Nearly horizontal narrow vein panel mining method

A mining method and ultra-thin ore technology, which is applied in ground mining, mining equipment, earth square drilling, etc., can solve the problem of increased dilution rate of mining width stope, affecting mining efficiency, and inability to use high-efficiency mining equipment and other issues, to achieve the effect of improving resource recycling and improving the efficiency of mining operations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0026] like figure 1 As shown, the panelized mining method of near-horizontal extremely thin veins, the method is carried out according to the following steps:

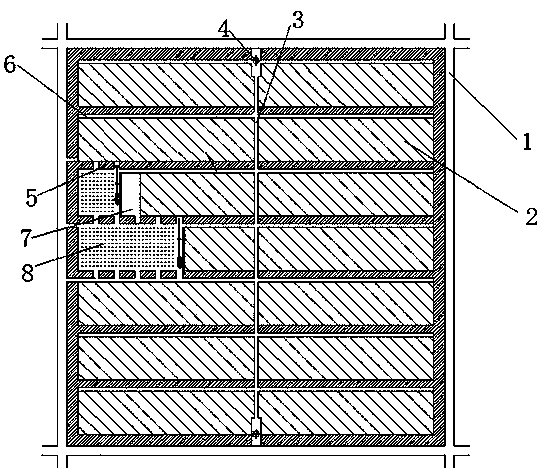

[0027] Step 1: Firstly, divide the ore body into a 200m×200m panel area 1 by developing roadways in the vein along the direction of the ore body;

[0028] Step 2: Divide ore block 2 in panel 1, each ore block 2 has a width of 22-26m and a length of panel 1, perpendicular to the direction of ore block 2, and arranges a 2m×2m strip in the center of panel 1 The main transportation lane 3 of the panel, and a panel chute 4 is arranged at both ends of the main transportation lane 3 of the panel;

[0029] Step 3: In the ore block 2, a stope 7 with a width of 22-26m and a height of 1.2m is arranged every 10m;

[0030] Step 4: Reserve a 4m×8m ore pillar 5 between every two ore blocks 2, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com