Semi-dry desulfurization and dust removal method for sludge sintering ceramic ceramsite waste gas

A technology of semi-dry desulfurization and sintered ceramics, which is applied in separation methods, chemical instruments and methods, gas treatment, etc., and can solve the problems of long wet desulfurization and dust removal process, high primary investment and operation costs, and large amount of desulfurization wastewater. , to achieve the effects of reduced floor space, reduced operating costs, and low investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

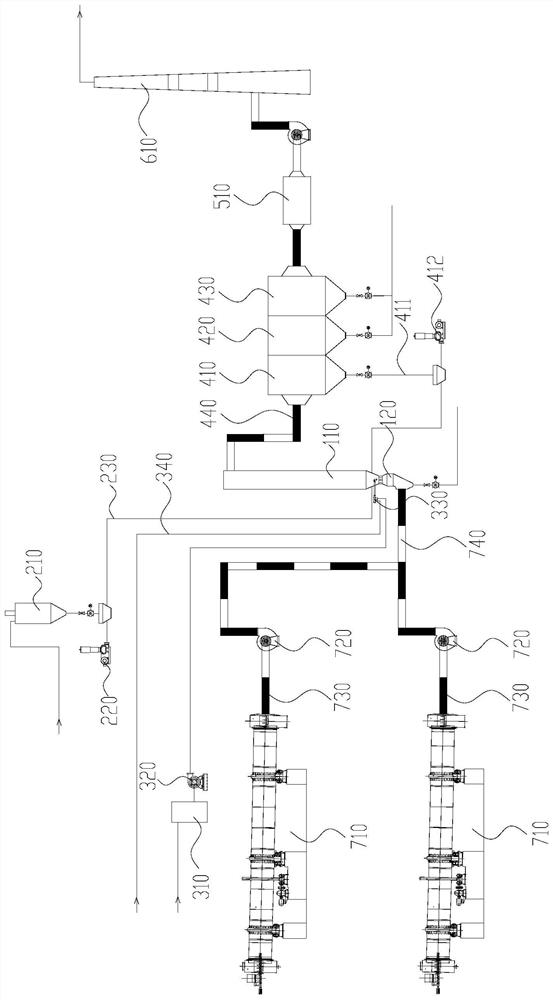

Method used

Image

Examples

Embodiment 1

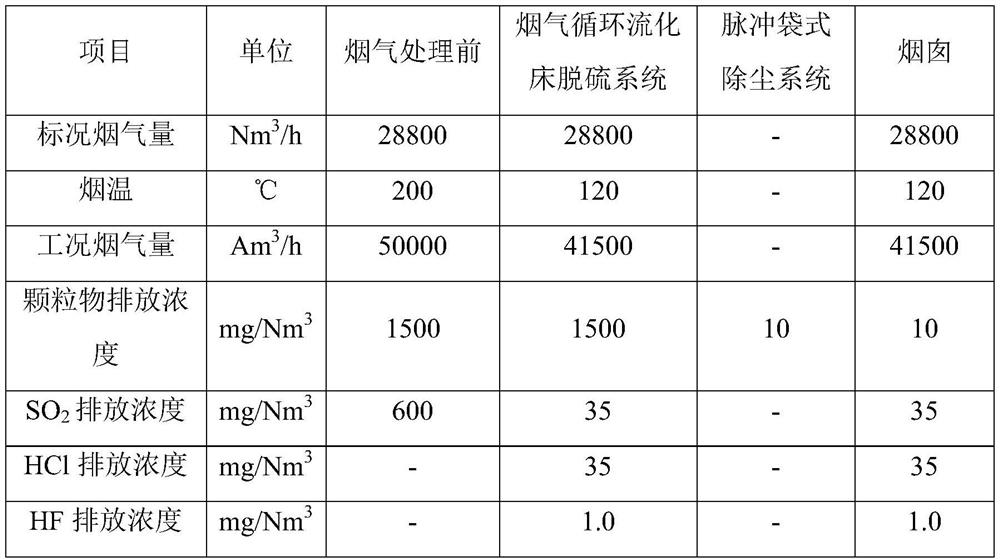

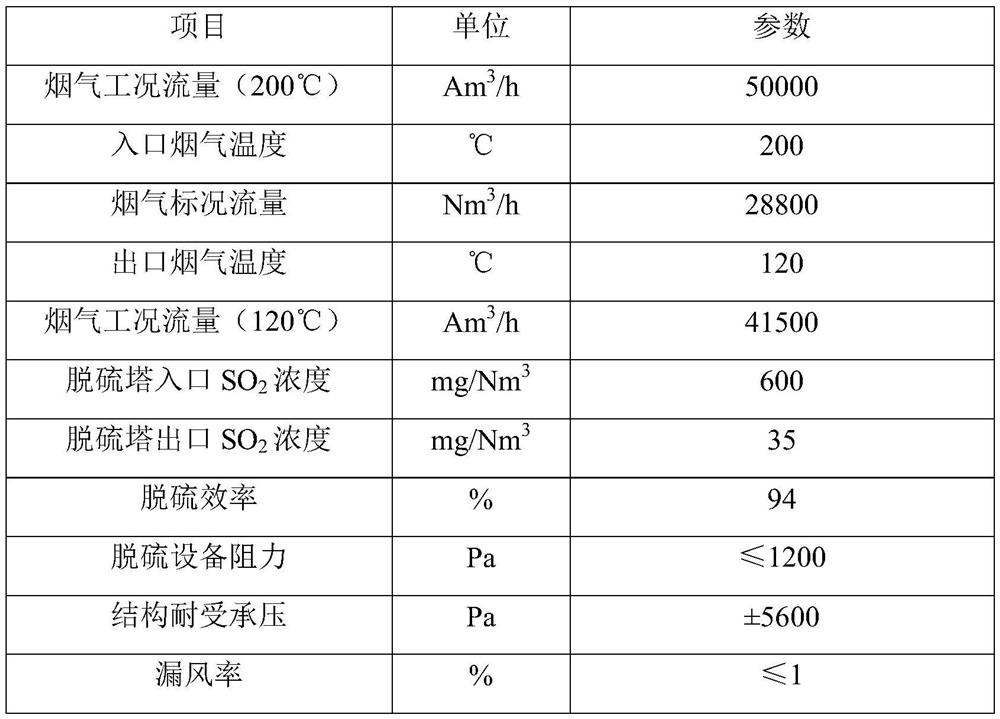

[0047] In a factory producing an environmentally friendly ceramsite filter, the generated exhaust gas is treated using the method of the present invention. Specifically, the present embodiment is processed using the following systems and methods.

[0048] Analysis of governance of sintering ceramic ceramic ceramic particles.

[0049] The plant produces environmentally-friendly ceramics filled with major raw materials, including buildings, river lakes, sludge, including municipal sludge, printing and dyed sludge, paper sludge and food sludge. The contaminants produced are mainly derived from the combustion decomposition of sludge organic components during ceramics of natural gas rotary kiln, mainly ingredients, acid gas (HF, HCl, SO) 2 SO 3 NO x , CO, heavy metals (CD, Ti, Sb, AS, PB, CR, CO, Cu, Mn, Ni, etc.), dioxin, a small amount of volatile organic (methane, ethane, propane, propionic acid, etc.), Some inorganic pollutants (NH 3 , HCN, etc.) and a lot of water vapor.

[0050] ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com