Ammonia-containing wastewater treatment method and system for blue carbon production

A treatment method and technology for a treatment system are applied in the field of treatment methods and systems for ammonia-containing wastewater produced by blue carbon, which can solve problems such as environmental pollution, and achieve the effects of low investment cost, improved water quality, and simple and easy implementation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described in detail below in conjunction with specific embodiments, which are explanations of the present invention rather than limitations.

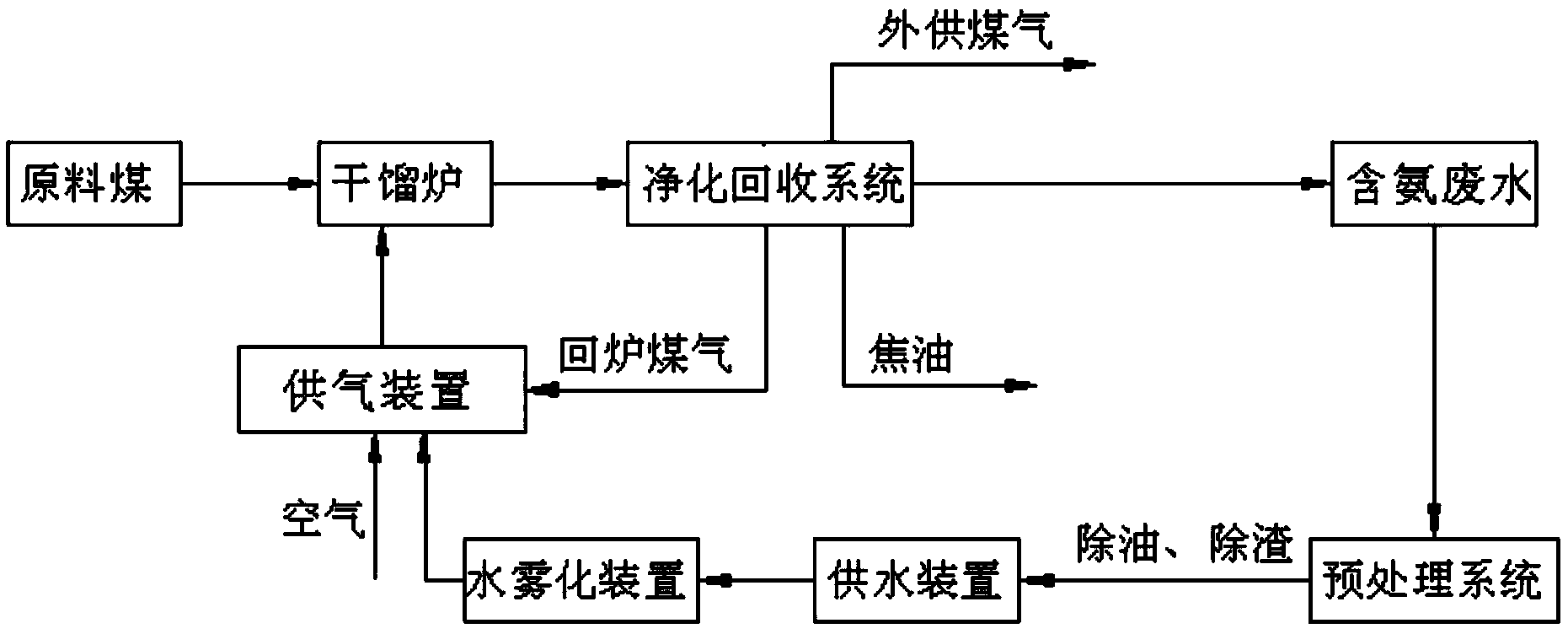

[0035] see figure 1 , the method for treating ammoniacal wastewater produced by blue charcoal of the present invention comprises the following steps:

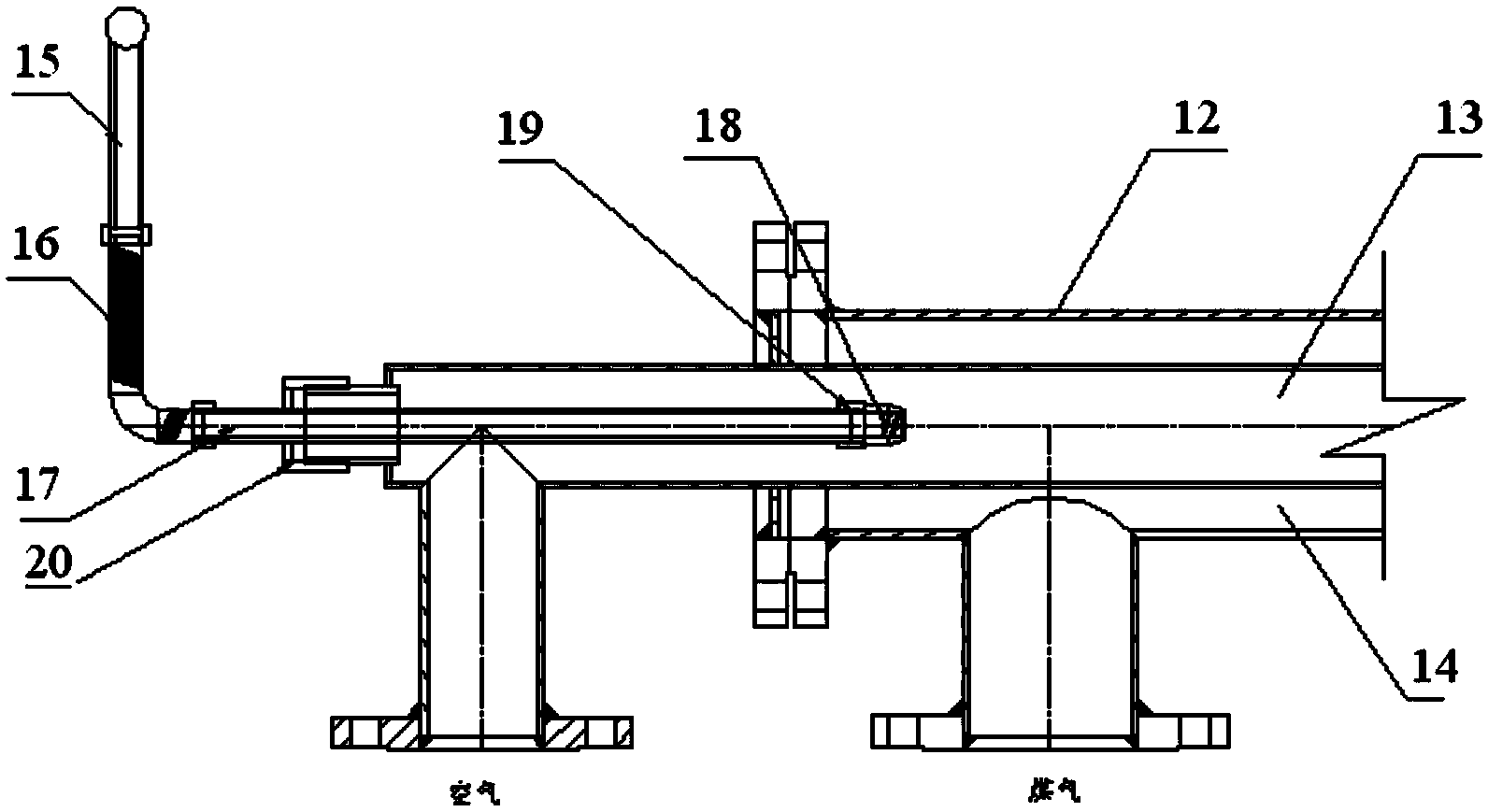

[0036] 1) Put the raw coal into the retort furnace, and undergo low-temperature retort treatment to produce semi-coke, coal tar, ammonia-containing waste water and gas; wherein, the gas includes two parts: externally supplied gas and returned furnace gas.

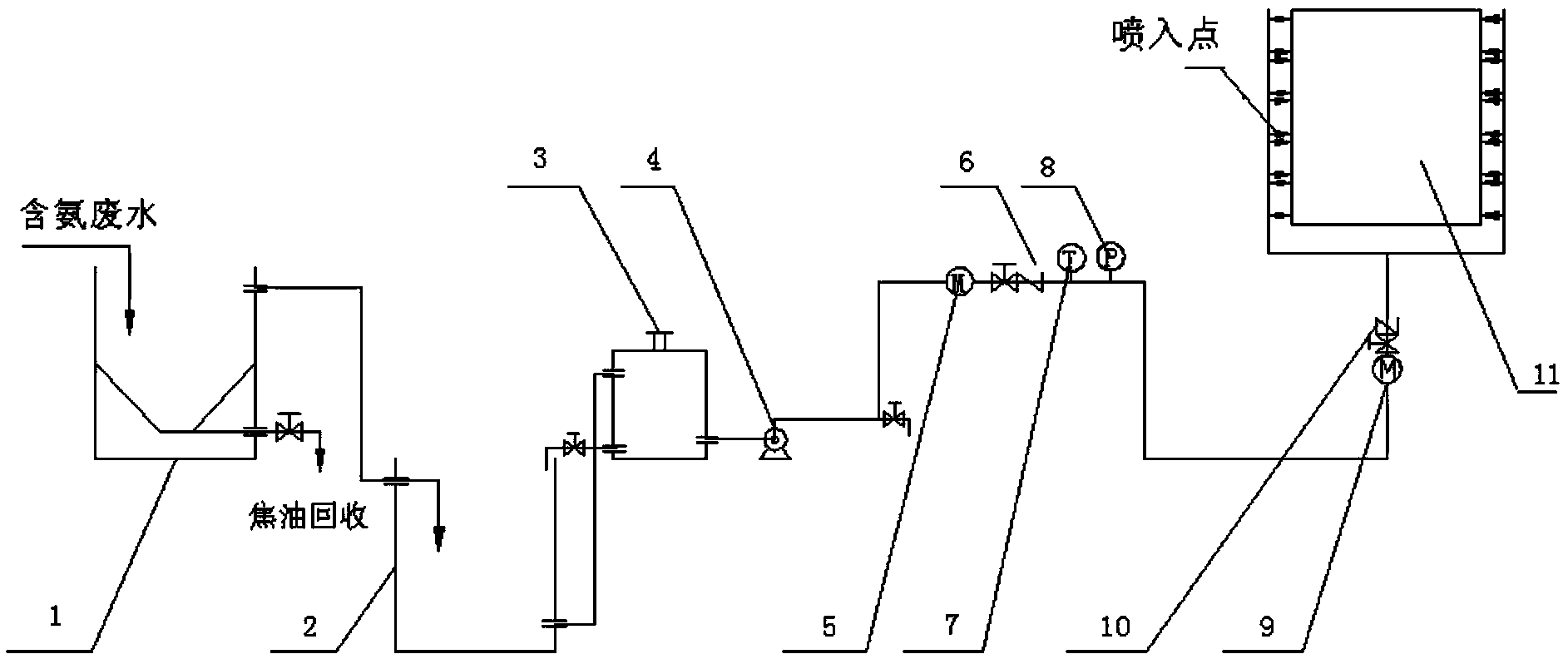

[0037] 2) Collect and filter ammonia-containing wastewater to obtain ammonia-containing wastewater after deoiling and slag removal;

[0038] The filtration includes two stages of filtration. The first stage of filtration is to carry out the first oil and slag removal treatment through the gravity oil removal tank; the second stage of filtration is to carry out the second slag removal treat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com