Workpiece attaching machine

A technology for placement machines and parts, which is applied in the field of placement machines, can solve the problems of limiting the types of operating parts, etc., and achieve the effects of improving the combination of finished products, improving precision, and increasing utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

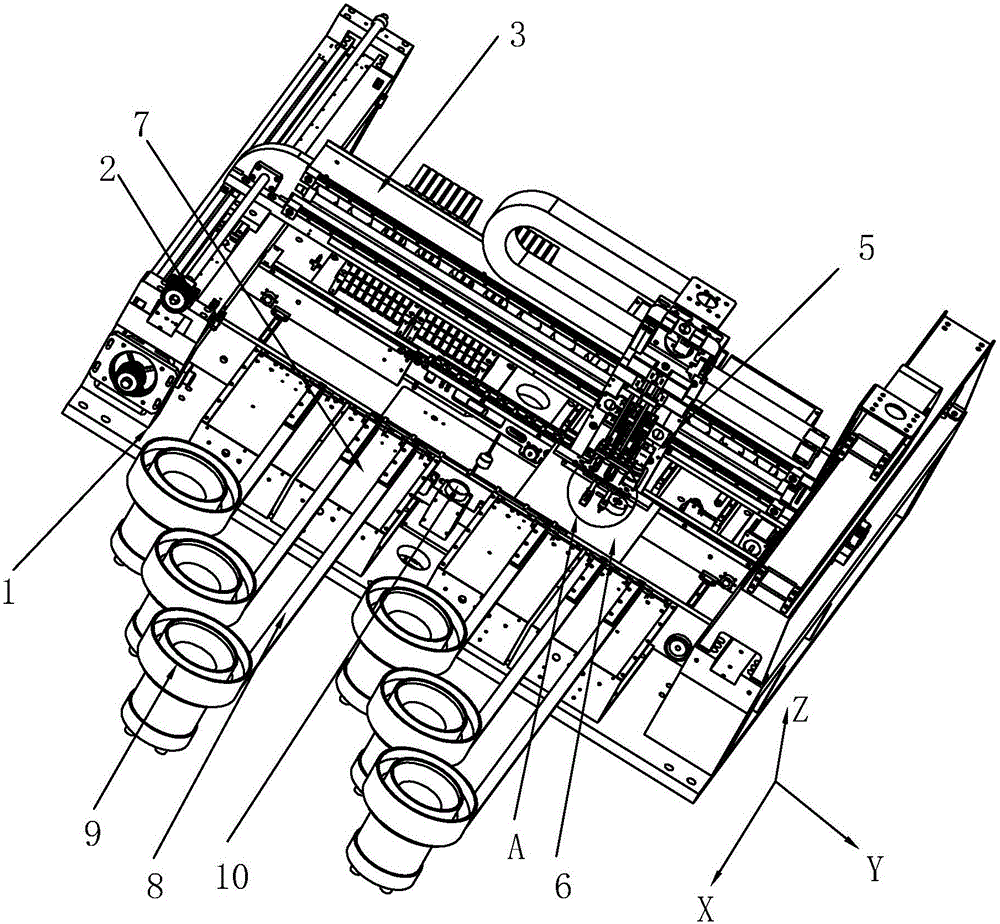

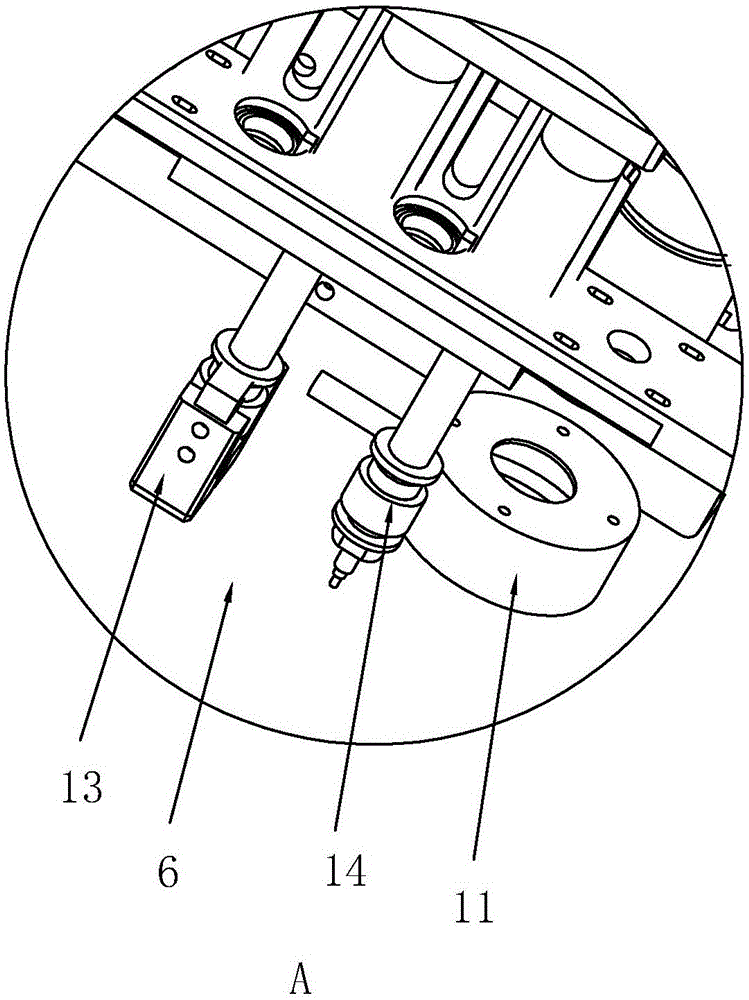

[0040] refer to Figure 1 to Figure 4 A specific embodiment of a mounting machine of the present invention will be further described.

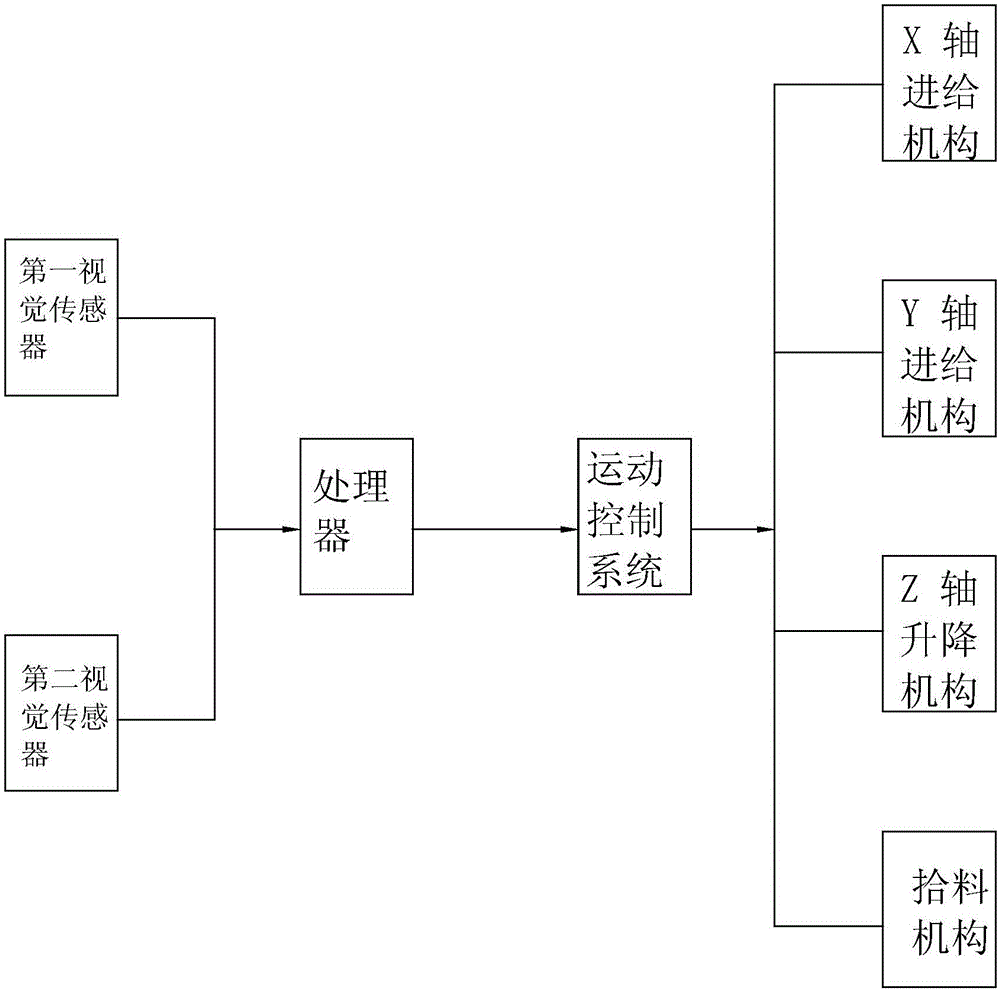

[0041] refer to Figure 1 to Figure 4 A placement machine shown includes a workbench 1 and a motion control system all arranged on the workbench 1, an X-axis feed mechanism 2, a Y-axis feed mechanism 3, and a Z-axis lift mechanism (the The X-axis feed mechanism 2, the Y-axis feed mechanism 3, and the Z-axis lifting mechanism are all described in detail in the invention patent with the application number 201410444923.6. The applicant does not explain the X-axis feed mechanism 2 and the Y-axis feed mechanism one by one. Concrete structure of feeding mechanism 3, Z-axis lifting mechanism) and material picking mechanism 5.

[0042] refer to figure 1 As shown, the pick-up mechanism 5 can move forward and backward in the X-axis direction under the action of the X-axis feed mechanism 2, and can move left and right in the Y-axis direction under the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com