Efficient spiral sliding cleaning orbit for bottle boxes

A technology of helical and helical guide rails, applied in cleaning methods and utensils, cleaning methods using liquids, chemical instruments and methods, etc. problem, to achieve the effect of facilitating thorough cleaning, low equipment failure rate, and small footprint

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] In order to make the technical means, creative features, goals and effects of the present invention realized easily

[0030] For clear understanding, the present invention will be further described below in conjunction with specific embodiments.

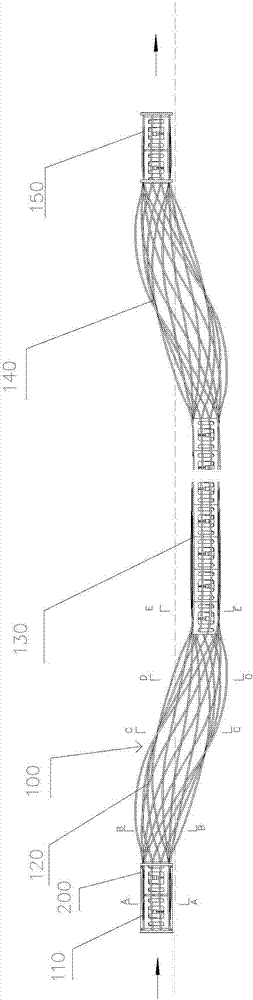

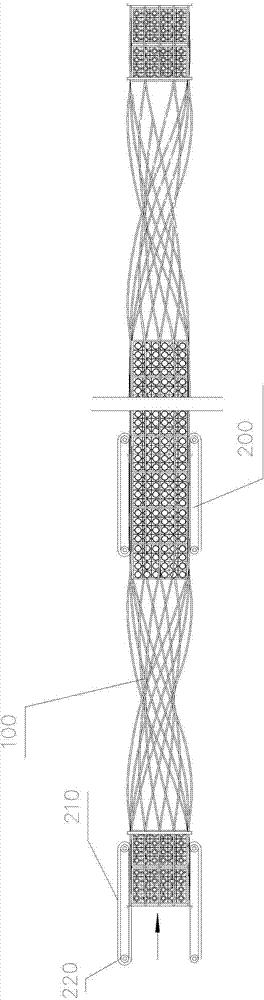

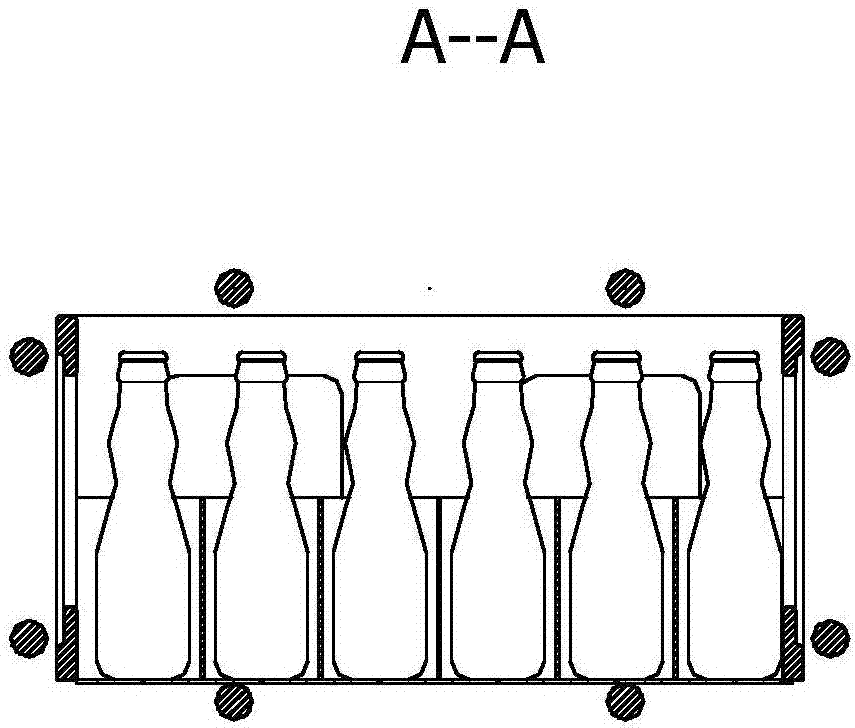

[0031] see figure 1 to map Figure 7 , the embodiment of the present invention provides four kinds of spiral bottle case sliding cleaning tracks, which are composed of bottle case spiral guide rails 101 for resisting the other four sides of the bottle case in the direction of movement to form a sliding spiral cleaning channel 100, The sliding spiral cleaning channel 100 is placed in the cleaning liquid of the box body, and its two ends are located on both sides of the box body.

[0032] In this embodiment, the bottle box spiral guide rails 101 on four sides constitute a 360-degree rotating sliding spiral cleaning channel 100, so that the bottle box can be turned and cleaned 360 degrees. As the optimal choice, there are two ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com