Baking-free type refuse burning flyash haydite and manufacturing method thereof

A technology of waste incineration fly ash and ceramsite, applied in the fields of building materials and environmental engineering, can solve the problems of power consumption, high temperature treatment, high treatment cost, secondary pollution, etc., and achieve the effect of low equipment investment and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

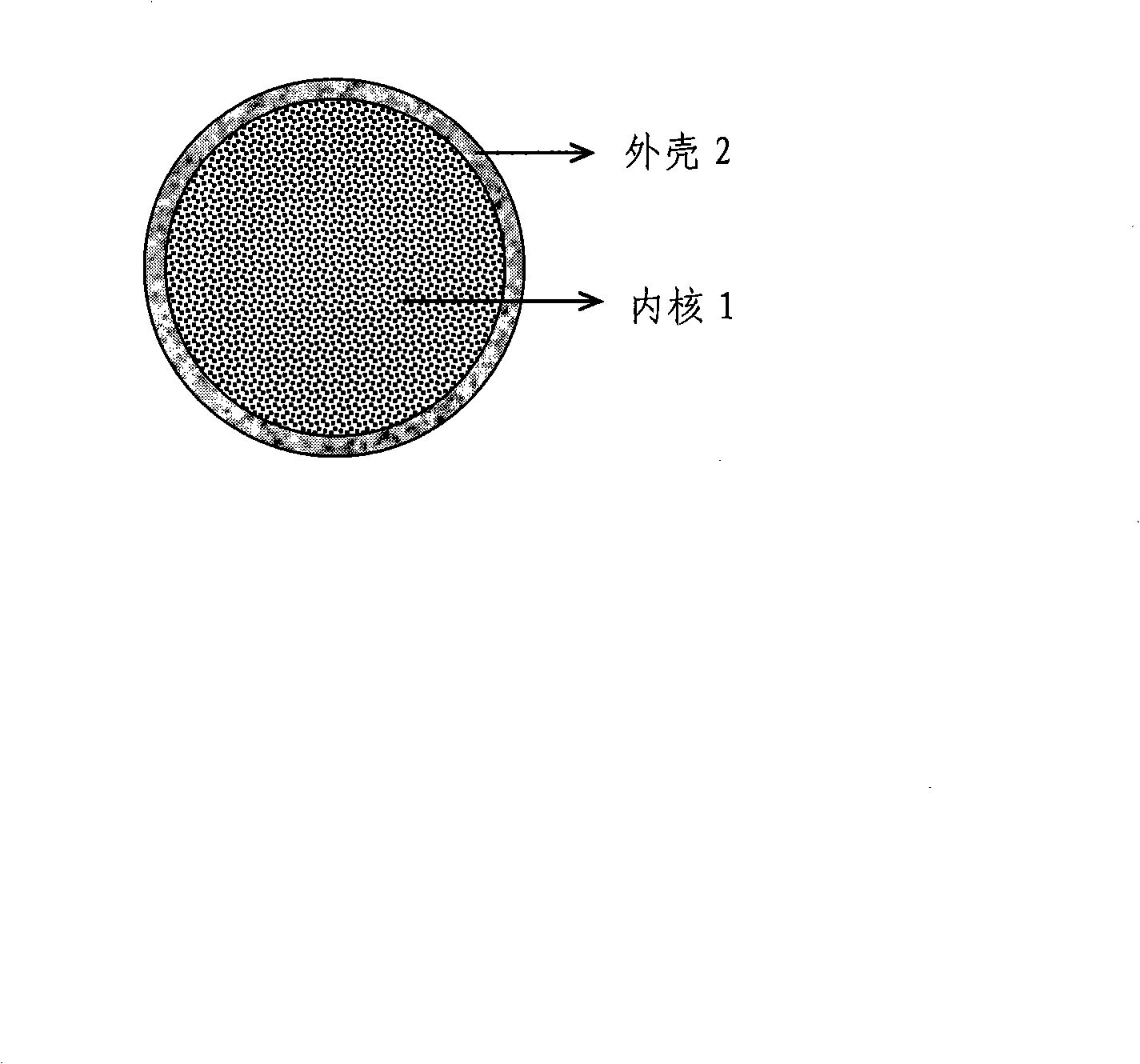

[0028] The composition (dry weight) of the core 1 is: waste incineration fly ash 50%, ordinary portland cement 44.8%, fly ash 5%, heavy metal stabilizer 0.2%. The heavy metal stabilizer is sodium sulfide. Firstly, the waste is incinerated for chemical stabilization treatment. The heavy metal stabilizing agent is made into an aqueous solution with a mass concentration of 2%, and then sprayed into the waste incineration fly ash, the amount of the aqueous solution added is about 20% of the weight of the fly ash, and the mixture is uniformly stirred. Ordinary Portland cement, fly ash and fly ash stabilized by chemicals are measured and sent to a mixer, mixed with water, and then sent to a disc granulator 1 for rolling granulation to form a spherical core 1 . The diameter of the core 1 is controlled to be 5-15 mm by adjusting the rotation speed, inclination angle and water spray volume of the original disc granulator. Send the kernel 1 into the disc granulator 2, sprinkle portlan...

Embodiment 2

[0030] The composition (dry weight) of inner core 1 is: waste incineration fly ash 69.5%, Portland cement 30%, heavy metal stabilizing agent 0.5%, heavy metal stabilizing agent is the combination of sodium sulfide and mercapto collector, heavy metal stabilizing agent The concentration of ceramsite is 3.5%, the granulation method is extruding into ball granulation, the cladding material is lime powder, and the natural curing condition of ceramsite is 30 days under the condition of 15-25 ℃. All the other steps are the same as in Example 1. The simple compressive strength of the present embodiment waste incineration fly ash ceramsite is 5-7MPa, and bulk density is 900-950kg / m 3 .

Embodiment 3

[0032] The composition (dry weight) of inner core 1 is: waste incineration fly ash 60%, Portland cement 25%, fly ash 14.6%, heavy metal stabilizing agent 0.3%, heavy metal stabilizing agent is soluble phosphate and mercapto collector The combination, the concentration of the heavy metal stabilizer is 3.5%, the granulation method is extrusion into ball granulation, the cladding material is Portland cement, and the natural curing condition of the ceramsite is 20 days at 20-30°C. All the other steps are the same as in Example 1. The simple compressive strength of the ceramsite in this embodiment is 6-8MPa, and the bulk density is 900-950kg / m 3 .

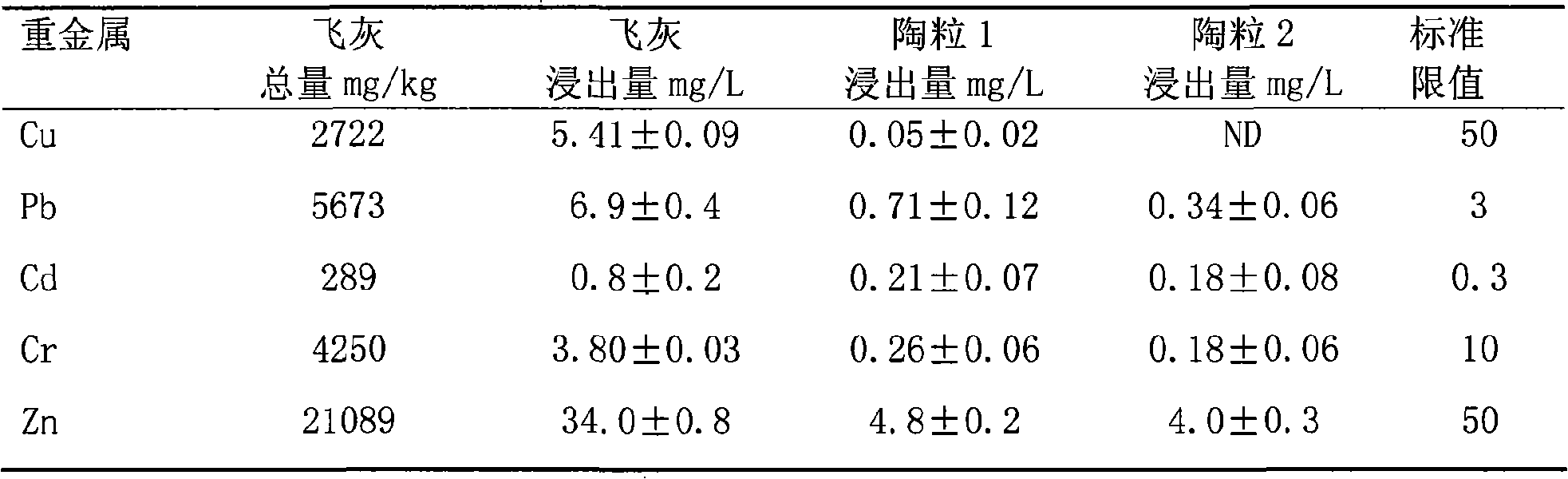

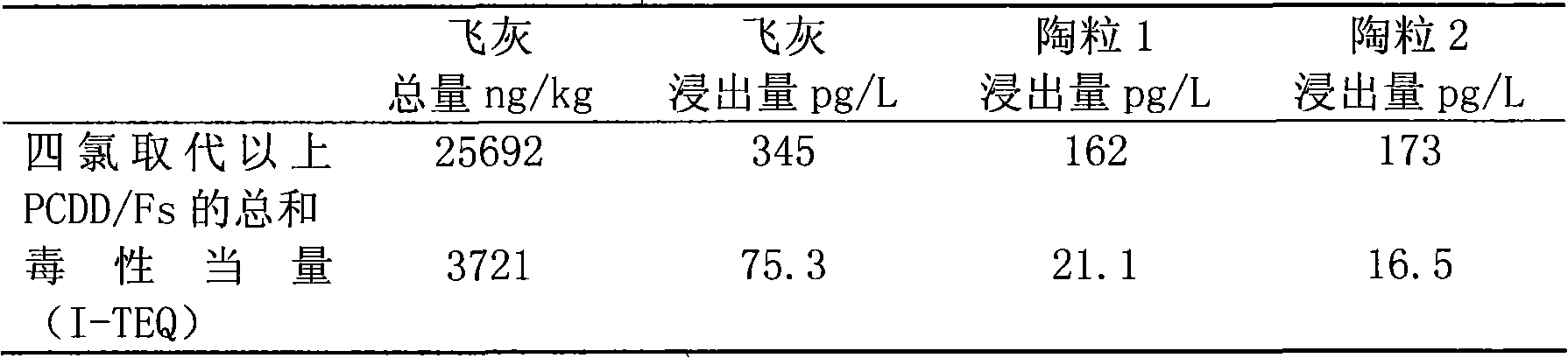

[0033]As mentioned in the technical background, waste incineration fly ash is a solid hazardous waste, which contains heavy metals such as Pb, Cd, Cr, Cu, Zn and Ni, etc., and contains highly toxic organic pollutants such as dioxin (PCDD / Fs). Therefore, it is very important to conduct an environmental risk assessment of unfired ceram...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| cylinder compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com