Electric self-suction closestool

A toilet and self-priming technology, which is applied to flushing equipment with water tanks, sanitary equipment for toilets, flushing toilets, etc., can solve problems such as unpleasant smell of dry toilets, waste of water resources, and impact on users' vision.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

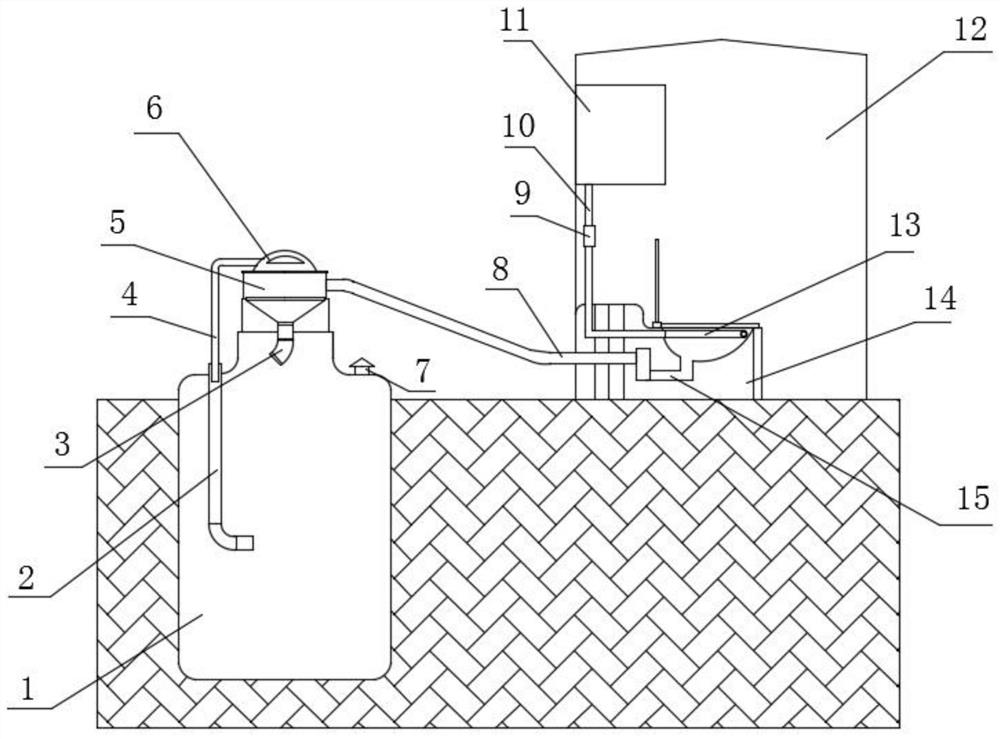

[0019] see figure 1 , the present invention provides specific embodiment 1: an electric self-priming toilet, including a fermentation tank 1, a vacuum pump 6, a vacuum tank 5 and a toilet body 14;

[0020] A flushing coil 13 is installed inside the toilet body 14 , a sewage channel 15 is formed in the inner part of the toilet body 14 , and one end of the sewage channel 15 is installed with a fecal suction pipe 8 , which runs through the surface of the wall body 12 and extend to the outside world;

[0021] A vacuum tank 5 is installed on the top of the fermentation tank 1, a vacuum pump 6 is installed on the top of the vacuum tank 5, one end of the suction pipe 8 is connected to the interior of the vacuum tank 5, and the output end of the vacuum pump 6 is connected to the interior of the vacuum tank 5. A check valve 3 is installed at the bottom of the 5, the check valve 3 is arranged inside the fermentation tank 1, a water supply mechanism is arranged between the wall 12 and t...

Embodiment 2

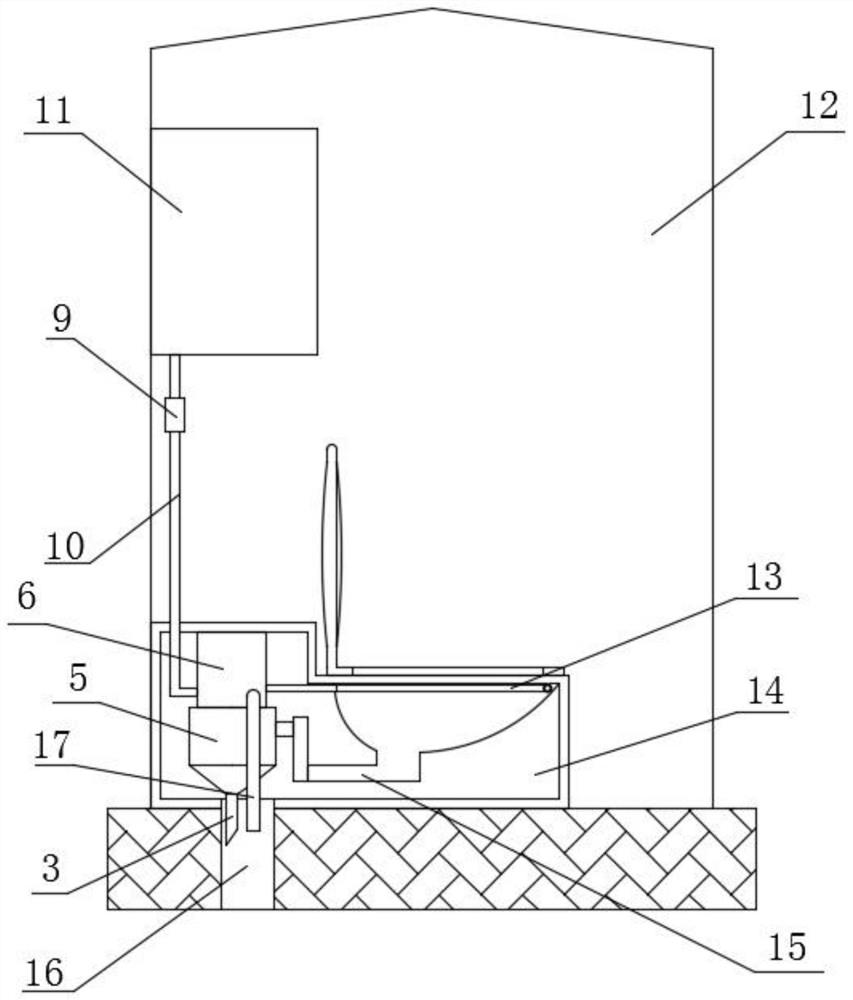

[0028] see figure 2 , the present invention provides specific embodiment 2: an electric self-priming toilet, including a sewer pipe 16, a wall body 12 and a toilet body 14;

[0029] A flushing coil 13 is installed inside the toilet body 14, a sewage channel 15 is formed in the inner part of the toilet body 14, and one end of the sewage channel 15 is installed with a fecal suction pipe 8;

[0030] A vacuum tank 5 is installed inside the toilet body 14, a vacuum pump 6 is installed on the top of the vacuum tank 5, one end of the suction pipe 8 is connected to the interior of the vacuum tank 5, and the output end of the vacuum pump 6 is connected to the interior of the vacuum tank 5. The vacuum pump 6 The output end is connected with an air outlet 17, a check valve 3 is installed at the bottom of the vacuum tank 5, the check valve 3 and the air outlet 17 are arranged inside the sewer pipe 16, and a water supply is arranged between the wall 12 and the toilet body 14 mechanism, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com