Liquid-collecting flow-guiding assembly and device

A liquid collection and assembly technology, applied in exhaust gas devices, combustion product treatment, combustion methods, etc., can solve problems such as condensate pollution of the environment, achieve outstanding technical advantages, avoid secondary entrainment, and optimize the effect of the chimney flow field

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043]In the vertical direction of the flue gas rising direction in the chimney 5, it is vertically in the horizontal direction of the flue gas rise.

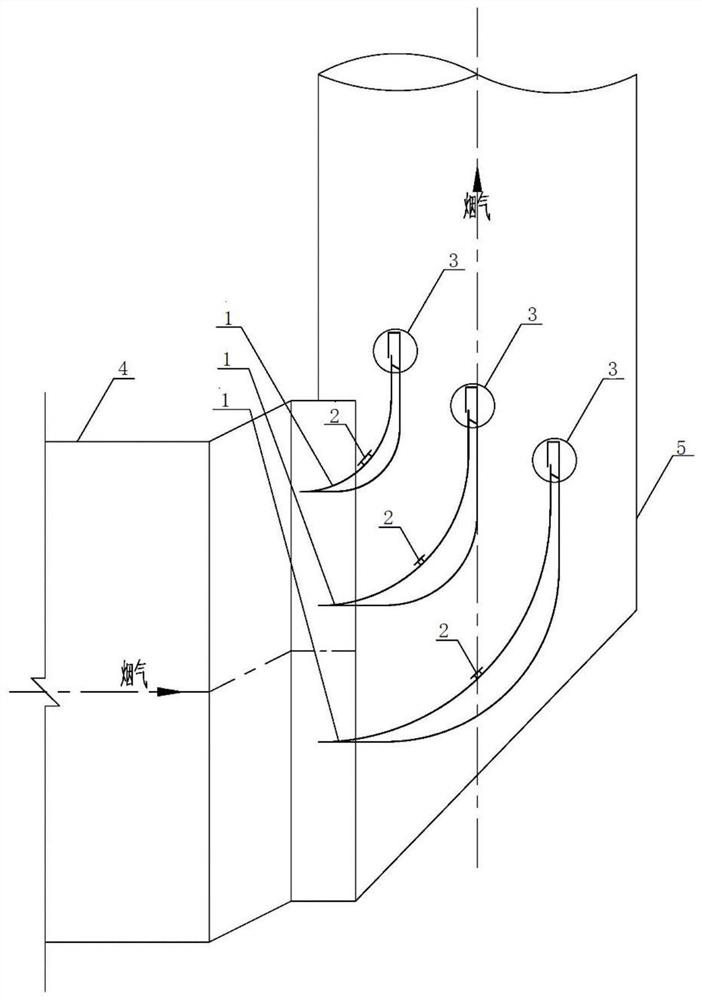

[0044]SeeFigure 1 to 5This embodiment provides a liquid collection flow assembly, including:

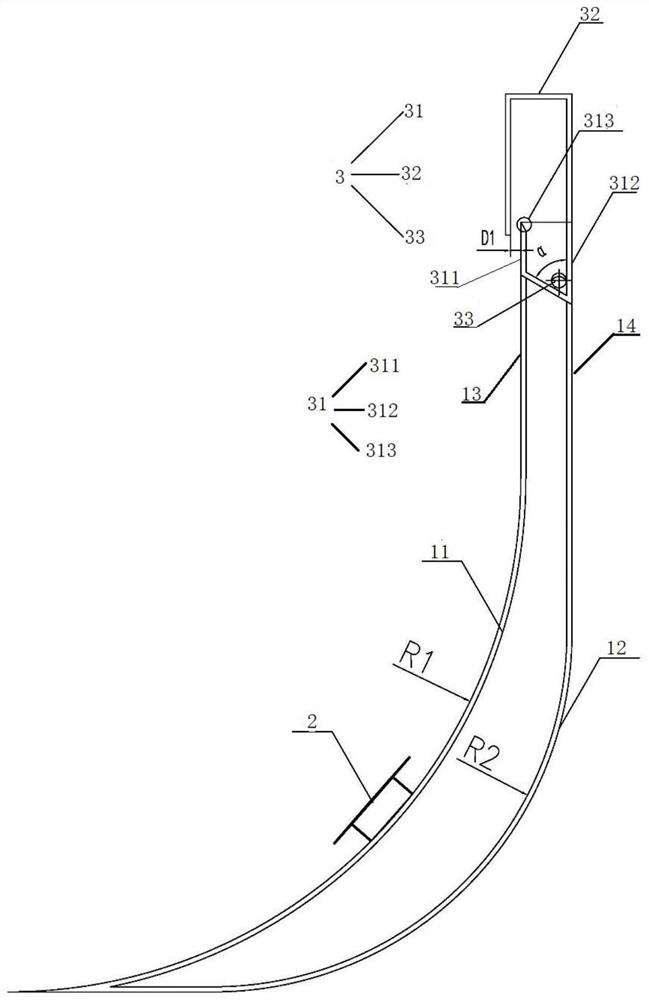

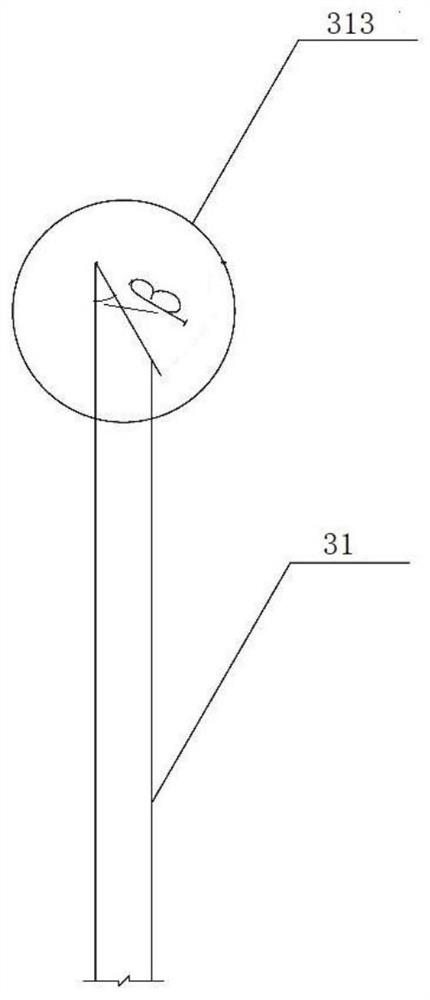

[0045]One or more heat exchange portions 1 disposed at the inlet of the lumen of the chimney 5, and the first collecting portion 2 and the second collecting portion 3 on the guide portion 1. On the left and right sides of the flow of the guide flow, the lumen wall surface is connected to the lumen surface of the chimney 5, and the flue gas flow channel is formed in the lumen surface of the chimney 5; wherein the flow channel 1 comprises the first and rear sides The circular arc surface and the second guiding surface, the center of the first passage of the arc surface and the second pilot curve is located on the same side of the guide portion 1, and the radius of the first passage arc surface is greater than the second guide. The radius of the arc...

Embodiment 2

[0055]Seefigure 1 In this embodiment, the present embodiment provides a liquid collection fluid device, from the entire working process to the liquid collection fluid flow from the whole process:

[0056]The cross-sectional size of the inner wall of the chimney 5, the cross-sectional size of the flue 4, the smoke port, and the simulation of the flue gas flow rate and combined with the CFD air flow tissue simulation, and several liquid collecting the flow of the flow of the flow of the flow rate increases step by step. The inner cavity of the chimney 5 or the adjacent flow passage portion 1 form a plurality of flue gas circulation channels, and the flue gas enters the chimney 5 after the flue 4, the flow of the flow line design of the flow of the liquid collecting the flow of the flow of the flow Next, the flue gas flow becomes slow, uniform, and the high flow rate is significantly reduced, and the flue gas flow field has been significantly improved, the system is compressed, and the op...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com