A geothermal composite mining pipe for geothermal wells

A technology for geothermal wells and production pipes, applied in the field of geothermal energy development and utilization equipment, can solve the cost of fracturing operations and repeated implementation, the difficulty of cycle implementation, the influence of the continuity and reliability of geothermal resource extraction, and the low utilization rate of resources. and other problems, to achieve the effect of improving flexibility and reusability, improving mining capacity and service life, and improving resource recycling utilization.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

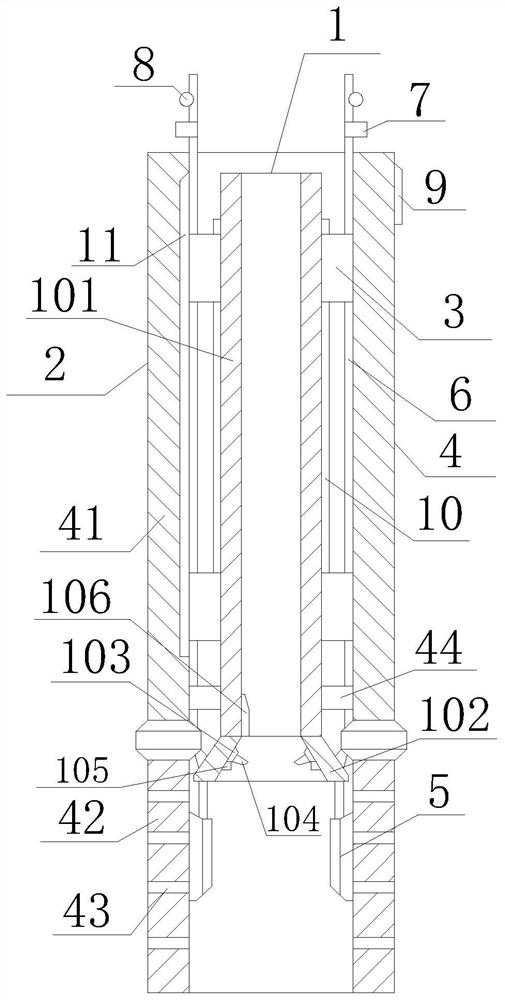

[0015] Such as figure 1 The geothermal composite recovery pipe for geothermal wells includes a drainage pipe 1, a carrier frame 2, a guide rail 3, a protective sleeve 4, a blast valve 5, a diversion pipe 6, a control valve 7, a pressure sensor 8, The connecting terminal 9 and the protective sleeve 4 are covered outside the extraction pipe 1, and are coaxially distributed with the extraction pipe 1. Several guide rails 3 are evenly distributed on the outer surface of the extraction pipe 1, and the guide rails 3 are connected with the extraction pipe 1. A closed ring structure with coaxial distribution of tubes 1, the inner surface of the protective sleeve 4 and the guide rail 3 are slidingly connected to each other, and at least one guide tube 6 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com