Modular integrated system and technology for treating non-fermented bean product production wastewater

A technology for producing wastewater and integrated systems, applied in the field of modularized integrated systems and processes, can solve problems such as insufficient system load, system instability, and microbial death, and achieve energy saving and cost savings in operation, advanced process combination technology, and modularization high degree of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

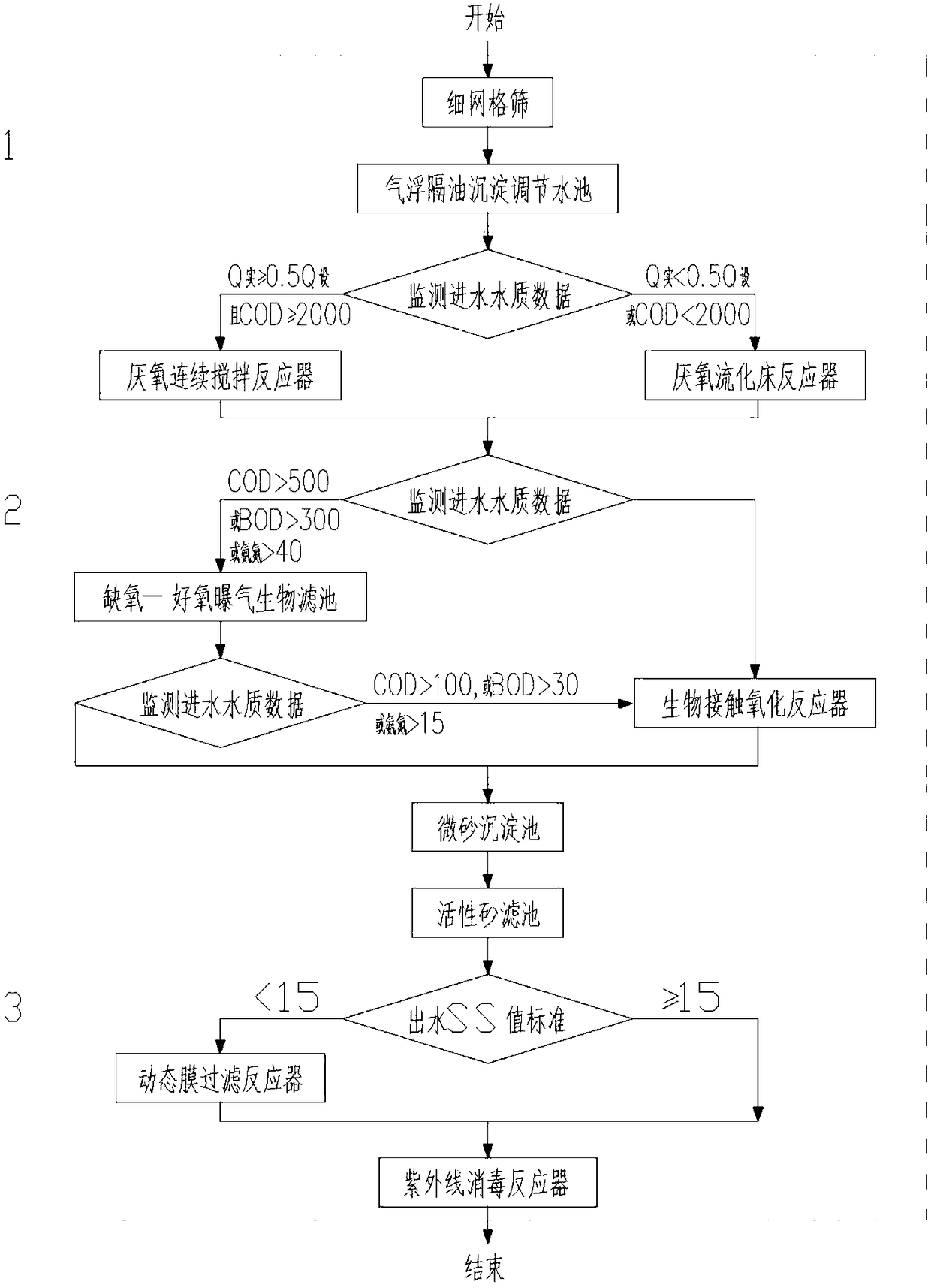

[0073] This embodiment adopts figure 1 The modular integrated process system and method shown in the figure treat wastewater from a non-fermented bean product processing factory in Shenyang. During the treatment process: the design mesh size of the fine mesh screen is 10 mm; The design residence time of the zone reaction zone is 5min, the design flow velocity of the contact chamber in the air flotation zone is 0.05m / s, the design residence time of the contact chamber is 2min, and the surface load of the separation chamber in the air flotation zone is 6m 3 / (m 2 h); oil separation area, design 2-stage oil separation lower baffle, 1st-stage oil separation upper baffle, 1 float oil skimmer, the float oil skimmer is set in front of the oil separation upper baffle; sedimentation area, including sediment 2 buckets, 1 set of slag discharge system; the design residence time of the regulating pool is 12h;

[0074] The design load of the anaerobic fluidized bed reactor is 5kgCOD / (m 3...

Embodiment 2

[0080] This embodiment adopts figure 1 The modular integrated process system and method shown in the figure treat wastewater from a non-fermented bean product processing factory in Shenyang. During the treatment process: the design mesh size of the fine mesh screen is 10 mm; The design residence time of the zone reaction zone is 5min, the design flow velocity of the contact chamber in the air flotation zone is 0.05m / s, the design residence time of the contact chamber is 2min, and the surface load of the separation chamber in the air flotation zone is 7m 3 / (m 2 h); oil separation area, design 2-stage oil separation lower baffle, 1st-stage oil separation upper baffle, 1 float oil skimmer, the float oil skimmer is set in front of the oil separation upper baffle; sedimentation area, including sediment 3 buckets, 1 set of slag discharge system; the design residence time of the regulating pool is 20h;

[0081] The design load of the anaerobic fluidized bed reactor is 6kgCOD / (m 3...

Embodiment 3

[0087] This embodiment adopts figure 1 The modular integrated process system and method shown in the figure treat wastewater from a non-fermented bean product processing factory in Shenyang. During the treatment process: the design mesh size of the fine mesh screen is 10 mm; The design residence time of the zone reaction zone is 5min, the design flow velocity of the contact chamber in the air flotation zone is 0.05m / s, the design residence time of the contact chamber is 2min, and the surface load of the separation chamber in the air flotation zone is 8m 3 / (m 2 h); oil separation area, design 2-stage oil separation lower baffle, 1st-stage oil separation upper baffle, 1 float oil skimmer, the float oil skimmer is set in front of the oil separation upper baffle; sedimentation area, including sediment 4 buckets, 1 set of slag discharge system; the design residence time of the regulating pool is 24h;

[0088] The design load of the anaerobic fluidized bed reactor is 8kgCOD / (m 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com