Treatment method of waste water discharged by silicon carbide micro powder production device

A technology for silicon carbide micropowder and production equipment, which is applied in chemical instruments and methods, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc. The effect of concentrated collection, easy collection and reduction of equipment investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

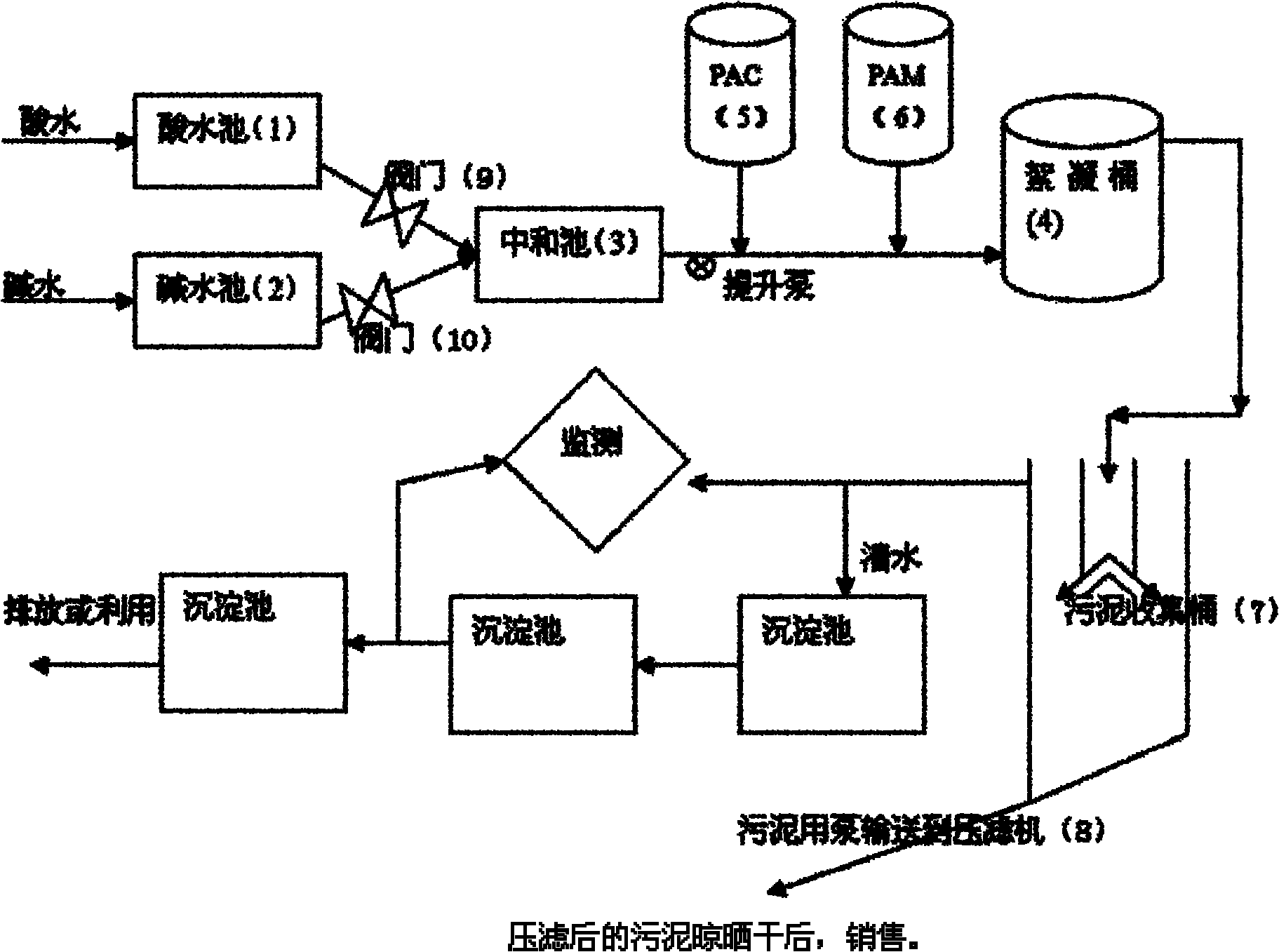

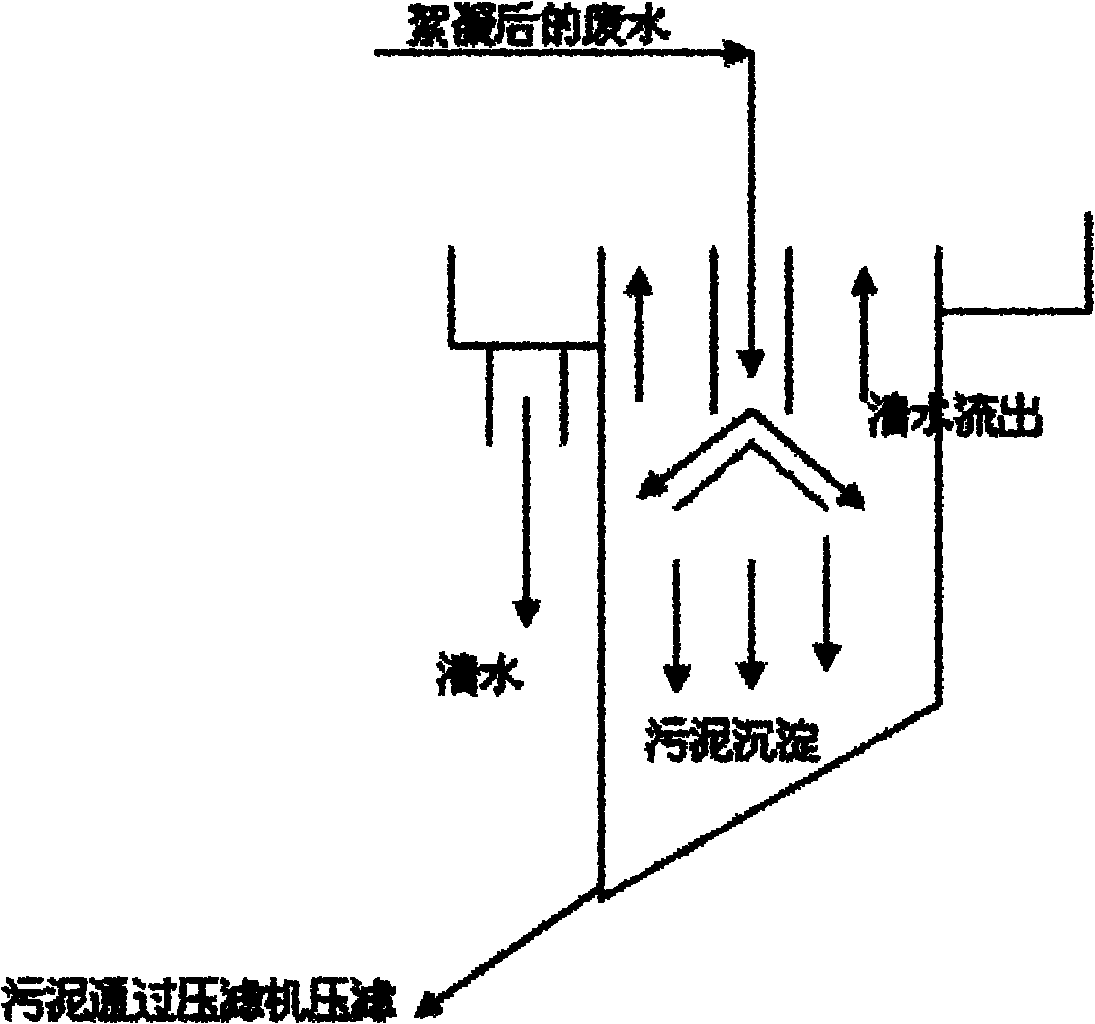

[0052] The method for treating wastewater discharged from a silicon carbide micropowder production device of the present invention is characterized in that:

[0053] ①. The wastewater discharged from the pickling section and the wastewater discharged from the alkali washing section are collected separately for pH adjustment of wastewater treatment;

[0054] ②. Composite flocculant formulated with inorganic flocculant A and organic flocculant B;

[0055] Including the following steps:

[0056] a. Neutralization

[0057] Appropriate amount of wastewater from pickling wastewater pool 1 and alkali washing wastewater pool 2 is controlled through valves 9 and 10, and added to the neutralization pool 3 of wastewater discharged from the silicon carbide micropowder production plant, and the pH is adjusted to 6-9;

[0058] b. Flocculation

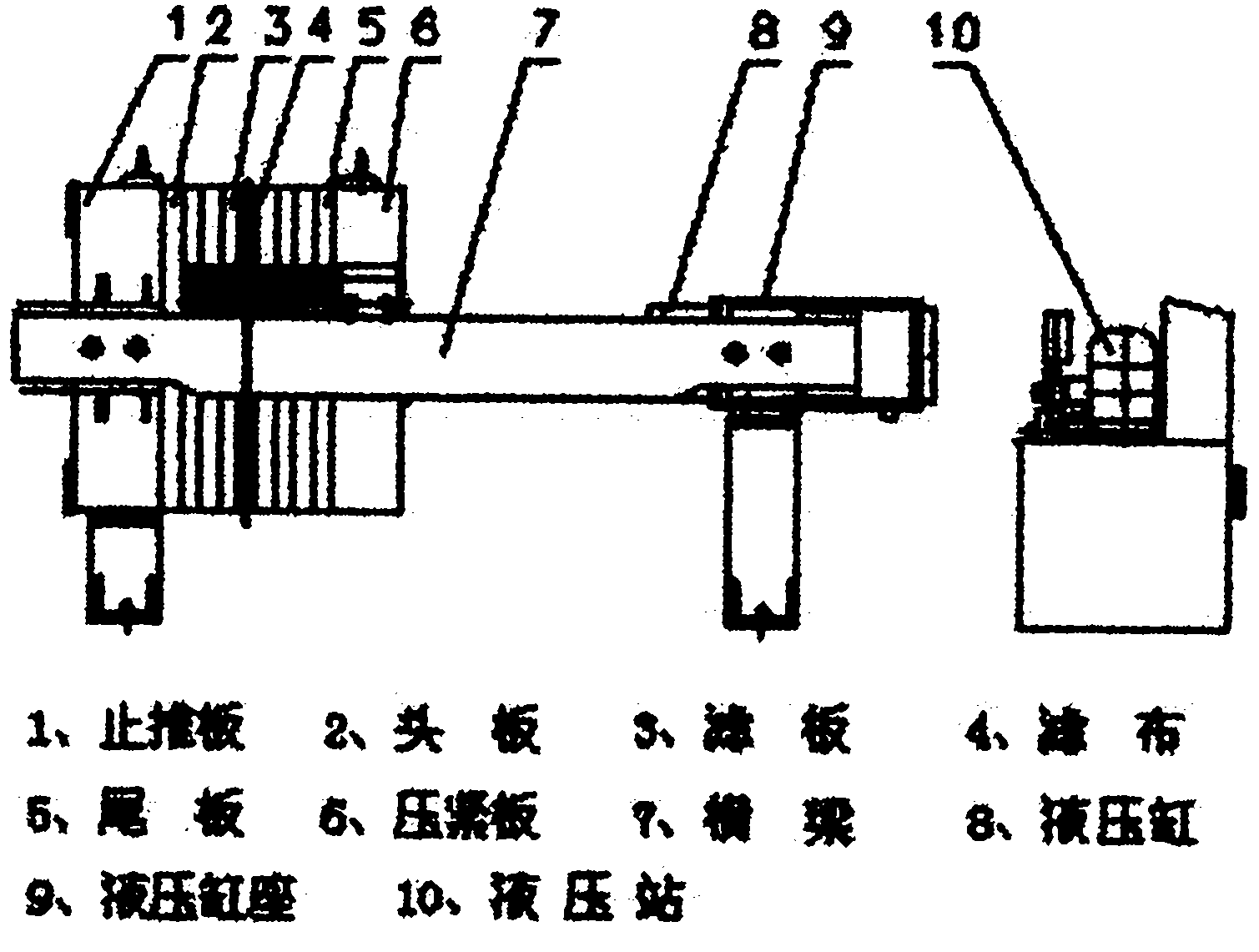

[0059] Pump the wastewater from the neutralization tank 3 with a pH of 6 to 9 into the flocculation tank 4, then add the inorganic flocculant A i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com