Patents

Literature

78 results about "Disposable Equipment" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Apparatus, devices, or supplies intended for one-time or temporary use.

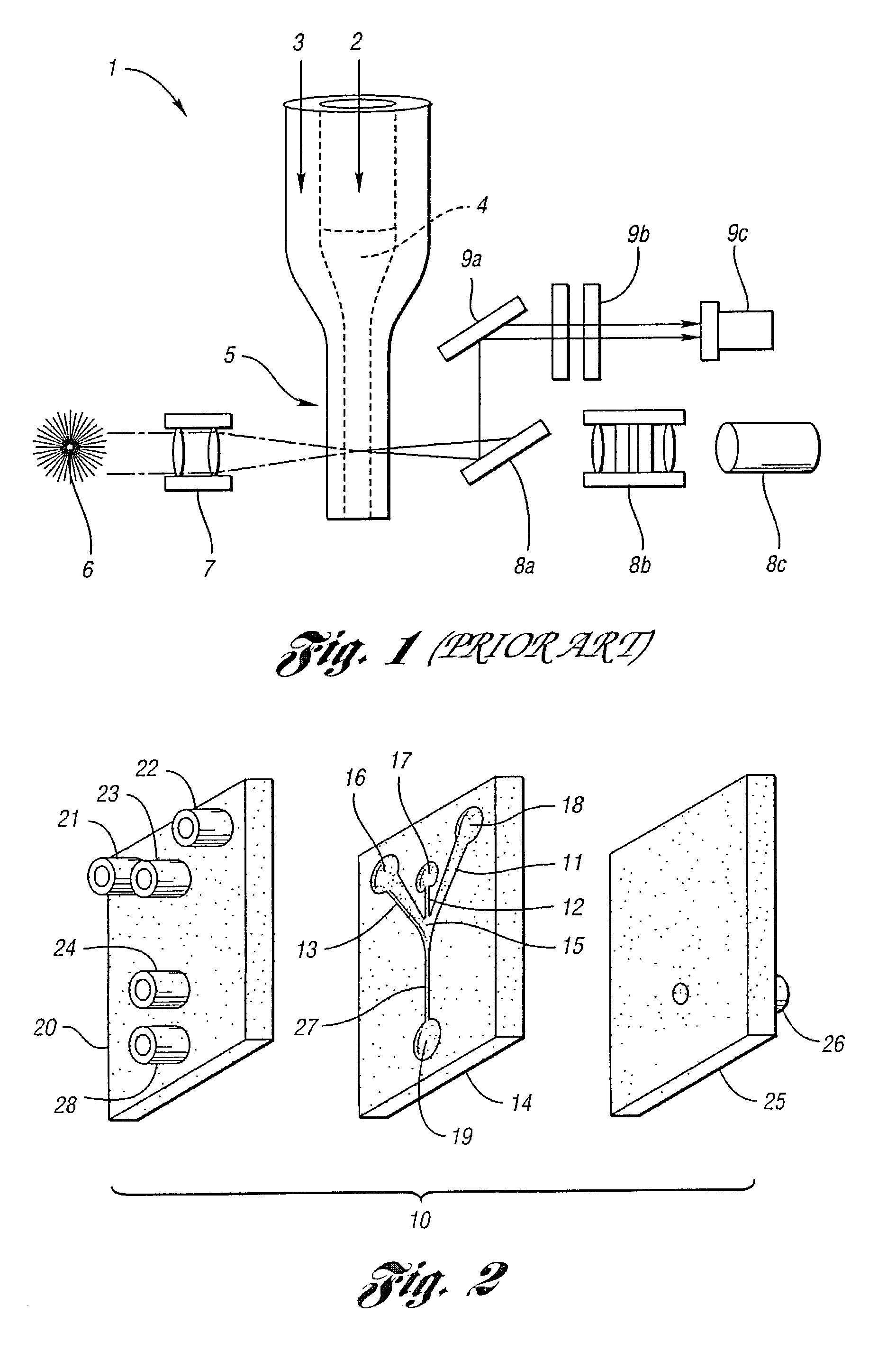

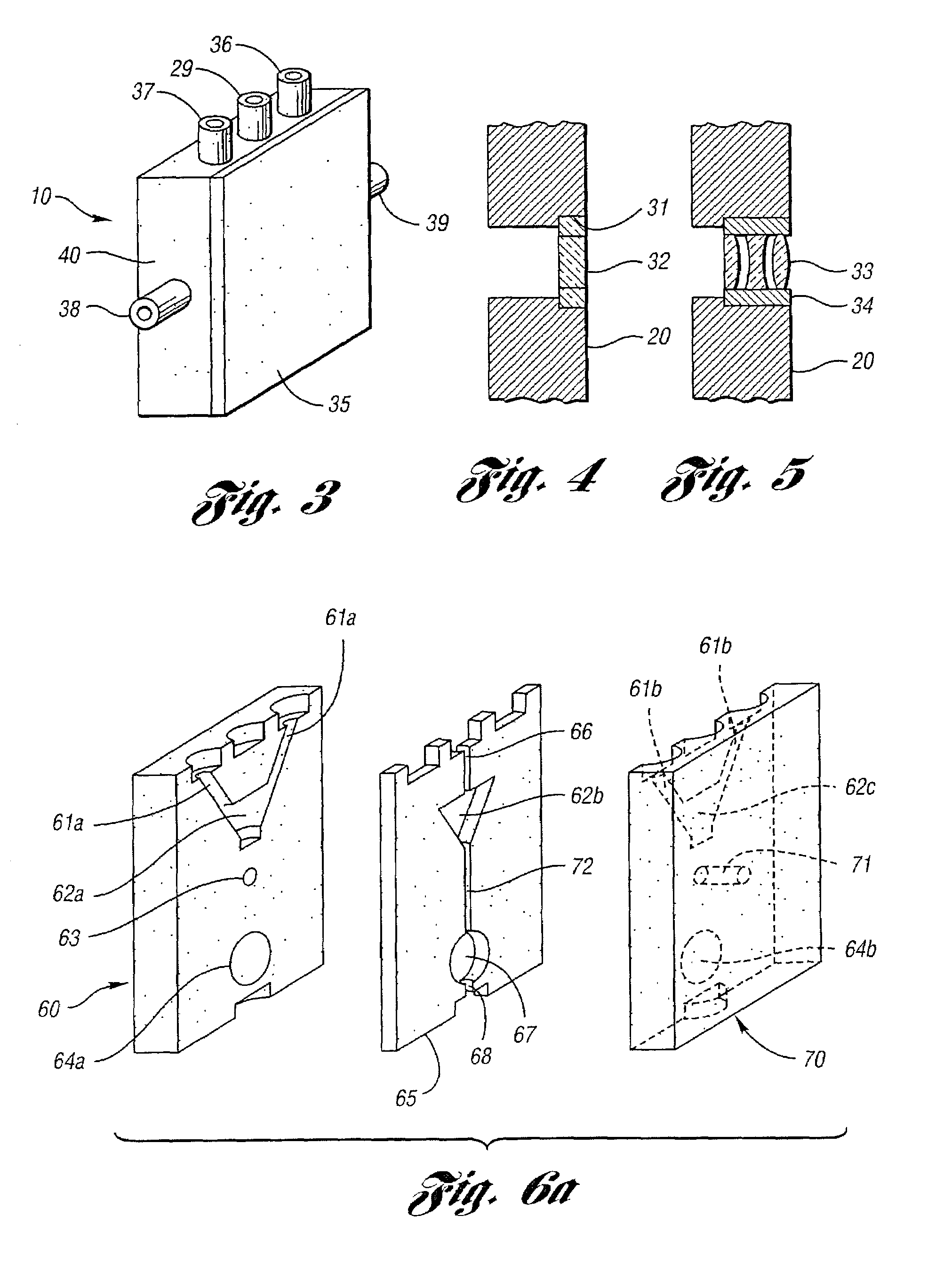

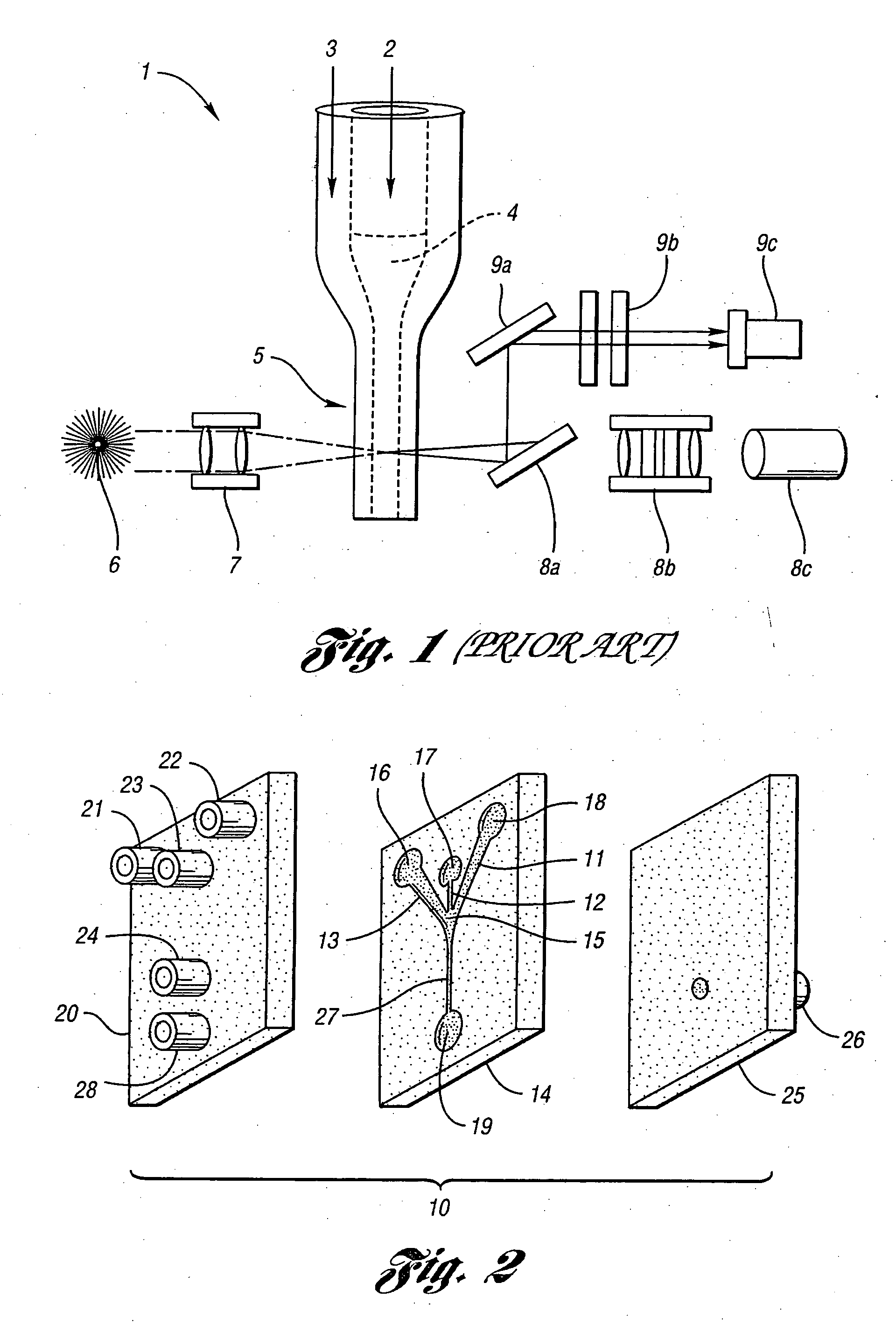

Flow cytometers and detection system of lesser size

InactiveUS7105355B2Increase the number ofMaximize signal to noiseWithdrawing sample devicesAnalysis by material excitationFiberManufacturing technology

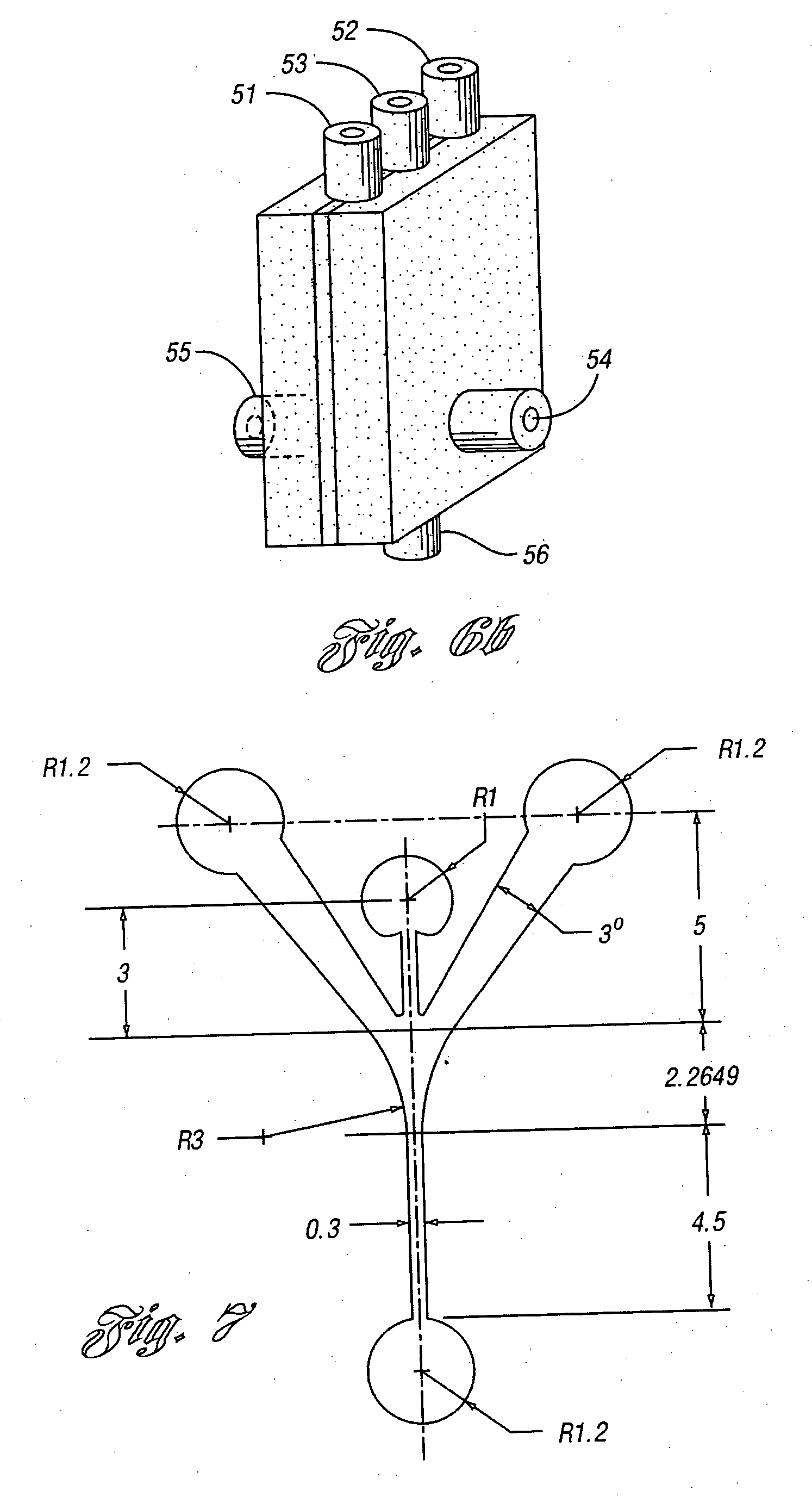

Gas focusing flow cytometers are fabricatable employing simple and inexpensive manufacturing techniques. When such cytometers or conventional cytometers are combined with fiber optical light paths and laser diode and semiconductor photodetectors, light weight and handheld, optionally disposable devices which maintain high performance are possible.

Owner:RGT UNIV OF MICHIGAN

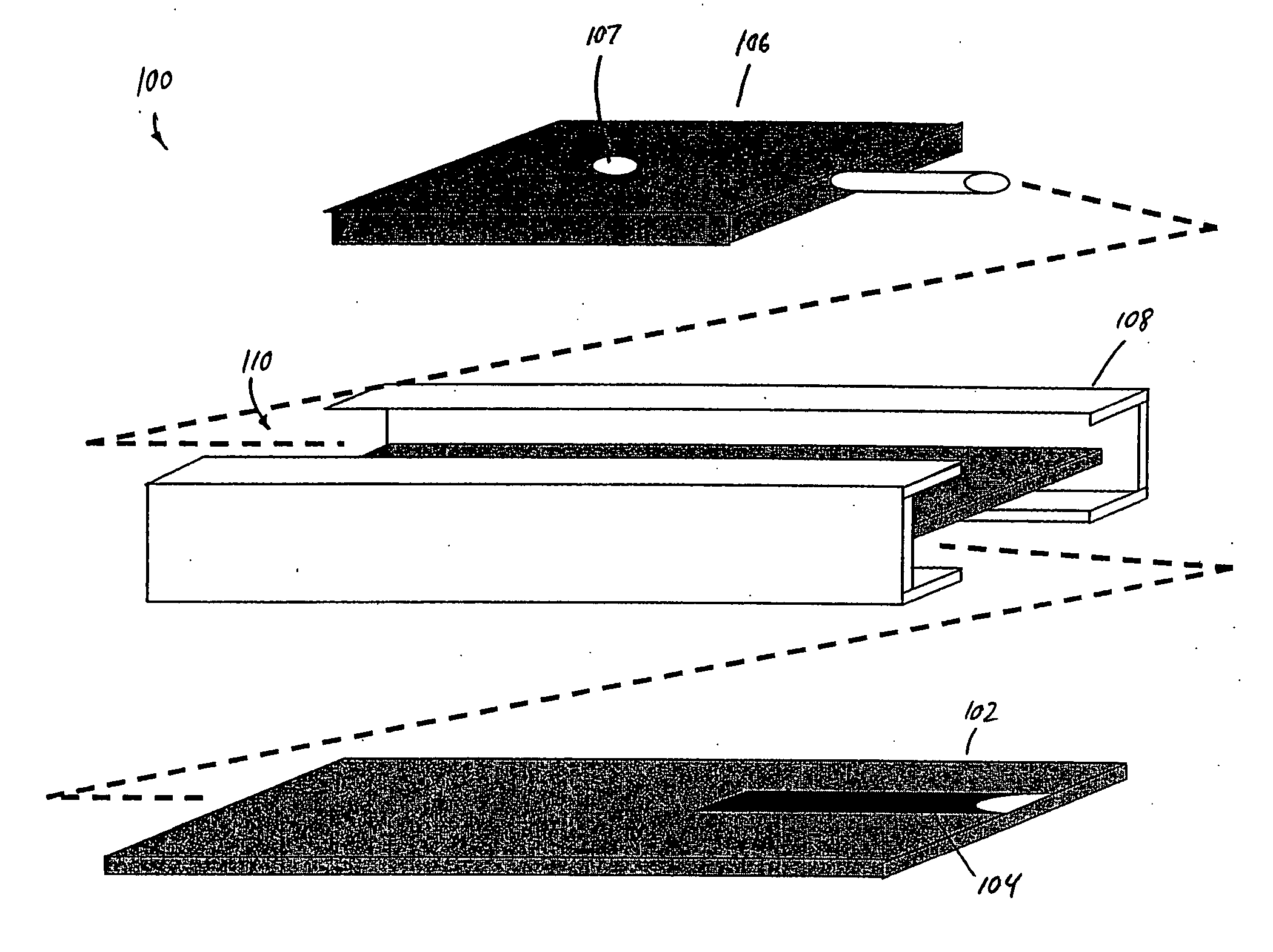

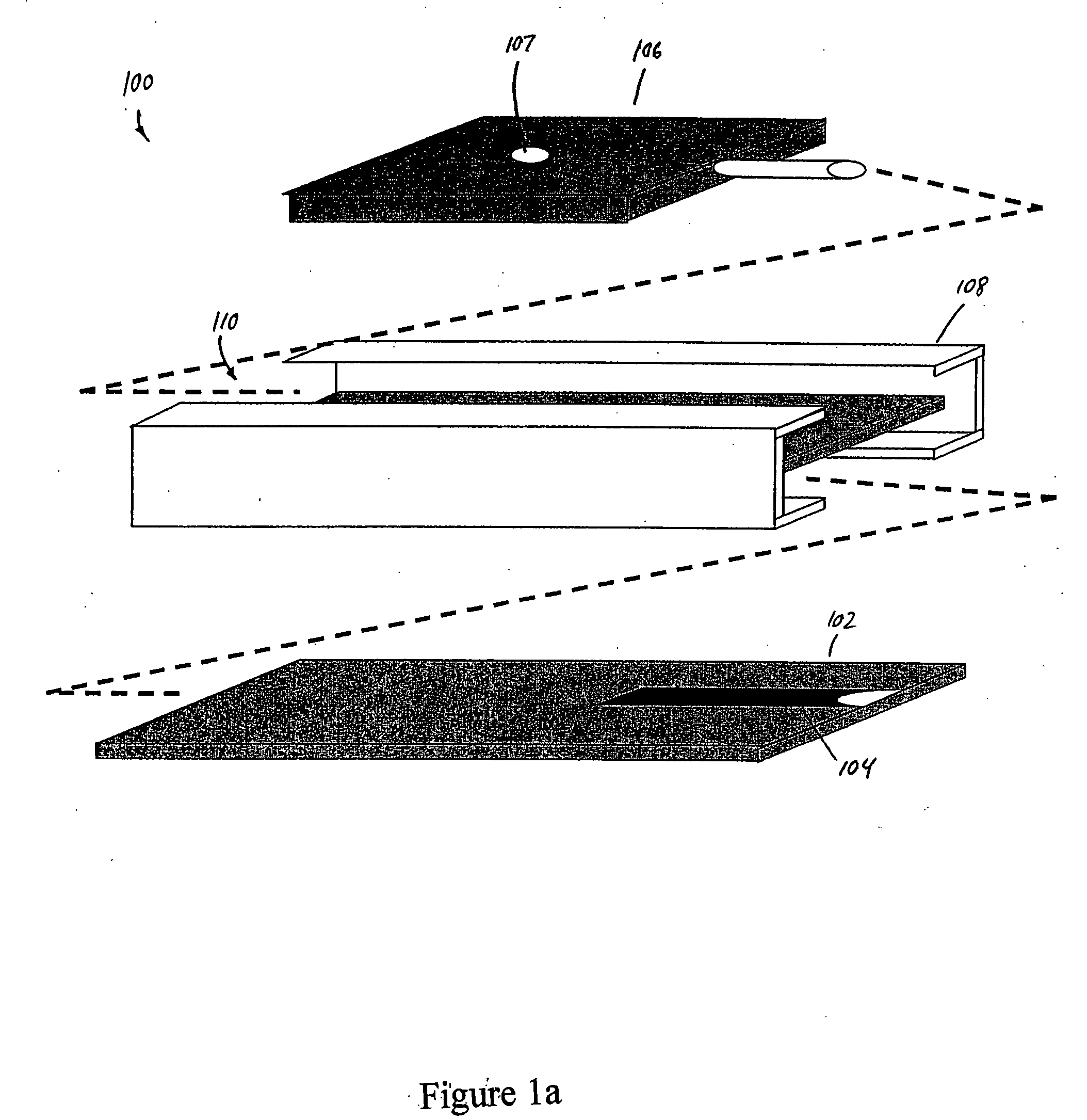

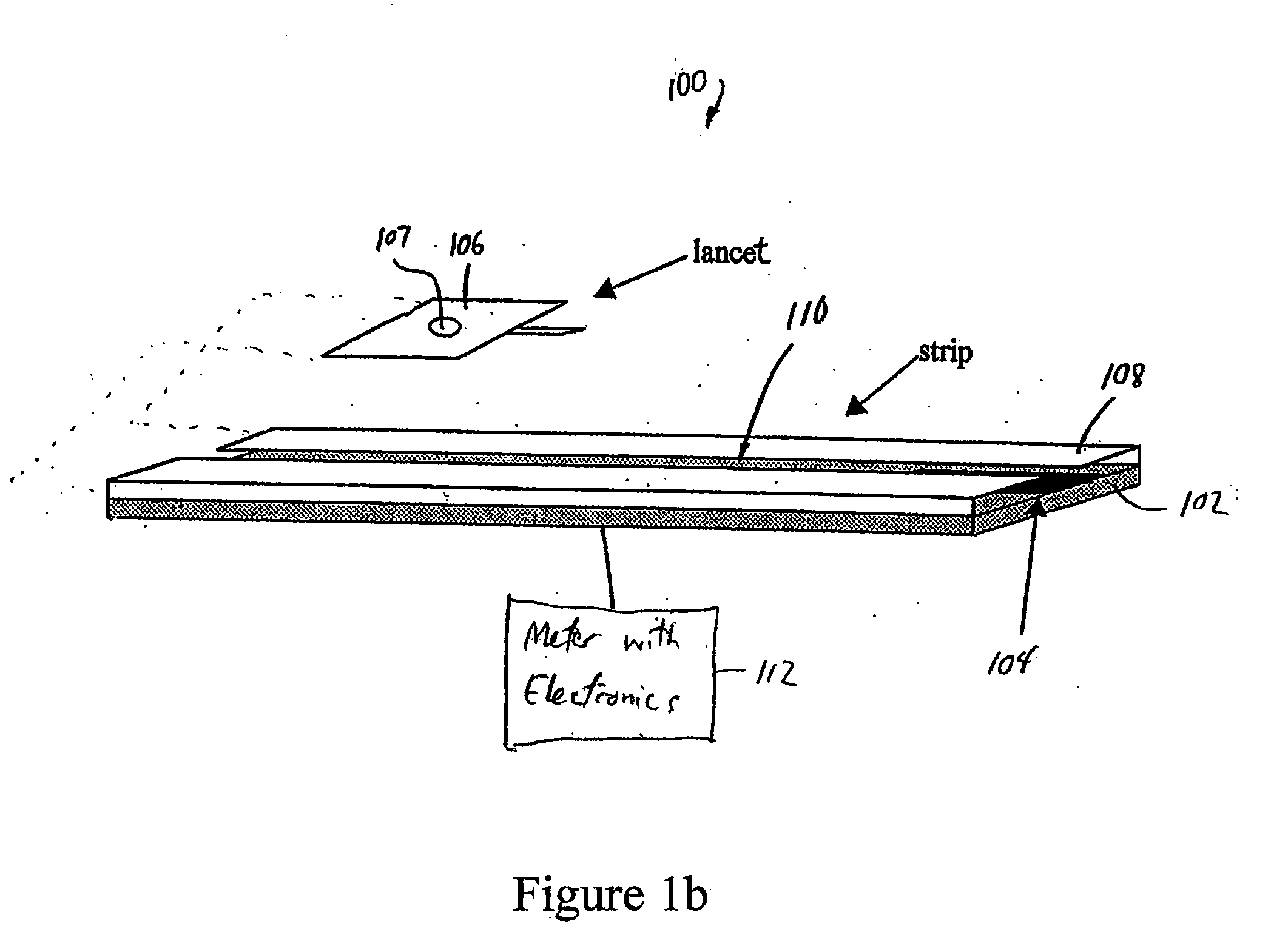

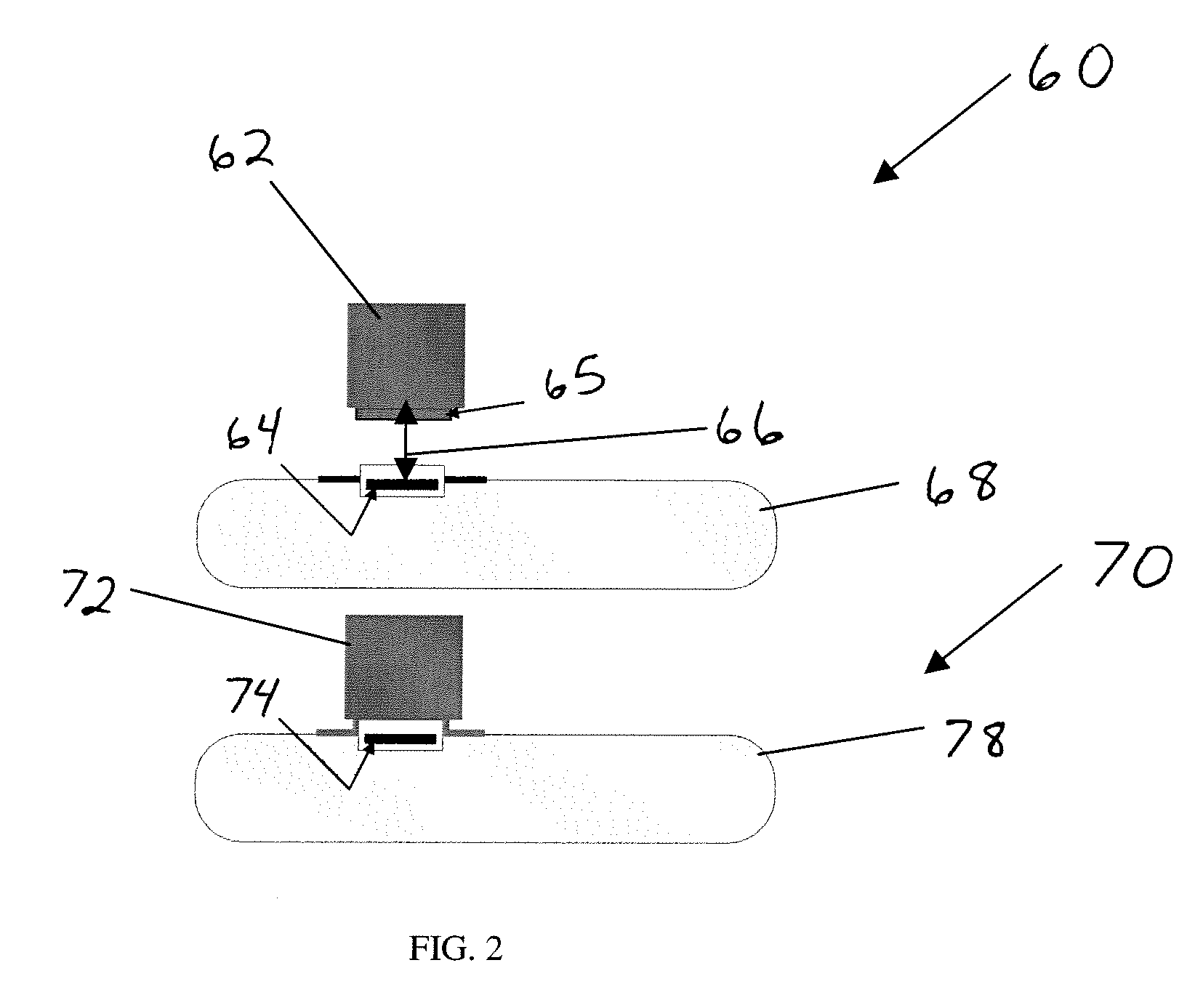

Integrated lancet and bodily fluid sensor

ActiveUS20070179406A1Easy to transportImmobilised enzymesBioreactor/fermenter combinationsAnalyteEngineering

A lancing device integrated with a sensing strip and method of making and using the same are provided. A lance and analyte sensing strip are combined in a single, preferably disposable, device. In a preferred embodiment, a slot is provided in a support member so the lance can be engaged by a lance driver and driven into the skin producing a bodily fluid sample from a wound. The sensing area of the sensing strip is adjacent to the wound location reducing dexterity requirements for patients.

Owner:EMBECTA CORP

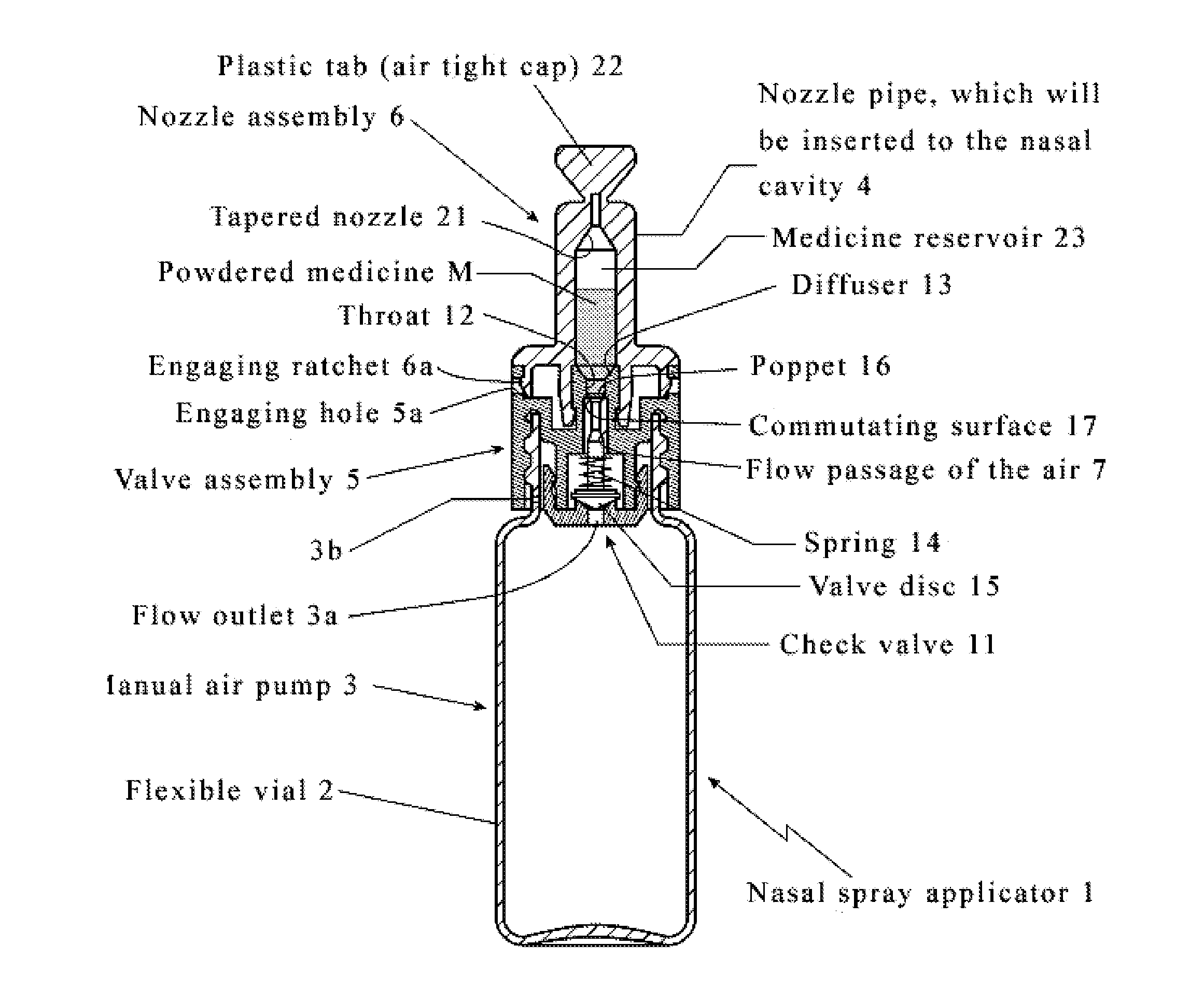

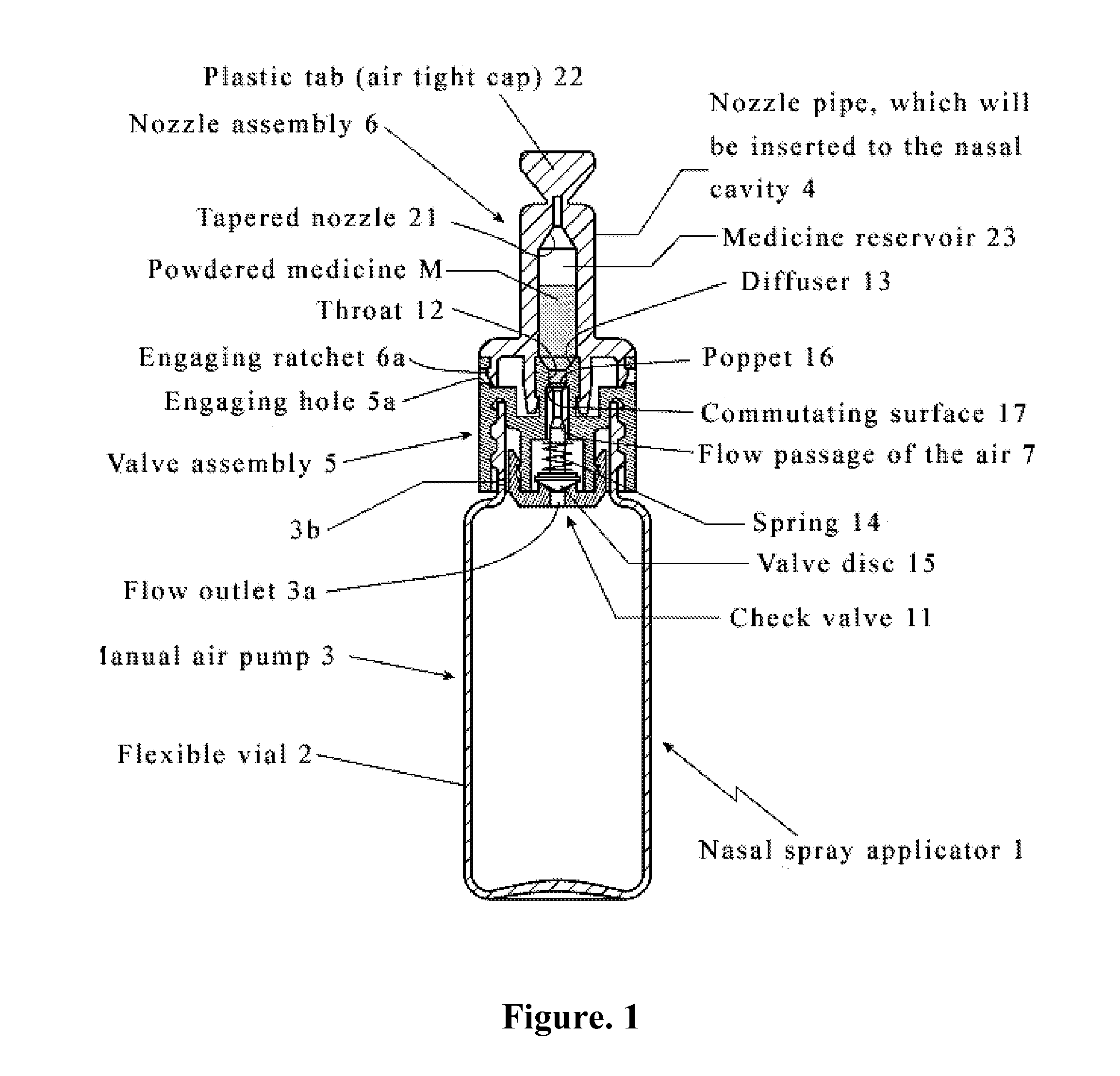

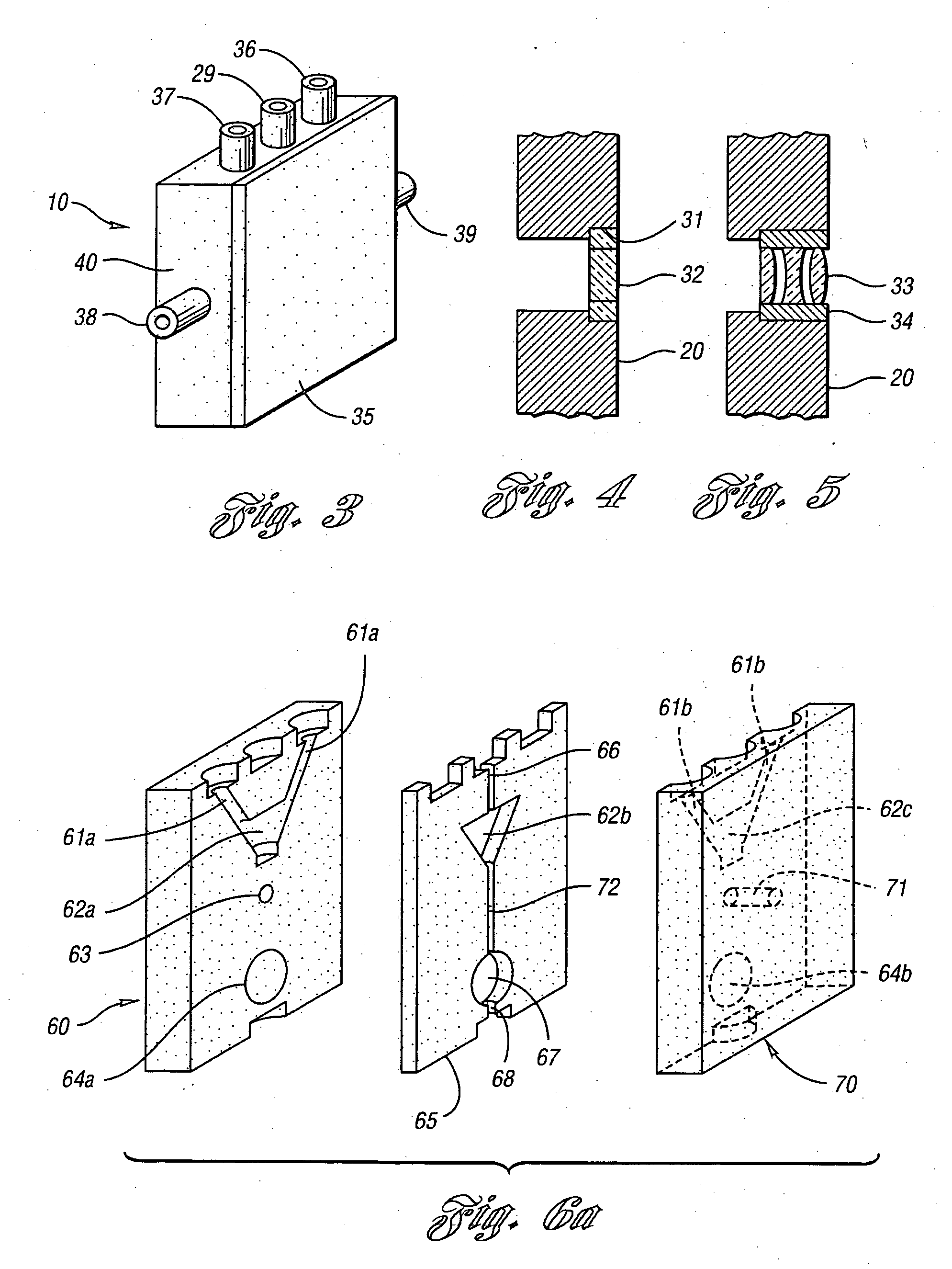

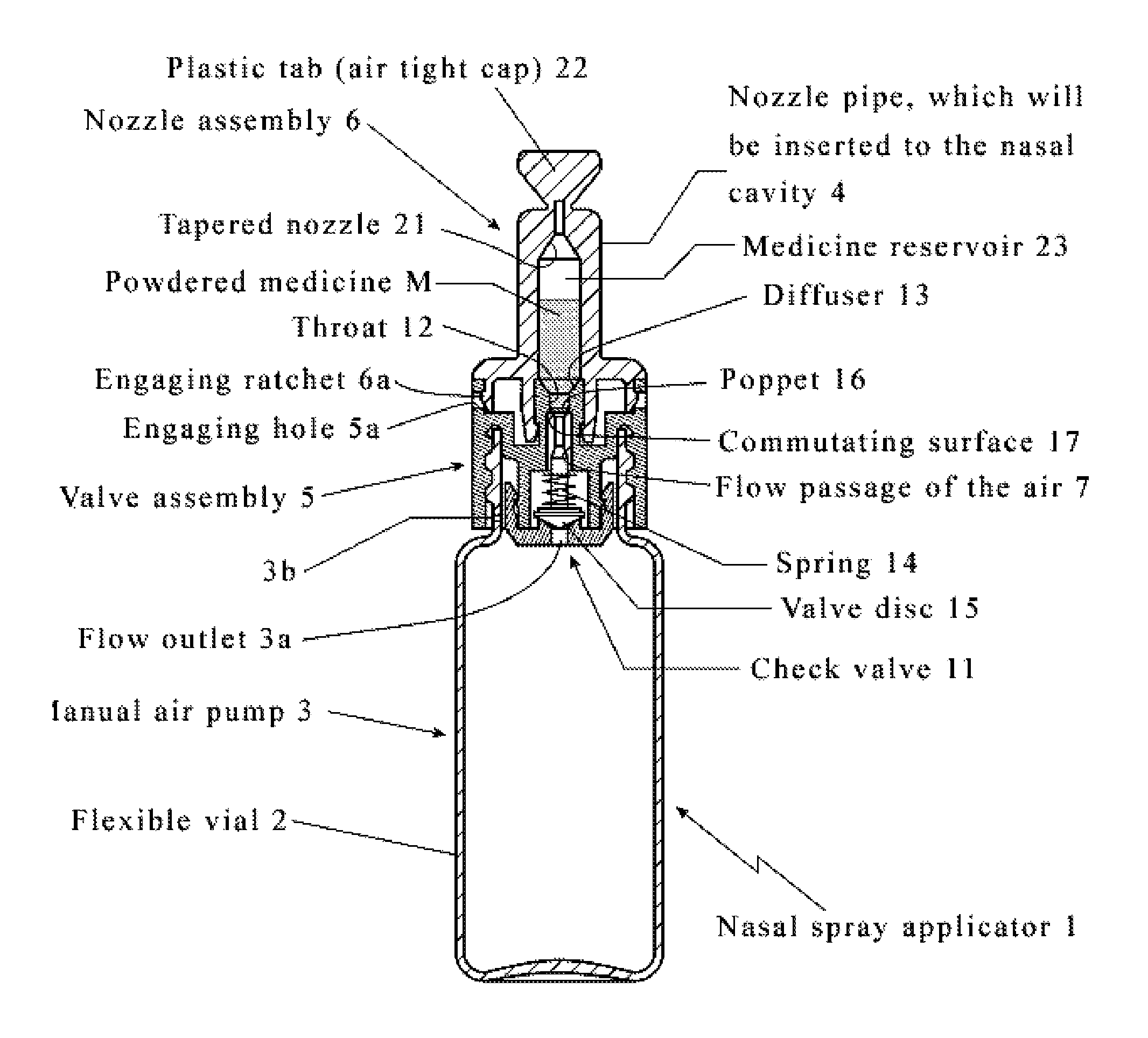

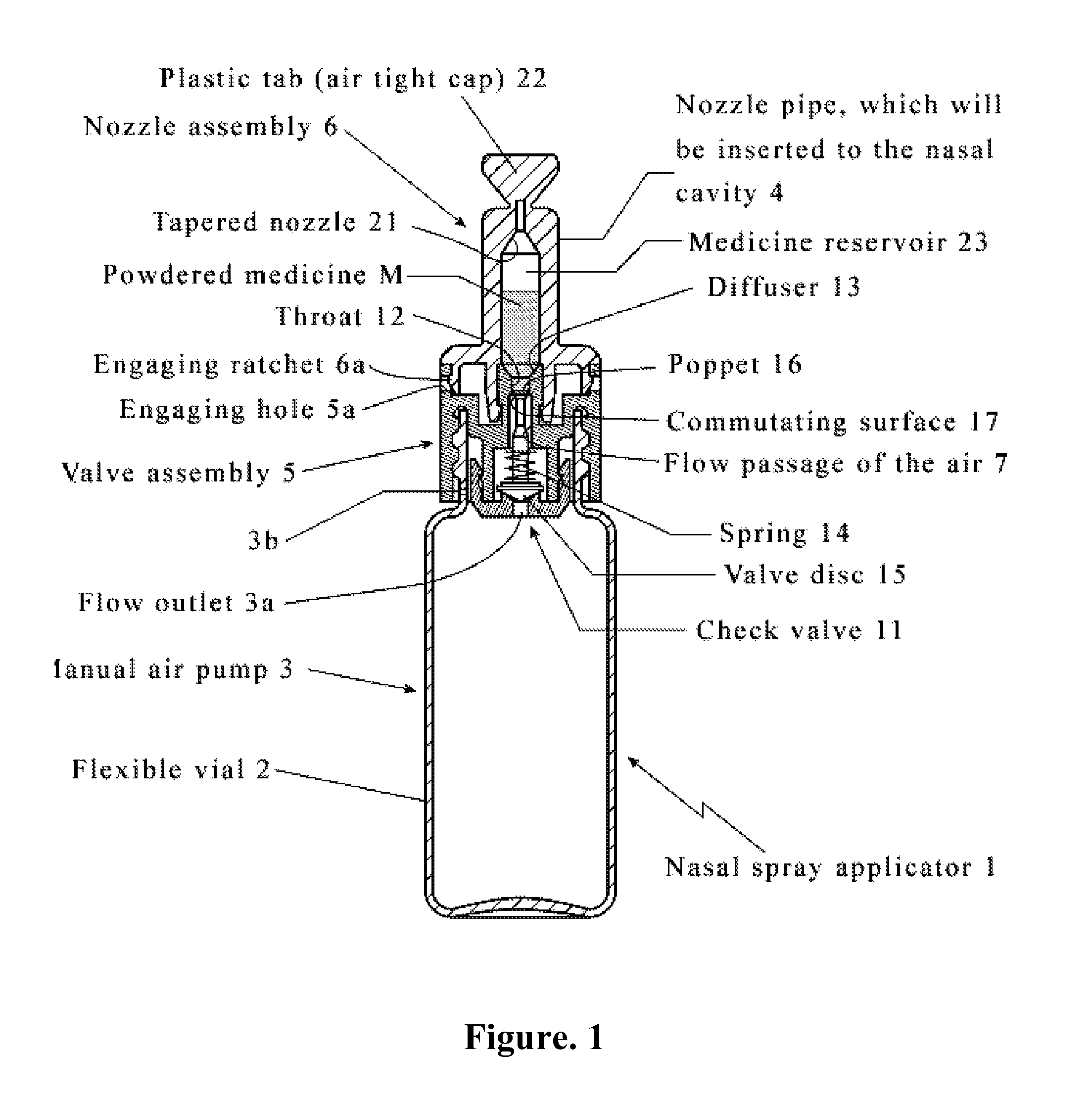

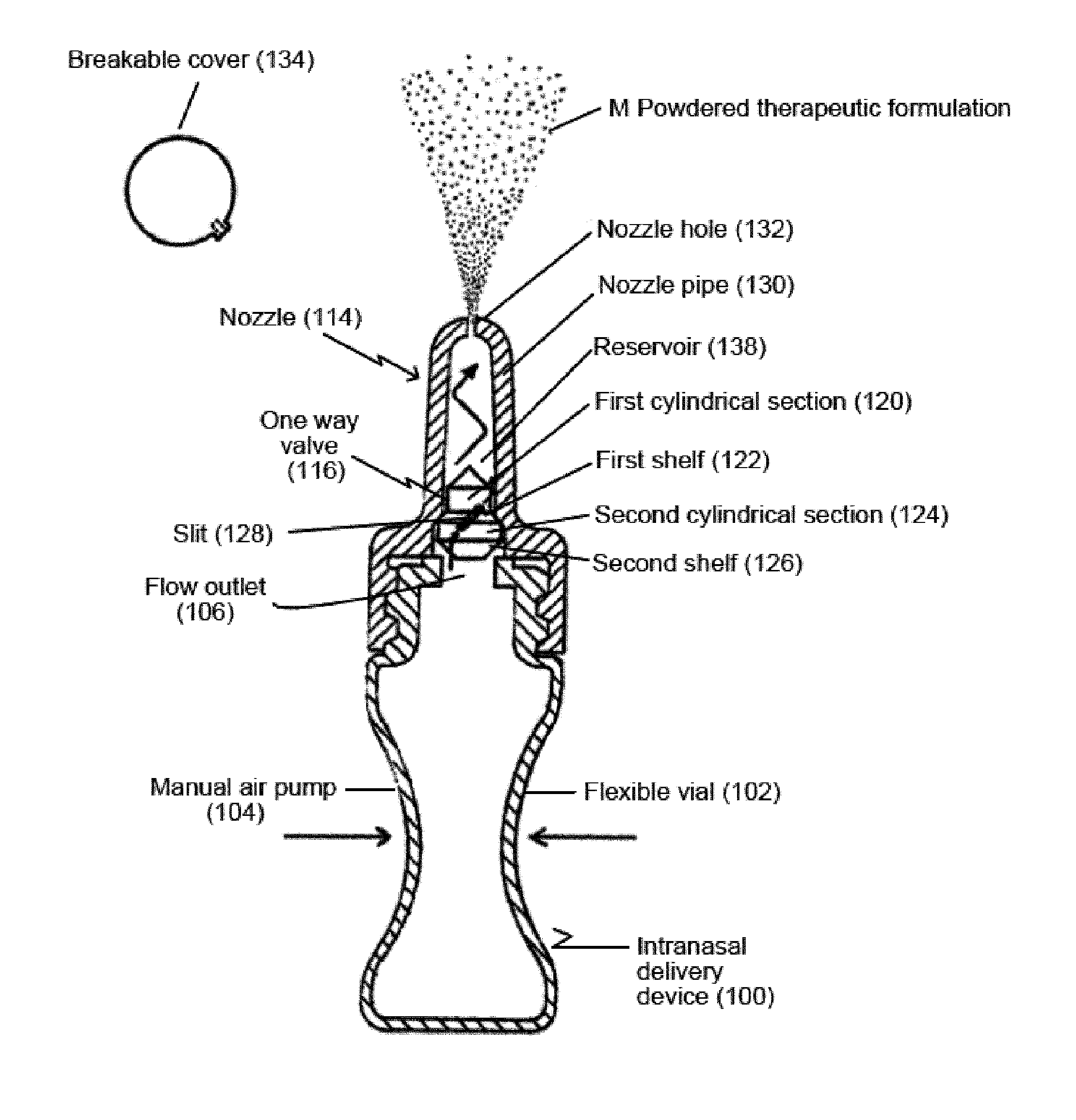

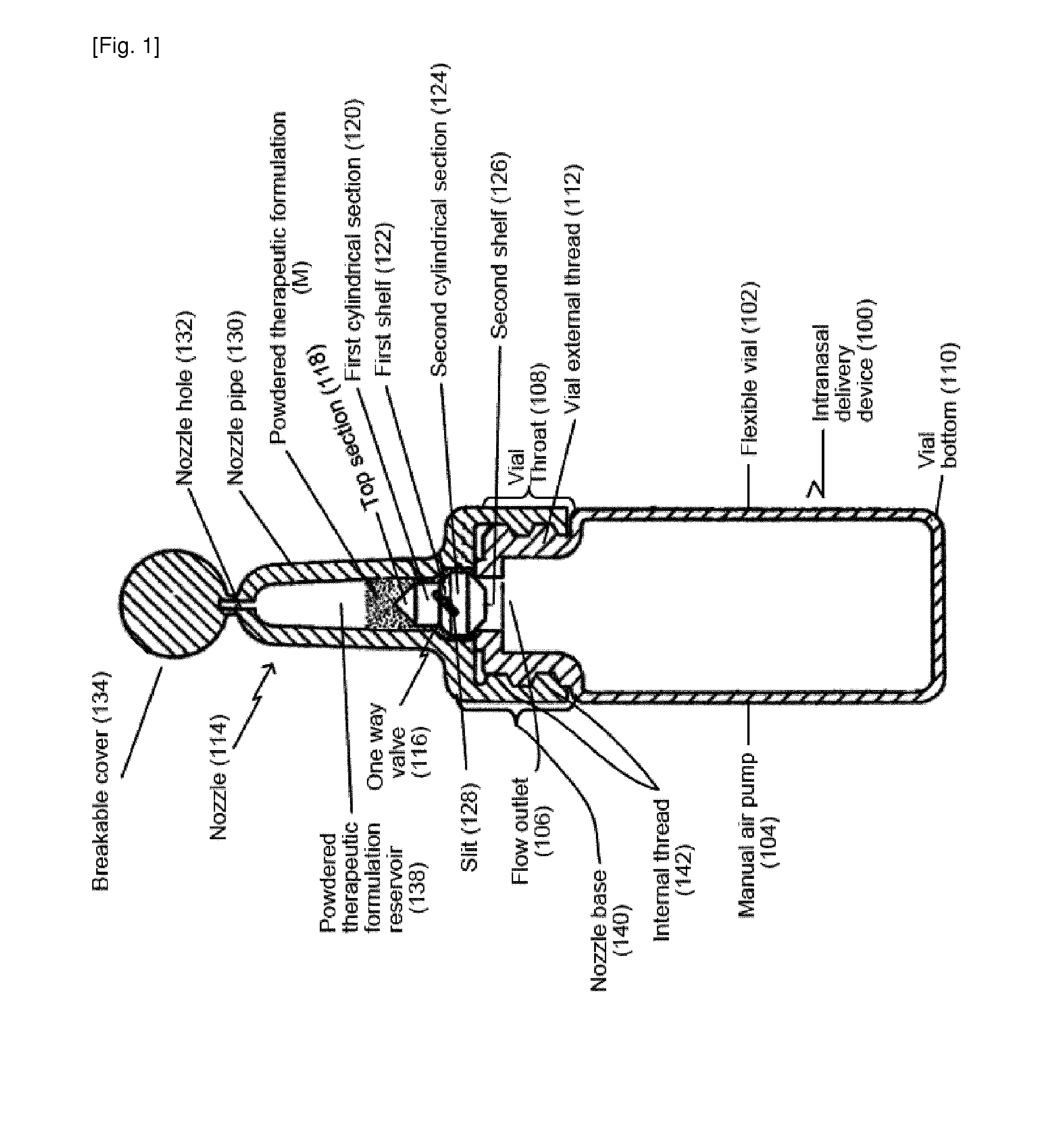

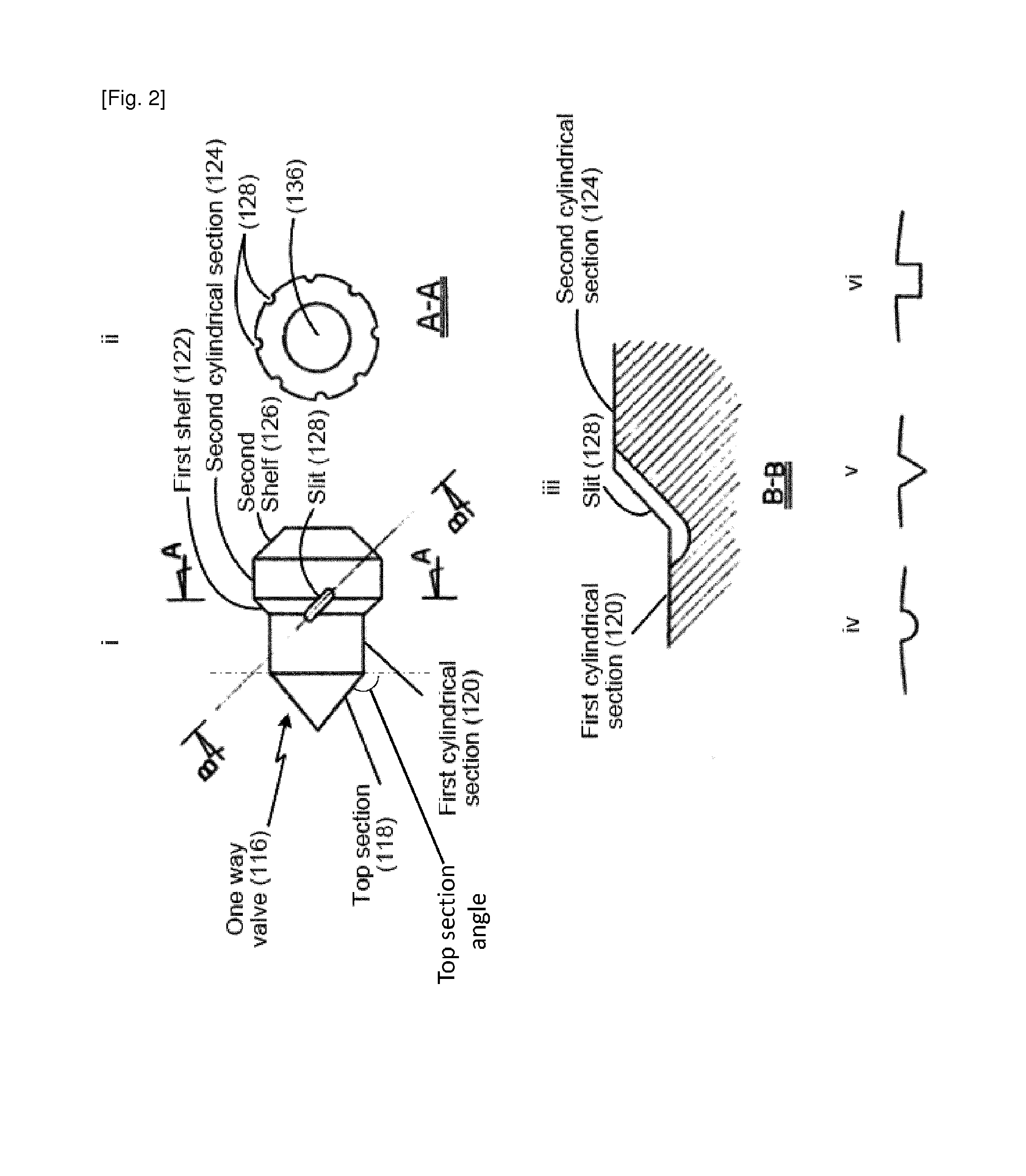

Intranasal granisetron and nasal applicator

Formulations and methods of manufacture are provided for granisetron dry powder compositions suitable for intranasal administration. Also provided are methods of use for preventing or controlling emesis and other diseases and disorders and devices, compositions, and methods for nasal delivery of therapeutic formulations. Devices for delivery of dry powder formulations are also provided. Devices can be single-use devices.

Owner:SHIN NIPPON BIOMEDICAL LAB

Optical markings

InactiveUS20080217391A1Input/output to record carriersComputer-assisted medical data acquisitionPatient dataManufacturing data

A method and system for cumulatively associating manufacture data and patient data with disposable equipment, particularly sample collection containers, in a medical or laboratory environment by permanently affixing unique code labels to the disposable equipment.

Owner:PATIENTSAFE SOLUTIONS

Methods and Apparatus for Near Field Irradiation

InactiveUS20090220968A1Cheap to makeDisposable deviceBioreactor/fermenter combinationsBiological substance pretreatmentsProximateEngineering

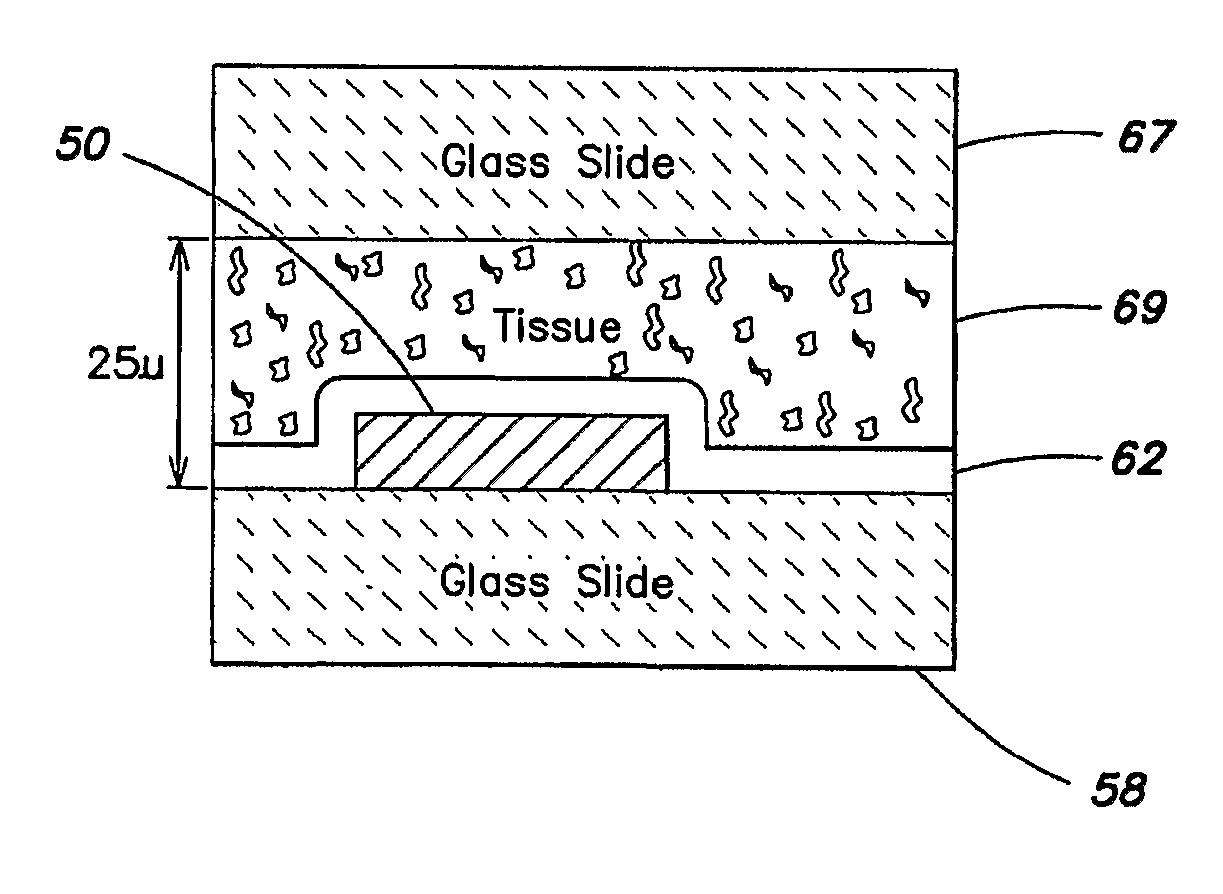

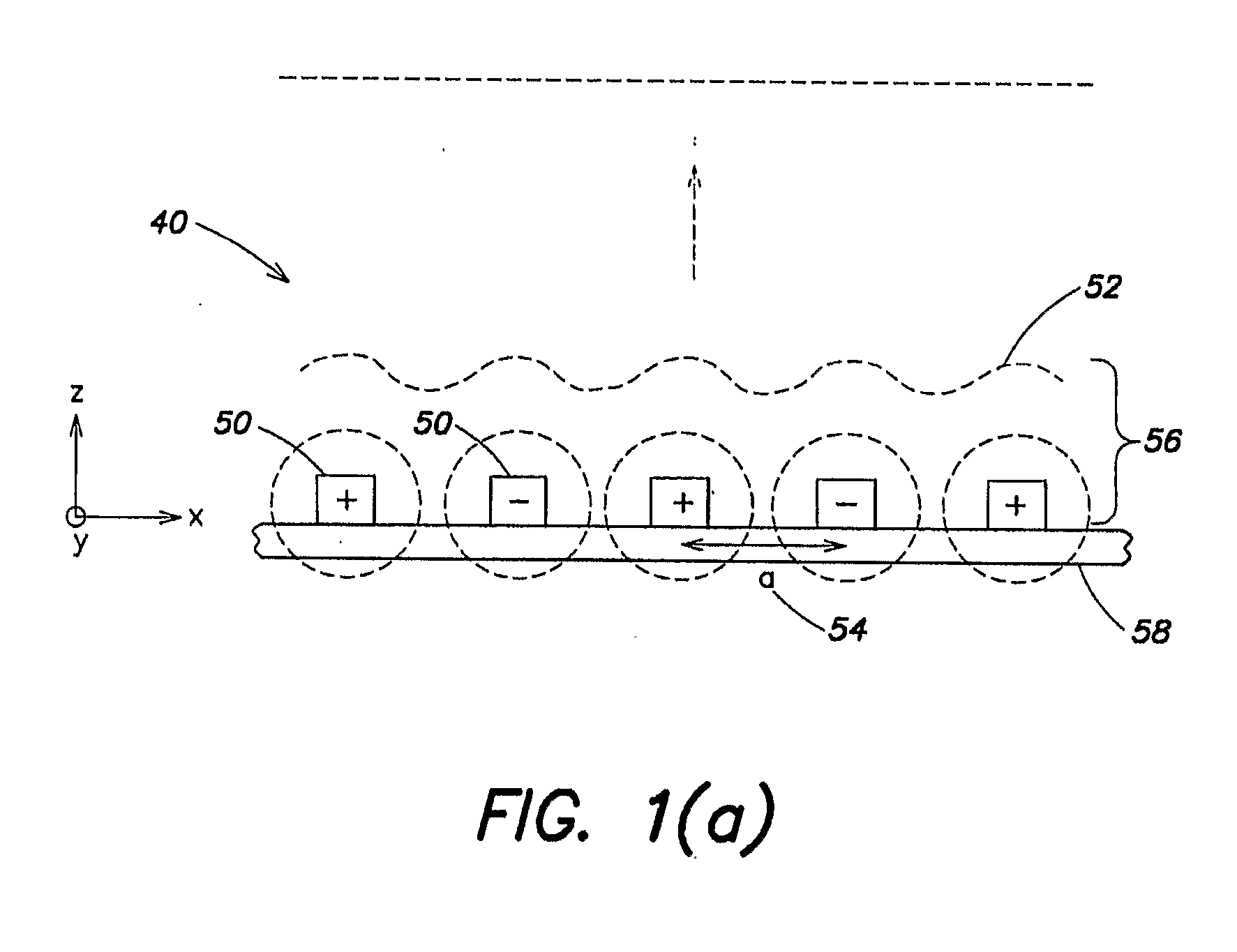

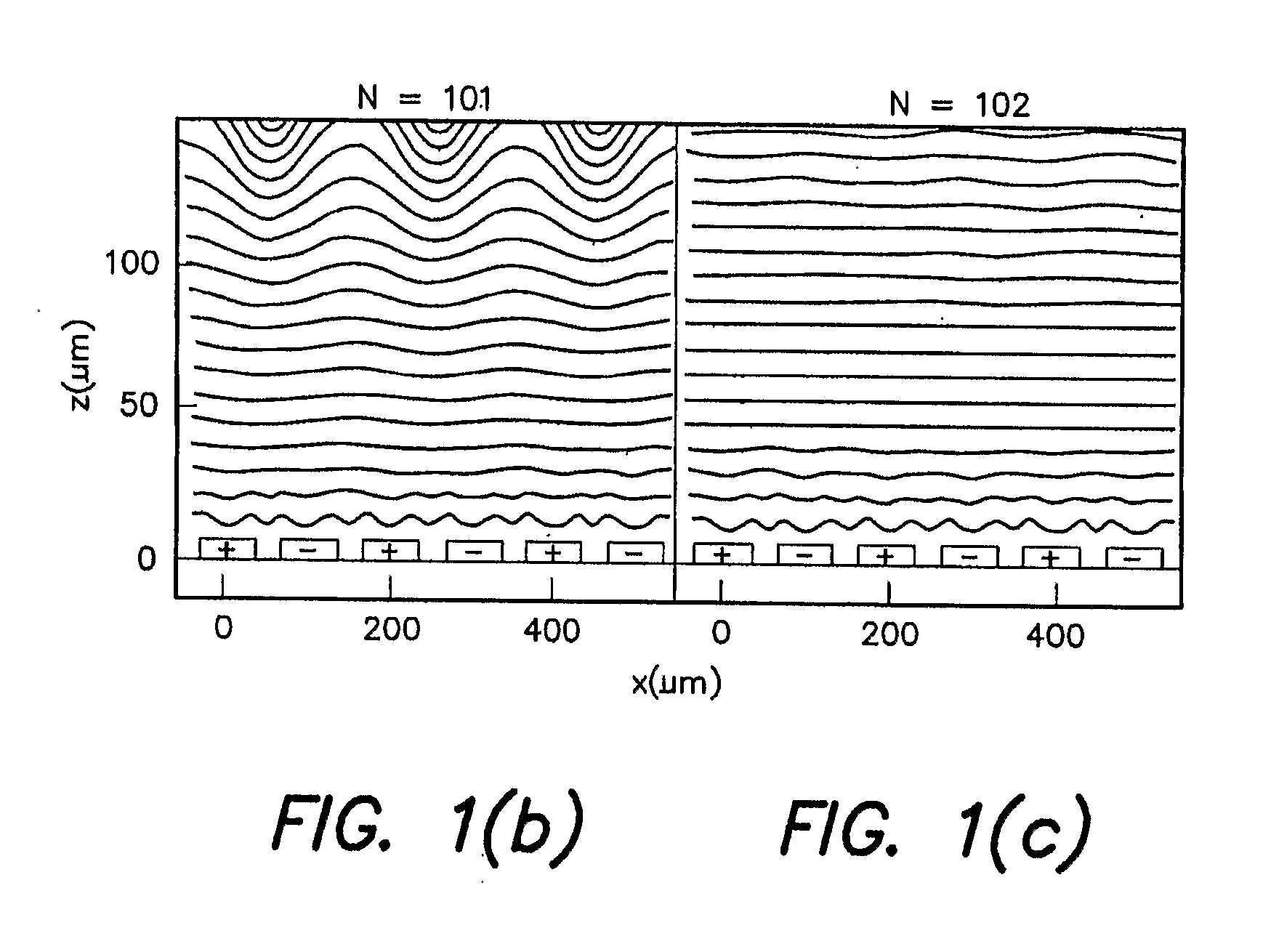

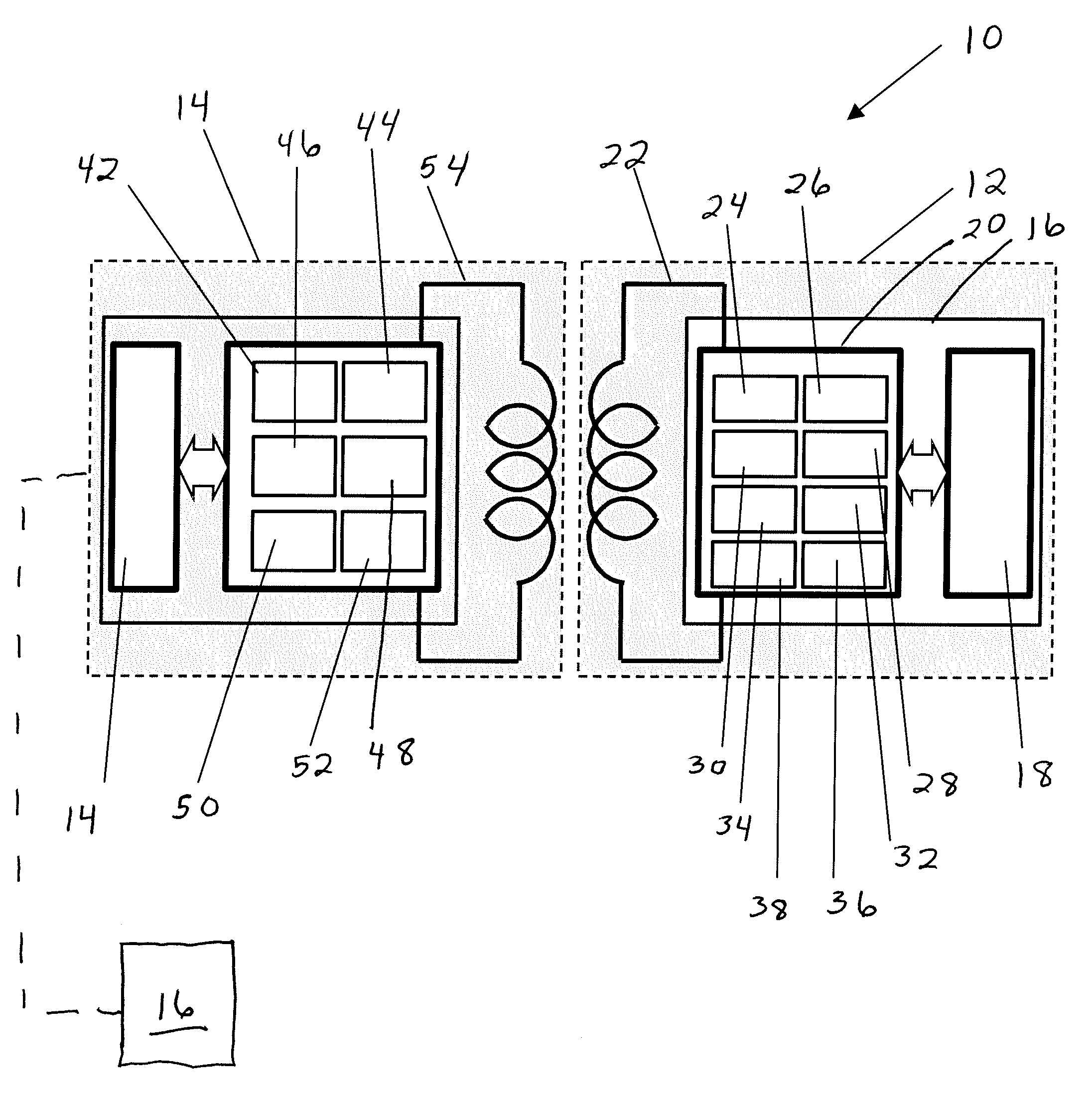

Irradiation methods and apparatus configured to deliver power, via electromagnetic fields at a variety of frequencies and power levels, in a localized fashion to a target area. In one example, an electromagnetic field generator is disposed on a substrate and configured to deliver power via electromagnetic energy to a thin region proximate to (above) a surface of the substrate, wherein electromagnetic field intensity decreases significantly beyond the thin region. Such methods and apparatus are particularly useful in a wide variety of processes involving chemical and / or physical interactions in connection with a sample of interest located in the thin region. In different aspects, irradiator apparatus may be configured as disposable devices, and / or used in combination with one or more microfluidic or sensing components, for a variety of medical / laboratory / diagnostic methods and instrumentation implementations.

Owner:PRESIDENT & FELLOWS OF HARVARD COLLEGE

RFID based methods and systems for use in manufacturing and monitoring applications

InactiveUS20090256679A1Auto-redundancy reductionFacilitate oneMain station arrangementsWireless architecture usageMemory chipCompound (substance)

Methods and systems for optimizing information associated with RFID devices that, include a memory chip written with redundant data and read by an RFID reader and, are adapted for operation of RFID tags and chemical, biological, and physical RFID sensors that are exposed to gamma radiation, such as disposable devices used in bioprocessing.

Owner:GENERAL ELECTRIC CO

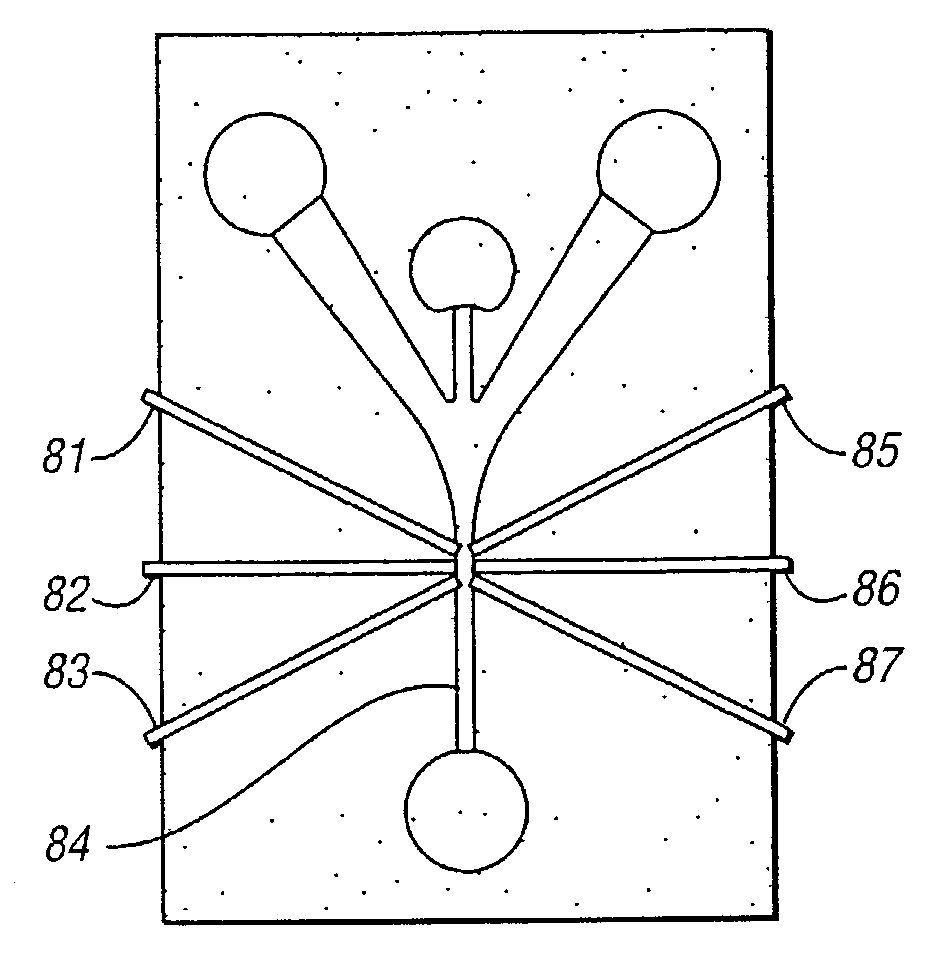

Flow cytometers and detection system of lesser size

InactiveUS20060177937A1Maximize signal to noise ratioIncrease the number ofWithdrawing sample devicesAnalysis by subjecting material to chemical reactionFiberPhotodetector

Gas focusing flow cytometers are fabricatable employing simple and inexpensive manufacturing techniques. When such cytometers or conventional cytometers are combined with fiber optical light paths and laser diode and semiconductor photodetectors, light weight and handheld, optionally disposable devices which maintain high performance are possible.

Owner:RGT UNIV OF MICHIGAN

Baking-free type refuse burning flyash haydite and manufacturing method thereof

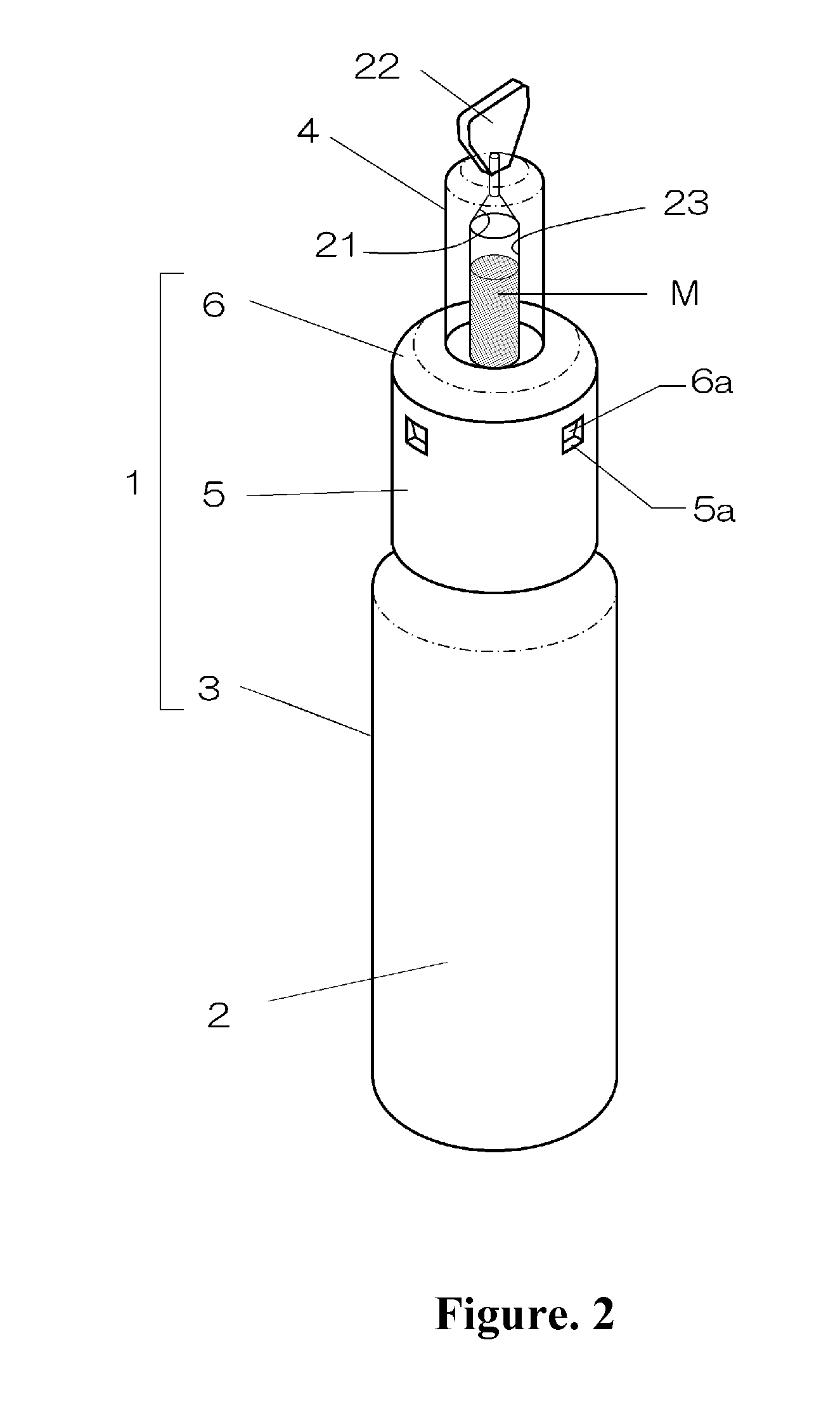

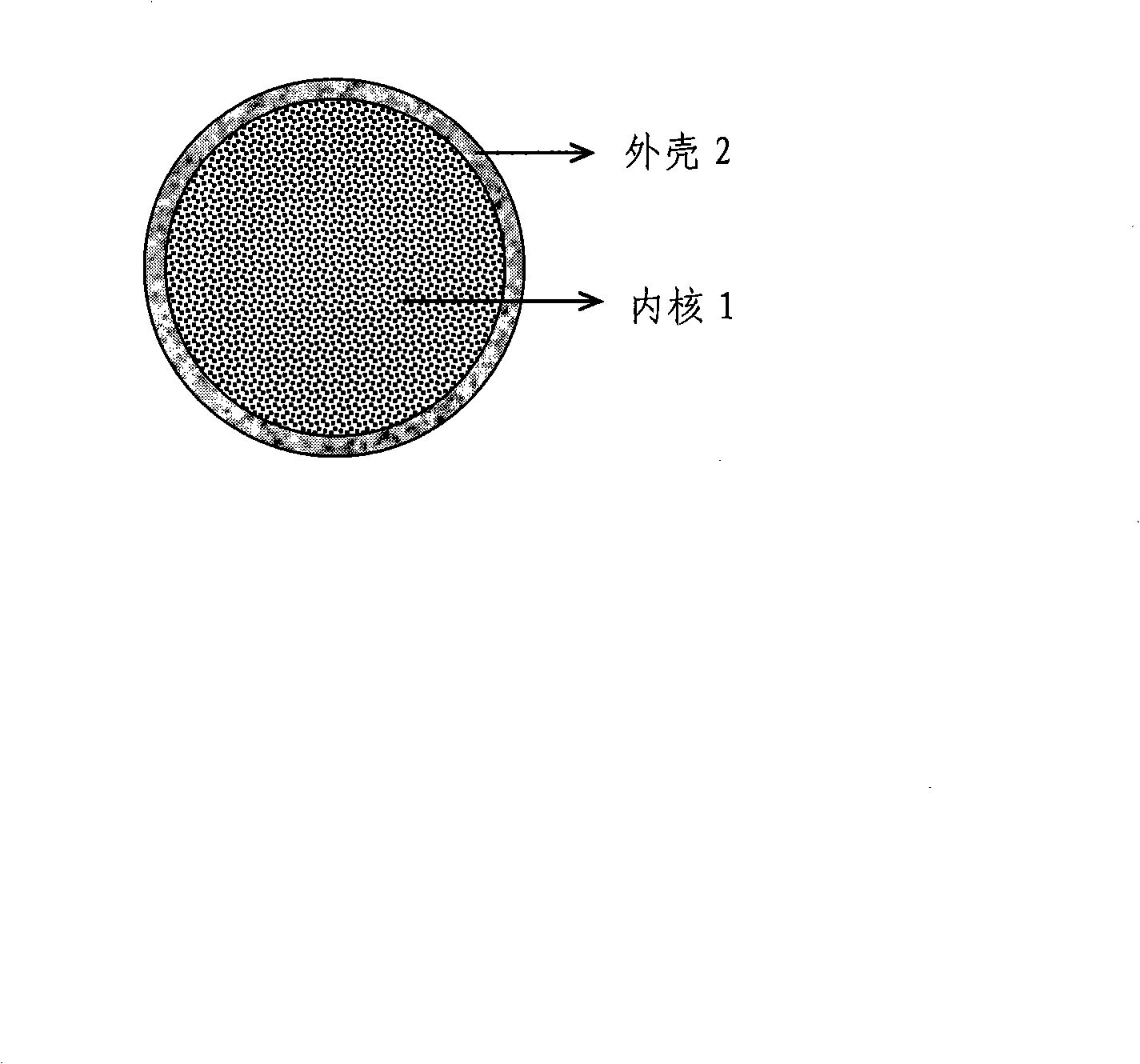

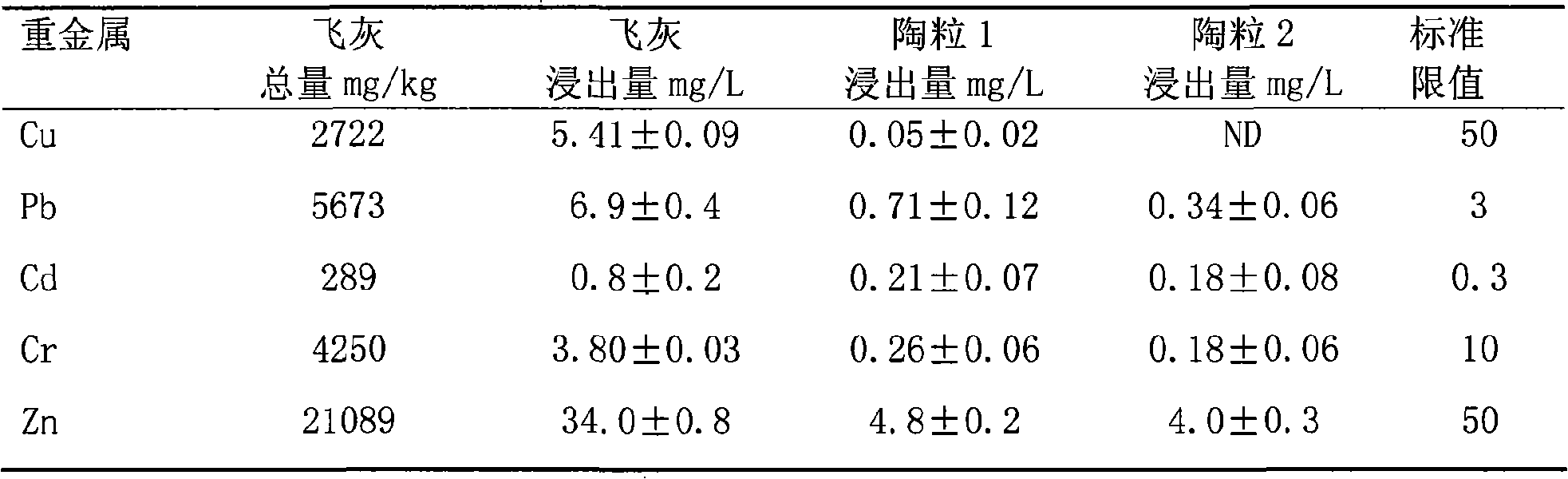

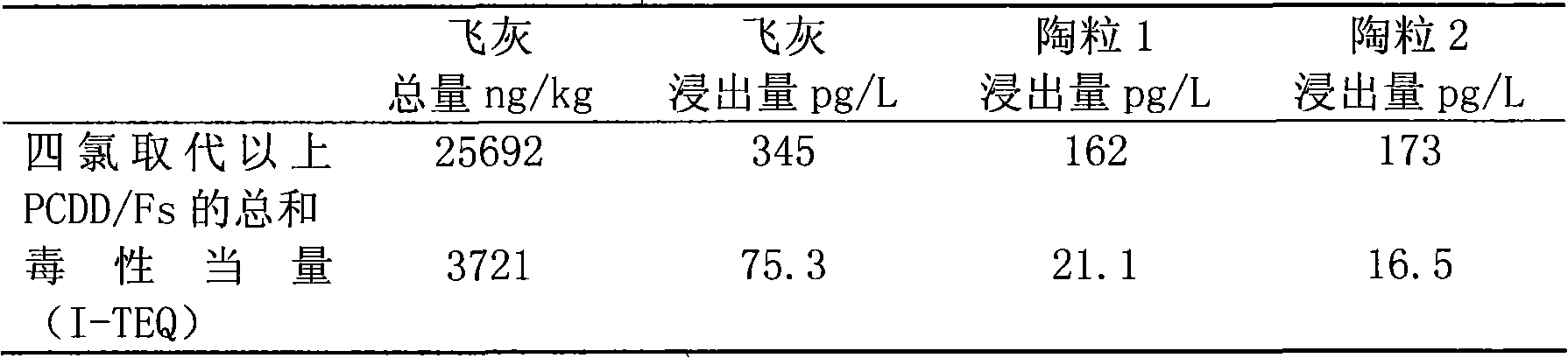

ActiveCN101357840ALow costNo need to worry about secondary pollutionSolid waste managementDry weightResource utilization

The invention provides a non-burned porcelain granule which adopts fly ash generated by waste incineration as the main raw material and a manufacturing method thereof; the non-burned porcelain granule comprises a spherical inner core 1 and a shell 2 attached outside; wherein, the components (dry weight) of the inner core 1 are as follows: 50 to 70 parts of fly ash generated by waste incineration, 25 to 50 parts of portland cement, 0 to 15 parts of coal ash and 0.2 to 0.5 part of heavy metal stabilized agent; the shell 2 adopts ordinary portland cement or lime. The method includes the following steps: firstly, the agent stabilization treatment is carried out on the fly ash generated by waste incineration; then the fly ash is mixed with the portland cement and coal ash to be granulated, thus manufacturing the inner core 1; finally, the inner core 1 is coated on the shell 2 in a pan granulator for natural curing. The method adopts the fly ash which is the dangerous waste as the raw material of the porcelain granule for resource utilization, realizes the harmlessness of the whole treatment process and has the advantages of economy, environmental protection and less investment of one-off equipment.

Owner:TIANJIN YIMING ENVIRONMENTAL TECH CO LTD

Method and apparatus for heating and applying warm antifog solution to endoscopes as well as a distal lens protector

InactiveUS20050234301A1Superior anti-fogging protectionAvoid condensationSurgeryEndoscopesElectricityEngineering

A sterile, self-contained, disposable apparatus used for heating and applying solution to the distal end of endoscopes as well as an endoscopic lens protector. The heating mechanism is chemical, electrical or a combination of both. Further the apparatus serves as a self sealing container for the storage and application of anti-fog solution. By placing the apparatus over the distal scope prior to surgery, the scope is protected from damage from other instruments or trays. At the same time the distal lens is submerged in the warm anti-fog solution and it is uniformly and completely coated. Heat is transferred to the instrument from the solution in one example to act as an important and additional measure to prevent fogging of the lens. By heating the solution and the instrument, the drastic temperature difference between the interior of the body (98.6) and the instrument is eliminated. This inhibits the condensation of moisture, which always occurs upon inserting the cool scope inside the warm body. The apparatus combines the use of an anti-fog solution as well, which helps prevent fogging during the procedure when smoke and heat is generated within the body during the procedure. Lastly, the apparatus is designed to be used as a holder of the scope while protecting it from impact with a shock absorbent outer shell prior to, during, and after the medical procedure. A new method for defogging endoscopes by which a sterile protective device is combined with a defogging mechanism and placed over the distal lens of endoscopes prior to the medical procedure, used intermittently during the procedure, then placed over the lens at the end of the procedure. The apparatus is not removed until scope reaches the cleaning facility. This apparatus is ideal for sterile operations where the instrument is used intermittently and repeatedly.

Owner:TYCO HEALTHCARE GRP LP

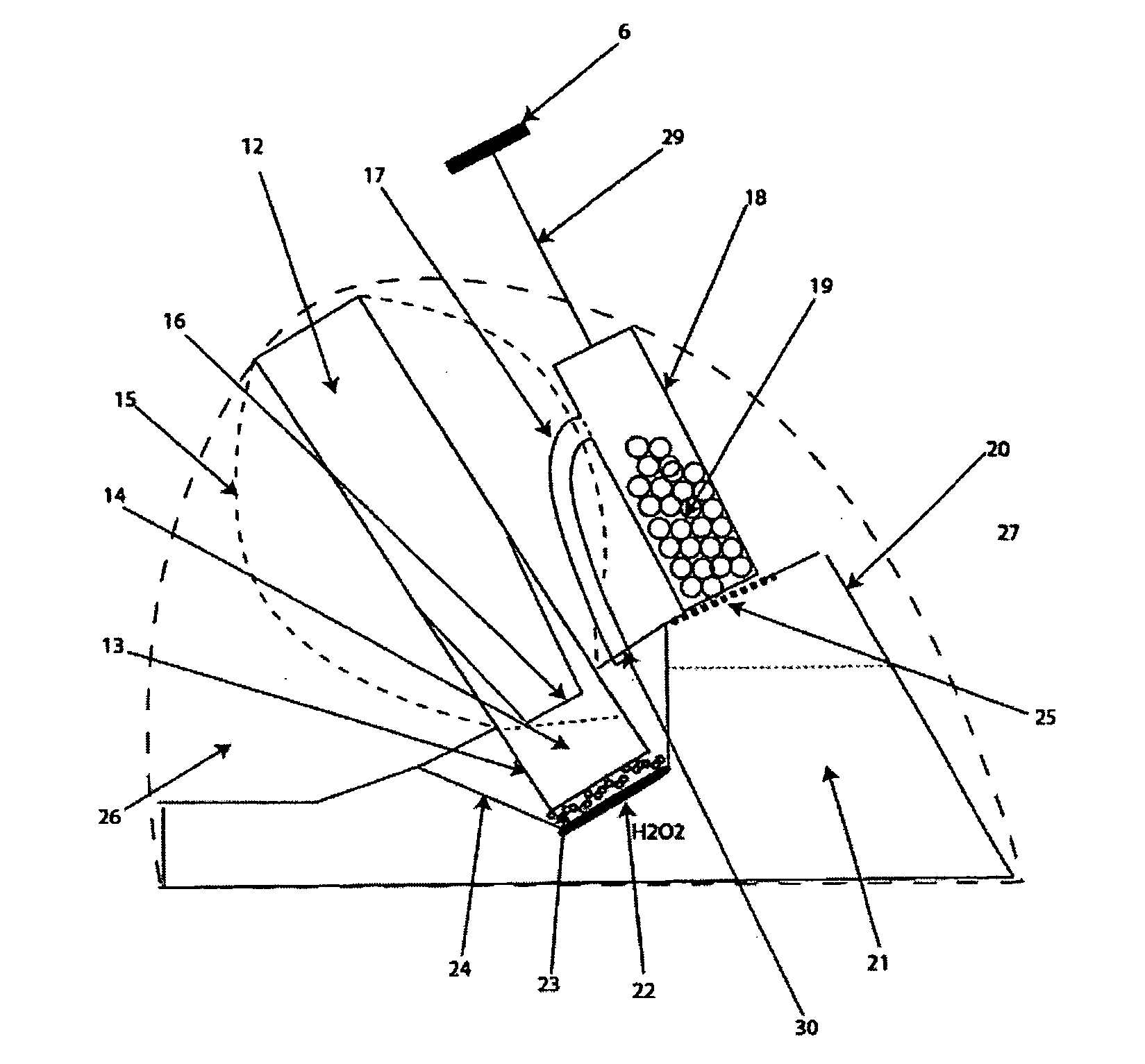

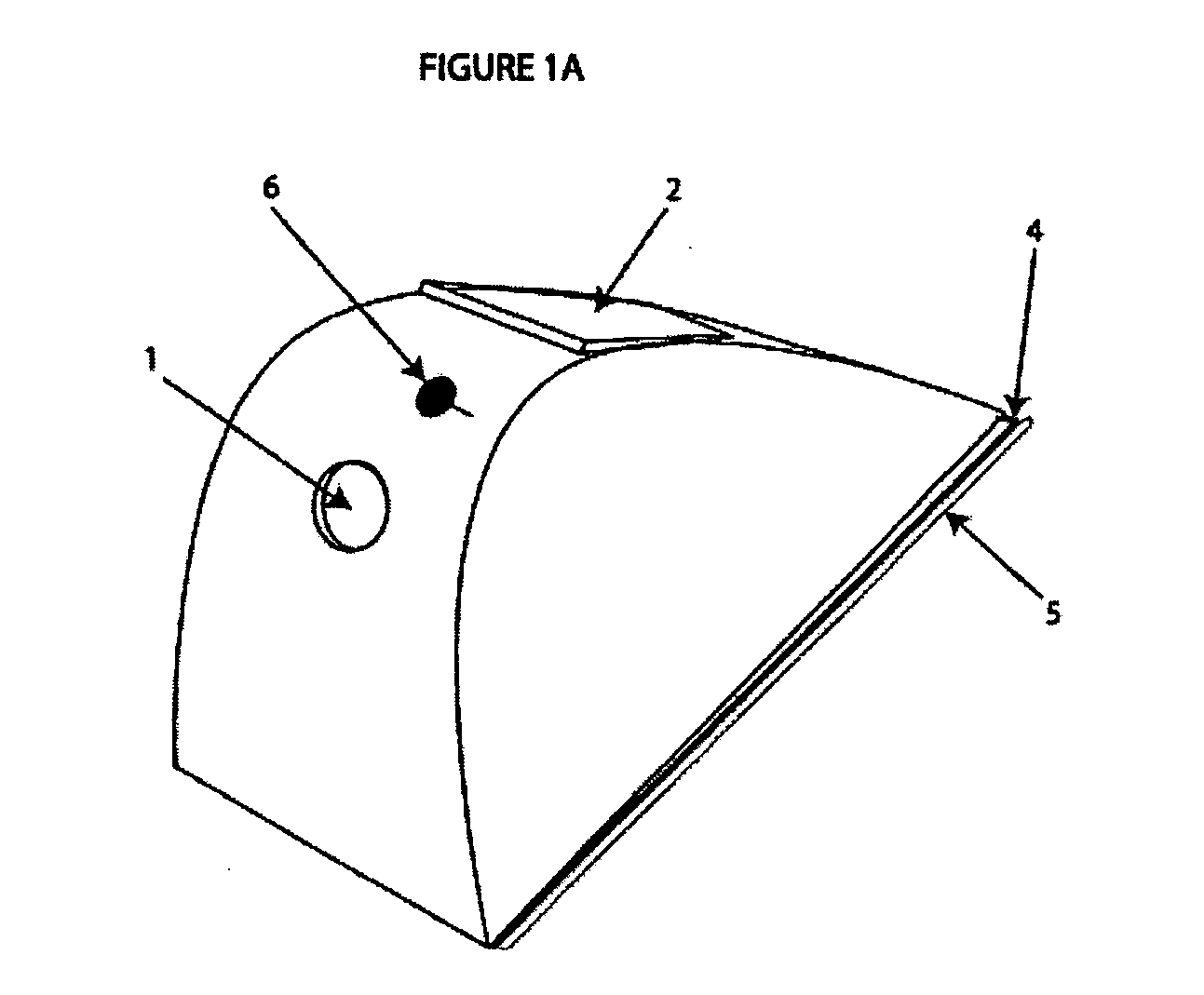

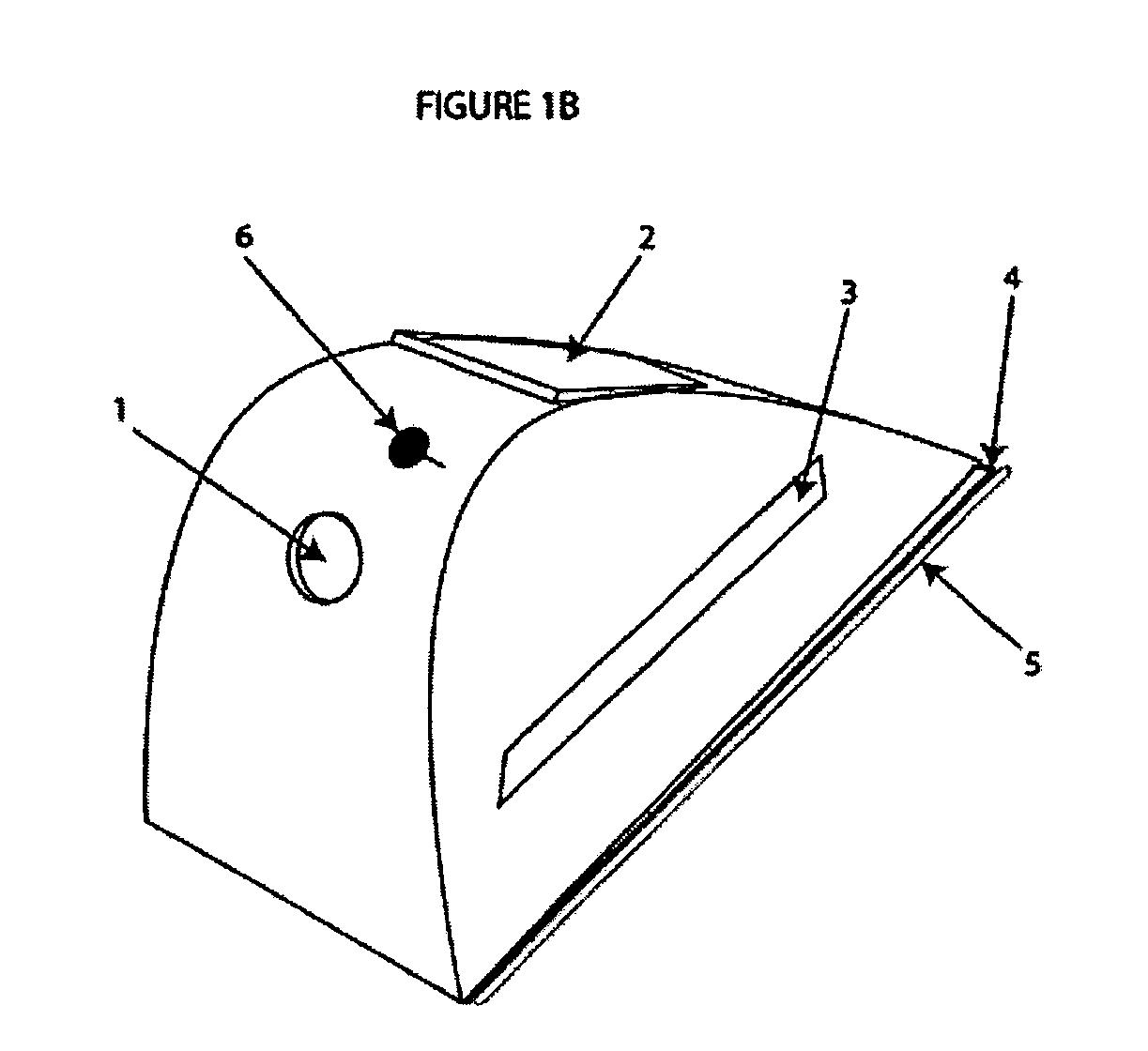

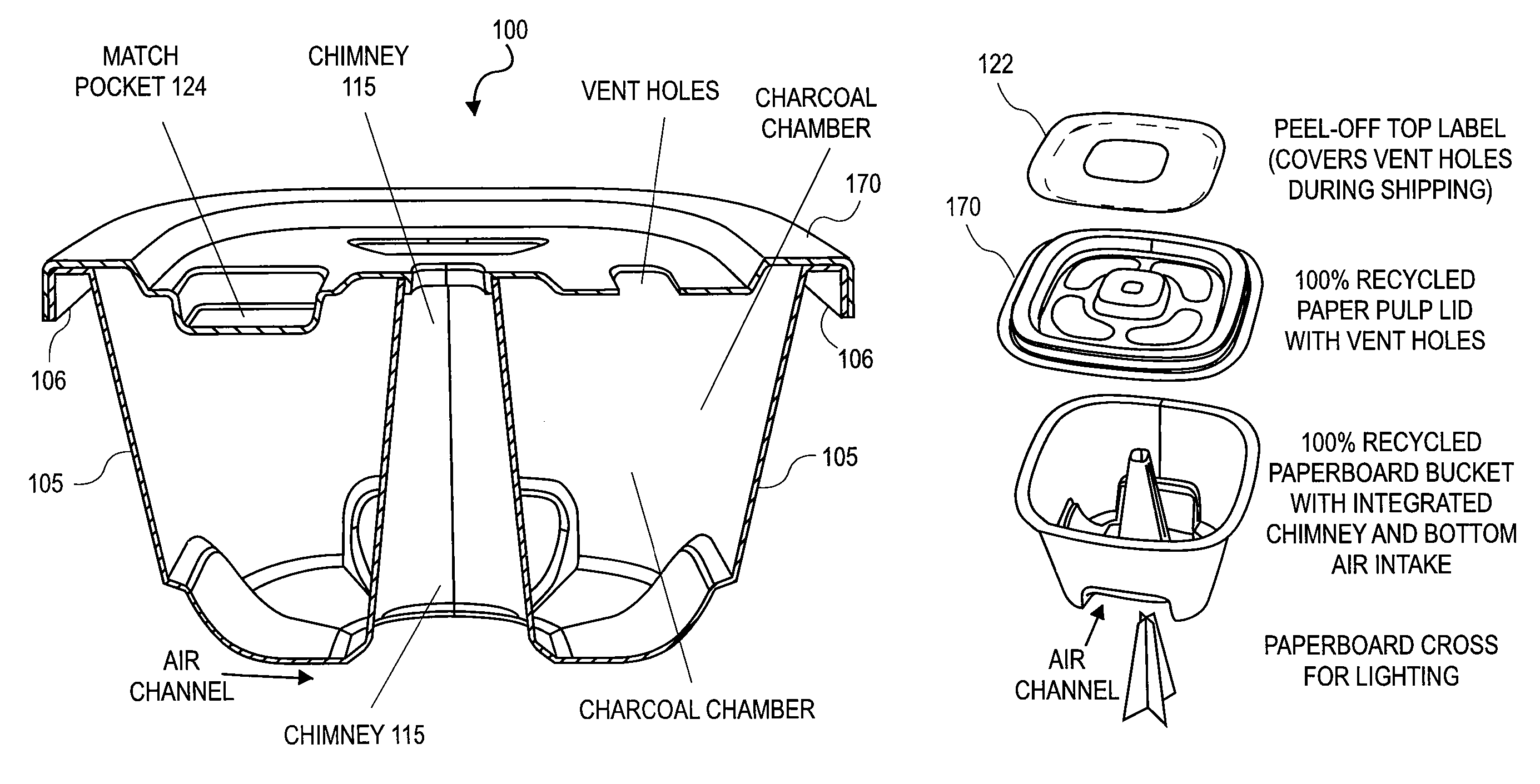

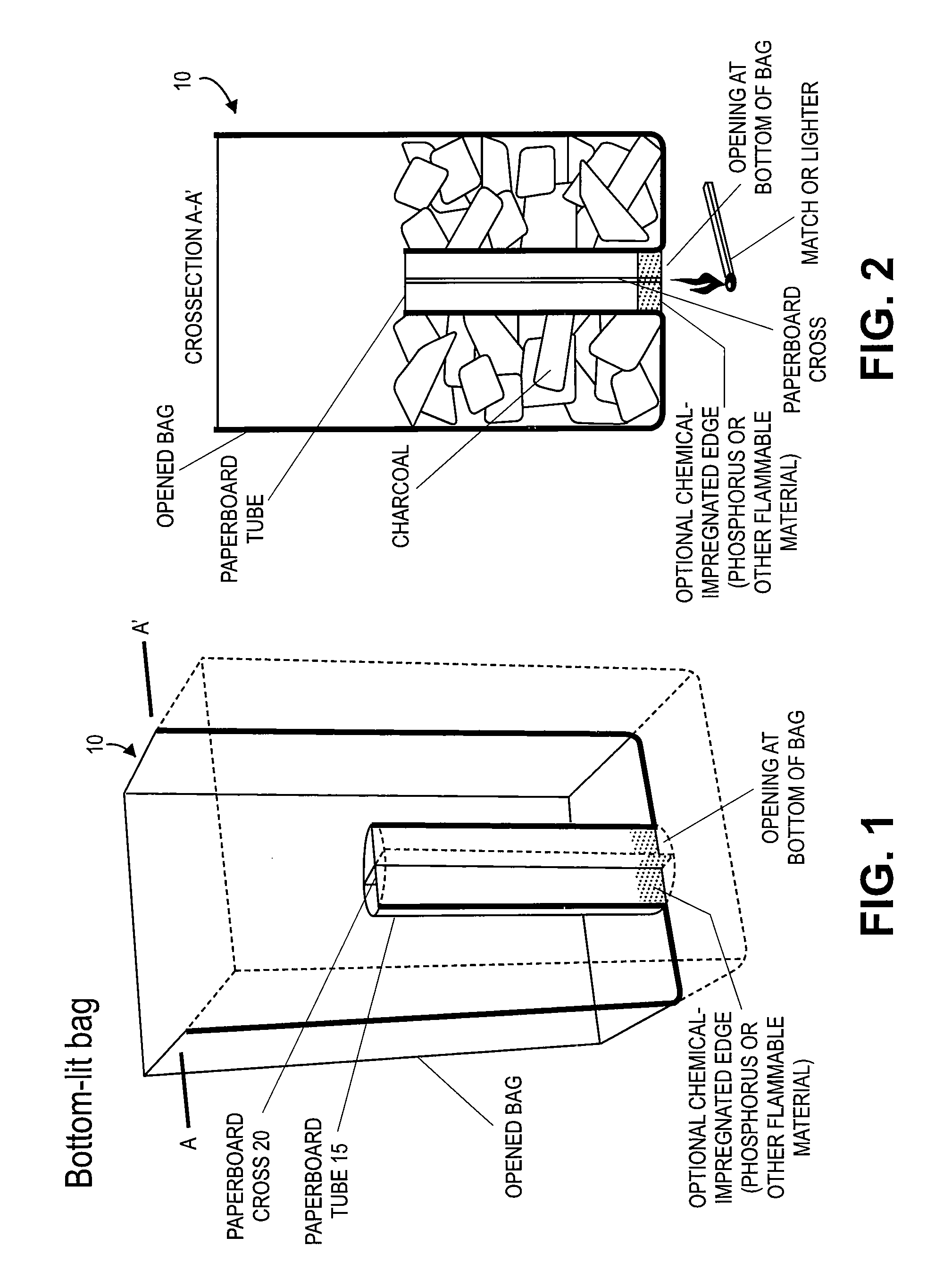

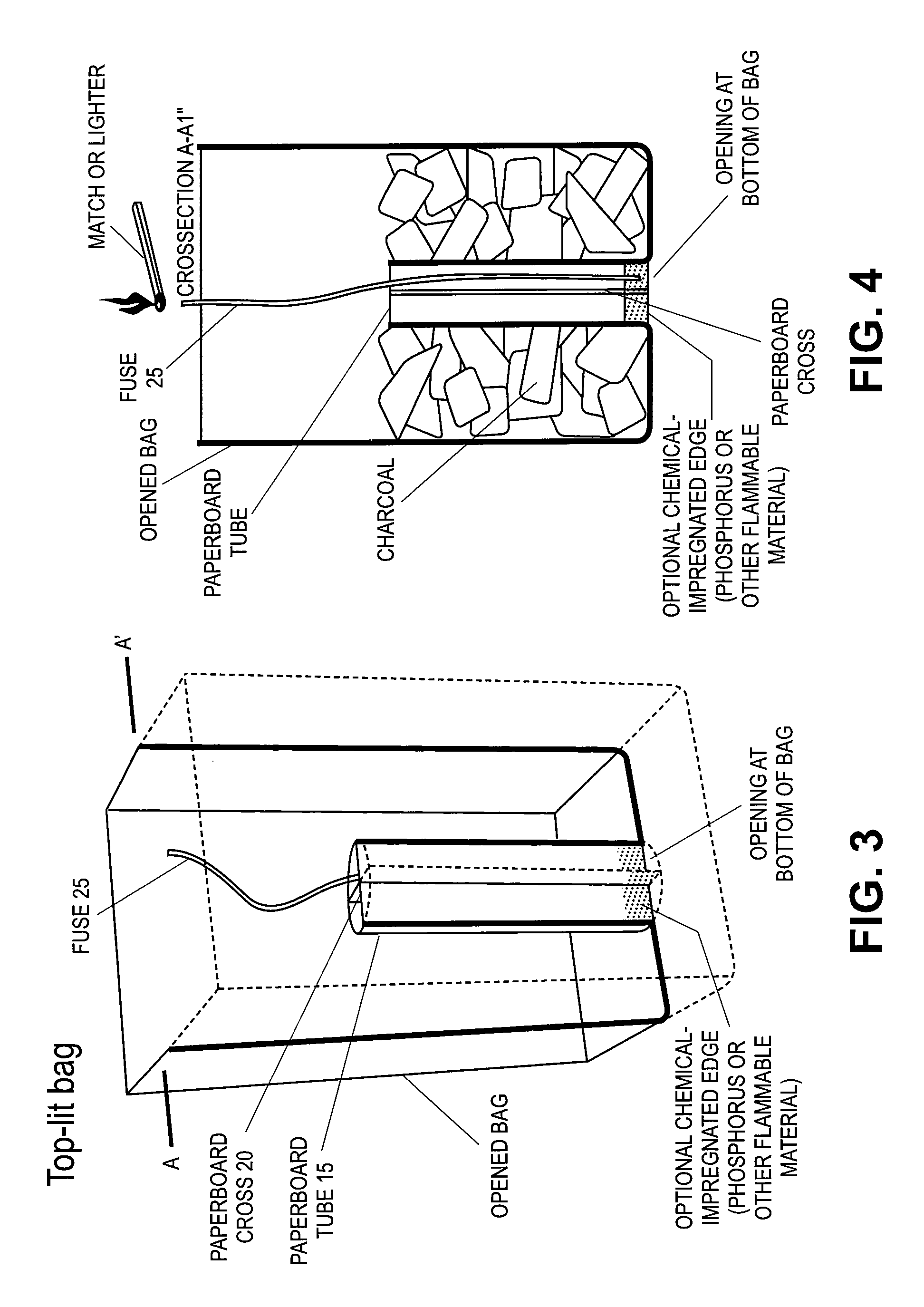

Disposable charcoal lighting apparatus

InactiveUS20080000467A1Increase surface area contactReduce airborn sparksDomestic stoves or rangesLighting and heating apparatusEffect lightPaperboard

A portable, disposable apparatus for lighting charcoal or other flammable material contained therein. A central compartment generally in the shape of a tube extends from a bottom portion of the apparatus up through the center of the main body of the apparatus. An ignition strip extends within the tube. The apparatus is made of paper or paperboard or other lightweight flammable, yet durable, material. The apparatus is used by lighting the bottom of the ignition strip, which thereby starts a fire within the central compartment. The fire in the tube then ignites the charcoal within the main body of the apparatus. As the charcoal burns, the apparatus eventually burns away, leaving the burning charcoal in a pile.

Owner:DESIGN ANNEX

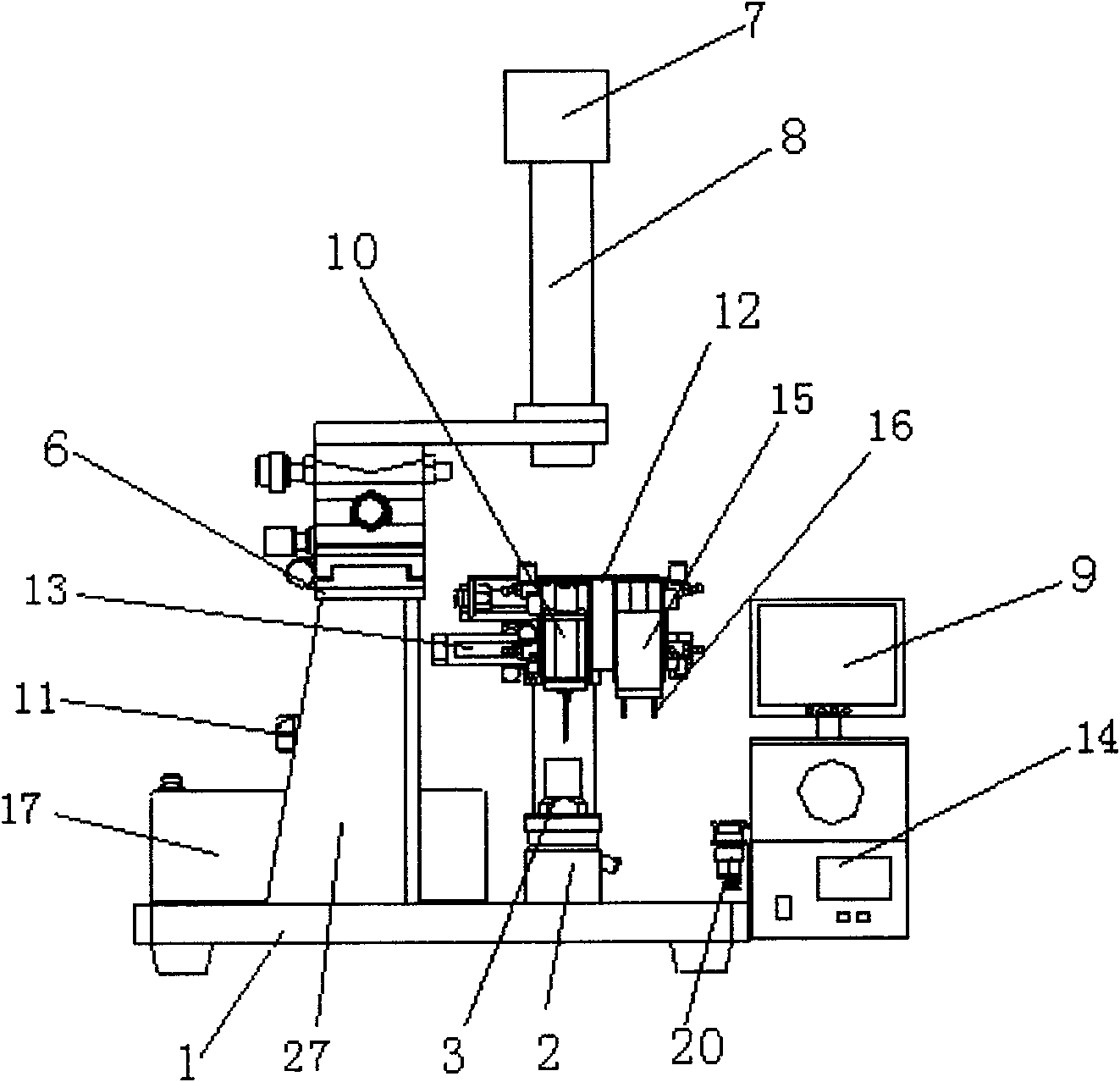

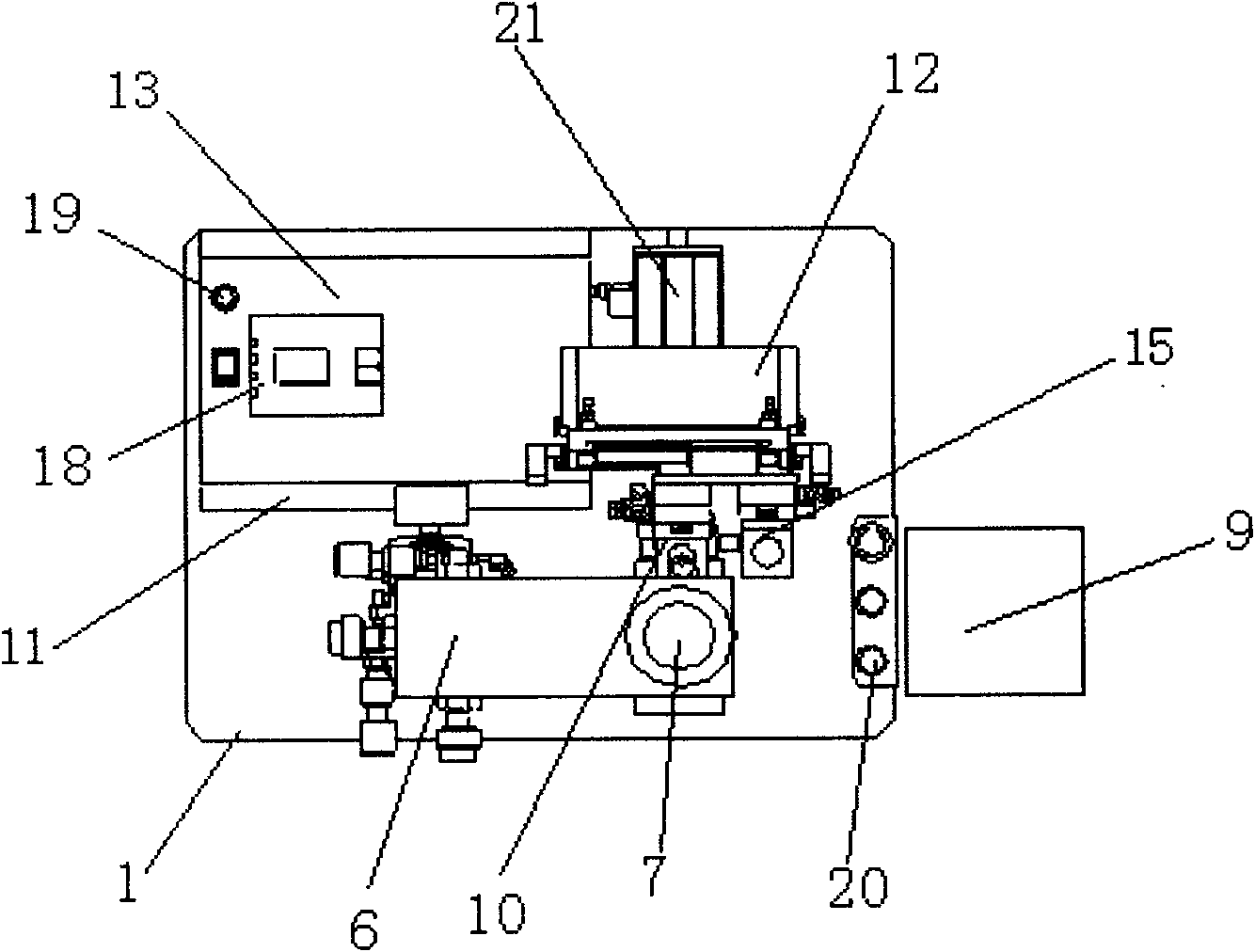

Automatic glue dispensing device for imaging lens

InactiveCN102145328AReduce the number of processesReduce cumbersome stepsPretreated surfacesCoatingsProduction rateControl system

The invention provides an automatic glue dispensing device for an imaging lens, and the automatic glue dispensing device is characterized by comprising a workpiece locating device, a workpiece detecting device, a glue dispensing device, a glue curing device and a control system which are all arranged on a working platform, wherein as the detecting equipments with various functions is arranged on the one working platform on which the workpiece locating device, the workpiece detecting device, the glue dispensing device, the glue curing device and the control system for the imaging lens are arranged, thereby reducing more and complex steps for the traditional lens assembling process, increasing the production efficiency and improving the quality of products. In addition, the automatic glue dispensing device for the imaging lens has the advantages of low disposable equipment cost investment, high degree of automation, simplicity and convenience for operation in production, labor cost reduction, production efficiency increment, reduction of interference from personal factors and improvement on product quality.

Owner:芜湖依维光电科技有限公司

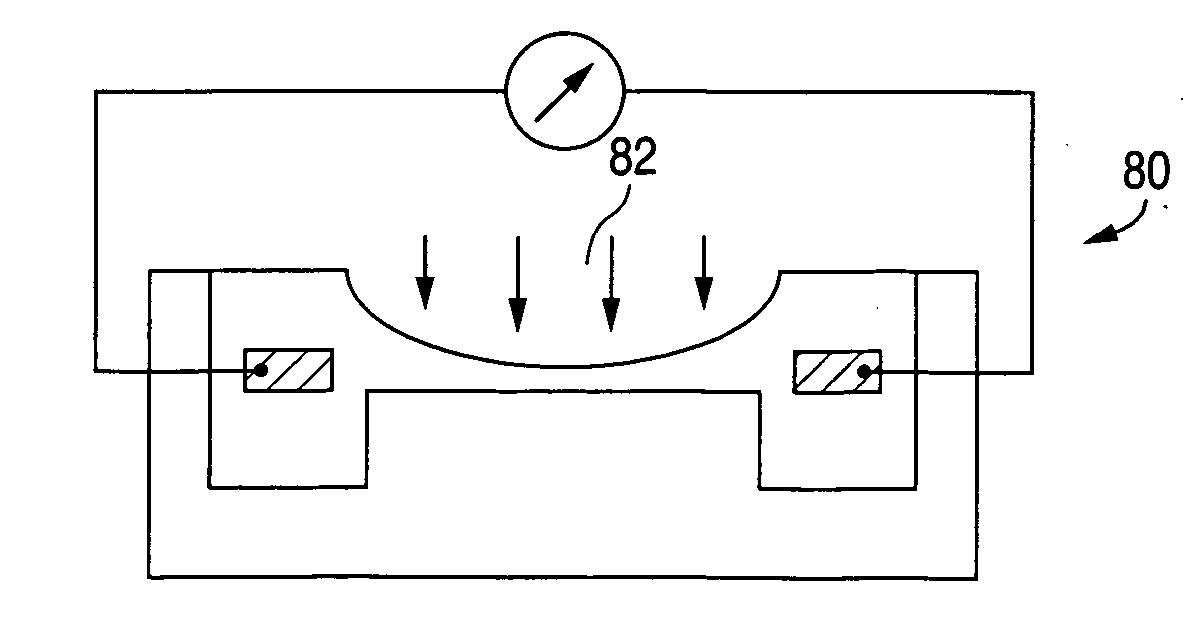

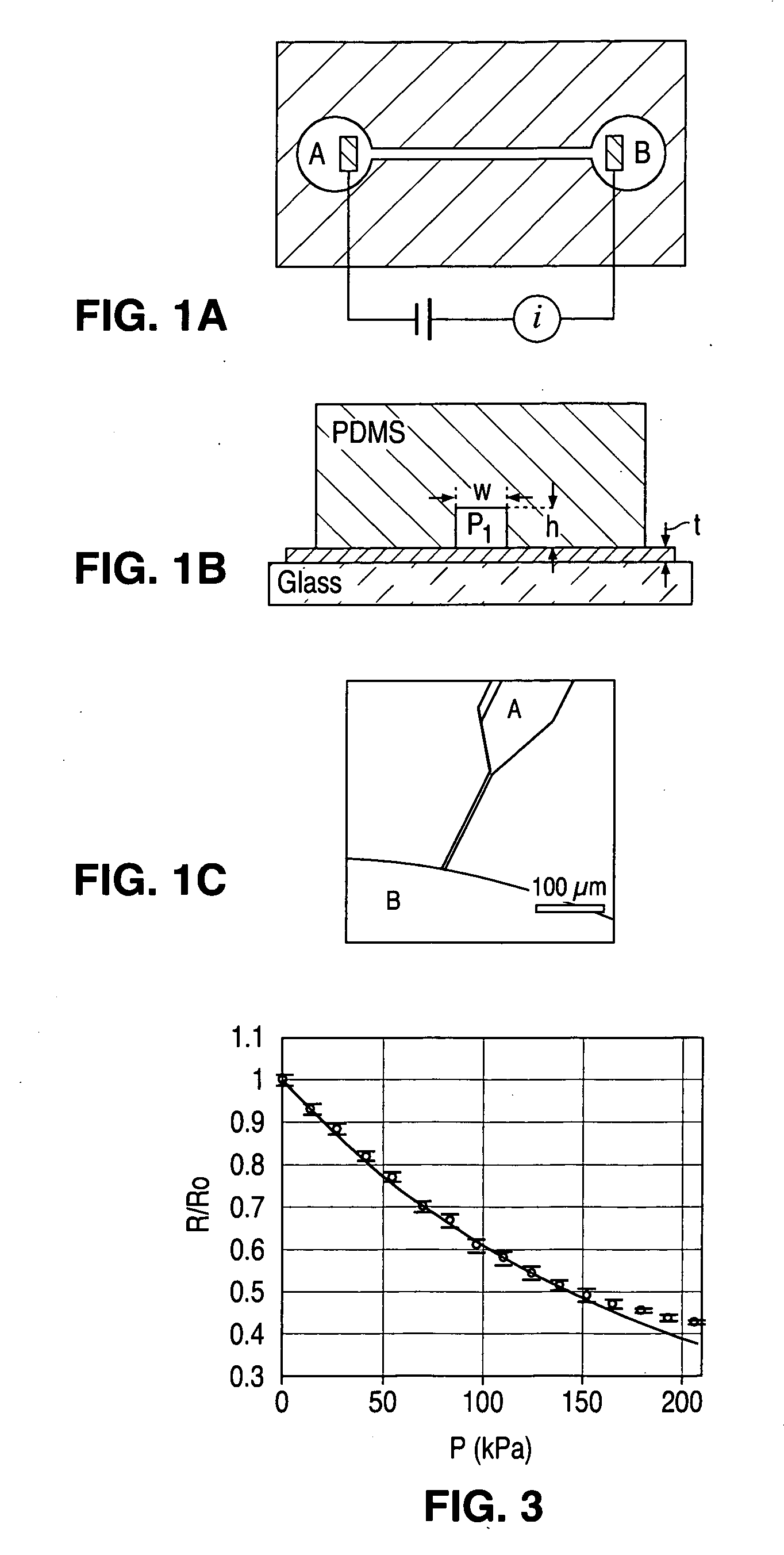

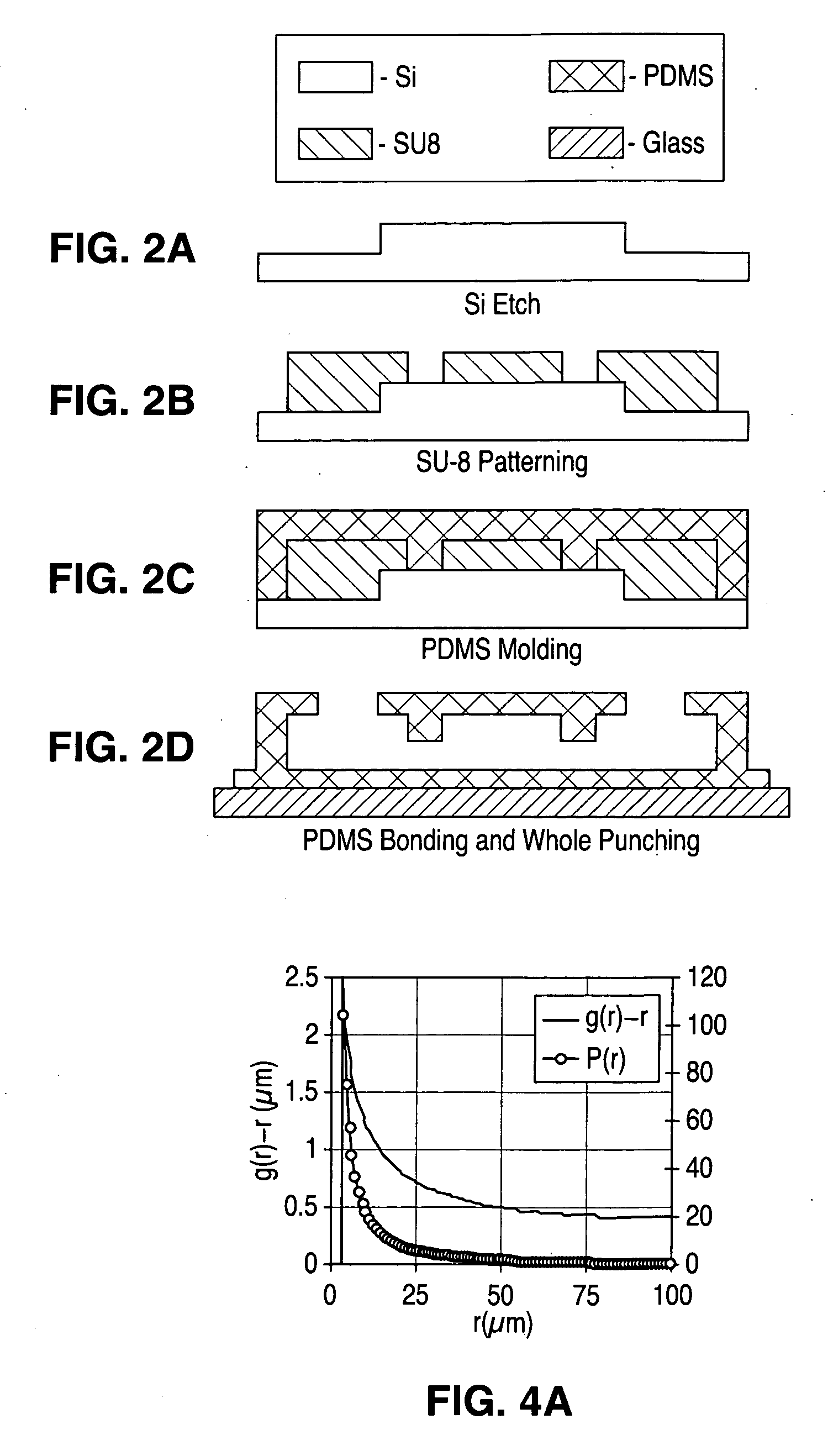

Apparatus and method for sensing pressure utilizing a deformable cavity

InactiveUS20070028683A1Easy to manufactureHigh sensitivityFluid pressure measurement by electric/magnetic elementsEvaluation of blood vesselsPressure senseDisposable Equipment

A pressure sensing device and method for sensing pressure utilizes a deformable cavity containing a conductive medium. Pressure changes induce deformations of the cavity, resulting in changes of conductivity, as measured by electrodes. The device may either sense pressure directly or may be used to sense the pressure in a separate cavity that is in close proximity. Since the measurements do not require electrodes in the sensing region, the device is simple to fabricate. The device also has high sensitivity, making it suitable for microfluidic or biomedical applications where a low profile and disposable device is required.

Owner:RGT UNIV OF CALIFORNIA

Intranasal granisetron and nasal applicator

Formulations and methods of manufacture are provided for granisetron dry powder compositions suitable for intranasal administration. Also provided are methods of use for preventing or controlling emesis and other diseases and disorders and devices, compositions, and methods for nasal delivery of therapeutic formulations. Devices for delivery of dry powder formulations are also provided. Devices can be single-use devices.

Owner:SHIN NIPPON BIOMEDICAL LAB

Resource utilization method of silicon wafer cutting and machining mortar at room temperature

The invention relates to a resource utilization method of silicon wafer cutting and machining mortar at room temperature. According to the technical scheme provided by the invention, the resource utilization method comprises the following steps of: 1. adding an interfacial modifier in the silicon wafer cutting and machining mortar and evenly mixing, wherein the amount of the interfacial modifier is 1-20 percent (weight ratio); 2. carrying out first-order or multi-order mechanical separation on the mixture in the step 1 through a mechanical separator to obtain a solid-phase material and a liquid-phase material; 3. carrying out alkaline-washing, acid-washing and cleaning on the solid-phase material in the step 2, and drying and grading the obtained wet material to obtain a high-purity silicon carbide product; 4. removing ions in the liquid-phase material in the step 2 through strong acid and strong base ion exchange resin, and controlling two key indexes of ion contents, conductivity, and the like; decoloring by using a decoloring agent, and separating by using the mechanical separator to obtain a recovered cutting fluid. From the step 1 to the step 4, except for the step 3 in whichthe drying temperature is necessary to improve according to drying working procedures in the drying process of the wet material, all other operation processes are respectively carried out at the roomtemperature. The method has low unit energy consumption and low one-time equipment investment, is used for industrial practice, and has the characteristics of simple and convenient implementation, distinct flow and stable components.

Owner:JIANGSU JIAYU RESOURCE UTILIZATION

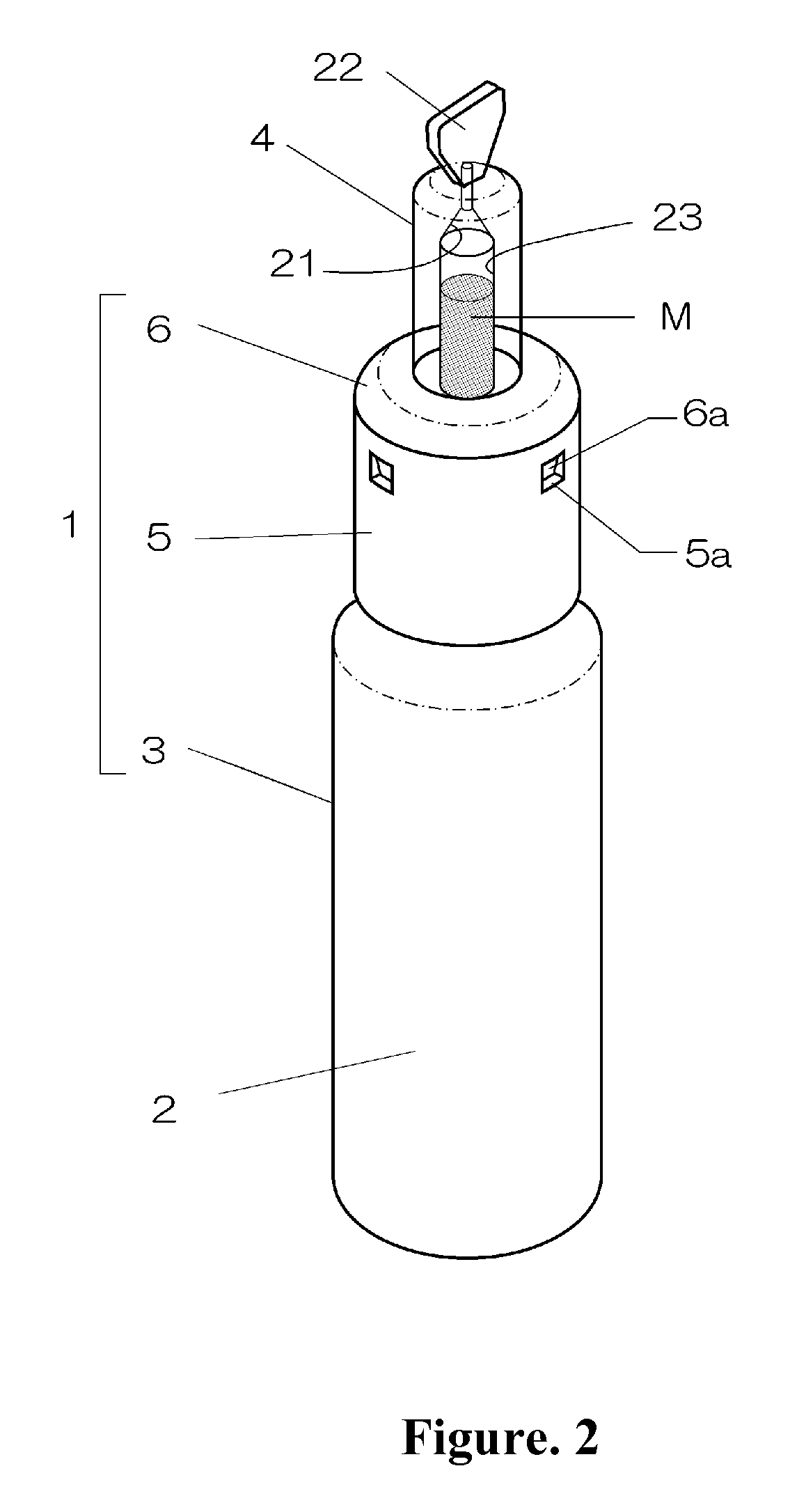

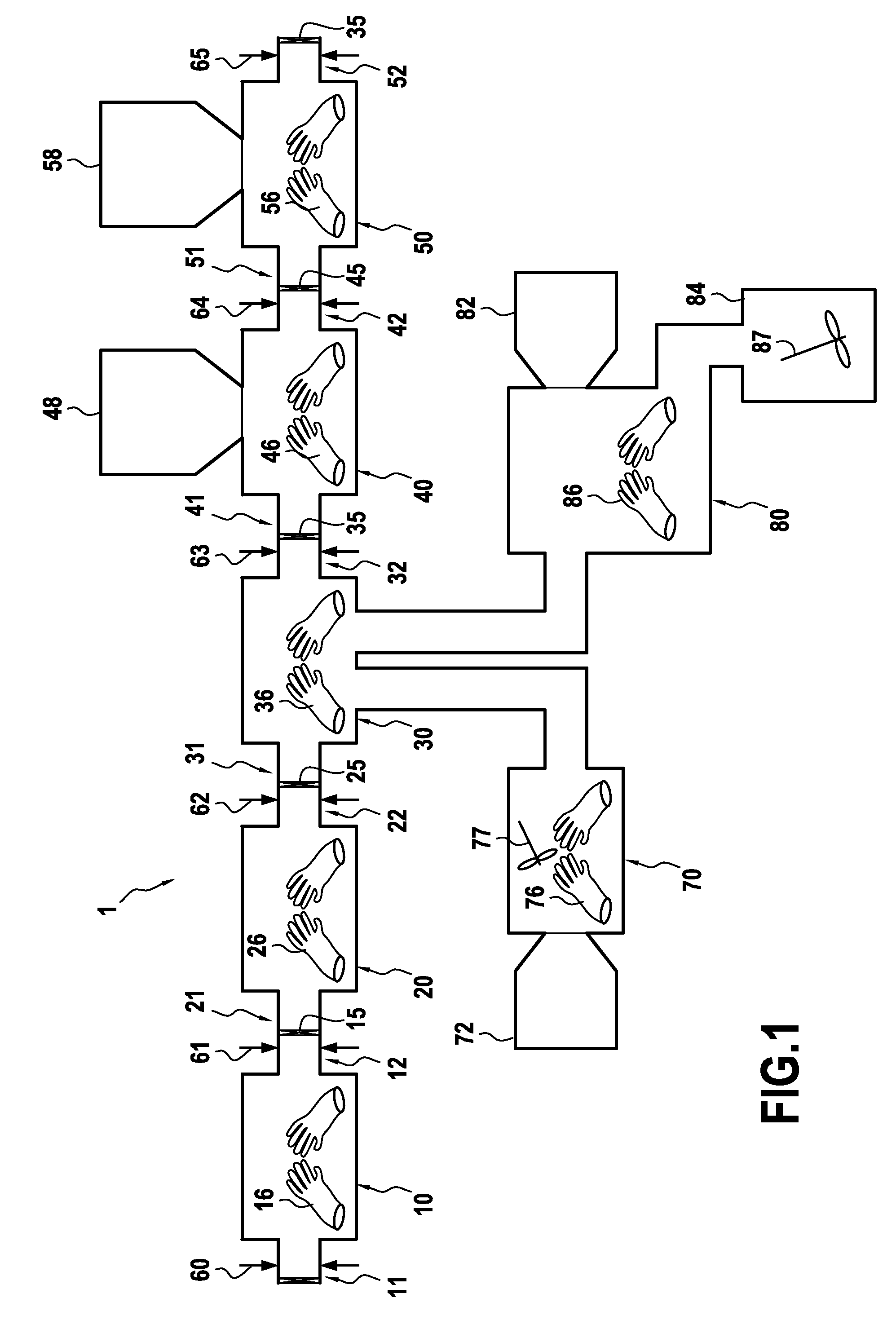

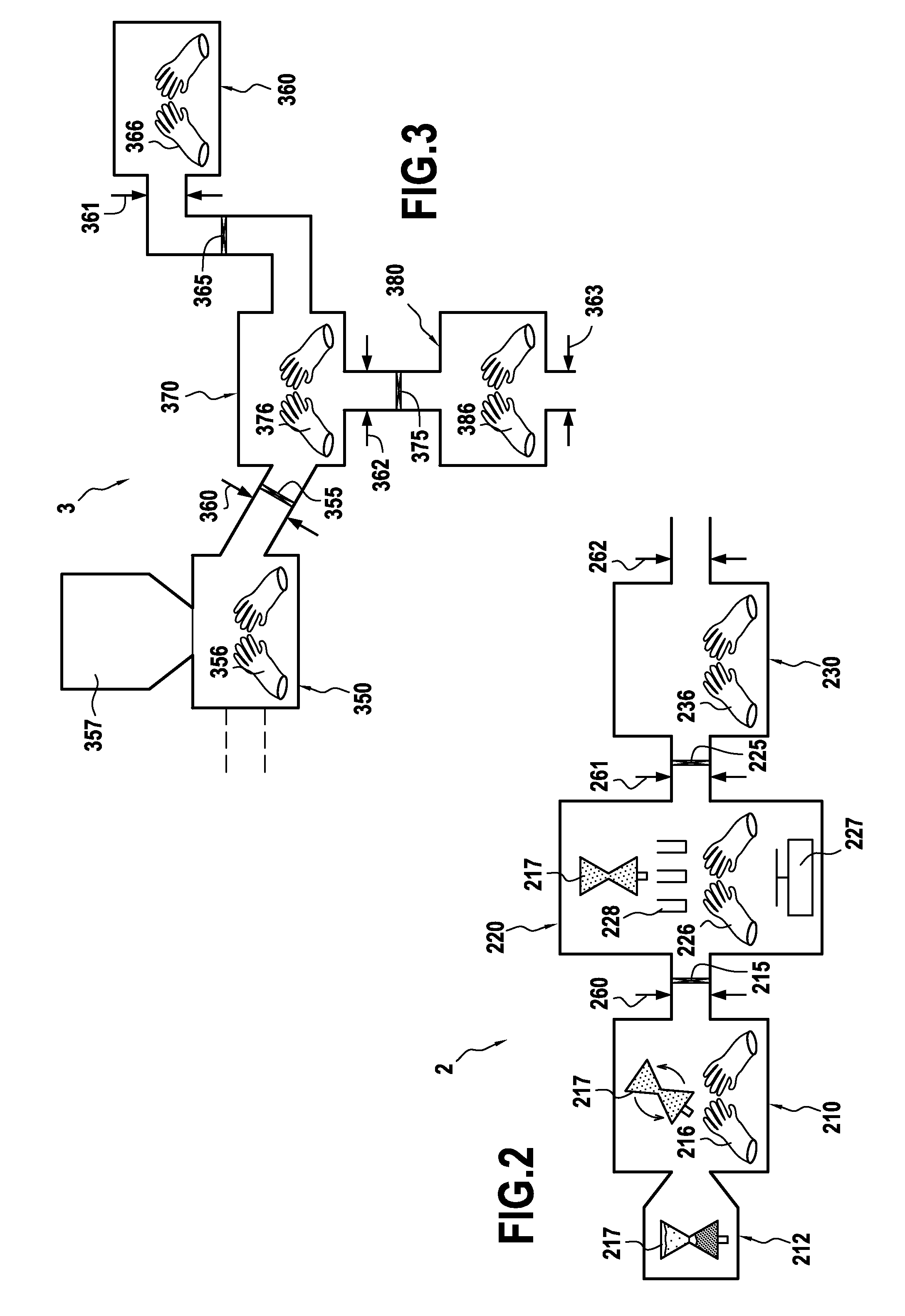

Disposable production line

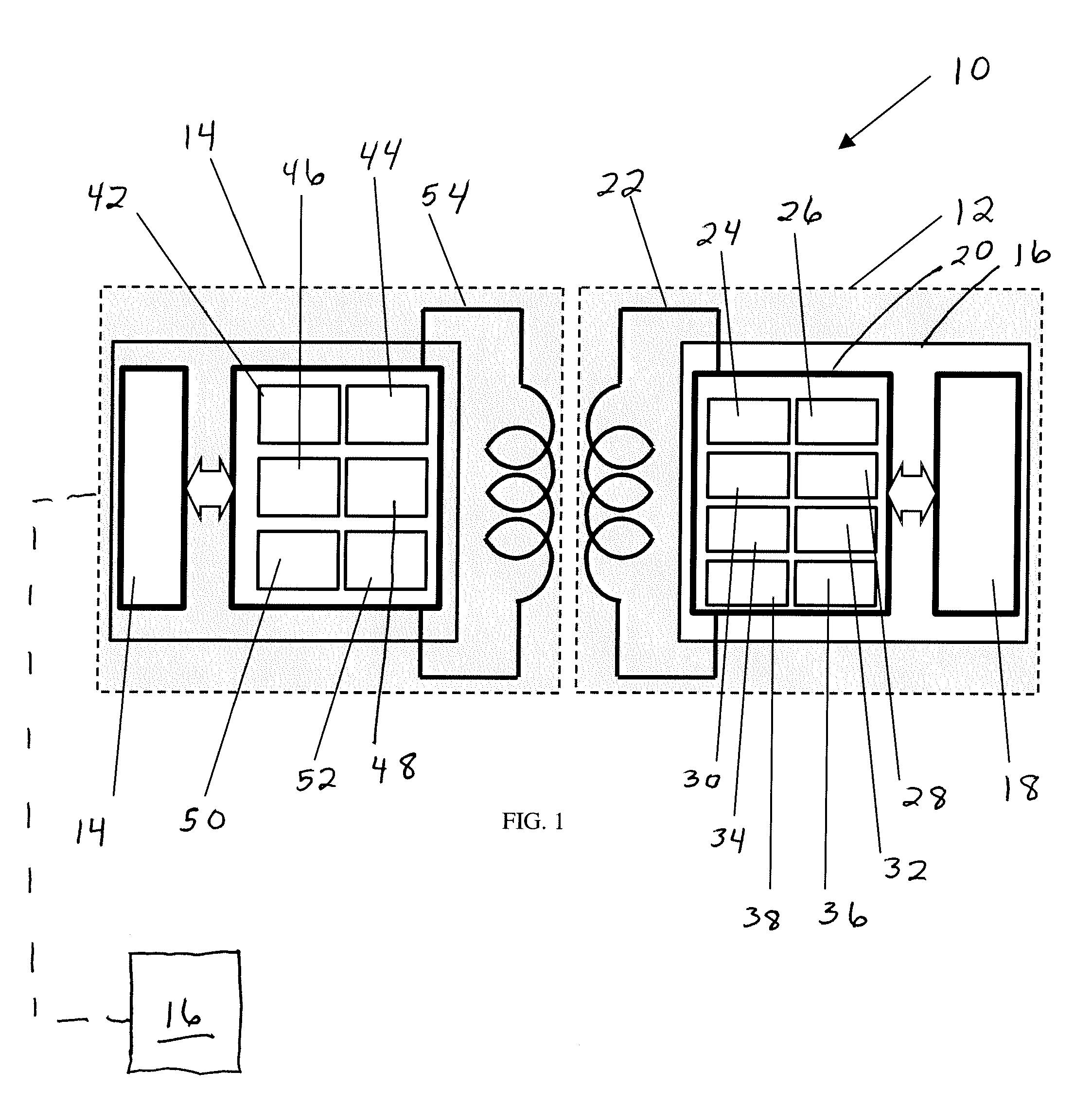

ActiveUS20120294697A1Minimum interruptionInert atmosphereApparatus sterilizationPackage sterilisationProduction lineDisposable Equipment

The invention relates to a disposable production line. The invention relates notably to a process for manipulating, manufacturing or packaging products or devices under inert atmosphere, and / or sterile conditions and / or pyrogen free environment.In particular the invention relates to a closed disposable equipment comprising at least two separate disposable isolators including a first disposable isolator and a last disposable isolator, wherein said separate disposable isolator is connected to at least one other separate disposable isolator by at least one connecting means, wherein each separate disposable isolator comprises a working place, said working place being located inside said separate disposable isolator, said working place being under inert atmosphere, and / or disinfected, and / or sterile and / or pyrogen free conditions, said working place enabling the manipulation of containers, products or devices, wherein said closed disposable equipment comprises at least one inlet for introducing containers, products or devices into said closed disposable equipment and at least one outlet for discharging said containers, products or devices from said closed disposable equipment.

Owner:PALL LIFE SCI BELGIUM

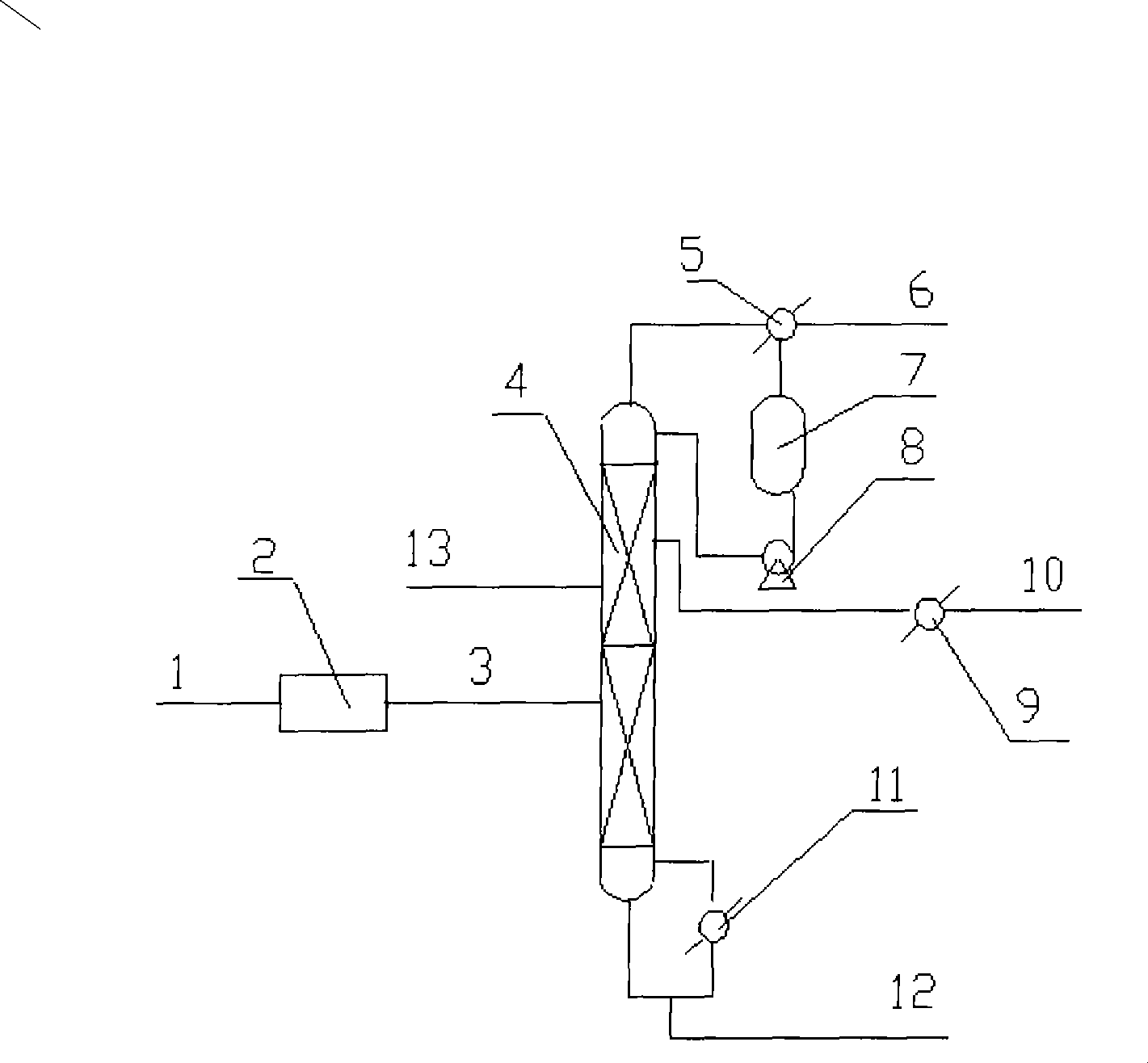

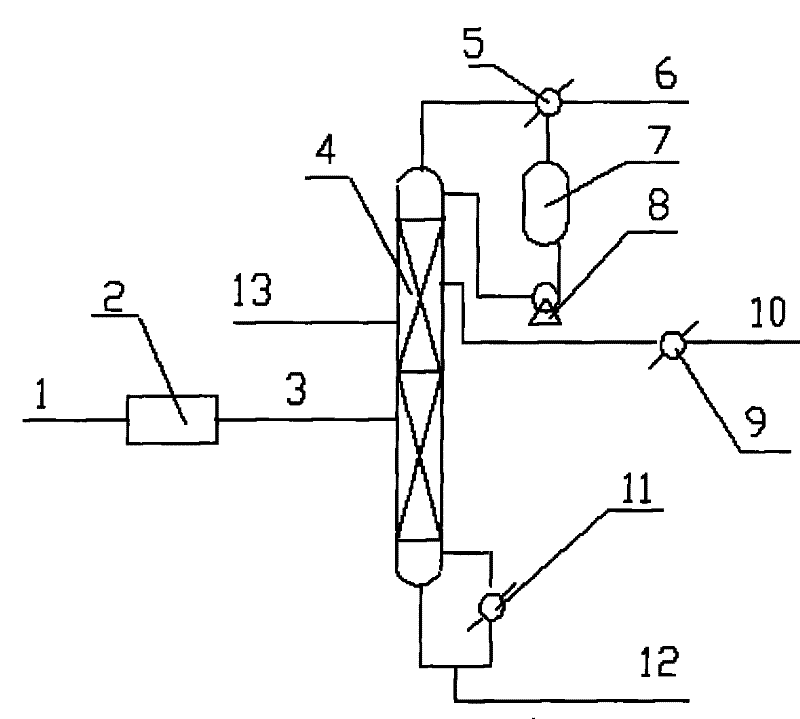

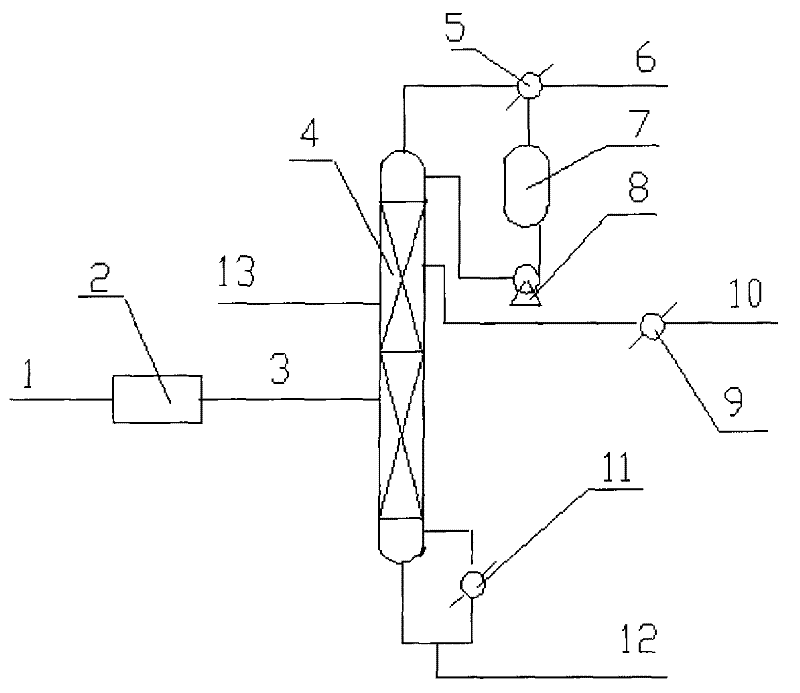

Methyl chloride recovery and refining method

ActiveCN101417923AReduce dosageMitigate the impact of stable operationGroup 4/14 element organic compoundsHalogenated hydrocarbon separation/purificationFluidized bedGas phase

The invention relates to a recycling and refining method of chloromethane. After being condensed by a chloromethane compressor, the coarse chloromethane gas from a washing tower end cooler enters into a chloromethane tower for refining in gas phrase state from an inlet under a return flow inlet of a coarse monomeric tower; the recycled chloromethane gas obtained from the upper lateral line of the chloromethane tower is directly led into a chloromethane superheater, is heated and then flows into a fluidized bed to carry out fluidized reaction. The invention improves the charging and discharging technical process of the present chloromethane refining tower and simplifies the unnecessary processes, which greatly reduces the investment to disposable equipment and the energy consumption in the production process, thereby reaching the purpose of saving equipment and energy.

Owner:SHANDONG DONGYUE ORGANIC SILICON MATERIAL +1

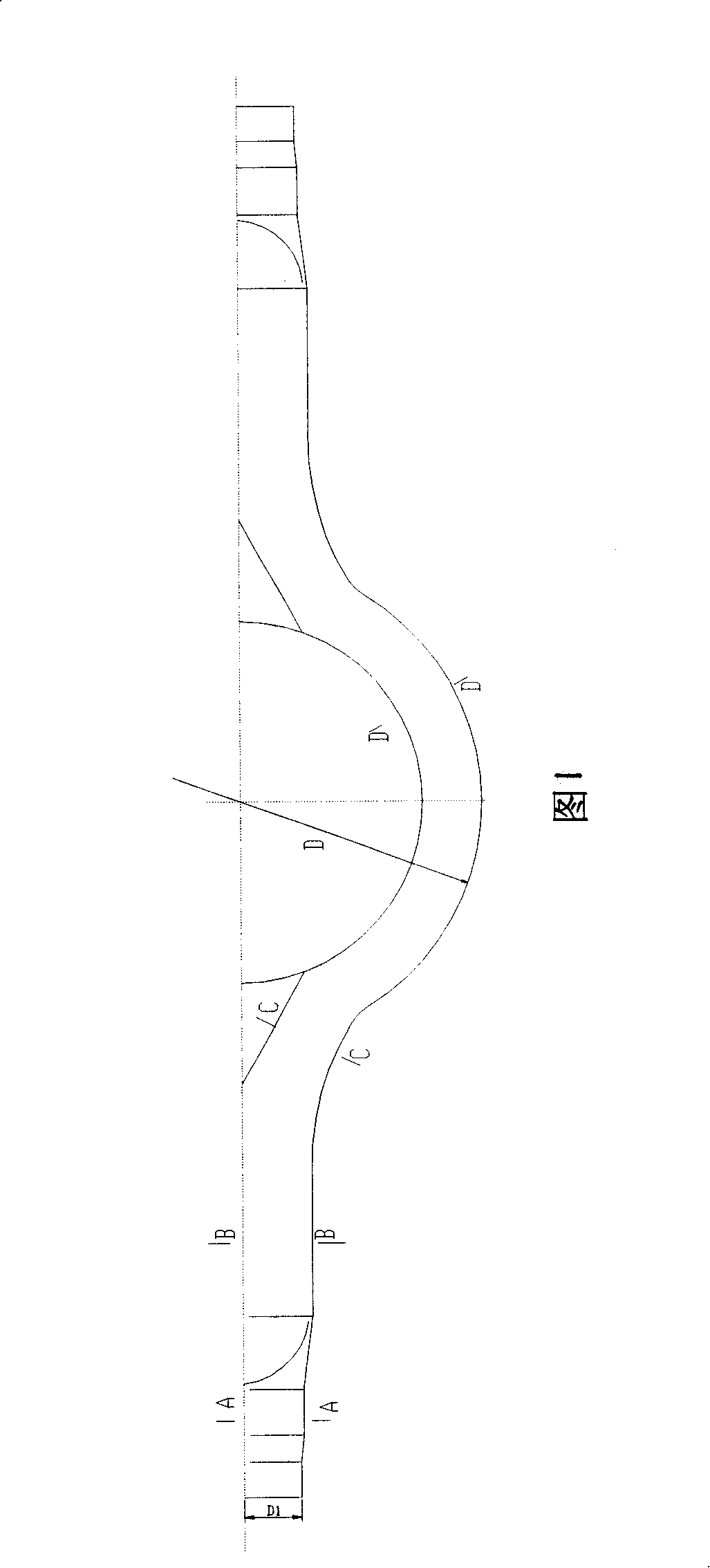

Manufacturing method of car axle case

InactiveCN101204776AHigh strengthLittle thinningOther manufacturing equipments/toolsEngineeringDisposable Equipment

The invention relates to a manufacturing method for automotive axle housing, which belongs to the manufacturing method for a steel automotive axle housing. The method comprises the following steps specifically: firstly utilizing a round steel tube to carry through diameter reducing at two ends and then utilizing a forcing press to carry through shape pressing on partial areas in the middle of a roughcast; opening a long slot passing from front to back in the middle of a tube roughcast; then carrying out extrusion in the middle of the tube roughcast to expand the middle of the tube roughcast to be jointed with the shape of a die; finally carrying out shaping on the axle housing to reach the roughcast dimension of an axle housing part. The roughcast is processed partially and welded with a set square to form a complete axle housing part. The method has the advantages of few working procedures, low cost, small attenuation degree in the middle area of the axle housing, high axle housing intensity, few disposable investments on device, high manufacturing efficiency, being suitable for batch manufacturing, simple technique of axle housing manufacturing, low reform cost and the die can realize standardization.

Owner:CHINA FIRST AUTOMOBILE

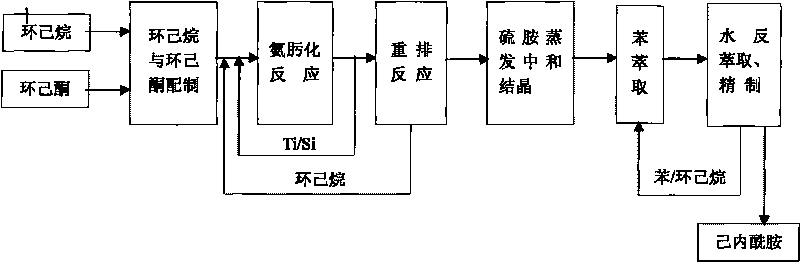

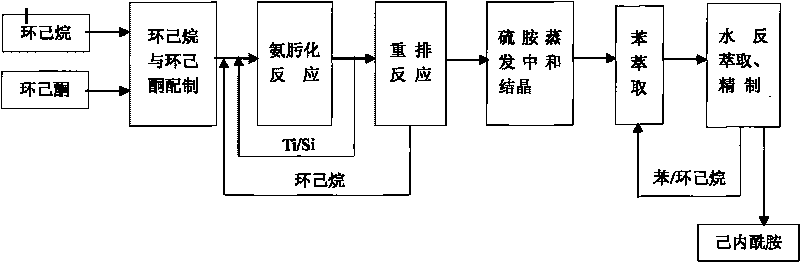

Process for preparing caprolactam

The invention discloses a process for preparing caprolactam, which comprises the following steps: after mixing cyclohexanone and cyclohexane evenly, carrying out an oxamidine reaction to obtain a cyclohexane solution of cyclohexanone oxime; enabling the cyclohexane solution of the cyclohexanone oxime and oleum to react to generate a caprolactam sulfate solution, curing the caprolactam sulfate solution, then carrying out a neutralization reaction on the cured caprolactam sulfate solution and ammonia, afterwards separating the two materials to obtain a crude product of caprolactam and then carrying out extraction and water back extraction respectively to prepare a finished product. Because of the existence of a cyclohexane inert solvent, rectification and separation do not need to be carried out after the oxamidine reaction, and only a rearrangement reaction needs to be carried out after the water phase of a catalyst is separated, thereby saving a rectification device and the steam consumption; as a result, a caprolactam enterprise with an annual yield of a hundred thousand tons can save energy worth approximately 60000000 yuan every year and can also save the one-off equipment investment totaling 60000000 yuan, the technological process of caprolactam is simplified, the procedures of water washing, extraction, distillation and the like are reduced, the production period is shortened, and the annual yield is enhanced.

Owner:河北美邦工程科技股份有限公司

Natural-energy seawater automatic distilling apparatus

InactiveCN101224913AImprove eco-efficiencySave energyGeneral water supply conservationSeawater treatmentGibbs free energyEngineering

The invention discloses an automatic seawater distilling device, which utilizes natural energy and is characterized in that the natural energy like atmospheric pressure, earth gravity, molecule Gibbs free energy and solar energy and so on is utilized as power, a reverse U-shaped tubular structure with certain height combines two open desalting system and salt-collecting system to form an automatic seawater distilling system at normal temperature and negative pressure and realize the automatic production of fresh water (distilled water) and salt. The invention has the advantages that: 1. the natural energy is utilized as the power to produce fresh water and salt, which does not discharge any pollutant, thus saving fuel energy and protecting environment; 2. ductwork is highly automatic and needs no manual operation, which is safe for production and can improve labor efficiency. In a word, no energy, raw material and labor investment is needed, only equipment investment at a first time is needed, and then profit can be obtained for a long time. The invention is also applied for a bitter water region or be installed on different large ships to produce fresh water by utilizing the afterheat of the power and the water in rivers, lakes and seas on the way; also the invention can be installed on a residential building to produce drinking water with tap water, which has good ecological effect, economic benefit and social benefit and wide market.

Owner:徐祯祥

An industrial semi-automatic raise seedling method for west cymbidium

The invention provides a factory half-automatic seed raising method of the broccoli, includes the following procedures: First, disk and loading stroma. The stroma adopts the even mixture of the turf and the perlite; cutting away the seeding cave from the stroma, and compacting the stroma in the cave disk by a press board; seeding by an air suction fine seeder. Second, earthing up, the stroma used in the earthing can also be the even mixture of the turf and the perlite. Third, watering after earthing up to ensure the water containing amount of the stroma to be kept in about 80-90 percent, and ensure the temperature during the time of emergence to be kept in 24-30 Deg C until the seeds come out. The invention has the advantages that the labor needed is relatively less, the air suction fine seeder is adopted, and the seed consumption is reduced greatly. The once-and-for-all equipment investment is less, the carriage is convenient, the device is portable, and special storehouse is not needed for storage; the seedlings are relatively even; and the whole seed raising method is simple with strong practicability.

Owner:慈溪市蔬菜开发有限公司

Color sensor with gas generating layer

PendingUS20180104017A1Self containedInhibition of activationMaterial analysis by observing effect on chemical indicatorDiagnosticsInterface layerColor changes

According to embodiments of the present application, a color change sensor comprises a color change indicator and a substrate comprising a gas disposed on the color change indicator. The sensor may further comprise an interface layer that assists in containing the gas within the substrate. The sensor may be used with limited use, restricted use, or disposable apparatuses. The user may actuate the sensor by disrupting or removing the gas-containing substrate and / or the interface layer. Methods of making and using the color change sensor and related apparatuses are also disclosed.

Owner:THERMOGRAPHIC MEASUREMENTS

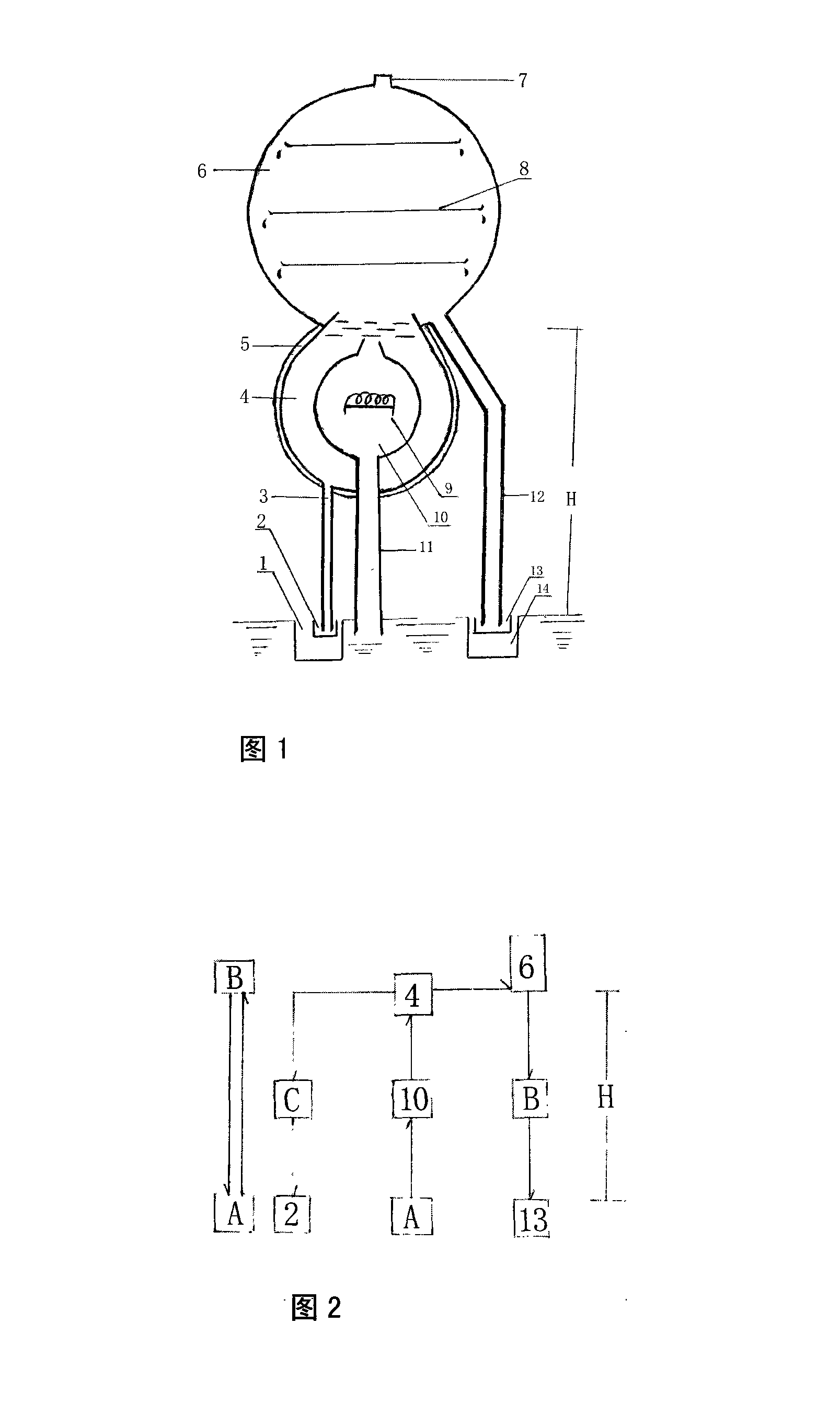

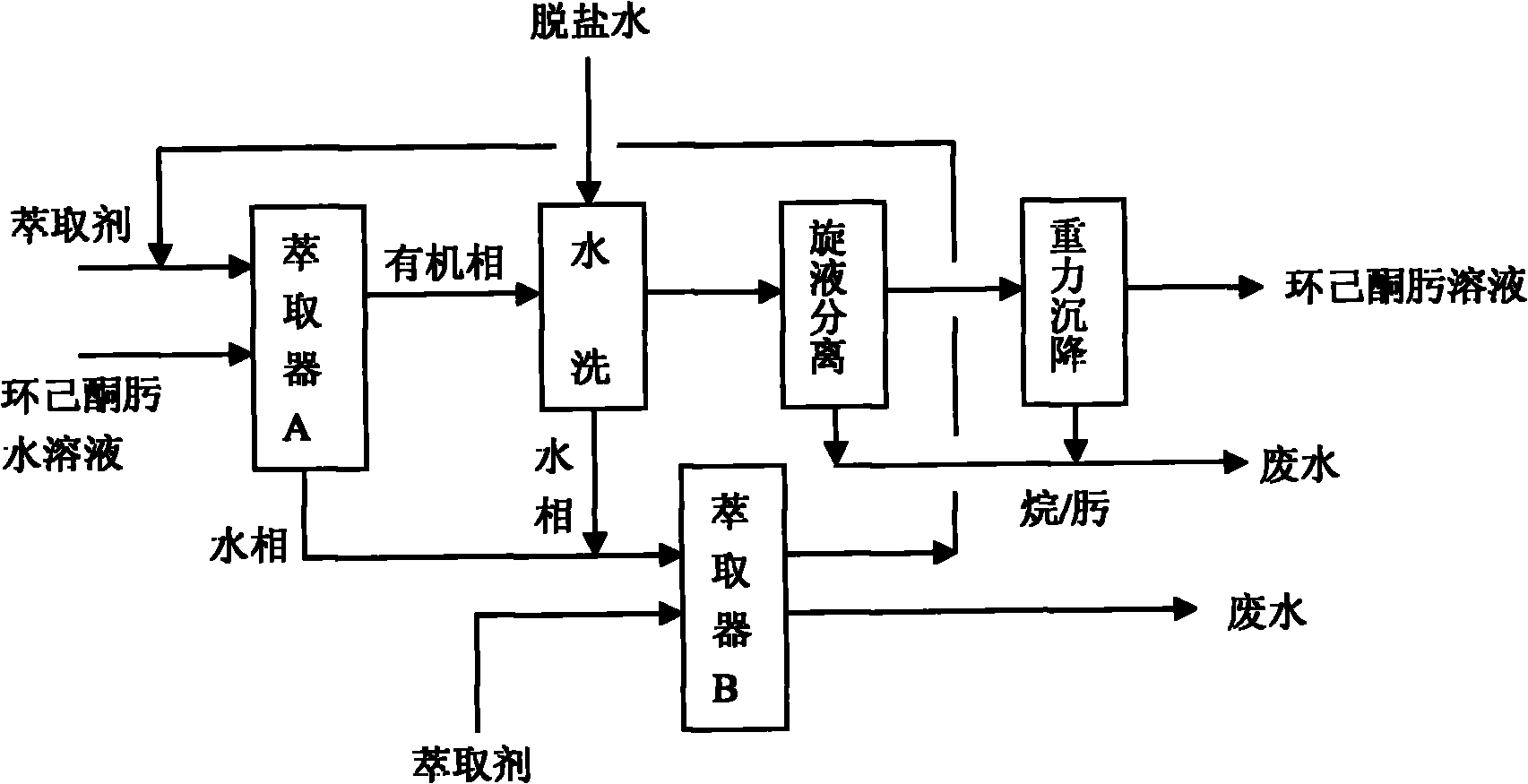

Process for extracting and washing cyclohexane oxime

ActiveCN101955445ASimple refining processFlexible refining processOximes preparationCycloneBeckmann rearrangement

The invention discloses a process for extracting and washing cyclohexane oxime. The process comprises the following steps of: extracting an extractant and aqueous solution of cyclohexane oxime in a weight part ratio of 1:1 to 2:1 at the temperature of between 45 and 55 DEG C; washing an organic phase obtained by the extraction with desalted water when the mass concentration of the cyclohexane oxime is less than 1 percent so as to remove salt ions in the cyclohexane oxime solution; mixing a water phase obtained after washing and a water phase obtained by extraction, and extracting the mixture by using a cyclohexane or hexane extractant in a weight part ratio of 0.5:1 at the temperature of between 45 and 55 DEG C so as to recycle the cyclohexane oxime in the mixture; and sequentially performing hydraulic cyclone separation and gravity settling separation on the washed organic phase when the mass concentration of the salt ions in the organic phase is less than 0.0001 percent so as to obtain the cyclohexane oxime. The process does not need a rectification process; the purity of the obtained cyclohexane oxime is high; beckmann rearrangement can be directly performed in the next process so as to prepare caprolactam; and for 100,000 t / a of cyclohexanone oxime devices, the process can save one-time equipment investment by about 20 to 30 million and can reduce energy consumption such as water, electricity, steam and the like by about 30 to 40 million.

Owner:河北美邦工程科技股份有限公司

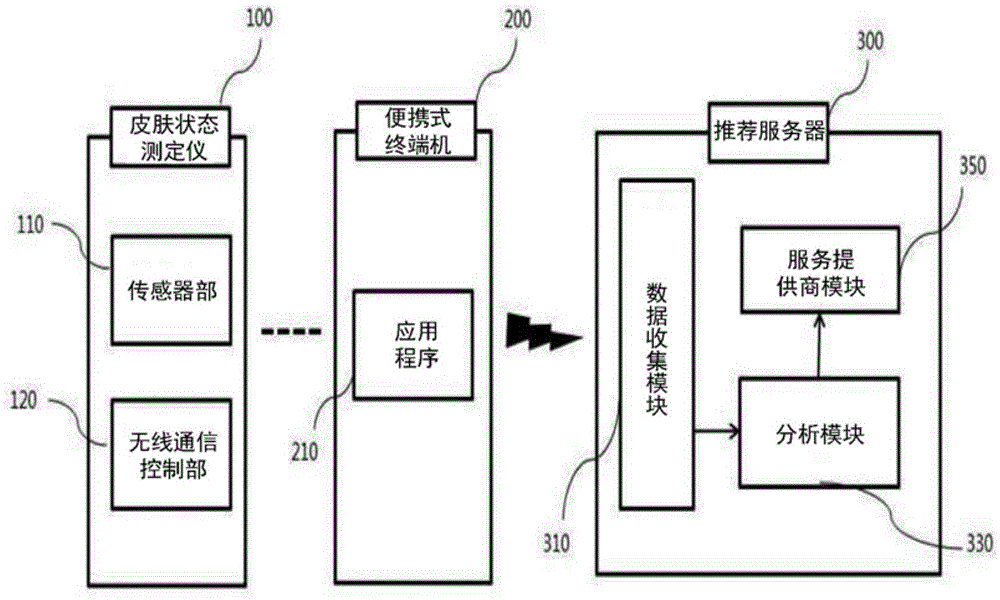

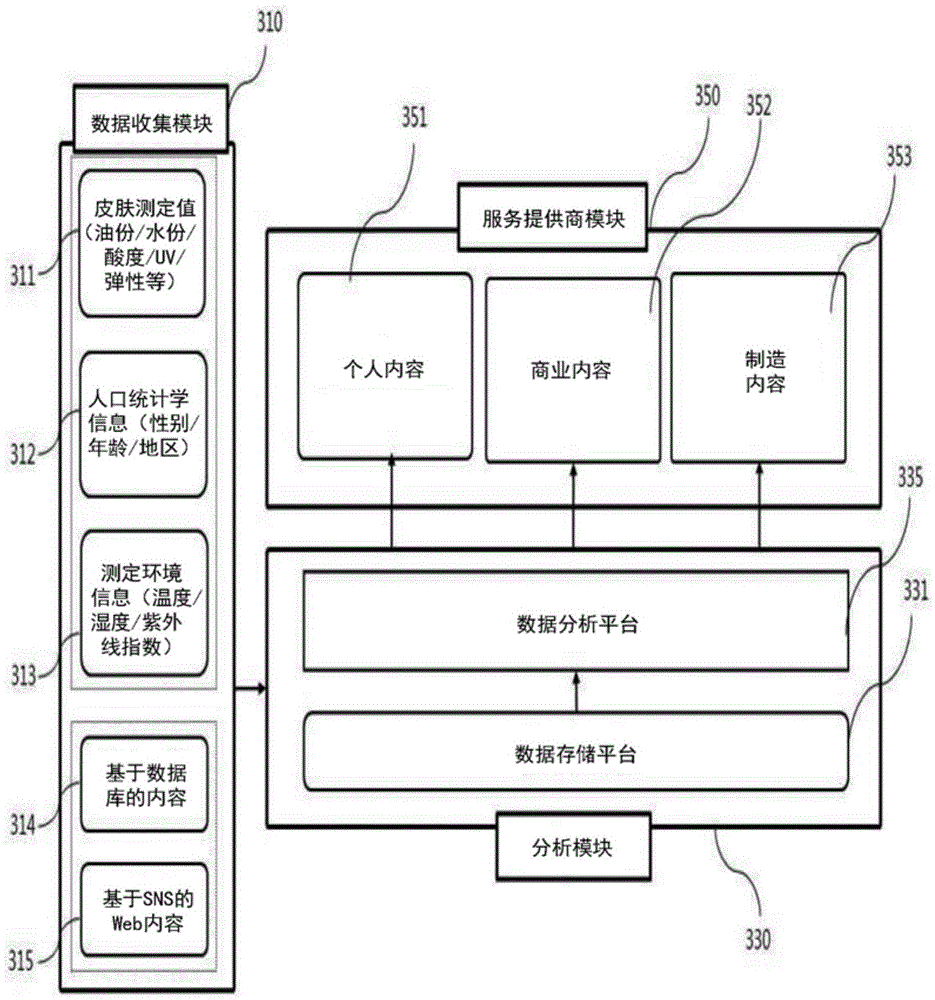

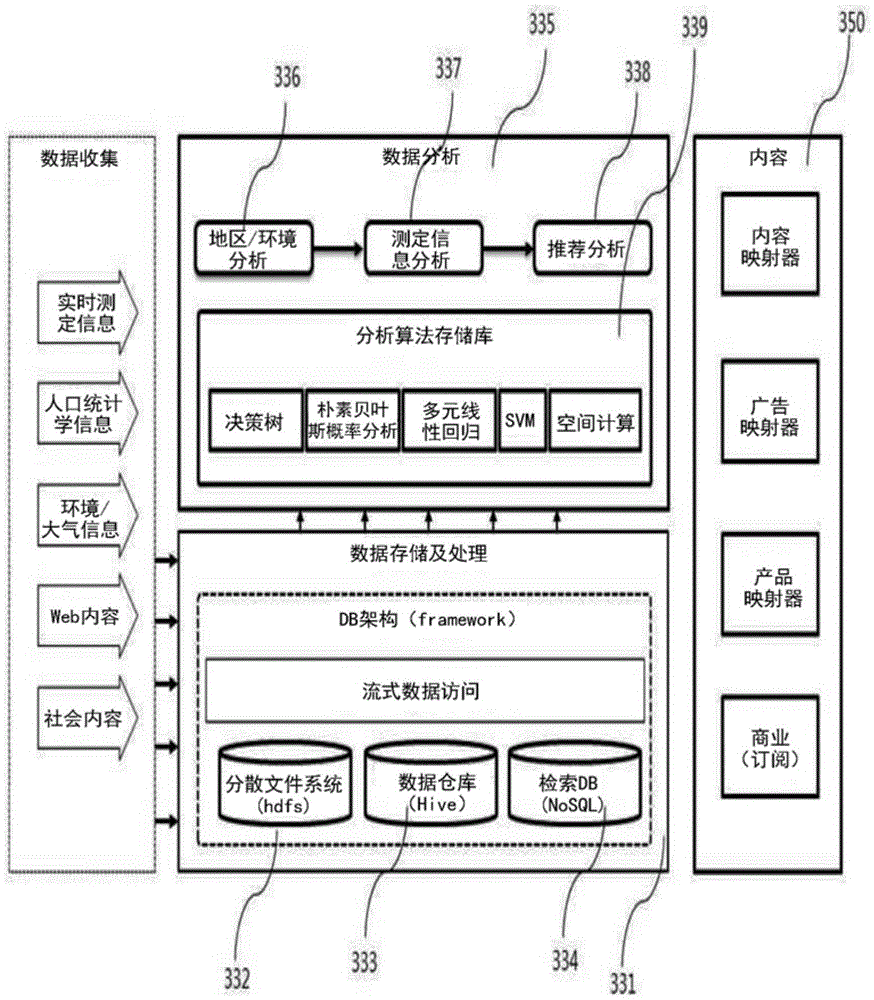

Skin status measurement system and individual skin management system therewith

InactiveCN106667431AOngoing managementIncrease profitMarket predictionsDiagnostic signal processingPersonalizationCommunication control

The invention relates to a skin management system which provides best skin management information to every person on the basis of result data measured by a skin status measurement system. The individual skin management system includes a skin status measurement instrument including a sensor portion for measuring the skin status and a wireless communication control protion that sends the measured value measured by the sensor portion in a wireless communication manner; a protable terminal machine, which displays the result data on the basis of the measured value on a display portion; a recommendation server, which receives the user information and result data from the protable terminal machine and transmits individual information on the basis of the user information and result data. The skin status measurement instrument is not a disposable device anymore and can durably manage skin of a person, and also can provide helpful invidual recommendation inforamtion on the basis of invidual user, thus greatly increasing utilization rate of the skin status measurement system.

Owner:INNOINSIGHT INC

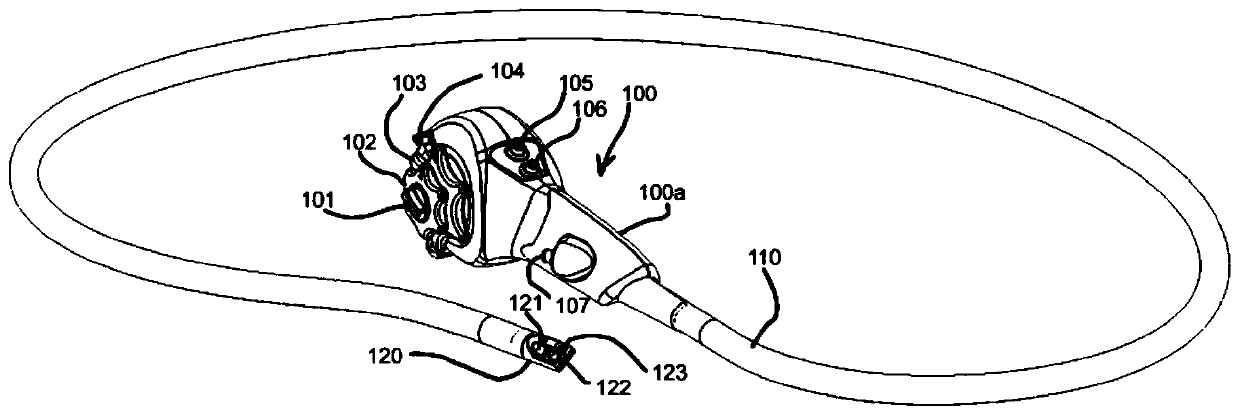

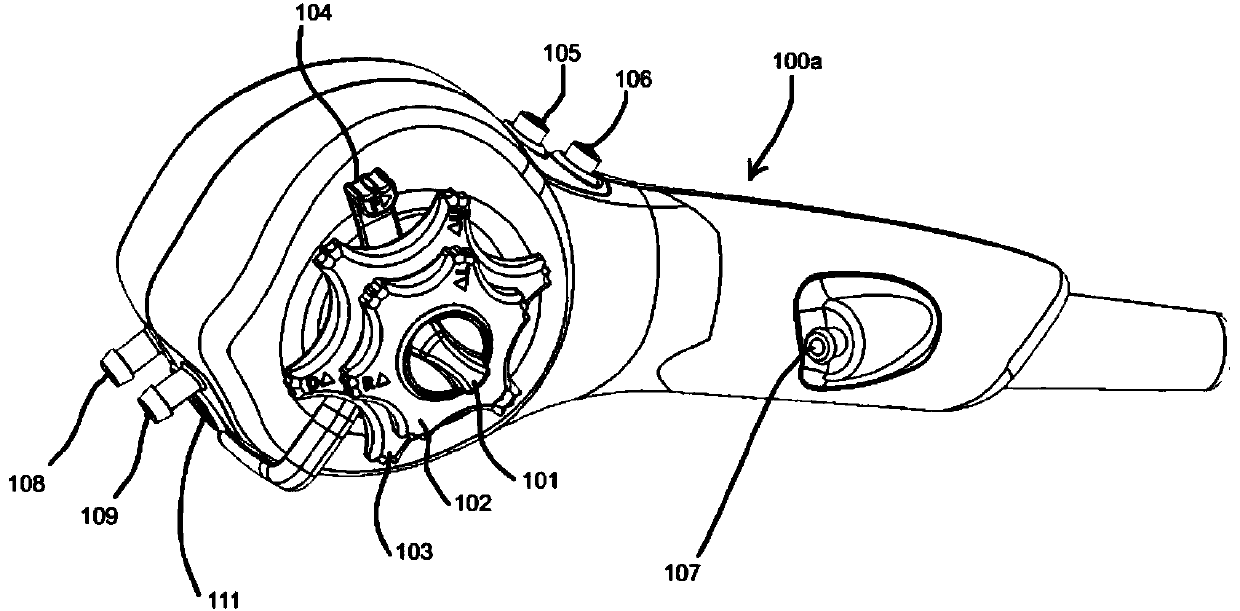

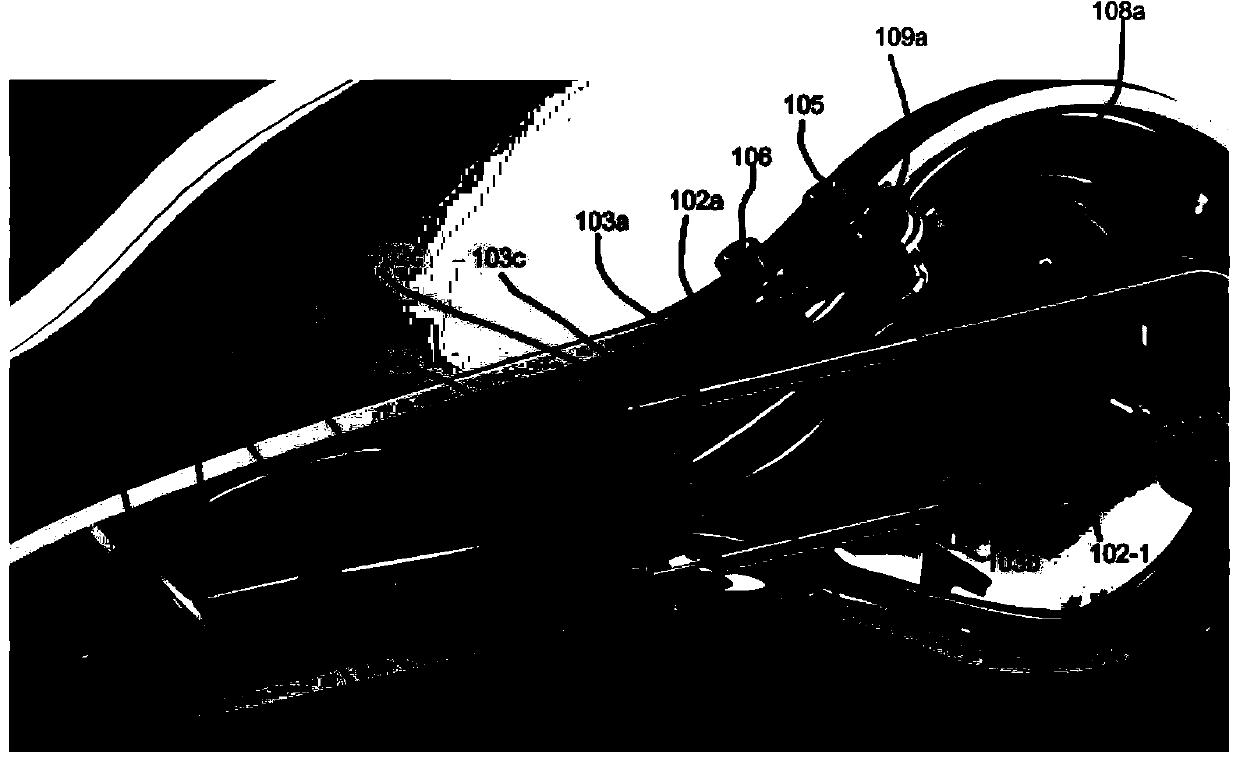

Intranasal delivery devices

ActiveUS20140060535A1Improve stabilityReduce deliveryRespiratorsLiquid surface applicatorsDiseaseSingle-Use Device

Devices for delivery of dry powder formulations are also provided. Devices can be single-use devices. Formulations and methods of manufacture are provided for dry powder compositions suitable for intranasal administration. Also provided are methods of use for preventing or controlling emesis and other diseases and disorders and devices, compositions, and methods for nasal delivery of therapeutic formulations.

Owner:SHIN NIPPON BIOMEDICAL LAB

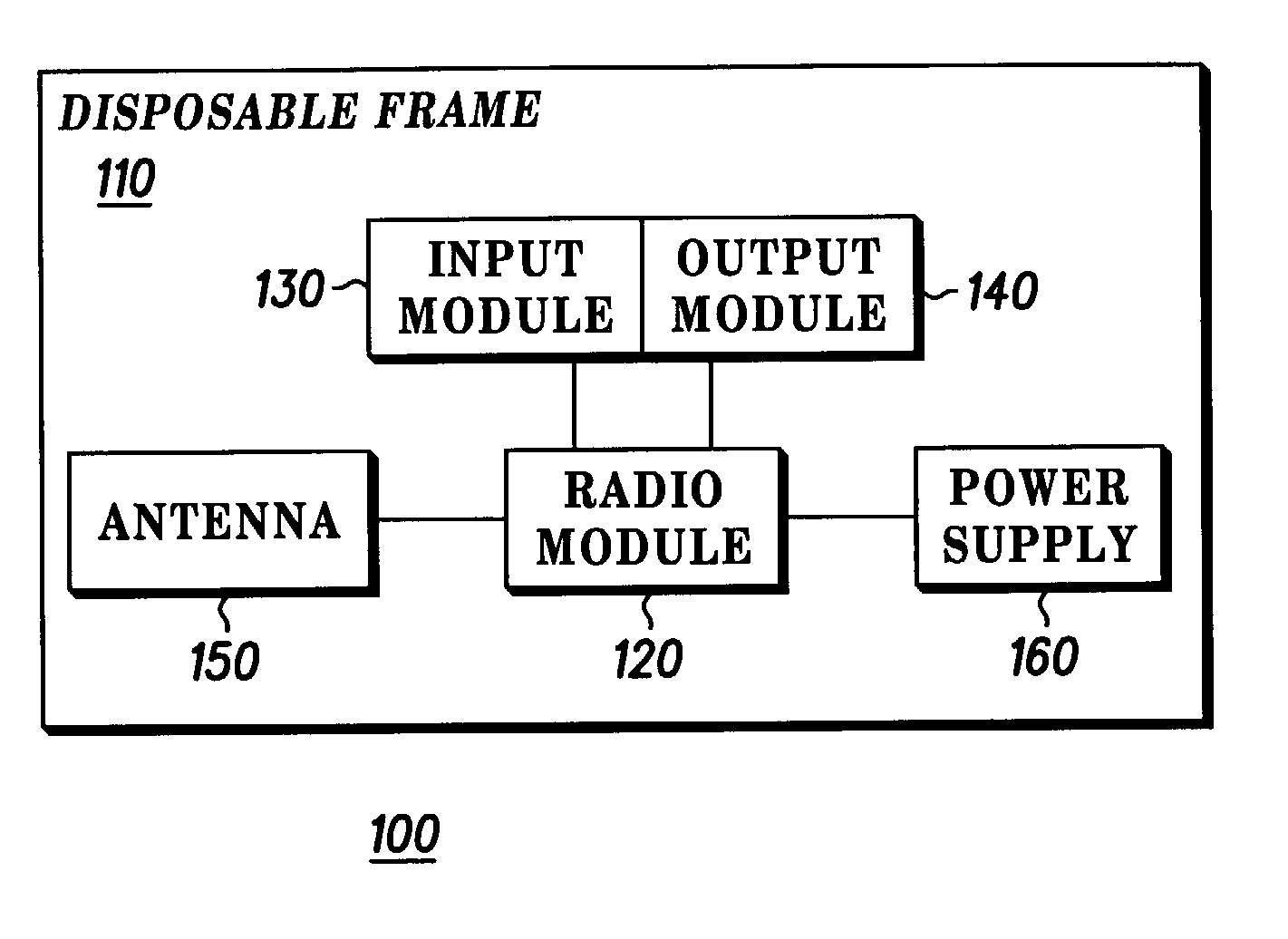

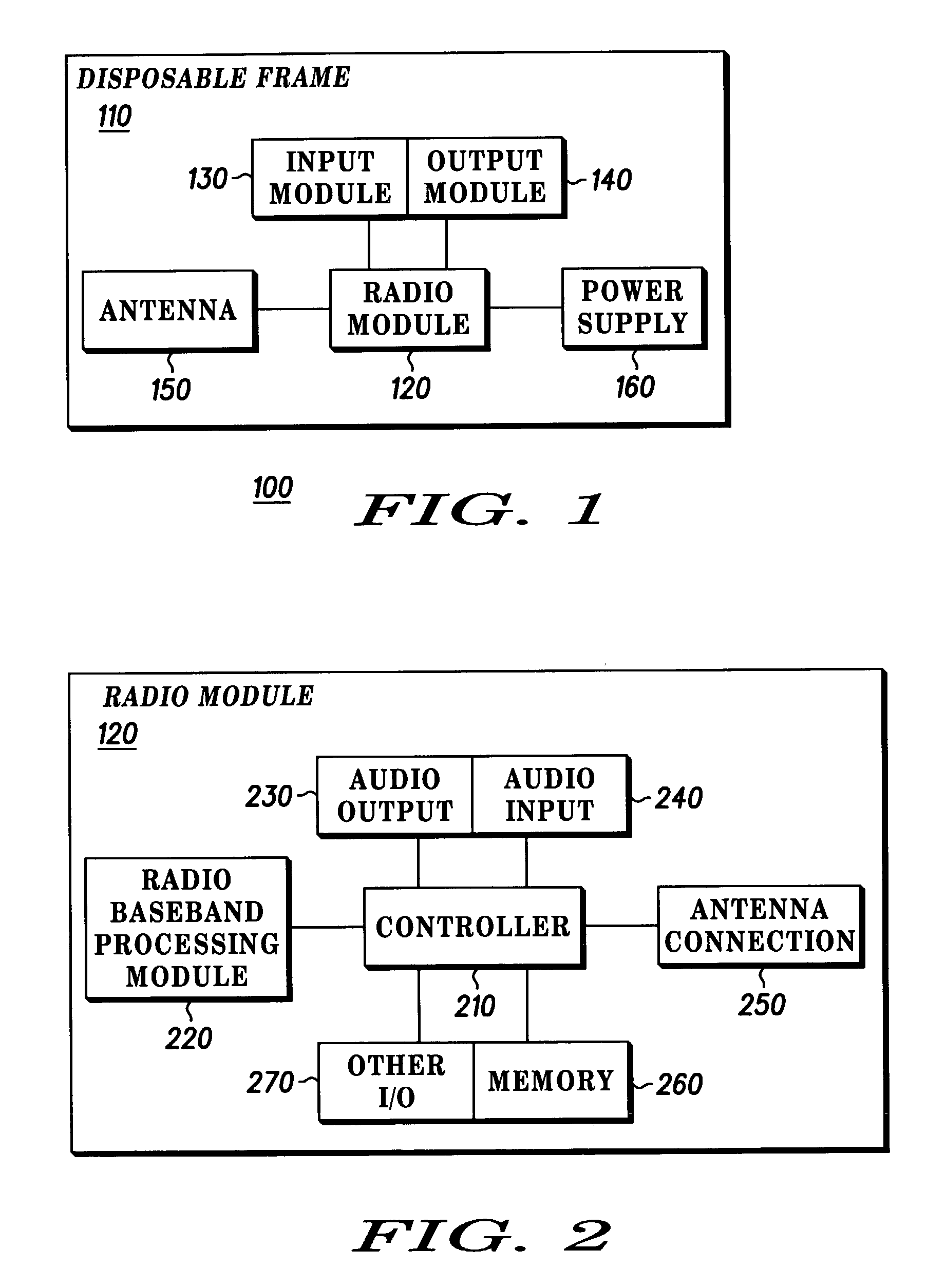

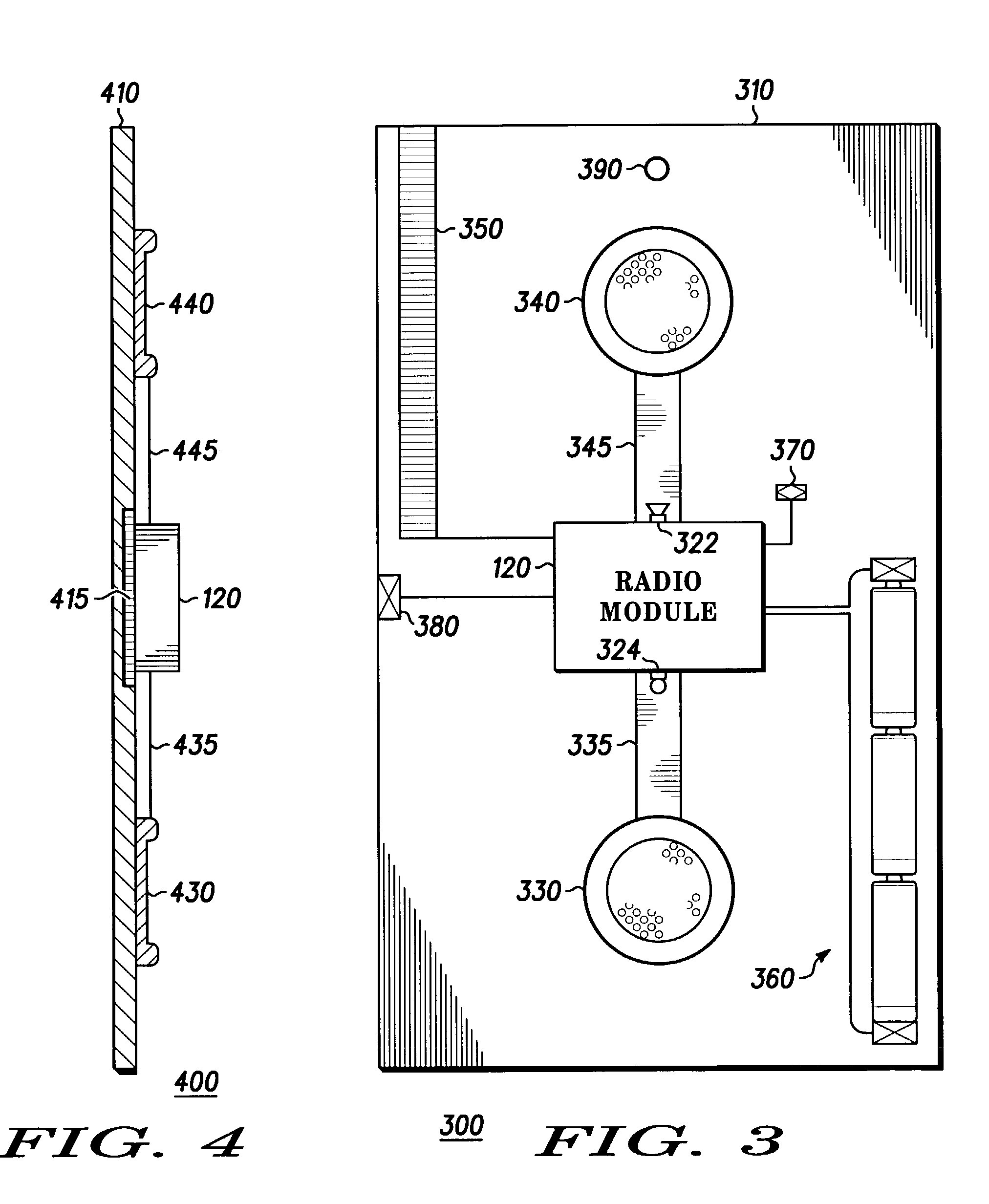

Disposable device with removable radio module

A method and apparatus for a disposable mobile communication device having a destructively removable radio module. The mobile communication device can include a disposable frame, a radio module coupled to the disposable frame, the radio module being irreplaceably removable from the disposable frame, an audio input module coupled to the disposable frame and the radio module, an audio output module coupled to the disposable frame and the radio module, a power supply module coupled to the disposable frame and the radio module, and an antenna coupled to the disposable frame and the radio module. The radio module can include a radio baseband processing module, an audio input, and an audio output.

Owner:GOOGLE TECH HLDG LLC

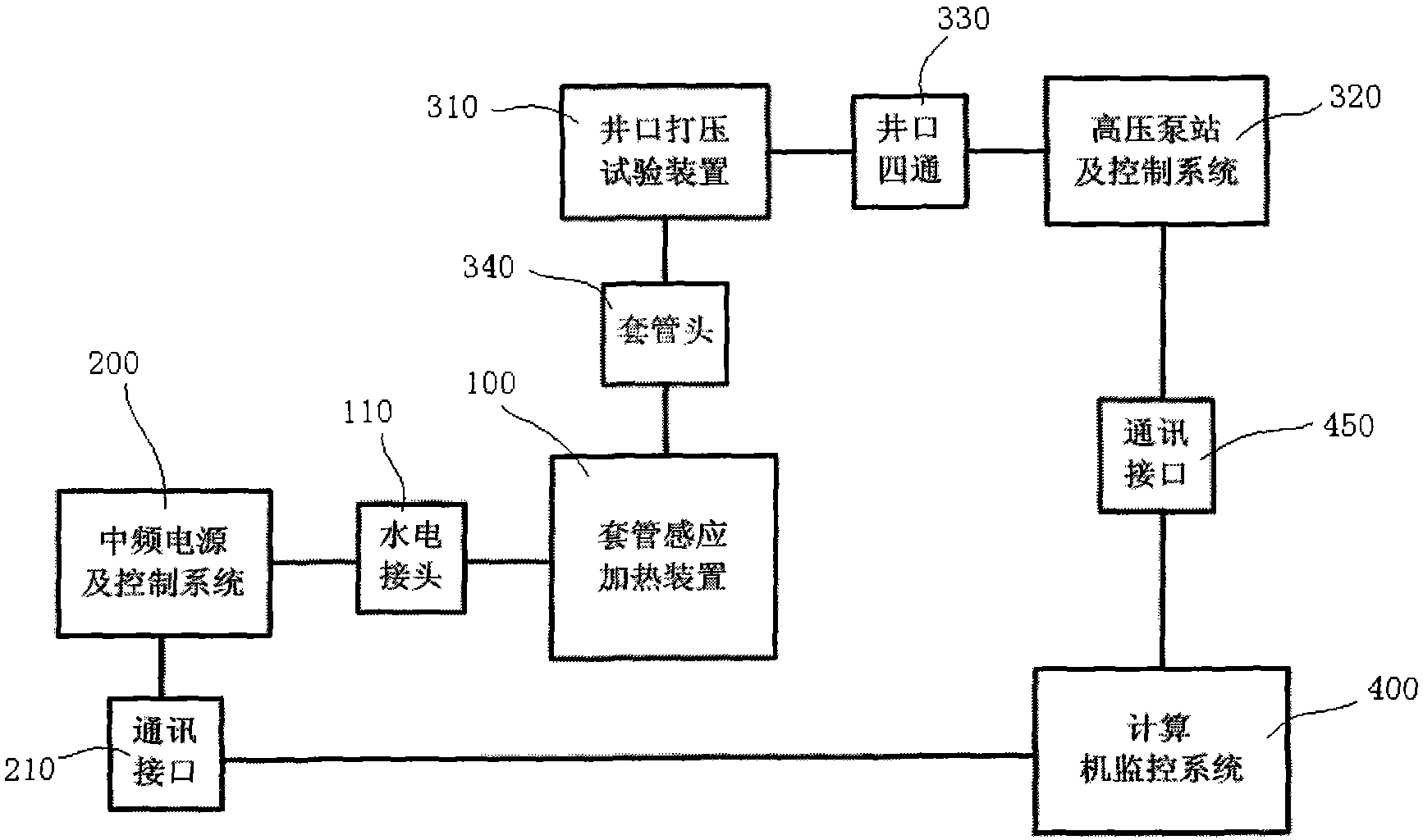

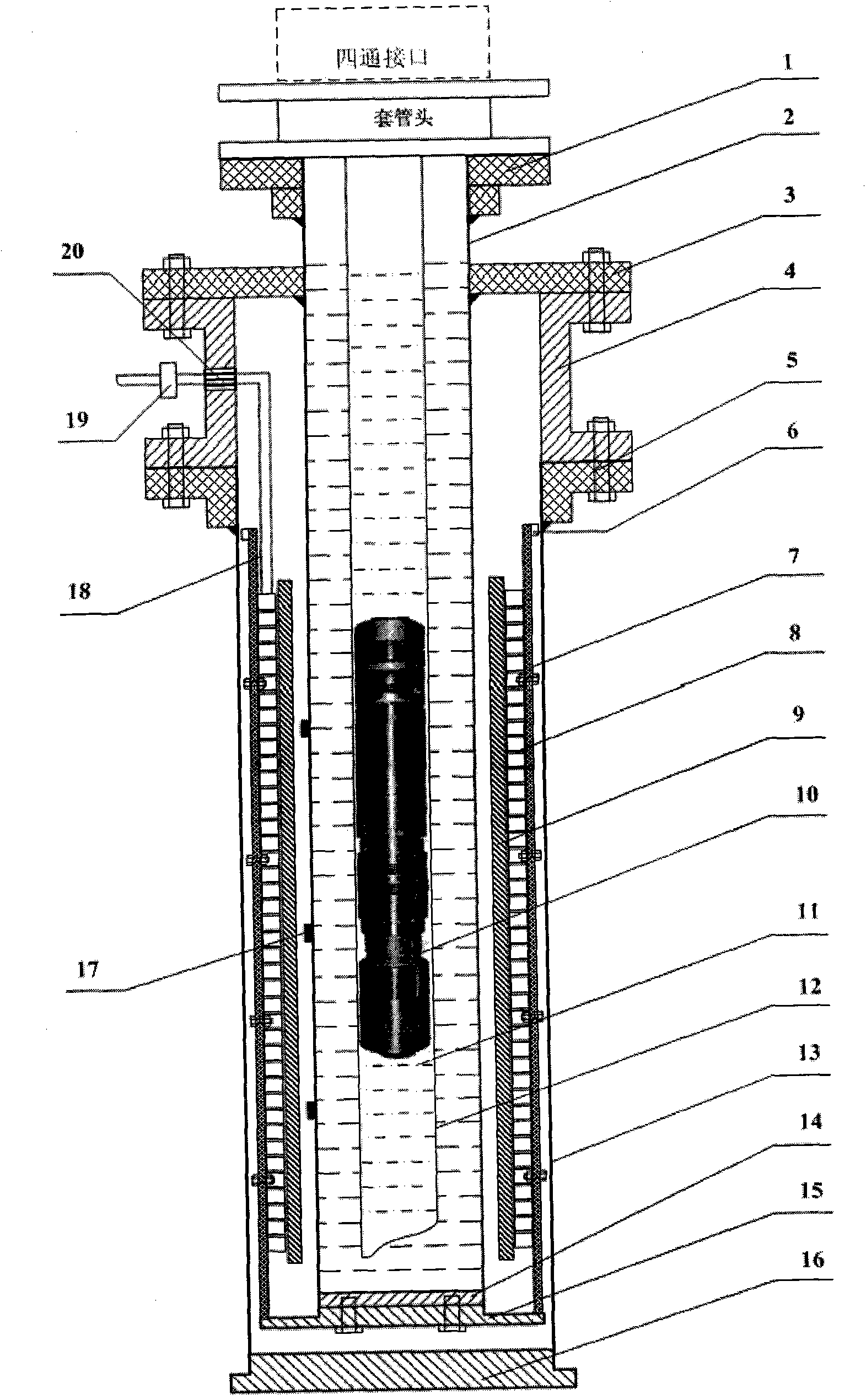

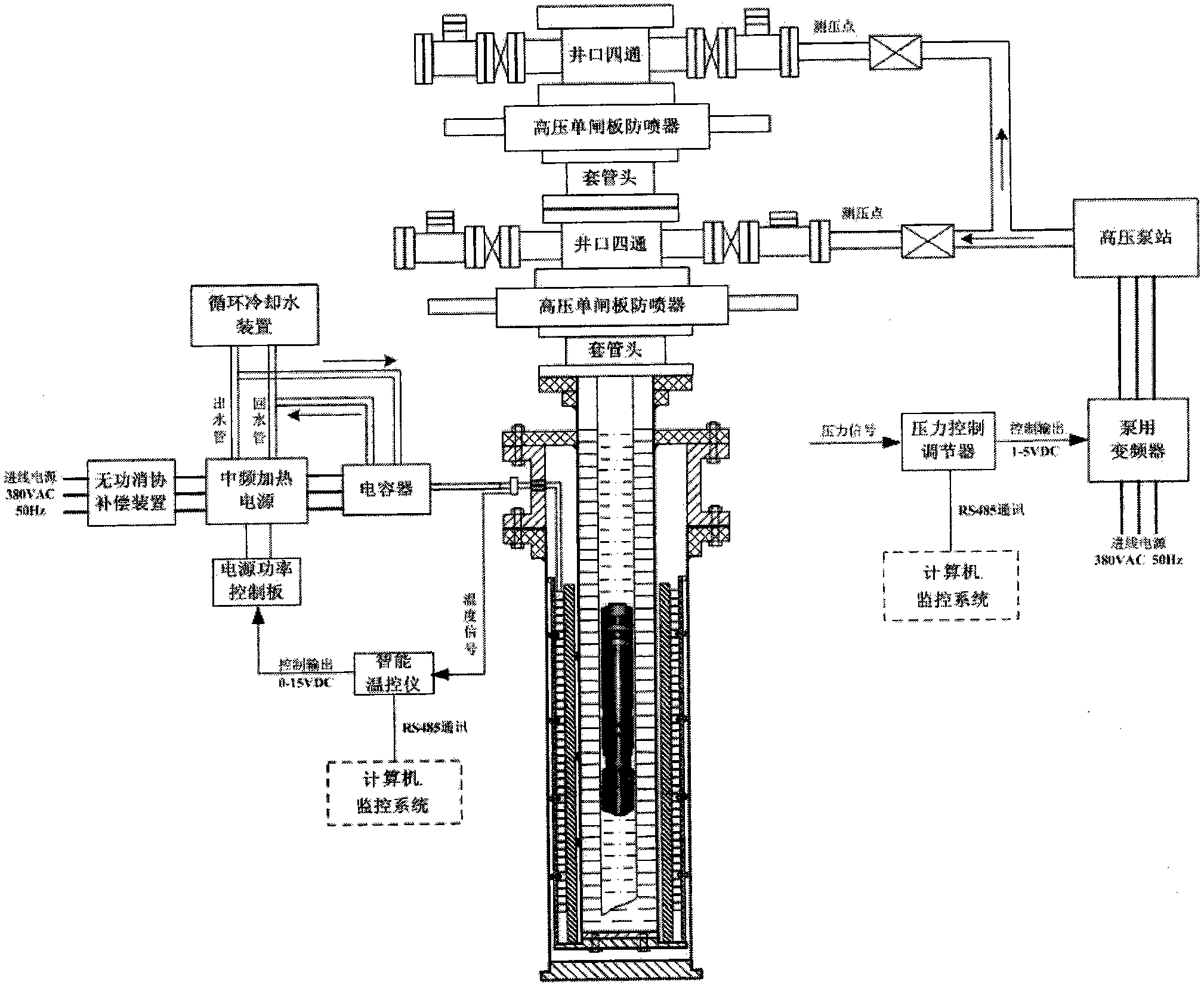

Simulation test system for temperature resistance and pressure resistance of packer rubber sleeve

ActiveCN103454107AFast heatingImprove test efficiencyStructural/machines measurementEnvironmental resistanceComputer monitoring

The invention discloses a simulation test system for the temperature resistance and the pressure resistance of a packer rubber sleeve. The simulation test system comprises a sleeve induction heating device, a middle-frequency power supply and control system, a pressurizing device and a computer monitoring system. The sleeve induction heating device comprises a surface sleeve, a heating sleeve arranged in the surface sleeve and an induction heating mechanism arranged on the surface of the heating sleeve, wherein heating sleeve is connected with the pressurizing device, and the induction heating mechanism is connected with a middle frequency power supply and control system. The middle frequency power supply and control system and the pressurizing device are both connected with the computer monitoring system. A pressurizing and heating experiment for an underground tool to be tested is finished in the heating sleeve. The simulation test system uses a middle frequency induction heating method, an induction heating coil is wound on the heating sleeve, the heating speed is quick, and accordingly the testing efficiency is improved. The simulation test system is simple in equipment structure, small in disposable equipment investment, low in operation management cost and good in safety and environmental friendliness.

Owner:NORTHWEST UNIV +2

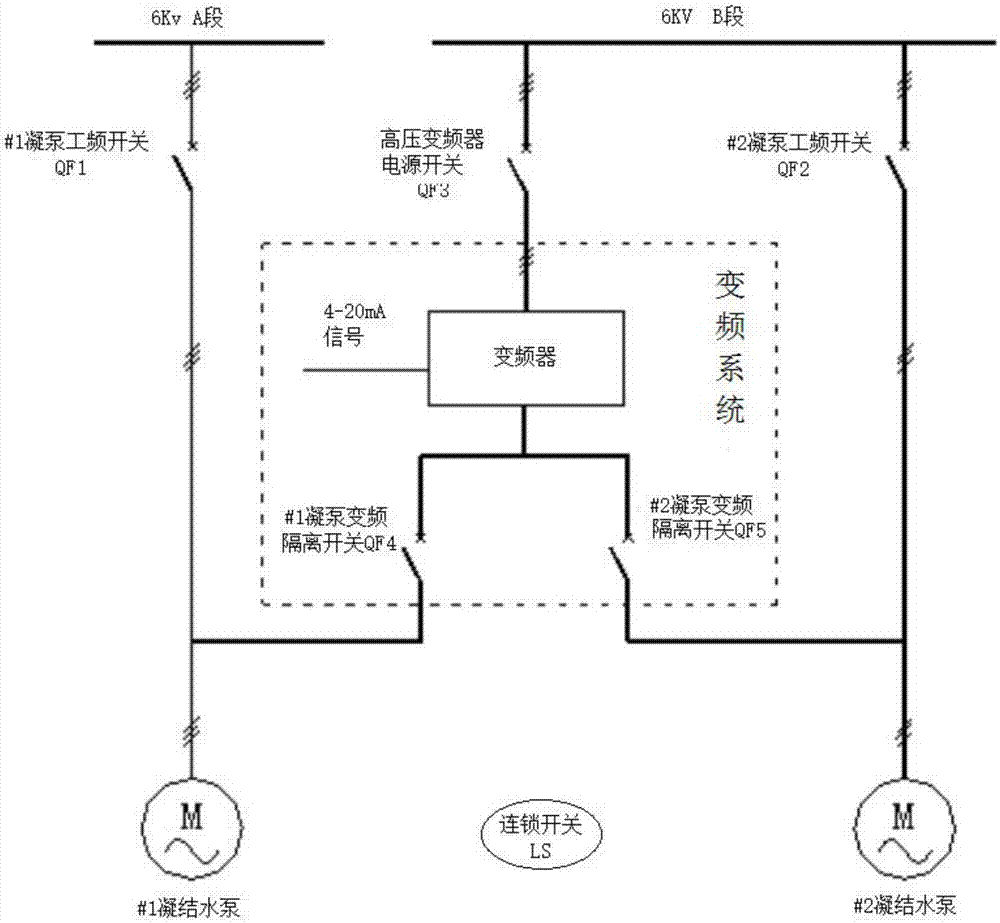

One-drive-two control implementing method of high voltage inverter of condensed water pumps of steam turbine unit

InactiveCN107100860AReduce investmentThe power consumption rate of the condensate pump is reducedPump controlPump installationsFrequency changerControl manner

The invention relates to a one-drive-two control implementing method of a high voltage inverter of condensed water pumps of a steam turbine unit. The method comprises the steps that: two condensed water pumps share one high voltage inverter, condensed water pumps No.1 and No.2 are respectively driven to carry out variable frequency operation to realize a one-drive-two control way of a frequency converter; through minimum disposable equipment investment, an energy-saving effect of the frequency converter can be developed to the greatest extent, and working frequency and variable frequency bypass switching locking protection of the condensed water pumps and working frequency interlocking start logical function of a standby pump are realized, and stable adjustment on the condensed water pumps of 600-1500rpm still can be realized by the condensed water pumps and the condensed water system under a failure condition of the high voltage inverter. According to the method, the disposable equipment investment is low; if the equivalent operation time of the unit is 4,000 hours every year, and the electricity quantity every one kilowatt is calculated based on 0.3 Yuan, so that about 700,000 Yuan can be saved in one year, and the equipment input cost can be recycled in two years; therefore, the economical benefit and the social benefit are both obvious.

Owner:STATE GRID TIANJIN ELECTRIC POWER +1

Methyl chloride recovery and refining method

ActiveCN101417923BReduce dosageMitigate the impact of stable operationGroup 4/14 element organic compoundsHalogenated hydrocarbon separation/purificationFluidized bedGas phase

The invention relates to a recycling and refining method of chloromethane. After being condensed by a chloromethane compressor, the coarse chloromethane gas from a washing tower end cooler enters into a chloromethane tower for refining in gas phrase state from an inlet under a return flow inlet of a coarse monomeric tower; the recycled chloromethane gas obtained from the upper lateral line of thechloromethane tower is directly led into a chloromethane superheater, is heated and then flows into a fluidized bed to carry out fluidized reaction. The invention improves the charging and discharging technical process of the present chloromethane refining tower and simplifies the unnecessary processes, which greatly reduces the investment to disposable equipment and the energy consumption in theproduction process, thereby reaching the purpose of saving equipment and energy.

Owner:SHANDONG DONGYUE ORGANIC SILICON MATERIAL +1

Devices and methods for internal imaging

The invention relates to devices and methods for visualizing and / or interacting with internal body tissues. More particularly, the present invention relates to endoscopic methods and devices for visualizing and / or interacting with the gastrointestinal and / or pancreaticobiliary systems, such as with one use or disposable devices, such as with duodenoscopes. A device for visualizing and / or interacting with internal body tissues may generally include a handpiece, a distal assembly, and / or a connecting conduit. A plurality of conduits and / or channels may span through the connecting conduit from the handpiece to the distal assembly, and may, for example, carry fluid / gas connections, electrical / sensor connections, such as for a camera, mechanical connections and / or carry medical devices througha working channel. The device may also reduce the needs associated with reusable devices such as for reducing risks associated with improper sterilization.

Owner:SAFEVIEW MEDICAL LLC

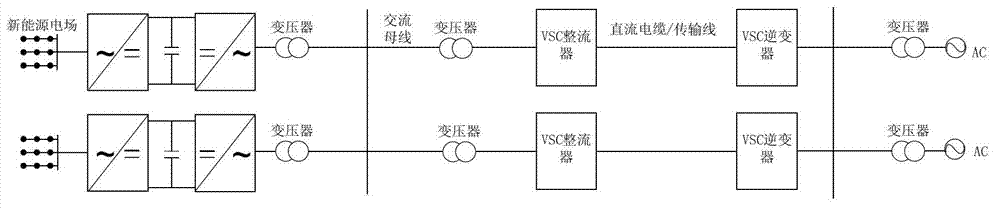

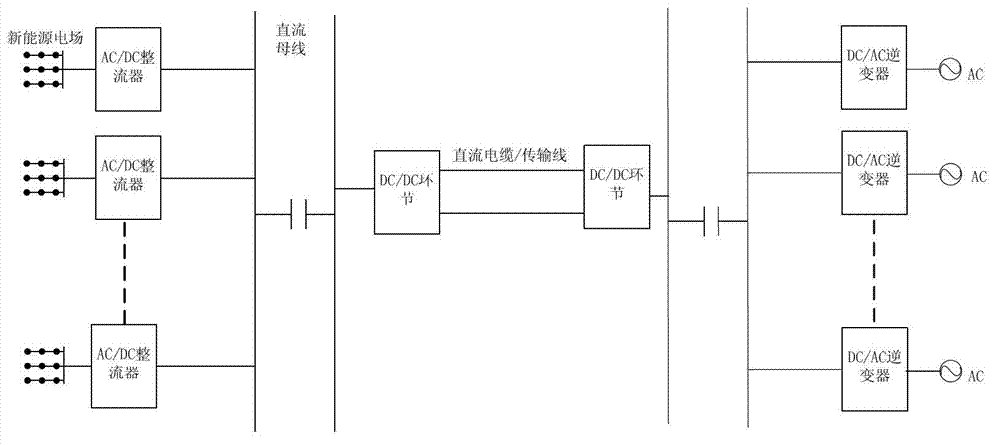

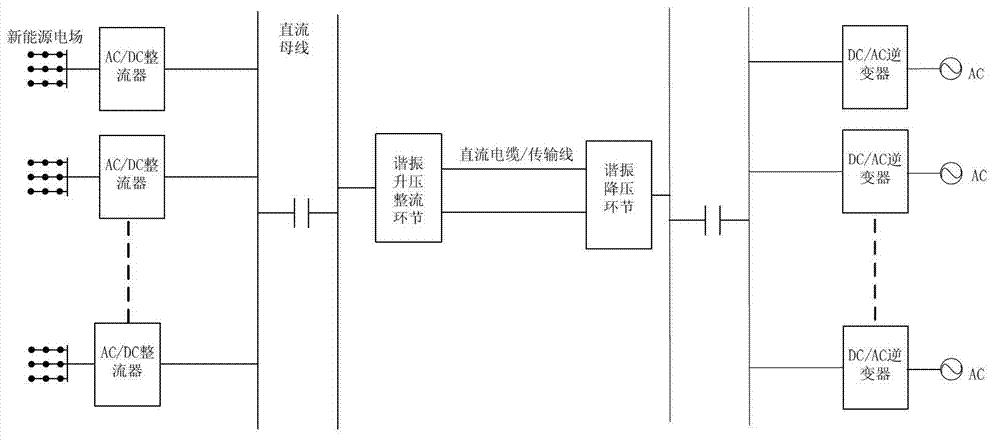

New energy grid connection system and achieving method thereof

ActiveCN102904275ASimple designEasy to manufactureSingle network parallel feeding arrangementsNew energyBusbar

The invention relates to a new energy grid connection system which comprises at least one new energy electric field, at least one voltage source converter (VSC) rectifier, a direct-current busbar, at least one VSC inverter, a resonance boosting rectifying link and a resonance voltage reduction link. The at least one new energy electric field is connected with the direct-current busbar respectively through at least one VSC; the direct-current busbar is connected with the resonance boosting rectifying link; the resonance boosting rectifying link is connected with the resonance voltage reduction link through a direct-current cable or a direct-current transmission line; and the resonance voltage reduction link is connected with the at least one VSC inverter through the direct-current busbar. The resonance boosting rectifying link and the resonance voltage reduction link are applied to the new energy grid connection system, and the resonance links are large disposable equipment, easy and convenient to design and manufacture, easy to control, and capable of reducing technological difficulty and reducing cost. The problem that high-voltage high-capacity VSC and direct current to direct current (DC / DC) links are high in manufacture cost and difficult to design in the new energy grid connection system is solved, a brand new technological path is provided for the new energy grid connection.

Owner:GLOBAL ENERGY INTERCONNECTION RES INST CO LTD +2

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com