Manufacturing method of car axle case

A manufacturing method and axle housing technology, applied in the direction of manufacturing tools, other manufacturing equipment/tools, etc., can solve the problems of uneven wall thickness and diameter at both ends, small internal space, and difficult shaping, and achieve low cost and variable Small thickness and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

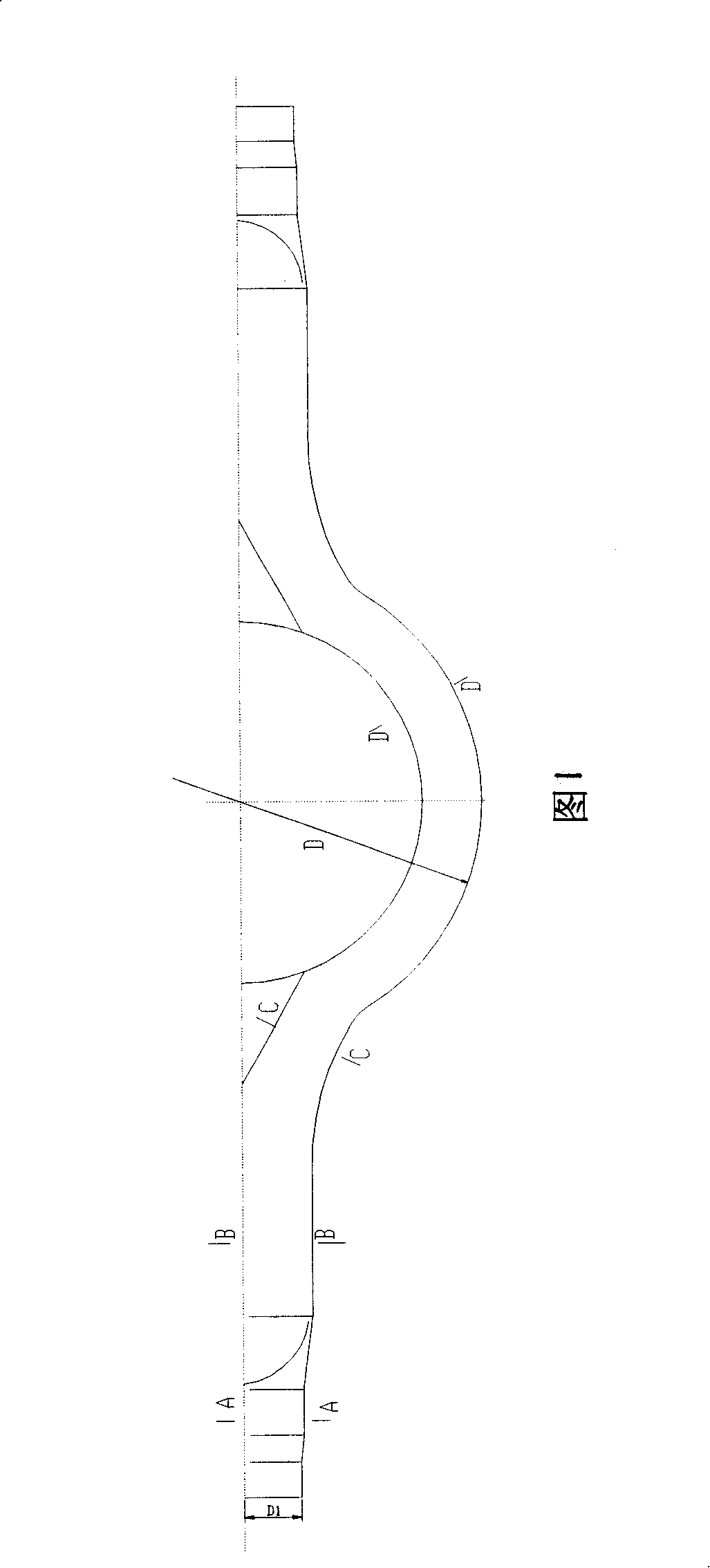

Image

Examples

Embodiment 1

[0017] (2) A truck axle housing

[0018] The axle housing is a part of a truck

[0019] The main parameters of the axle housing:

[0020] wxya

135mmX150mm

D

508mm

D1

135mm

[0021] Among them, B: the thickness of the axle housing, B1: the width of the square mouth of the axle housing, D: the maximum diameter of the axle package in the middle of the axle housing, D1: the diameter of the end of the axle housing

[0022] The axle housing adopts the shrinking-local pressing-extrusion bulging process as follows: first select the tube blank with a diameter of φ170mm, that is, seamless steel tube, then reduce the diameter of both ends of the tube blank, and directly shrink two The required size of the end is 135mm; the middle of the tube blank including the leaf spring seat area is pressed to 135mmX150mm; the middle of the tube blank is extruded and bulged and the parts are shaped to reach the drawing size, the bevel is made and the tri...

Embodiment 2

[0024] The axle housing is part of another truck

[0025] The main parameters of the axle housing:

[0026] wxya

150mmX160mm

D

532mm

D1

150mm

[0027] Among them, B: the thickness of the axle housing, B1: the width of the square mouth of the axle housing, D: the maximum diameter of the axle package in the middle of the axle housing, D1: the diameter of the end of the axle housing

[0028] The axle housing adopts the shrinking-local pressing-extrusion bulging process as follows: first select the tube blank with a diameter of φ185mm, that is, seamless steel tube, then reduce the diameter of both ends of the tube blank, and directly shrink two The required size of the end is 150mm; the middle of the tube blank including the leaf spring seat area is pressed to 150mmX160mm; the middle of the tube blank is extruded and bulged, and the parts are shaped to reach the drawing size, and the bevel is opened and the triangular plate is welded ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com