A method for power generation by pyrolysis of domestic waste

A domestic waste and pyrolysis technology, applied in the direction of steam generation using heat carrier, internal combustion piston engine, engine components, etc., can solve the problems of low work efficiency, achieve high power generation, good economic benefits, eliminate harmful substances and The effect of impurities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

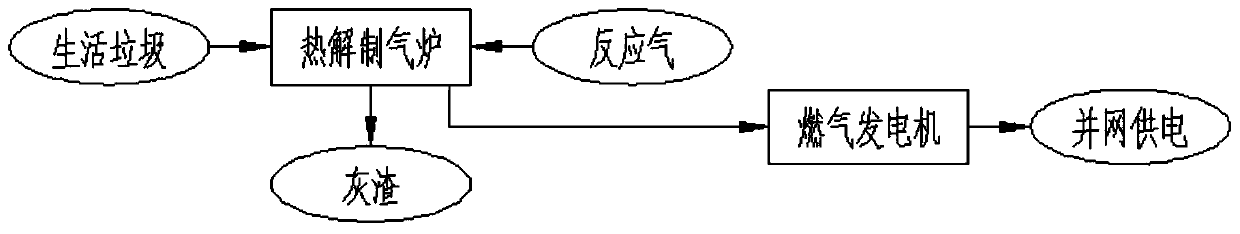

Embodiment 1

[0042] The domestic waste pyrolysis power generation method of the present embodiment comprises the following steps:

[0043] S1. Put domestic garbage into the pyrolysis gas-making furnace for pyrolysis and gasification, and feed reaction gas into the pyrolysis gas-making furnace. The content of oxygen in the reaction gas is 30%-93%, and a product including combustible gas is obtained;

[0044] S2. Detect the calorific value of the generated combustible gas, and adjust the content of oxygen in the reaction gas fed into the pyrolysis gas furnace in real time, so that the calorific value of the obtained combustible gas can be output stably;

[0045] S3. Send the combustible gas obtained in step S2 into a gas generator to generate electricity.

[0046] In the domestic waste pyrolysis power generation method, the reaction gas is fed into the pyrolysis gas furnace. The reaction gas includes oxygen that participates in the reaction and other remaining gases that do not participate i...

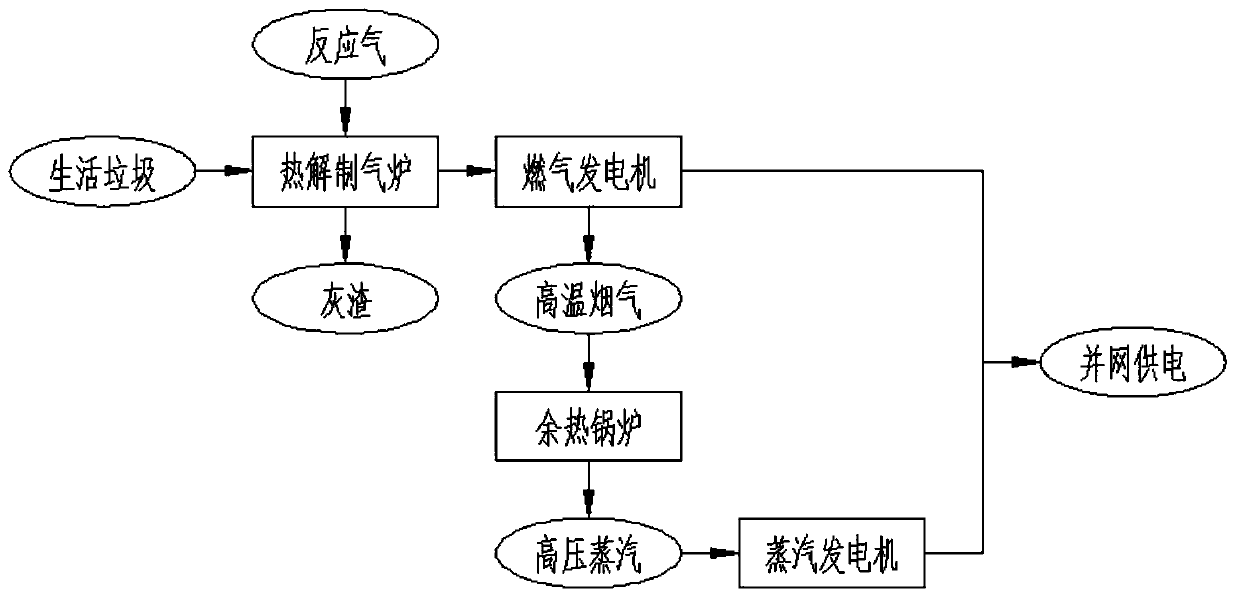

Embodiment 2

[0048] The domestic waste pyrolysis power generation method of the present embodiment comprises the following steps:

[0049] S1. Put domestic garbage into the pyrolysis gas-making furnace for pyrolysis and gasification, and feed reaction gas into the pyrolysis gas-making furnace. The content of oxygen in the reaction gas is 30%-93%, and a product including combustible gas is obtained;

[0050] S2. Detect the calorific value of the generated combustible gas, and adjust the content of oxygen in the reaction gas fed into the pyrolysis gas furnace in real time, so that the calorific value of the obtained combustible gas can be output stably;

[0051] S3. sending the combustible gas obtained in step S2 into a gas generator to generate electricity;

[0052] S4. Pass the high-temperature flue gas obtained in step S3 into the waste heat boiler, and pass water into the waste heat boiler to obtain high-pressure steam;

[0053] S5. Pass the high-pressure steam into the steam generator ...

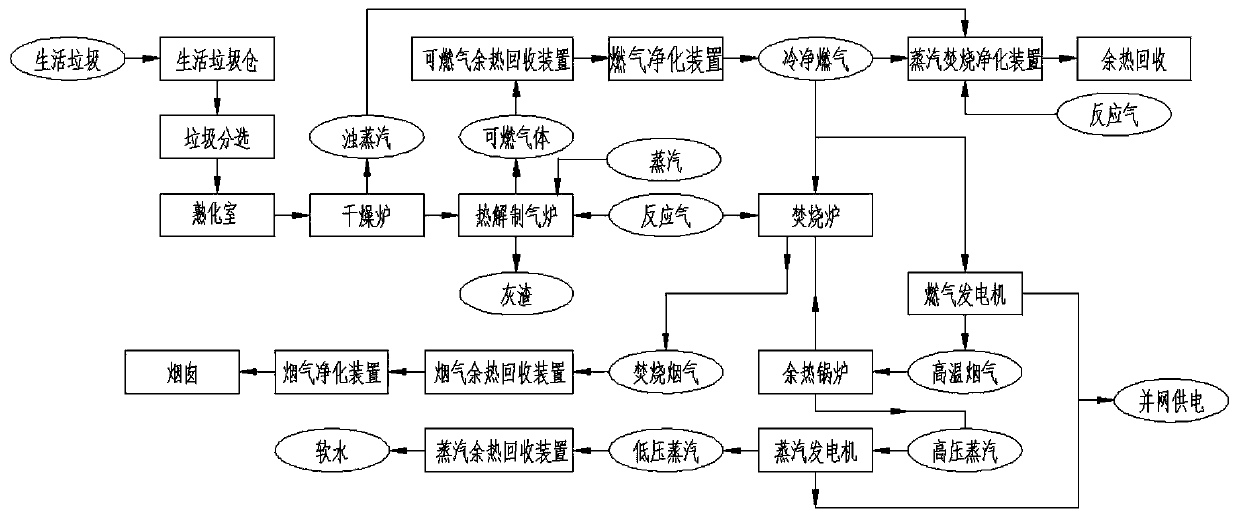

Embodiment 3

[0056] The domestic waste pyrolysis power generation method of the present embodiment comprises the following steps:

[0057] S1. Put domestic garbage into the pyrolysis gas-making furnace for pyrolysis and gasification, and feed reaction gas into the pyrolysis gas-making furnace. The content of oxygen in the reaction gas is 30%-93%, and a product including combustible gas is obtained;

[0058] S2. Detect the calorific value of the generated combustible gas, and adjust the content of oxygen in the reaction gas fed into the pyrolysis gas furnace in real time, so that the calorific value of the obtained combustible gas can be output stably;

[0059] B1. Pass the combustible gas obtained in step S2 into the combustible gas waste heat recovery device to recover heat;

[0060] B2. Pass the combustible gas discharged from the combustible gas waste heat recovery device in step B1 into the gas purification device for purification;

[0061] S3. Send the combustible gas purified in ste...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com