An open-pit mining method for mining inclined ore seams in medium-thick ore bodies

A mining method and thick ore body technology, applied in surface mining, underground mining, special mining, etc., can solve the problems that safety cannot be fully guaranteed, the production efficiency of mining enterprises is reduced, and labor intensity is high, so as to avoid roadway support operations, improving the efficiency of mining operations, and simplifying the mining process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The technical solution of the present invention is further described below, but the scope of protection is not limited to the description.

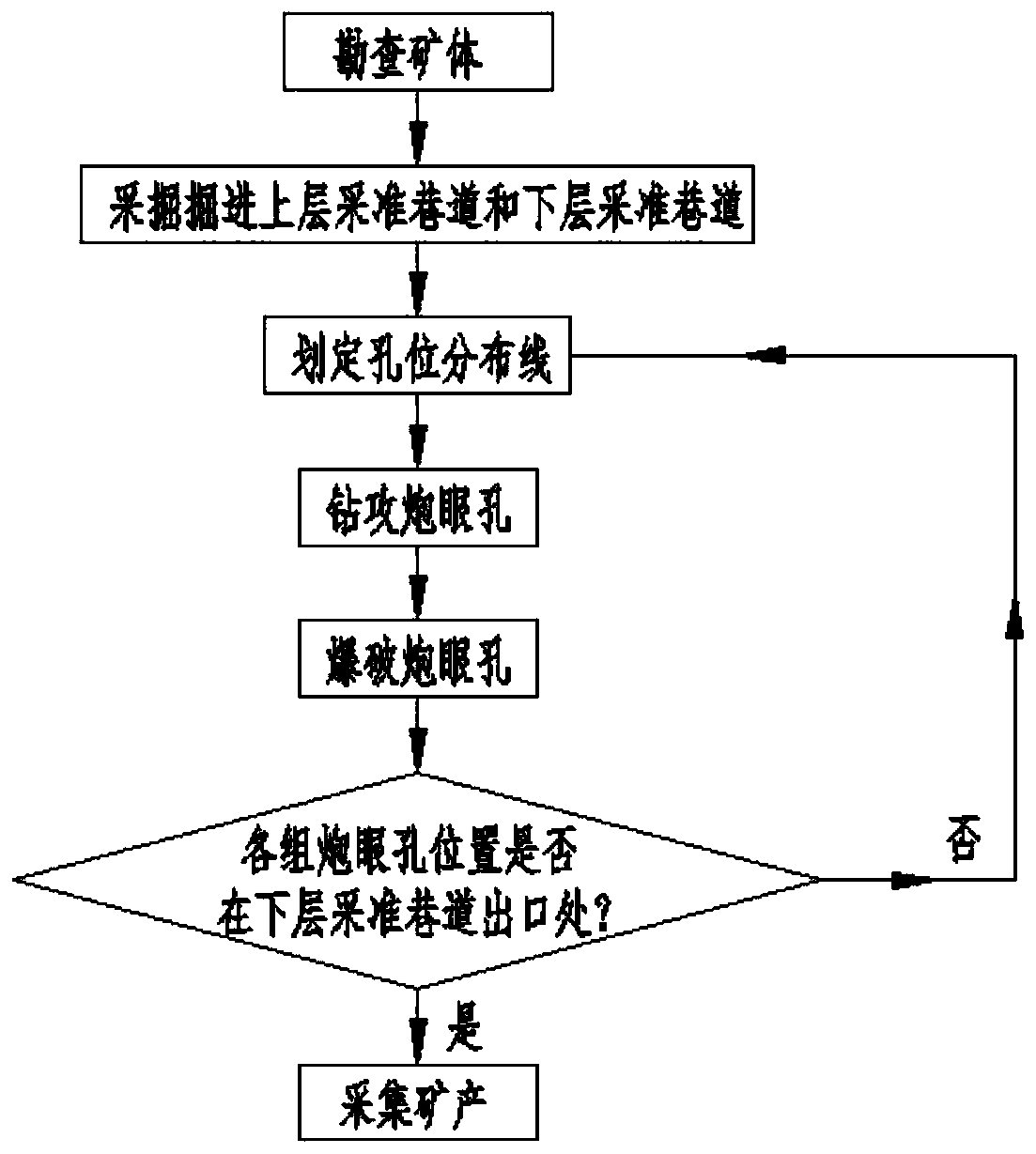

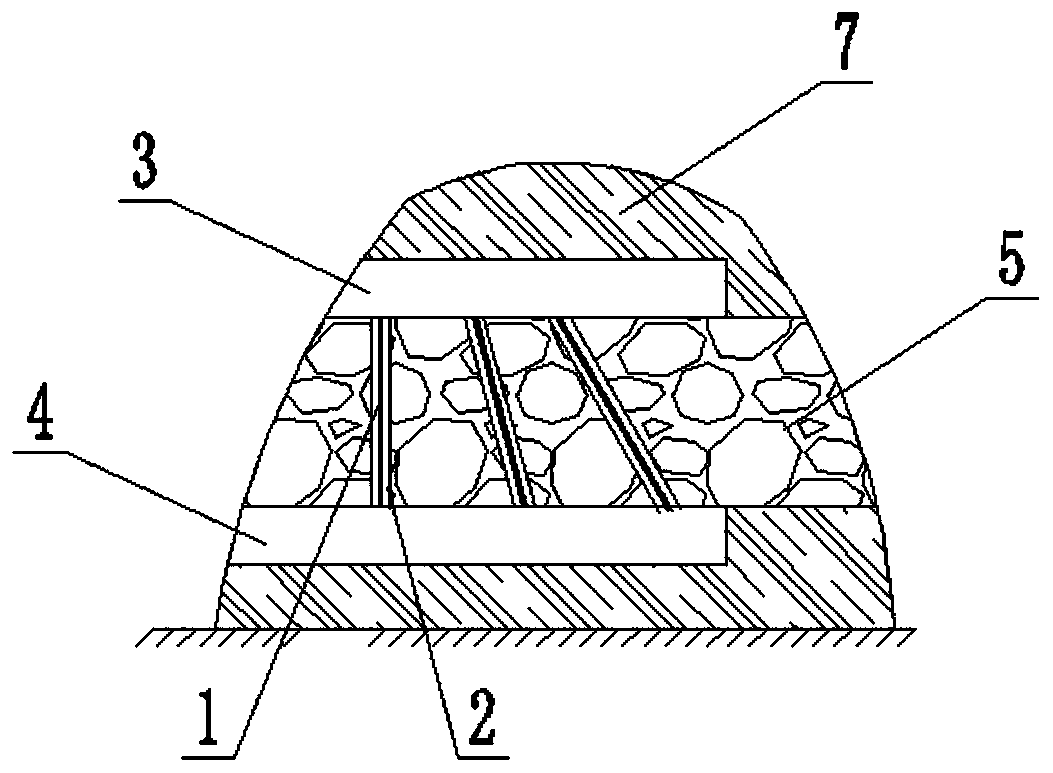

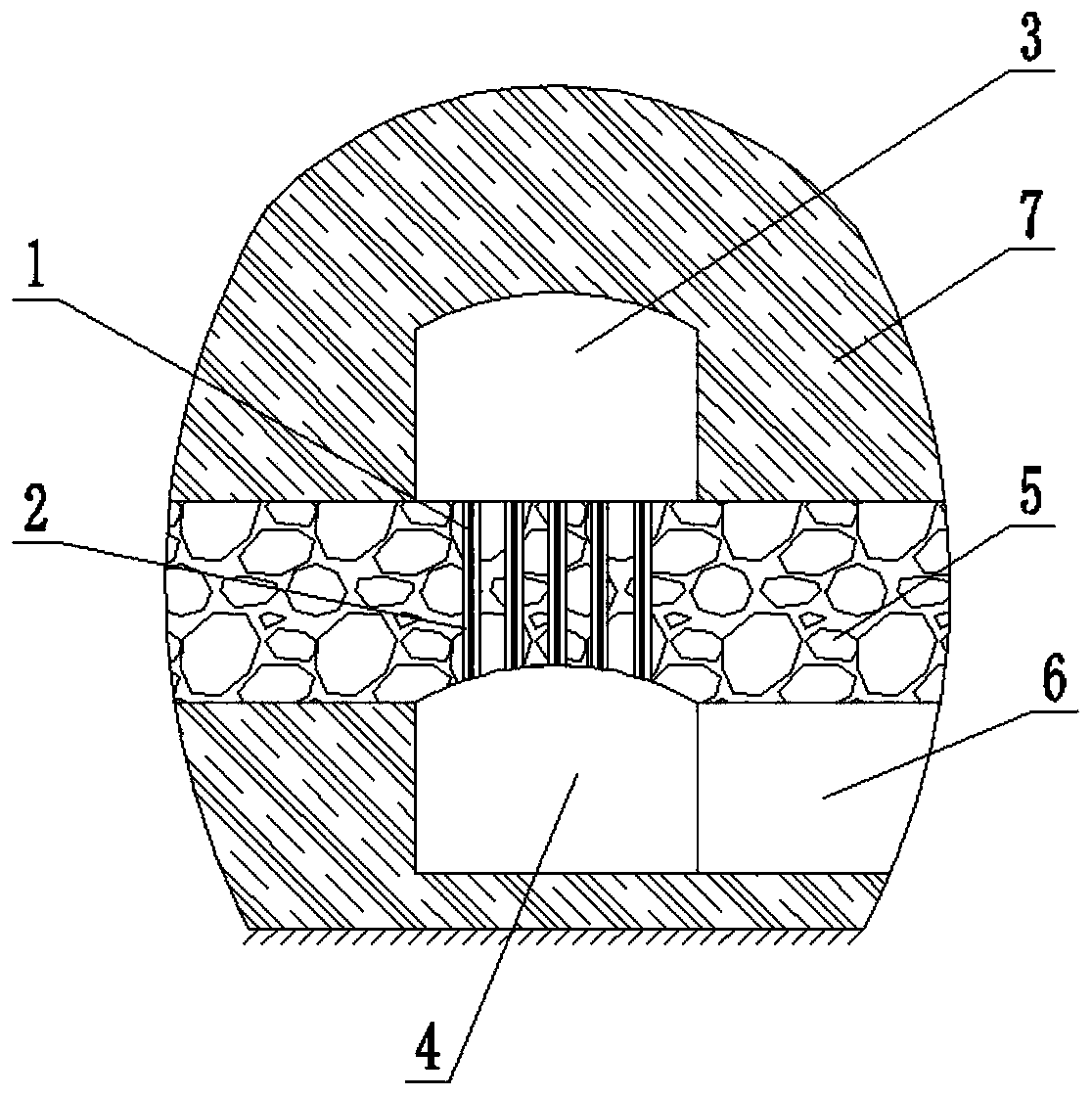

[0026] Such as figure 1 , figure 2 , image 3 As shown, the present invention provides a kind of open-field mining method of mining inclined ore seam in medium-thick ore body, comprises the following steps:

[0027] Step 1: Exploring the ore body: find a geological body with mining value somewhere in the geographical location as the ore body, and the ore body has an ore layer inclined relative to the horizontal plane;

[0028] Step 2: Excavating roadway: Excavate and excavate into the ore body described in step 1, and form an upper layer mining roadway and a lower layer mining standard roadway relatively parallel to each other at the upper and lower ends of the ore seam respectively; further, the tunneling roadway also includes Excavating into the ore body forms a development stone gate connected with the lower mining roadway, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com