A cyclone demister

A mist eliminator and cyclone technology, which is applied in the field of gas-liquid separation equipment, can solve problems such as it is difficult to meet the emission standards of flue gas, and achieve the effects of reducing one-time investment costs, avoiding secondary entrainment, and improving mist removal efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

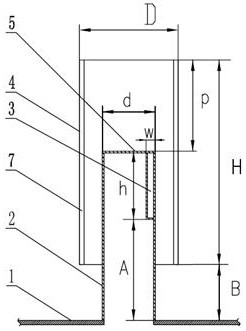

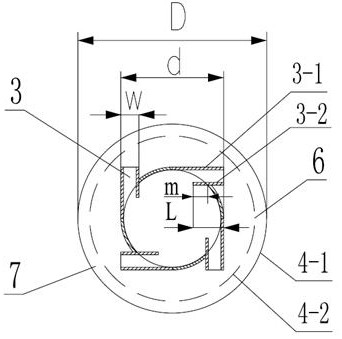

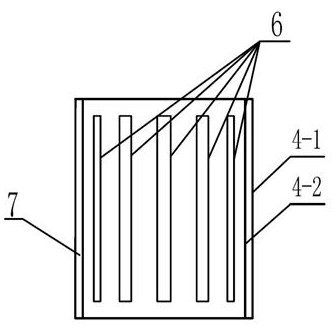

[0057] as attached Figure 1~3 As shown, the lower end of the gas riser 2 of the cyclone demister is flush with the tray 1, and four rectification channels 3 are arranged on the gas riser 2. The cross-sectional shape of the rectification channel 3 is rectangular, and the side wall II 3-2 of the rectification channel 3 The end extends into the interior of the air riser 2 for a certain distance m, m is 0.5 times the length L of the rectification channel 3, L is 3.5 times the width w, and the total cross-sectional area of the rectification channel 3 is 0.8 times the cross-sectional area of the air riser 2, The distance A between the bottom of the rectifying channel 3 and the tray 1 is 100 mm.

[0058] The outer cylinder 4 of the cyclone demister is a cylinder, the diameter D of the outer cylinder 4 is three times the diameter d of the air riser 2, and the distance P between the upper edge of the outer cylinder 4 and the upper edge of the air riser 2 is the height h of the rec...

Embodiment 2

[0062] as attached Figure 4~6 As shown, the lower end of the gas riser 2 of the cyclone demister is lower than the tray 1, the distance C between the lower end of the gas riser 2 and the tray 1 is 50mm, and the gas riser 2 is provided with 6 rectification channels 3, and the rectification channel 3 The cross-sectional shape is rectangular, the end of the side wall II 3-2 of the rectification channel 3 is flush with the inner wall of the air riser 2, the length L of the rectification channel 3 is 4 times the width w, and the total cross-sectional area of the rectification channel 3 is the cross section of the air riser 2 0.7 times the area, the distance A between the bottom of the rectifying channel 3 and the tray 1 is 300 mm.

[0063] The outer cylinder 4 of the cyclone demister is a cylinder, the diameter D of the outer cylinder 4 is 4 times the diameter d of the air riser 2, and the distance P between the upper edge of the outer cylinder 4 and the upper edge of the air ri...

Embodiment 3

[0067] as attached Figure 5 , 7 As shown in ~8, the lower end of the gas riser 2 of the cyclone demister is lower than the tray 1, the distance C between the lower end of the gas riser 2 and the tray 1 is 30mm, and 6 rectification channels 3 are arranged on the gas riser 2 (attached Figure 5 ), the cross-sectional shape of the rectification channel 3 is circular, the end of the side wall II 3-2 of the rectification channel 3 is flush with the inner wall of the air riser 2, the length L of the rectification channel 3 is 2.5 times the width w, and the total cut-off of the rectification channel 3 The area is 0.6 times of the cross-sectional area of the gas riser 2, and the distance A between the bottom of the rectifying channel 3 and the tray 1 is 350 mm.

[0068] The outer cylinder 4 of the cyclone demister is a cylinder, the diameter D of the outer cylinder 4 is 2.5 times the diameter d of the air riser 2, and the distance P between the upper edge of the outer cylinder 4 a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com