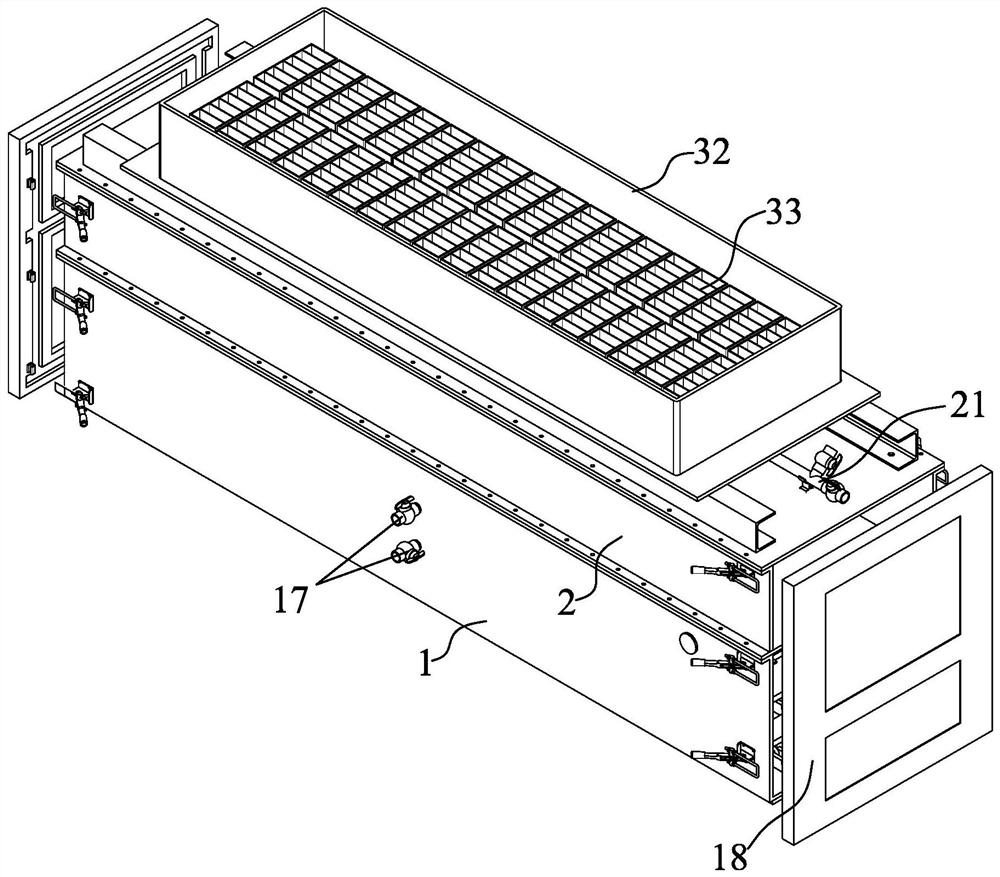

[0051] like Figures 1 to 5 As shown in the figure, a battery acid addition and formation system includes a three-layer structure distributed in sequence from bottom to top: a battery vacuum box 1, an acid pot vacuum box 2 and a quantitative acid addition system 3.

[0052] The battery vacuum box 1 is used to place the storage battery 6 to be processed, and has a first negative pressure system 17 for pumping negative pressure to the inner cavity of the battery vacuum box 1 during formation. The first negative pressure system 17 includes two pipelines, each tube A valve is set on the road, one of the pipelines is used to connect external negative pressure equipment, such as an independent negative pressure fan or connected to the negative pressure pipeline of the entire workshop, and the other pipeline is used to open the inner cavity when needed. pressure. The air inlet of the first negative pressure system 17 can be arbitrarily set in the battery vacuum box 1 . At least one...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com