A method for comprehensive utilization of pleuromutilin waste bacteria residue resources

A technology of waste and recycling of pleuromutilin, which is applied in the field of resource recycling, can solve the problems of increasing secondary pollution, increasing floor area, management confusion, etc., and achieves the effects of improving economic benefits, increasing utilization rate, and increasing potency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

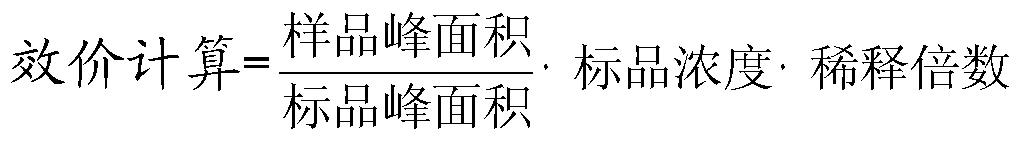

Method used

Image

Examples

Embodiment 1

[0042] 1) Weigh 800 g of pleuromutilin waste slag with a water content below 2%, add 4Kg of water to the pleuromutilin waste slag, let it stand for 15 minutes, then add 4mol / L phosphoric acid to adjust the pH value to 5.0, to obtain Fungus residue liquid;

[0043] 2) Add 0.08 g of compound enzyme to the bacterial residue liquid obtained in 1), the compound enzyme is composed of cellulase: xylanase: β-glucanase in a mass ratio of 1:1:1, at 30°C Decompose for 60 minutes, filter to remove undecomposed residue, and the filtrate is protein nutrient solution;

[0044] 3) Take the strain and inoculate it into the seed medium, the inoculum size is 1cm 2 The slant was cultivated at 25.5°C for 65 hours, the pH value of the seed medium was 6.15, the ventilation rate was 1.0vvm, and the rotation speed was 220rpm.

[0045] The classification of the strain is named as clitopilus prunulus, and the Latin literary name is clitopilus prunulus. It is preserved in the General Microbiology Cente...

Embodiment 2

[0054] 1) Weigh 1.1Kg of pleuromutilin waste residue with a water content of less than 2%, add 5.5Kg of water to the waste pleuromutilin residue, let it stand for 15 minutes, then add 4mol / L phosphoric acid to adjust the pH to 5.0 , to obtain the slag liquid;

[0055] 2) Add 0.11 g of compound enzyme to the bacterial residue liquid obtained in 1), the compound enzyme is composed of cellulase: xylanase: β-glucanase in a mass ratio of 1:1:1. Decompose for 70 minutes, filter to remove undecomposed residue, and the filtrate is protein nutrient solution;

[0056] 3) Take the strains and inoculate them into the seed culture medium, the inoculum size is 1.5cm 2 The slant was cultivated at 26°C for 68 hours, the pH of the seed medium was 6.2, the ventilation rate was 1.1vvm, and the rotation speed was 230rpm.

[0057] The classification of the strain is named as clitopilus prunulus, and the Latin literary name is clitopilus prunulus. It is preserved in the General Microbiology Cente...

Embodiment 3

[0066] 1) Weigh 50Kg of pleuromutilin waste slag with a water content below 2%, add 250Kg of water to the pleuromutilin waste slag, let it stand for 15min, then add 4mol / L phosphoric acid to adjust the pH value to 5.0, to obtain Fungus residue liquid;

[0067] 2) Add 5 g of compound enzyme to the bacterial residue liquid obtained in 1), the compound enzyme is composed of cellulase: xylanase: β-glucanase in a mass ratio of 1:1:1, and enzymatically hydrolyzed at 30°C 90min, filter to remove undecomposed residue, the filtrate is protein nutrient solution;

[0068] 3) Get the strain and inoculate it into the seed culture medium, the inoculum size is 2cm 2 The inclined plane was cultivated at 26.5°C for 70 hours, the pH value of the seed medium was 6.25, the ventilation rate was 1.1vvm, and the rotation speed was 250rpm.

[0069] The classification of the strain is named as clitopilus prunulus, and the Latin literary name is clitopilus prunulus. It is preserved in the General Mic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com