Process for extracting and washing cyclohexane oxime

A technology of cyclohexanone oxime and water extraction, which is applied in oxime preparation, organic chemistry, etc., can solve the problems of increasing cost and increasing difficulty, and achieve the effects of reducing water and electricity, saving equipment investment, and simplifying the refining process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

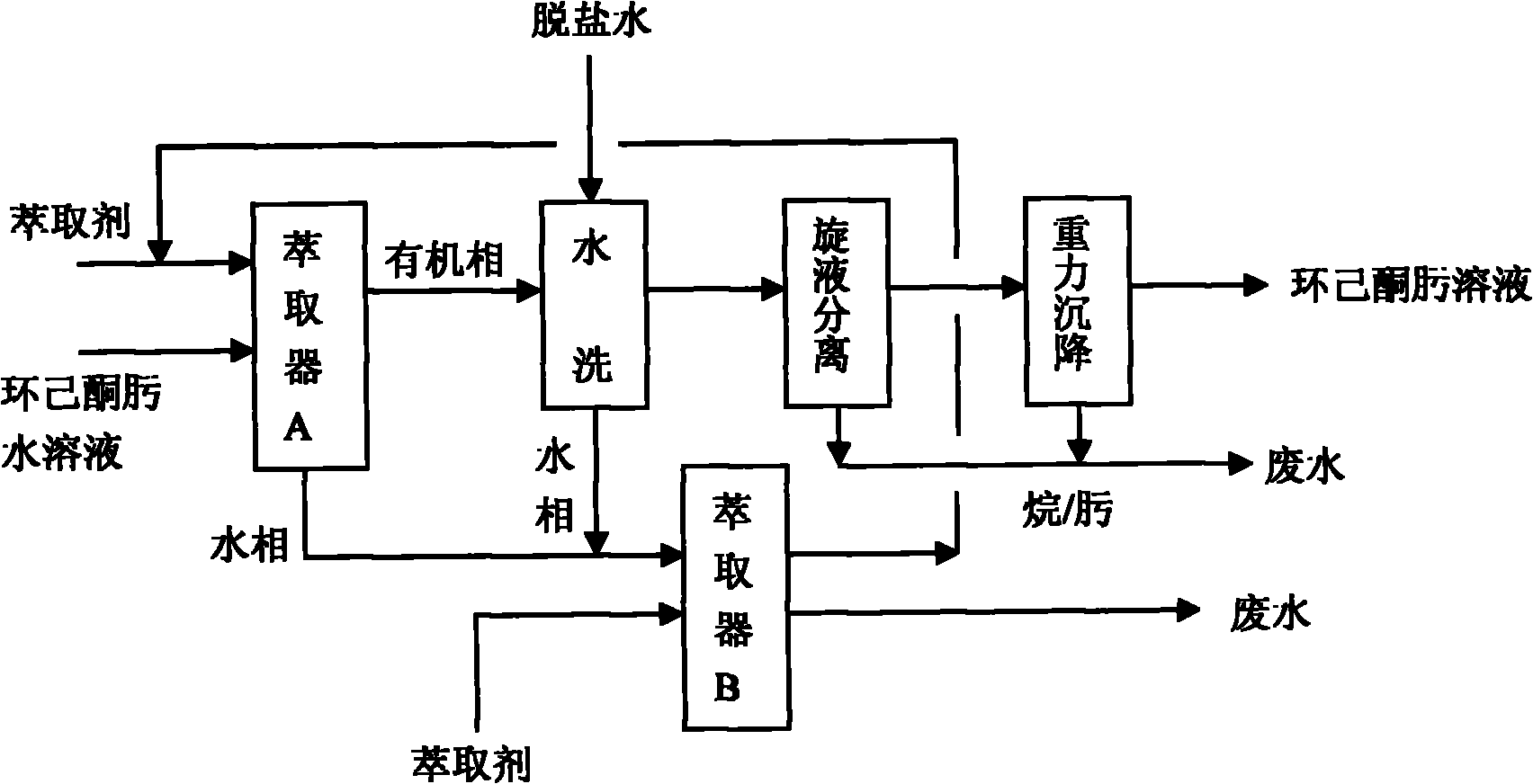

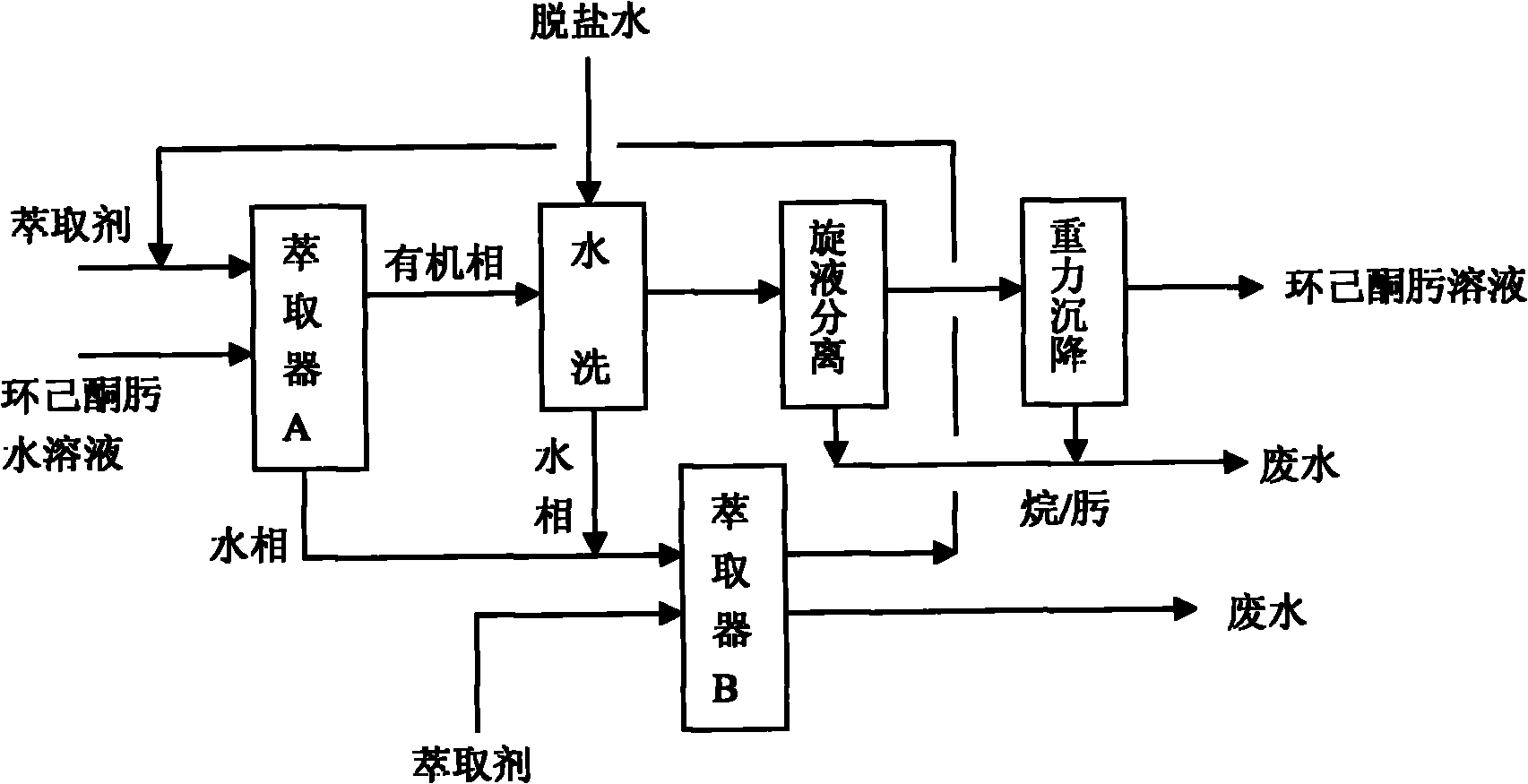

[0017] Embodiment 1: as figure 1 Shown, technological process of the present invention is as follows:

[0018] a. Put 37550kg / h cyclohexane and 30150kg / h cyclohexanone oxime aqueous solution into the supergravity centrifugal extractor A respectively, and control the temperature at 45-55°C for extraction;

[0019] b. When the mass concentration of cyclohexanone oxime in the cyclohexanone oxime aqueous solution is less than 1%, the organic phase coming out from the extractor A at this time is about 50500kg / h, and is washed with 5000kg / h desalted water to remove the salt ions therein;

[0020] c. when the mass concentration of salt ions in the organic phase in step b is less than 0.001%, the washed organic phase is subjected to hydrocyclone separation and gravity sedimentation separation to obtain a cyclohexane solution of about 50300kg / h cyclohexanone oxime;

[0021] d. After mixing about 17200kg / h of the water phase from the extractor A in step b and about 5050kg / h of the wate...

Embodiment 2

[0022] Embodiment 2: the difference between this embodiment and embodiment 1 is that n-hexane replaces cyclohexane as the extraction agent.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com