A batch type wastewater treatment equipment and its working method

A technology for wastewater treatment and equipment, applied in water/sewage multi-stage treatment, adsorbed water/sewage treatment, water/sludge/sewage treatment, etc., can solve the problems of difficult maintenance, high operating energy consumption, and reduce operating energy consumption , The effect of reducing investment costs, reducing maintenance links and personnel expenses

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

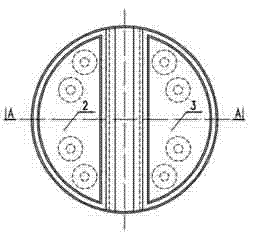

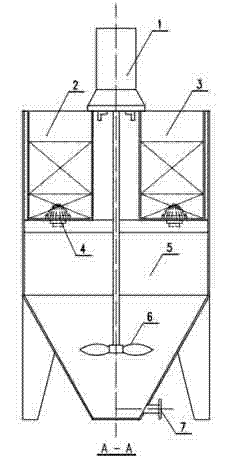

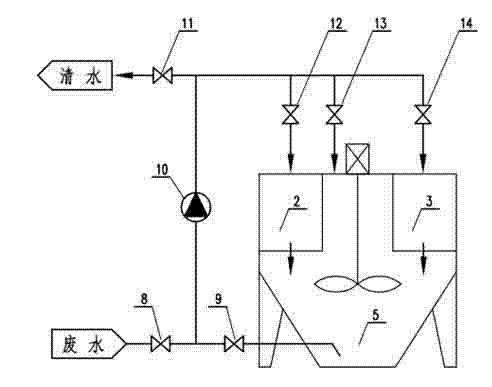

[0015] Such as figure 1 with figure 2 , The batch-type wastewater treatment equipment of the present invention, the main body is a metal shell, the motor reducer 1 is arranged on the top of the shell, and the inside of the shell is divided into upper and lower parts, and the upper part is equipped with separate quartz The sand filter zone 2 and the activated carbon adsorption zone 3; the quartz sand filter zone 2 and the activated carbon adsorption zone 3 are provided with a filter cap 4 at the bottom. The output shaft of the motor reducer extends downwards to the main reaction zone 5 inside the shell. A stirring blade 6 is provided on the top of the output shaft. The quartz sand filter zone 2, the activated carbon adsorption zone 3 and the main reaction zone 6 are respectively equipped with pipes and wastewater. Connected, the liquid outlet 7 is arranged at the bottom of the housing.

[0016] The equipment integrates the functions of dosing mixing reaction, flocculation reactio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com