PTA production method with low energy consumption, low material consumption andlow refuse discharge

A waste discharge and production method technology, applied in chemical instruments and methods, preparation of organic compounds, separation/purification of carboxylic acid compounds, etc., can solve the problems of high energy consumption in dehydration systems, PT acid loss, and high cost of wastewater reuse , to achieve the effect of promoting energy saving, environmental protection and clean production, reducing sewage discharge, and reducing sewage discharge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

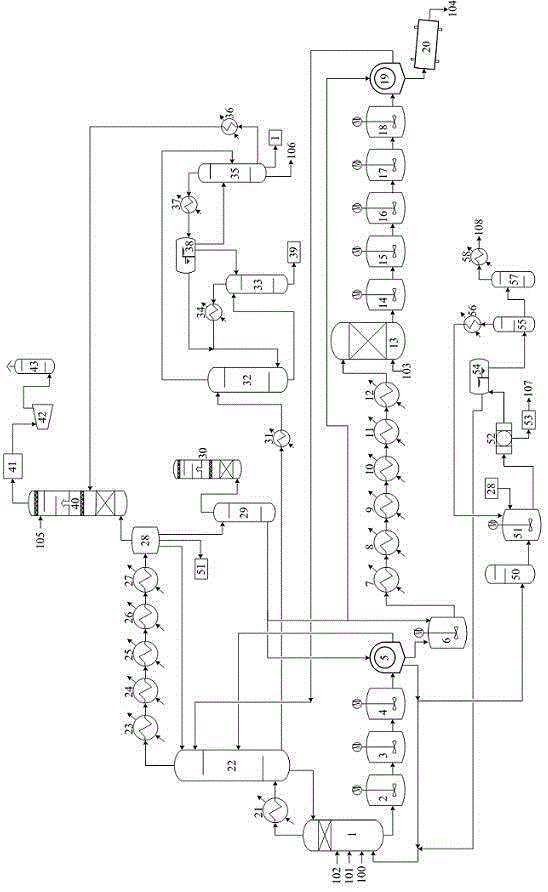

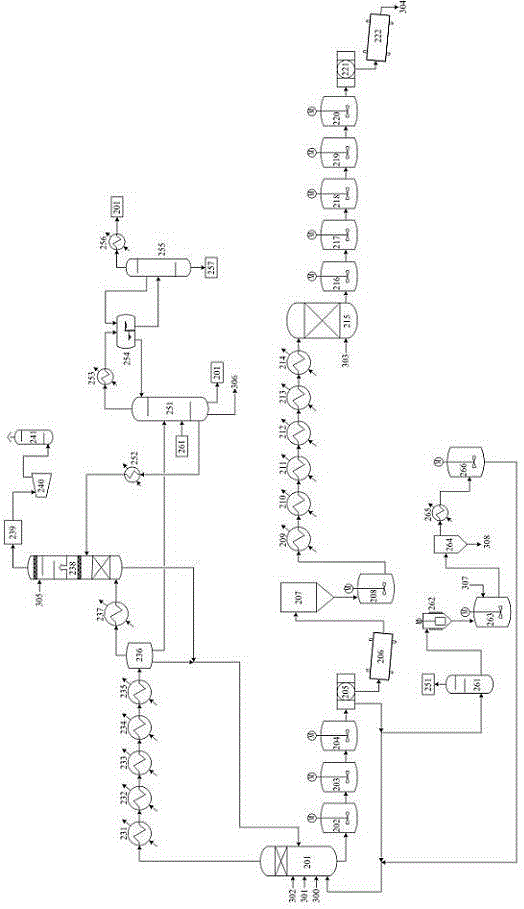

[0056] figure 1 Provided to implement the technological process of the present invention, comprise following five components:

[0057] (1) P-xylene oxidation subsystem: In the oxidation reactor 1, acetic acid is used as the solvent, cobalt acetate, manganese acetate, and hydrobromic acid are used as the catalyst, and the raw material p-xylene 100 and air 101 are reacted under the action of the catalyst 102 to form CTAs. The reactor is a non-stirred reactor with a dehydration section, and it can also be any type of reactor used in other existing PTA devices. The operating temperature is 180-200 ° C, and the operating pressure is 1-1.5 MPa (absolute pressure). This references patents ZL03142246.2 and ZL200910076703.1 here. The dehydration section at the top of the tower plays the role of separating acetic acid and water and reducing solid phase entrainment. The height of the dehydration section can be adjusted according to the water content in the oxidation reactor, the steam...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com