Internal battery holding structure in mobile equipment

A technology with built-in batteries and batteries, which is applied to the structure of telephones, small-sized batteries/battery packs, structural parts, etc., and can solve the problems of easily damaged battery covers and disconnected wires.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

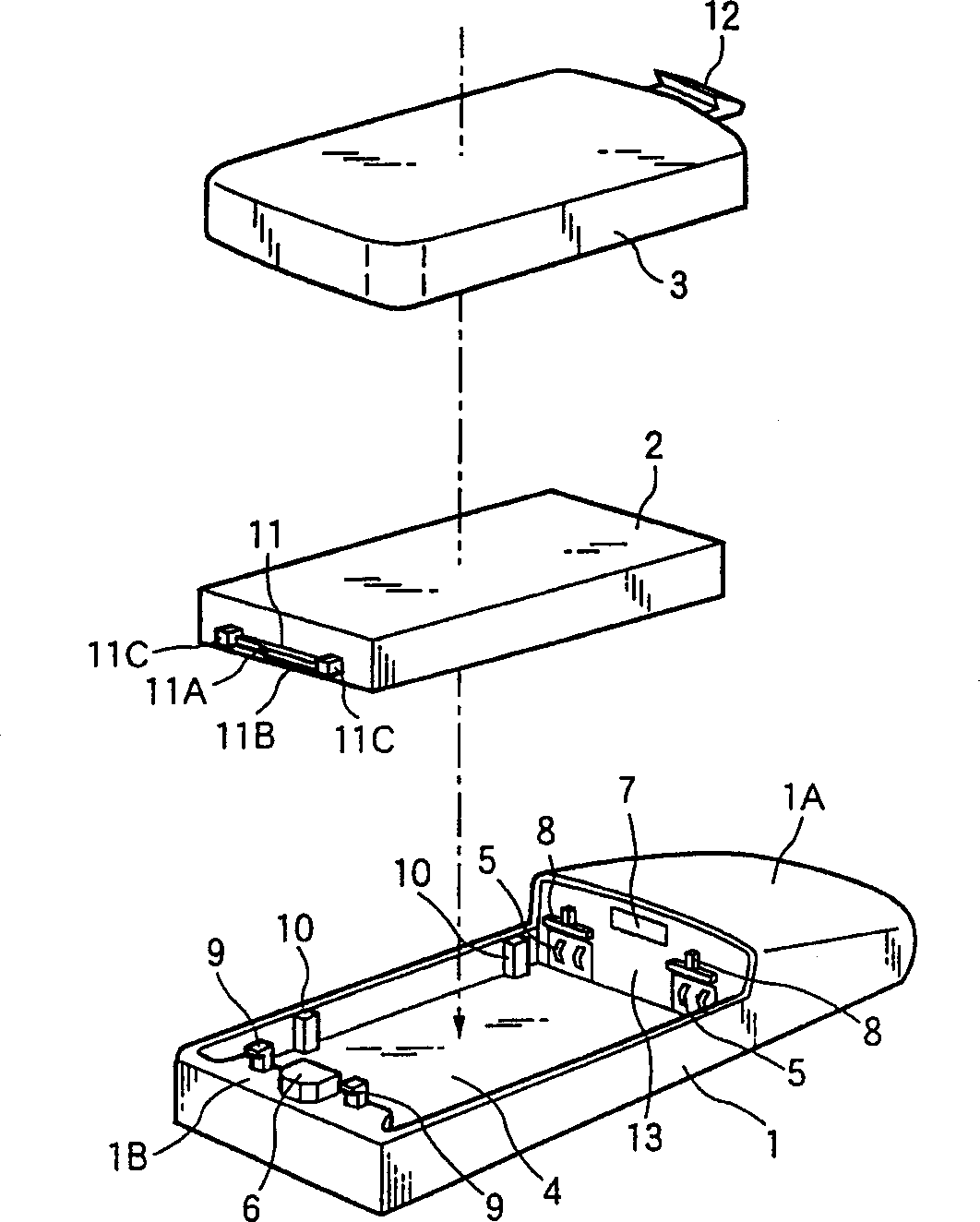

[0022] Embodiments of the present invention will be specifically described below in conjunction with the accompanying drawings.

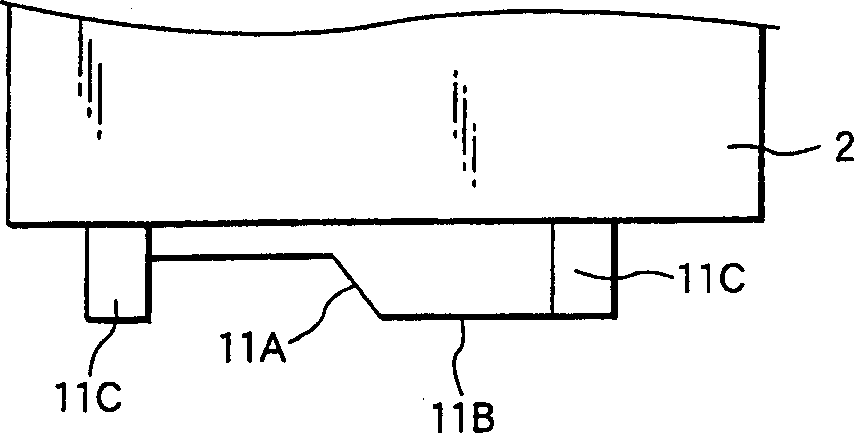

[0023] figure 1 is a perspective view schematically showing a built-in battery holding structure according to an embodiment of the present invention. Such as figure 1 As shown, the built-in battery 2 is placed in the recessed battery box portion 4 on the rear case 1 of the mobile phone, and then the battery cover 3 is mounted to the rear case 1 from above. Thus, the built-in battery 2 is incorporated into the mobile phone.

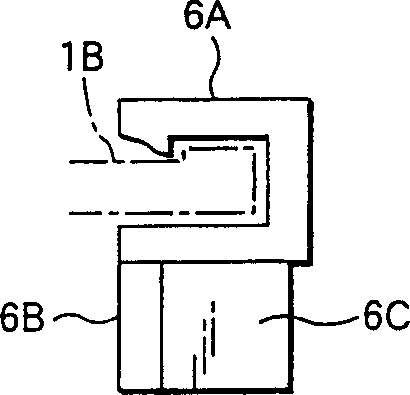

[0024] The battery case portion 4 is concave downward and is formed in a substantially rectangular parallelepiped shape on the surface of the rear case 1 . The inner wall surface on the front end is provided with a pair of connectors 5 , a rectangular fitting hole 7 , and a pair of first engaging protrusions 8 . A pair of connector terminals is exposed on the surface of the connector 5 . The first engaging protrusion 8 pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com