Patents

Literature

101results about How to "Improve the mining effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

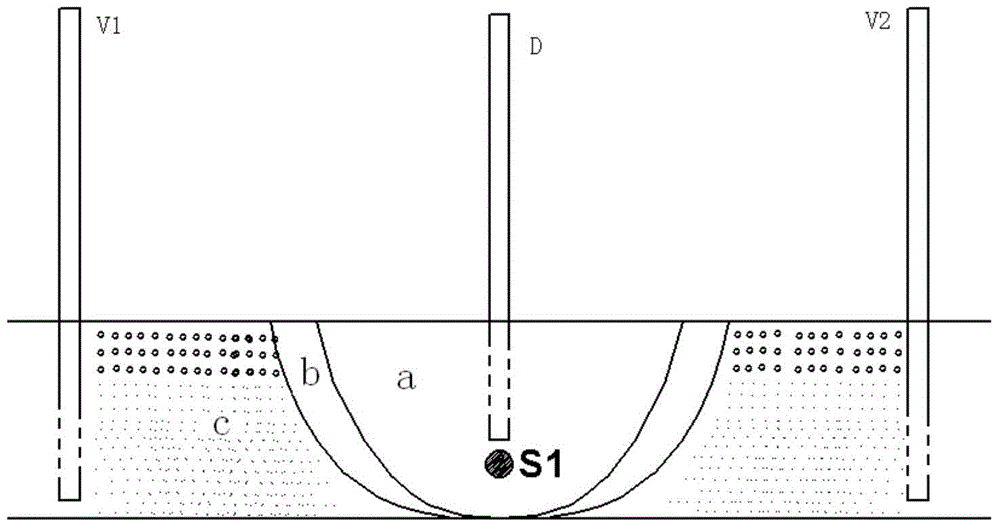

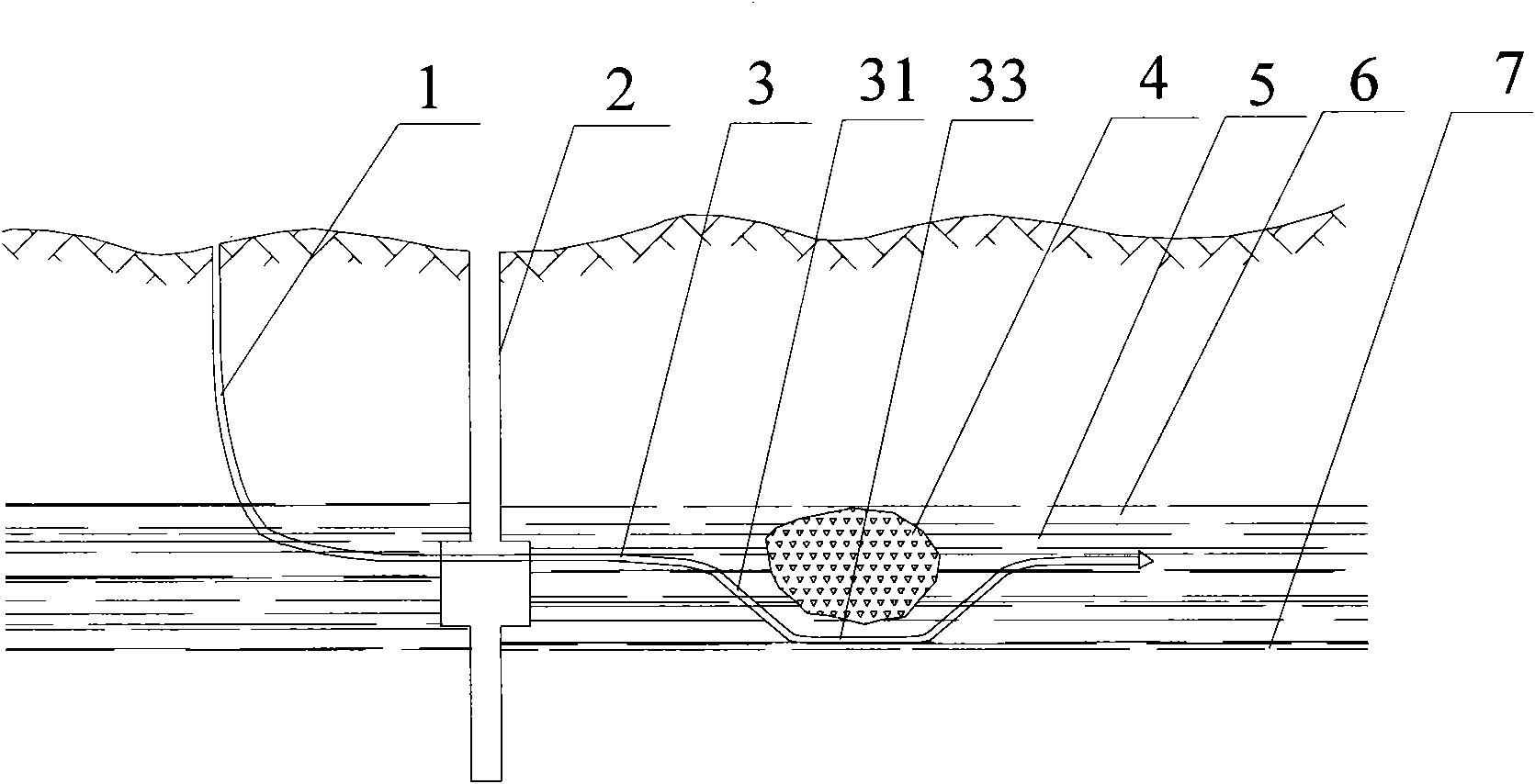

Mining method for heavy oil reservoir and well network thereof

The invention relates to a mining method for a heavy oil reservoir and a well network used in the same. The mining method comprises a well network arrangement stage, a preheating stage, a gravity fire flooding stage and a steam flooding stage; the gravity fire flooding stage comprises an ignition stage and a fire wire propulsion stage. The well network comprises a plurality of mining well groups. Each mining well group comprises a horizontal well, a middle vertical well and a plurality of side vertical wells, wherein the plurality of side vertical wells are arranged in two lines; the first line of the side vertical wells and the second line of the side vertical wells are symmetrical about the horizontal well; each line of side vertical wells are arranged at intervals in the direction from the tiptoe to the heel of the horizontal well and are in parallel to the horizontal well. According to the invention, combination of gravity fire flooding and steam flooding is adopted, so that utilization of heat after fire flooding is improved; thermal communication of injection and production wells is established by steam huff and puff auxiliary gravity fire flooding, so that a steam flooring mining effect is improved; well completion cost and drilling cost are reduced.

Owner:PETROCHINA CO LTD

High-temperature foam scrubbing agent for drainage gas recovery

The invention relates to a high-temperature foam scrubbing agent for drainage gas recovery. The agent comprises the following components in parts by weight: 10-15 parts of sodium lauryl sulfate, 2-5 parts of alkyl glucoside, 15-18 parts of AES ( Alcohol Ether Sulphate), 20-25 parts of sodium lauryl sulfonate, 5-10 parts of biosurfactant and 27-48 parts of water. The high-temperature foam scrubbing agent has very high thermal stability and high foamability.

Owner:SUNCOO PETROLEUM TECH

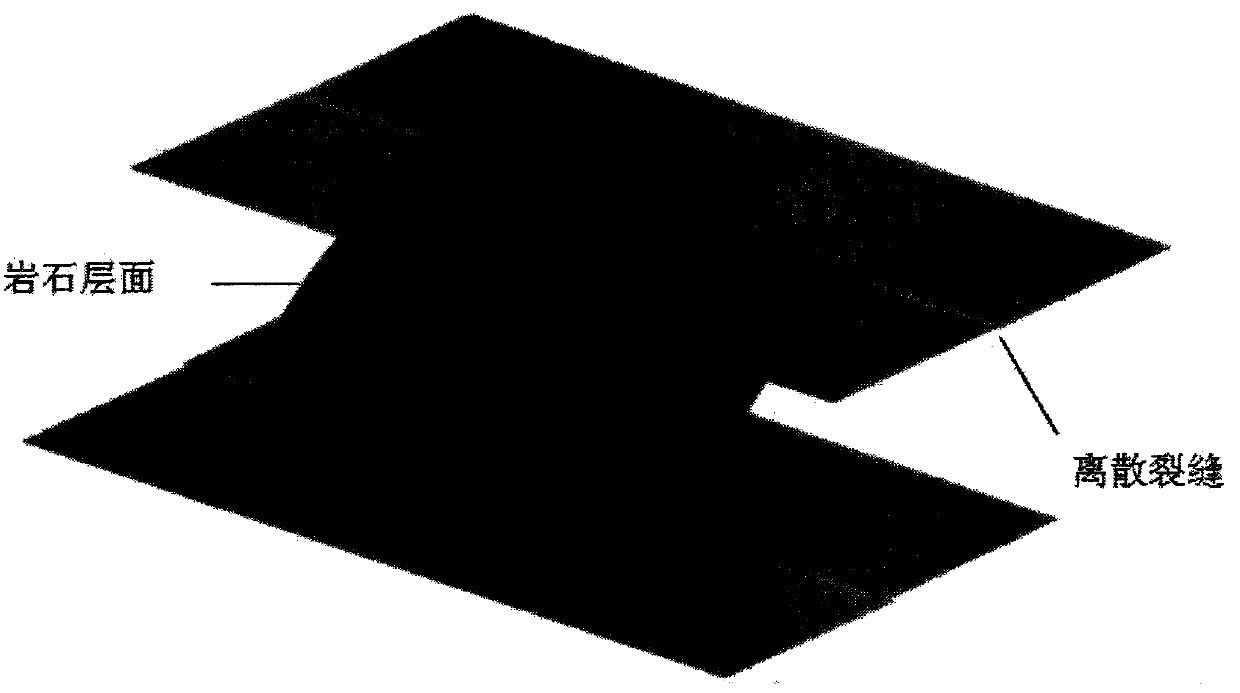

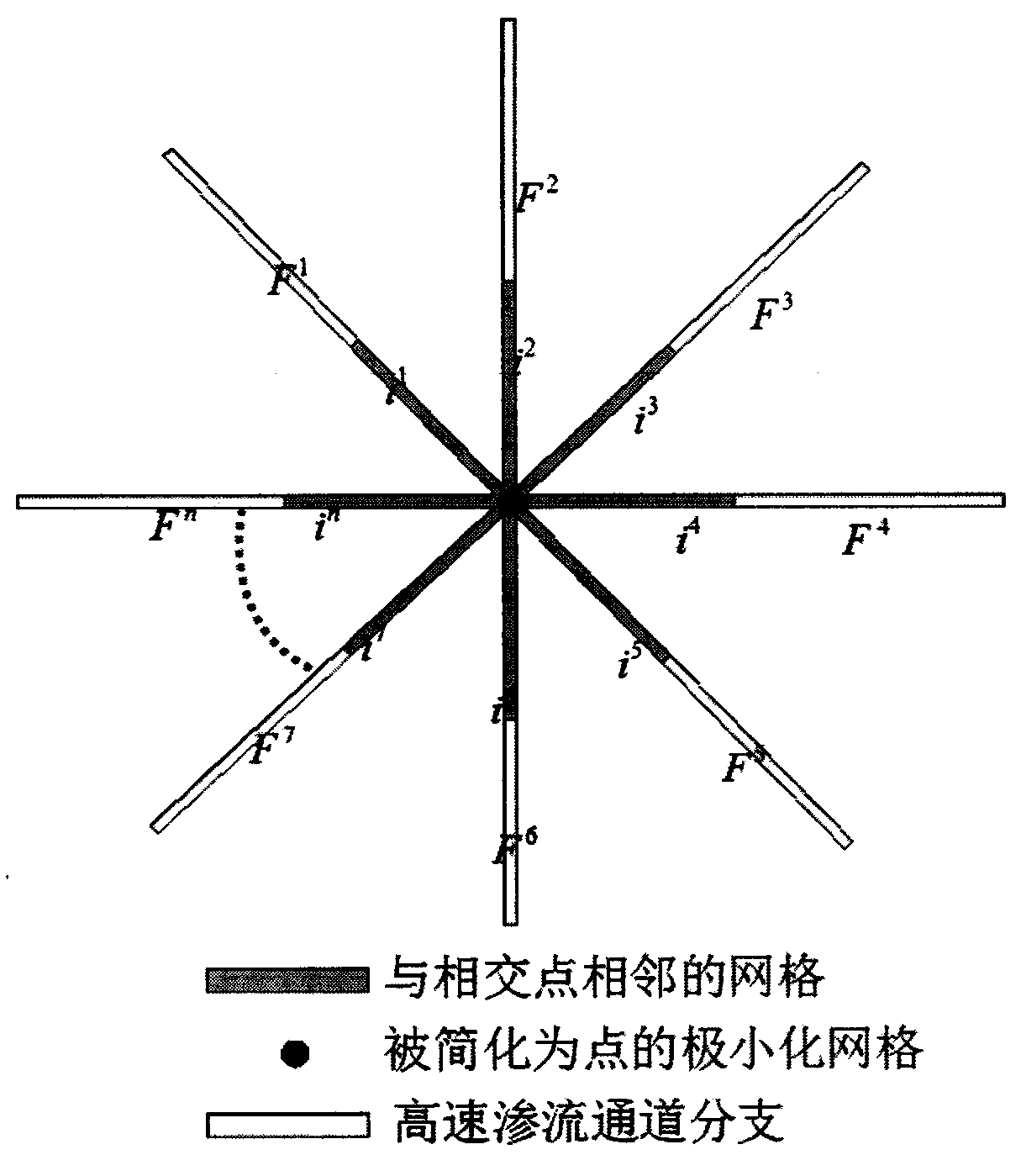

Numerical reservoir simulation method for measuring flowing situation of a plurality of intersected discrete cracks

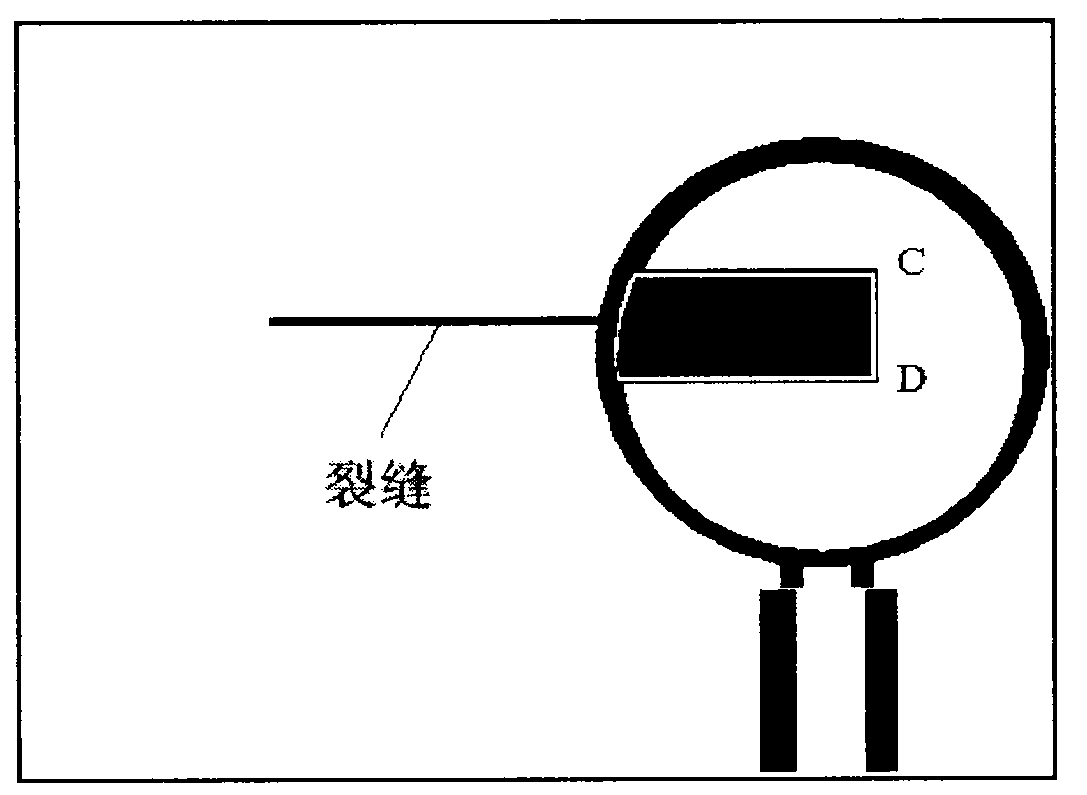

InactiveCN103400020ADoes not affect calculation resultsSolve the problem of excessSpecial data processing applicationsLine segmentOil well

The invention discloses a numerical reservoir simulation method for measuring the flowing situation of a plurality of intersected discrete cracks. The method comprises the steps that a reservoir is divided into a continuous medium and a discrete crack medium; in order to remove extremely small grids, when a reservoir grid is created, a discrete crack endpoint is deformed or is simplified to be a segment by neglecting the thickness, then a rock stratum face grid is established, and a three-dimensional reservoir grid is established; practically measured reservoir parameters of holes, leakage, saturation and the like are input into a simulator, then a real value instead of a grid display value is used as the width of each discrete crack, and accuracy of a measured and calculated result is not lowered by deformation processing; the volume of the intersecting area of the discrete cracks is neglected, and a flow formula of the discrete cracks in the intersecting area is established; the reservoir parameters are corrected by utilizing the history fitting method; then well yield and remaining oil gas distribution and reserves are measured and calculated. The numerical reservoir simulation method can solve the problems that the discrete crack value simulation technology is prone to interruption and failure and is long in consumed time for measurement and calculation, so that the technology can achieve measurement and calculation in the whole process of full three-dimensional reservoir development, and improves accuracy of the measured and calculated result.

Owner:SOUTHWEST PETROLEUM UNIV +1

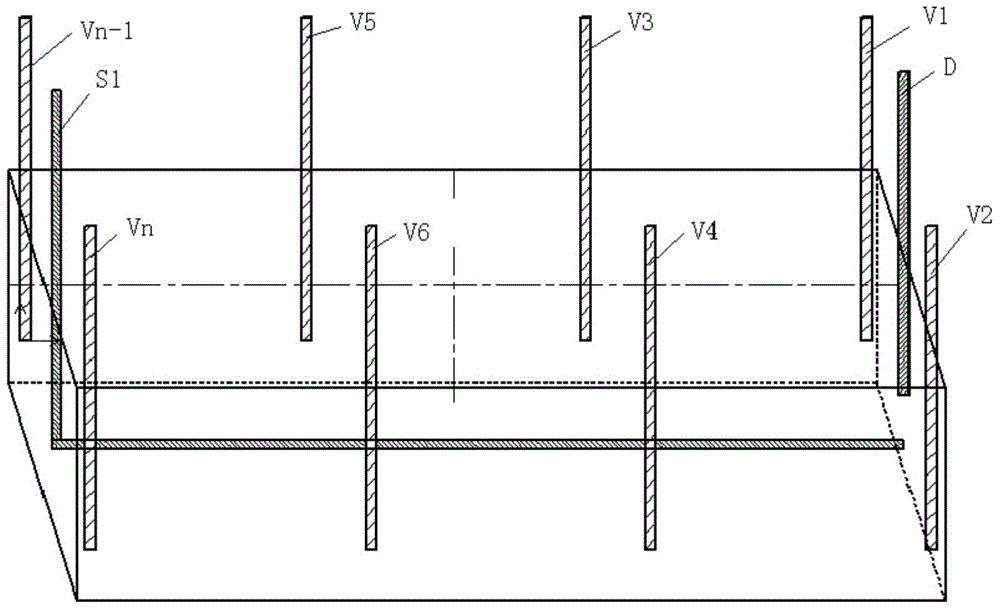

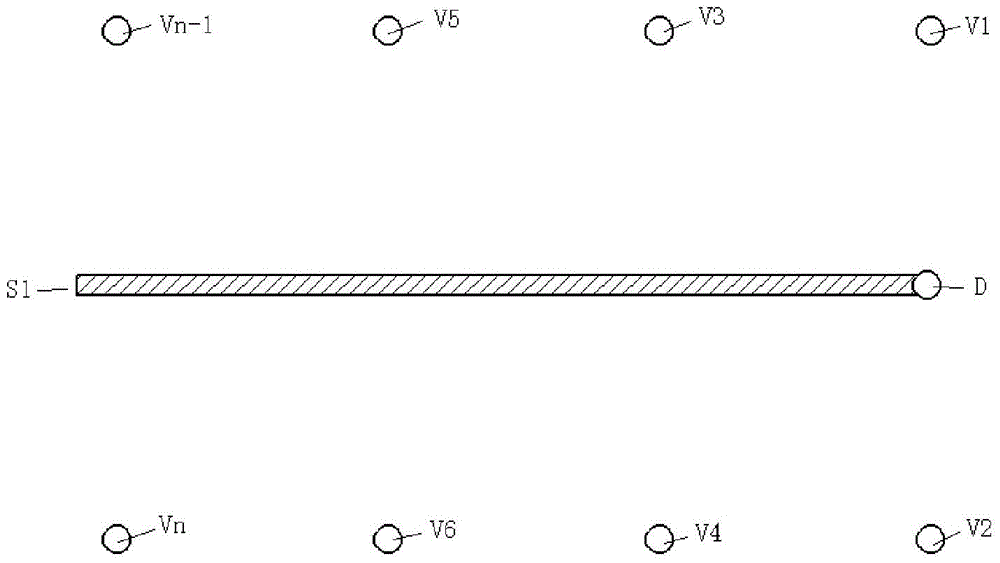

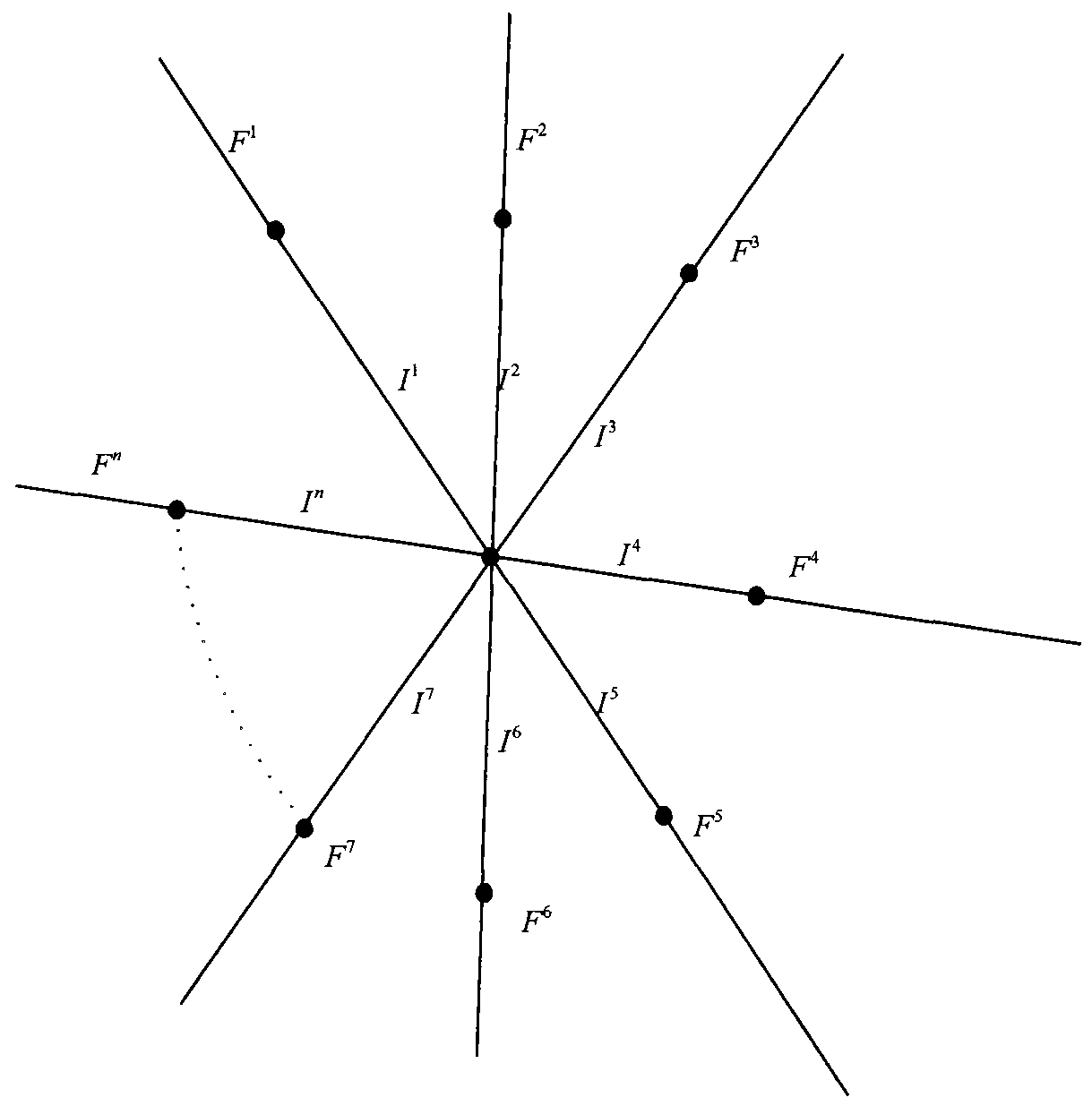

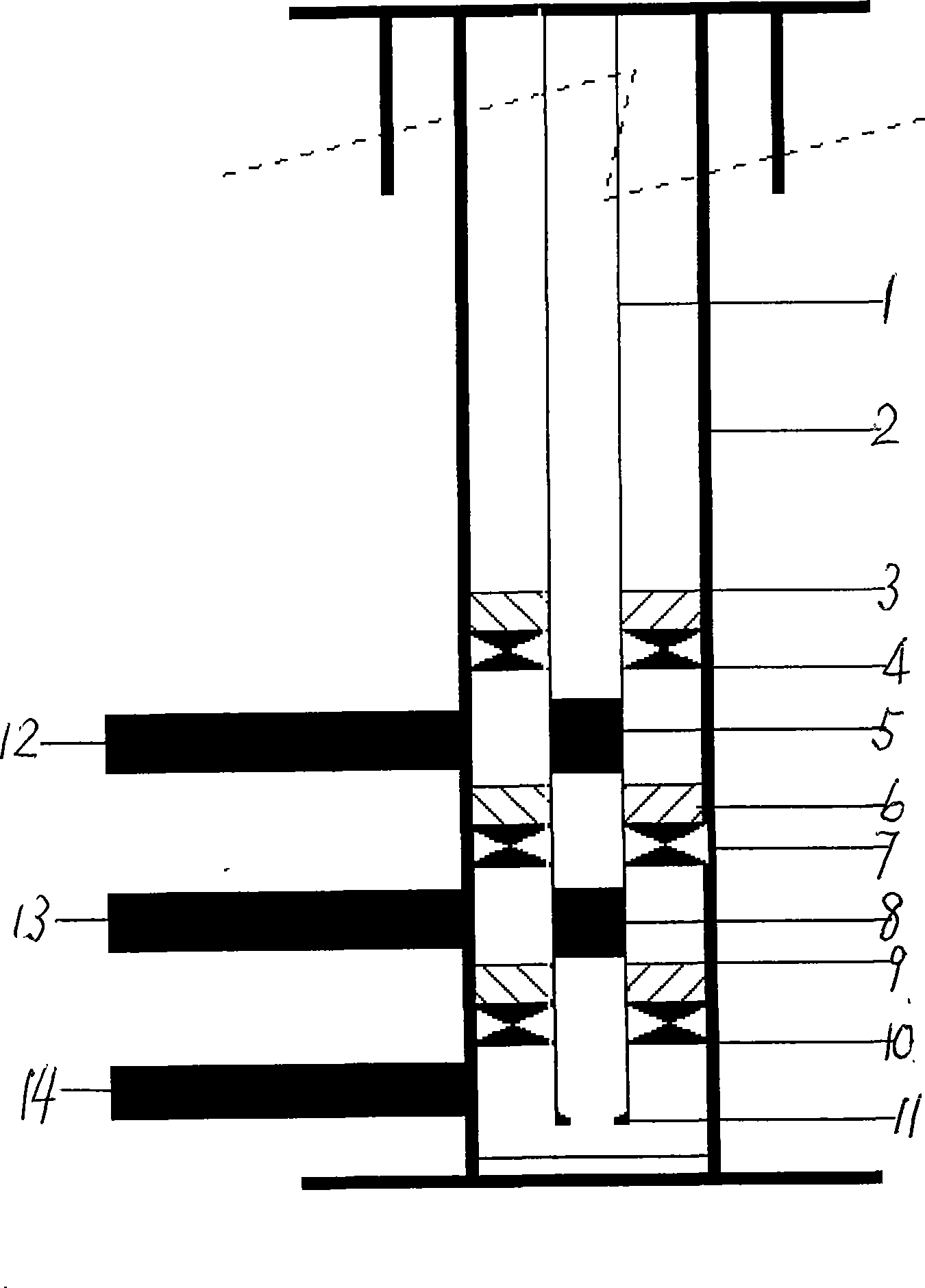

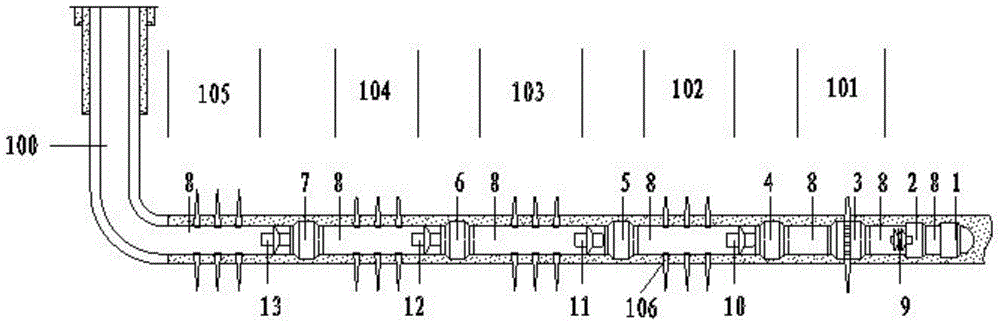

Method for uniformly injecting multi-component thermal fluid in horizontal well

The invention provides a method for uniformly injecting a multi-component thermal fluid in a horizontal well. The method comprises the following steps: (1) segmenting horizontal segments in the horizontal well; (2) initially setting the size of each discharge orifice on a tubular column in each segment of the horizontal well and the number of discharge orifices at a tail end; (3) detecting the temperature, pressure and dryness of the multi-component thermal fluid; (4) obtaining the on-way temperature, pressure, dryness and heat loss of each shaft segment of the horizontal well by iterative calculation; (5) obtaining the actual number of the discharge orifices on the tubular column in each segment of the horizontal well and the size of each discharge orifice by iterative calculation; and (6) drilling the tubular column based on the calculation result, putting the tubular column subject to drilling down into the well, and injecting the multi-component thermal fluid in the tubular column. The invention has the advantages of wide oil pool application range, relatively simple technology and low cost, and ensures that the oil pool at the horizontal well segment can be subject to uniform steam injection without changing the traditional well orifices and steam injection pipes. Besides, by using the invention, the producing degree of the oil reservoir is improved and the optimal exploitation effect can be ensured by injecting the multi-component thermal fluid in the horizontal well of the exploited oil pool.

Owner:CHINA NAT OFFSHORE OIL CORP +2

Once tubular column process for combination oil production by multiple fracturing for oil gas well

InactiveCN101418681AReduce operational riskShorten working timeDrilling rodsFluid removalOil productionOil field

The invention relates to a process for fracturing reconstruction and extraction for oil and gas well in oil field. In the process, different fracture technology parameters are determined based on geology materials, then down-hole tools such as a hydraulic anchor, a packer, a sliding sleeve, a ball cup and the like are put into the well in order, the packer is packed and the hydraulic anchor is anchored by once tamping, then deliver balls perform corresponding fracturing reconstruction to the oil gas reservoirs through the switch function of the sliding sleeves, and after the construction works are completed, the merged extraction can be performed. The process determines corresponding fracture pipe string structures based on different reservoirs and different fracture parameters, can realize the selective fracture reconstruction and commingled production mode for the reservior by onetime, has full controllability for each reservior fracture order, has little work risk, can greatly shorten the operation time of fracture construction, and can achieve the purpose of improving the yield of the oil and gas well and the extraction effect.

Owner:CNPC GREATWALL DRILLING ENG

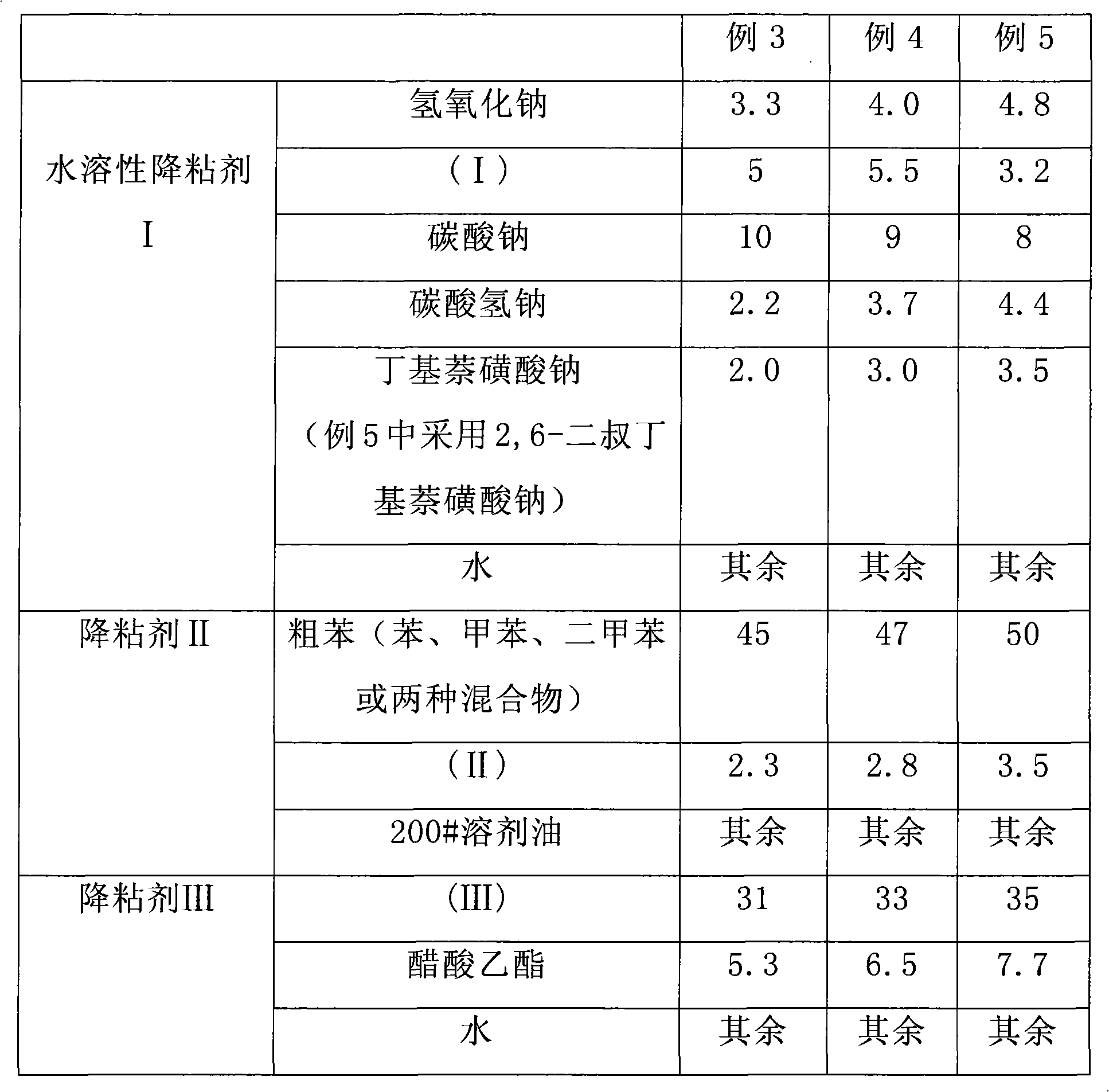

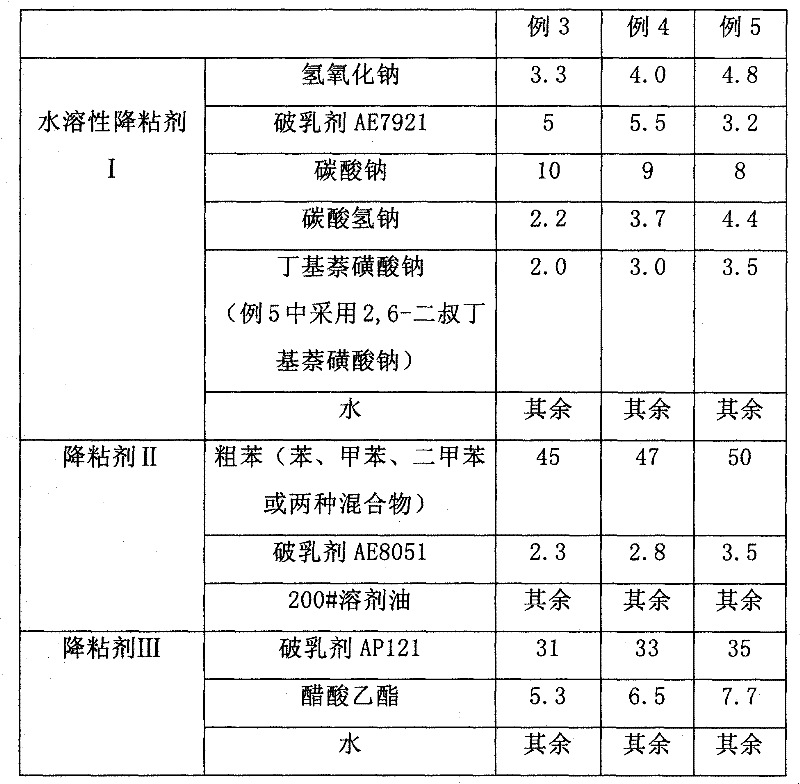

Method for extracting thick oil

ActiveCN101328798AImprove liquiditySolve the problem of difficult flow into the wellboreFluid removalDrilling compositionOil productionScrew pump

The invention provides a heavy oil cold production method applied to the production of oilfield heavy oil reservoirs at normal temperature and pressure. The method is characterized by comprising: a. a step of preparing water-soluble viscosity reducer I; b. a step of preparing viscosity reducer II; c. a step of preparing viscosity reducer III; d. a step of squeezing the water-soluble viscosity reducer I into oil reservoirs; and e. a step of using an oil pumping unit or screw pump lifting equipment to lift produced well fluid and adding the pitshaft viscosity reducer II or the pitshaft viscosity reducer III from an annular space between an oil pipe and an casing pipe of an oil well according to the different viscosity of produced fluid crude oil. The method has the advantages that: a chemical method is adopted to reduce the viscosity of heavy oil in the oil reservoirs and well fluid inside pitshafts, so as to improve heavy oil production effect; and the method has the continuous production time of the oil wells far more than that of the production methods in the prior art, greatly reduces production operation cost, and is obviously superior to the prior heavy oil production technology.

Owner:PETROCHINA CO LTD

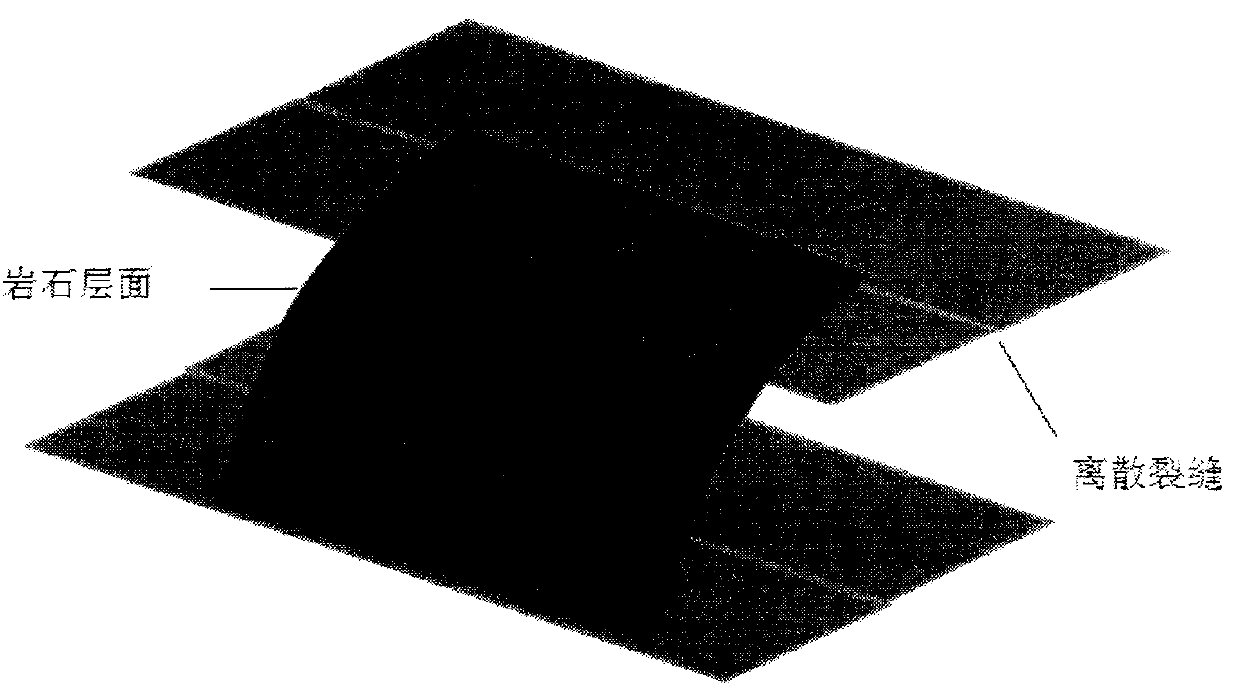

Method for improving oil reservoir exploitation effect by utilizing discrete fracture endpoint deformation numerical simulation

InactiveCN103279991AImprove accuracyImprove reliabilitySpecial data processing applications3D modellingResidual oilReservoir storage

The invention discloses a method for improving an oil reservoir exploitation effect by utilizing discrete fracture endpoint deformation numerical simulation. The method comprises the following steps of dividing an oil reservoir storage body into a continuous medium and a discrete medium according to a characteristic scale; deforming the end part of a discrete fracture from a square shape into a pointed shape to eliminate tiny grids, establishing rock stratum surface grids, and establishing three-dimensional oil reservoir grids; inputting measured oil reservoir parameters such as porosity, permeability and water saturation into a simulator, wherein a real value rather than a grid display value is used for the width of the discrete fracture; correcting the oil reservoir parameters by using a history matching method; and measuring and calculating the well productivity, residual oil and gas reserves and the distribution positions of residual oil and gas, and making a subsequent oil reservoir exploitation plan. According to the method, a discrete fracture numerical simulator can be prevented from measurement and calculation interruption and failures, the whole links of oil reservoir exploitation can be actually measured and calculated to improve the measurement and calculation accuracy of the well productivity and the residual oil and gas distribution of an oil reservoir, and a more effective development plan can be made to improve the oil reservoir exploitation effect.

Owner:SOUTHWEST PETROLEUM UNIV +1

Nano-surfactant for oil production and method for preparing the same

The invention provides a nanometer surface active agent for oil exploitation and method for making same, the surface active agent is prepared from nano material, 4A-zeolite, sodium carbonate, sodium sulfate, sodium silicate, polyoxythylene fatty alcohol ether sodium sulfate, dodecylbenzene sulfonic acid sodium, dodecylbenzene sulfonic acid and aromatic hydrocarbon dissolvent through mixing, heating, and stabilizing.

Owner:马冬兰

Nitrogen-aided thickened oil formation emulsification and viscosity reduction exploitation method

The invention provides a thickened oil exploitation method. The thickened oil is explored by employing the nitrogen-aided thickened oil formation emulsification and viscosity reduction exploitation method. According to the method, a certain amount of emulsification and viscosity reduction system comprising 0.3-0.5 percent of surfactant A, 0.03-0.08 percent of polymer B and the balance of water is injected into the formation through a pump truck, so that the emulsification and viscosity reduction system is mixed with thickened oil in the formation, and the viscosity of the thickened oil is improved; a certain amount of nitrogen is injected into the formation from the wellhead, the emulsification and viscosity reduction system is replaced to the deep part of the formation, the acting radius is enlarged, the emulsification and viscosity reduction effect is enhanced, and the construction cost is reduced; and moreover, after nitrogen is injected, the wellhead is closed, soaking is performed within 1-2 days, and then the well is opened for normal production. The field test shows that the construction effect is good, and the method can be widely applied to the field of thickened oil exploitation.

Owner:SOUTHWEST PETROLEUM UNIV

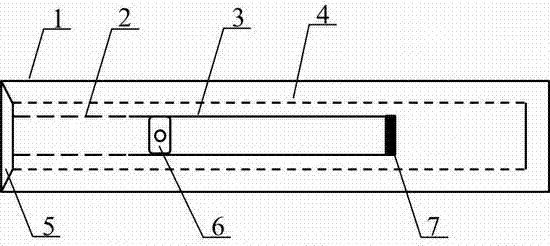

Multi-cluster perforating and fracturing completion pipe string and construction method

ActiveCN104420835AImprove the mining effectSimplify the construction processDrilling rodsFluid removalMulti clusterWell cementing

The invention relates to a multi-cluster perforating and fracturing completion pipe string and construction method. The pipe string is composed of a completion pipe string body, a well cementation rubber plug, a plurality of blockers, a multi-cluster perforating gun and a cable. The completion pipe string body is formed by sequentially connecting a float shoe, a float collar, an explosion valve and a plurality of preset ball seats through a casing pipe, and the well cementation rubber plug is located at the upper end of the float collar in the well cementation work later period; the outer diameters of the blockers are sequentially increased according to grades, and the blockers are inserted in the preset ball seats respectively; and the multi-cluster perforating gun is connected with the tail ends of the blockers, and the tail end of the multi-cluster perforating gun is connected with the cable. The method comprises the steps that firstly, the completion pipe string body is sent to the designated position inside a naked-eye shaft; well cementation work is carried out; and first-stage fracturing work, second-stage fracturing work, third-stage fracturing work, fourth-stage fracturing work and fifth-stage fracturing work are sequentially completed. The pipe string and the construction method are applicable to multi-cluster perforating and fracturing construction of the shale oil and gas reservoir layer.

Owner:PETROCHINA CO LTD

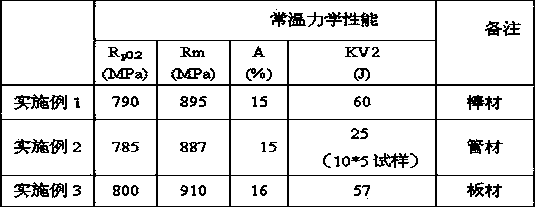

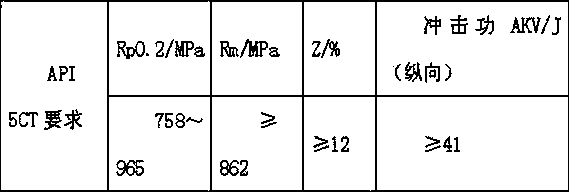

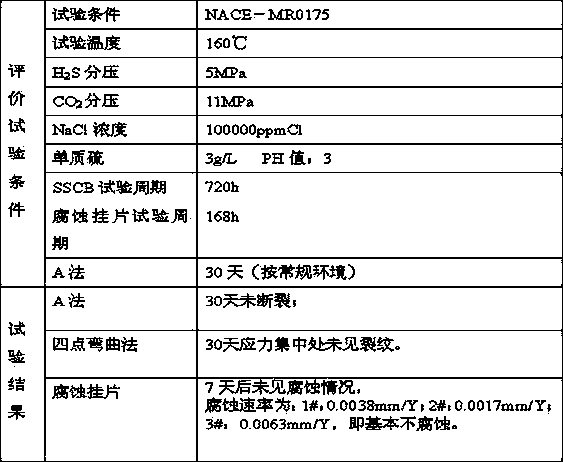

High-strength high-impact-toughness titanium alloy used for oil well and gas well, and preparation method thereof

The invention relates to high-strength high-impact-toughness titanium alloy comprising the chemical components of, by weight: 4.0-9.0% of Al, 0.5-5.0% of Mo, 1-5% of Nb, 1-5% of Zr, and balance of Ti. The preparation method comprises mixing, electrode rod pressing, vacuum consumption and twice smelting, such that an alloy ingot is prepared. The titanium alloy provided by the invention assists in well solving a problem of poor H2S and CO2 corrosion resistance of an existing P110 steel oil well and gas well pipe material. Also, 40% weight reduction can be realized, such that drilling rig power is greatly reduced. With the alloy, petroleum and natural gas exploration capacity of our nation can be greatly improved.

Owner:725TH RES INST OF CHINA SHIPBUILDING INDAL CORP

Method for oil deposit flow state digifax calculating with discrete fracture line processing

InactiveCN103399970AReduce in quantityFewer segmentation failuresSpecial data processing applicationsLine segmentOil well

The invention discloses a method for oil deposit flow state digifax calculating with discrete fracture line processing. First, an oil deposit storage layer is divided into continuous media and discrete fracture media; in order to remove minimum meshes, discrete fracture thicknesses are ignored when oil deposit meshes are established, the section of a discrete fracture on a plane is changed to a line segment, then rock stratum meshes are established, three-dimensional oil deposit meshes are then established; oil deposit parameters such as practical measuring holes, leakage, saturation are recorded into a simulator, wherein real values are used for discrete fracture widths, mesh display values are not used, accuracy of calculating results is not lowered by deformation; the oil deposit parameters are corrected through a history fitting method; then oil well yield, surplus oil-gas distribution and storage amount are calculated. The problems that a discrete fracture numerical simulation technique can be easily interrupted and fail, calculating time is long can be solved, the whole process of practical oil deposit development can be really calculated through the technology, so that accuracy of oil deposit flow state calculating is improved, and accordingly an effective development scheme is formulated to improve oil deposit development effect.

Owner:SOUTHWEST PETROLEUM UNIV +1

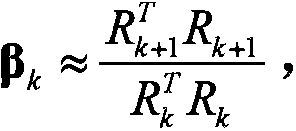

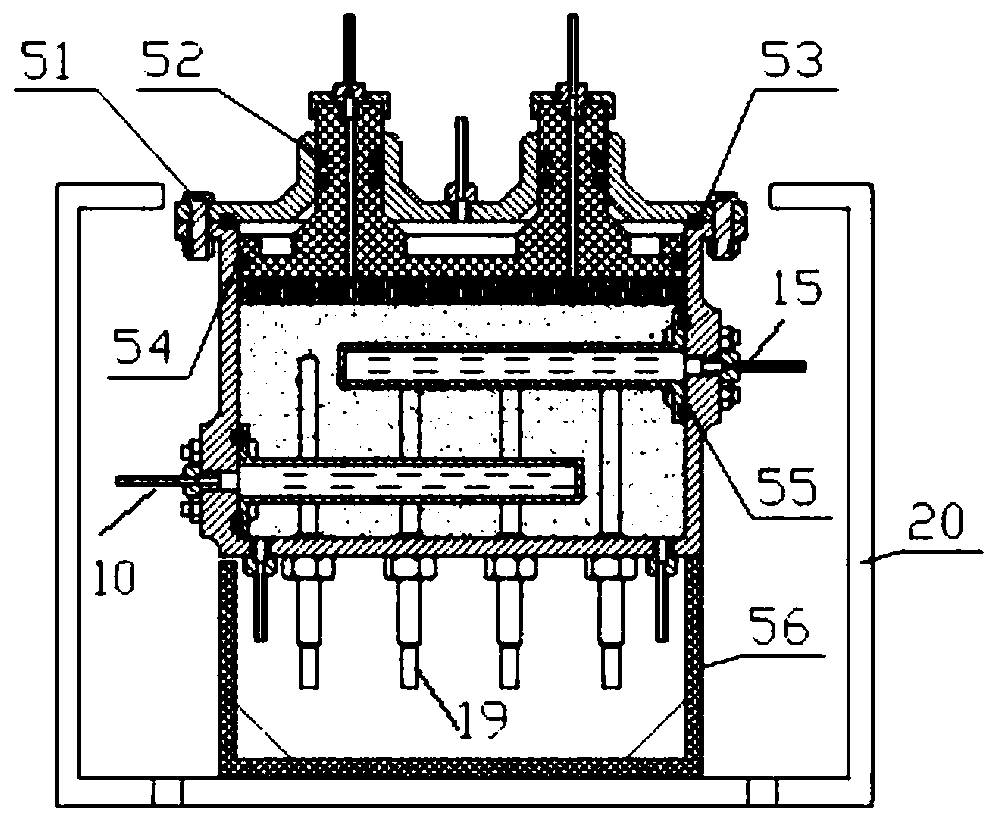

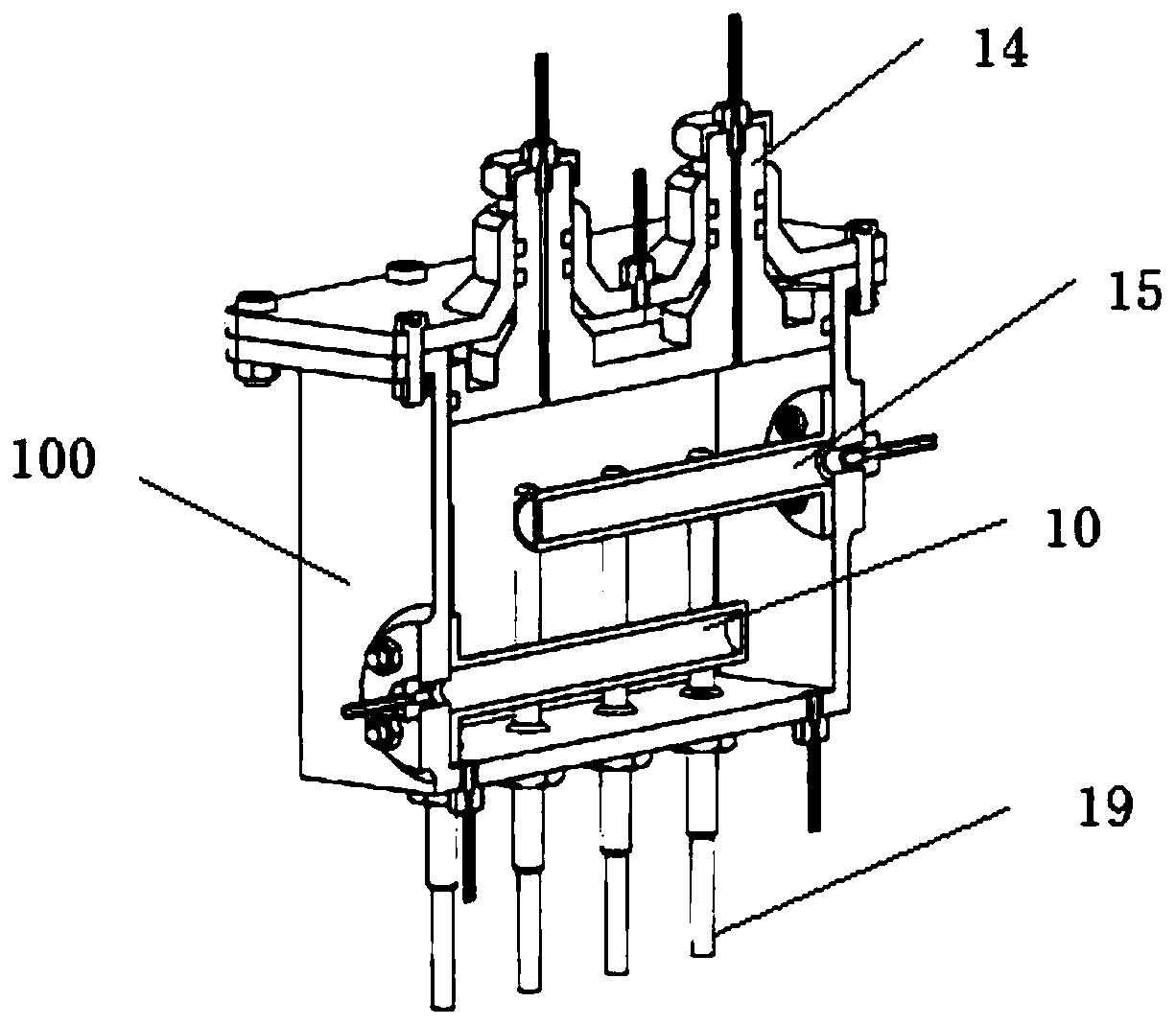

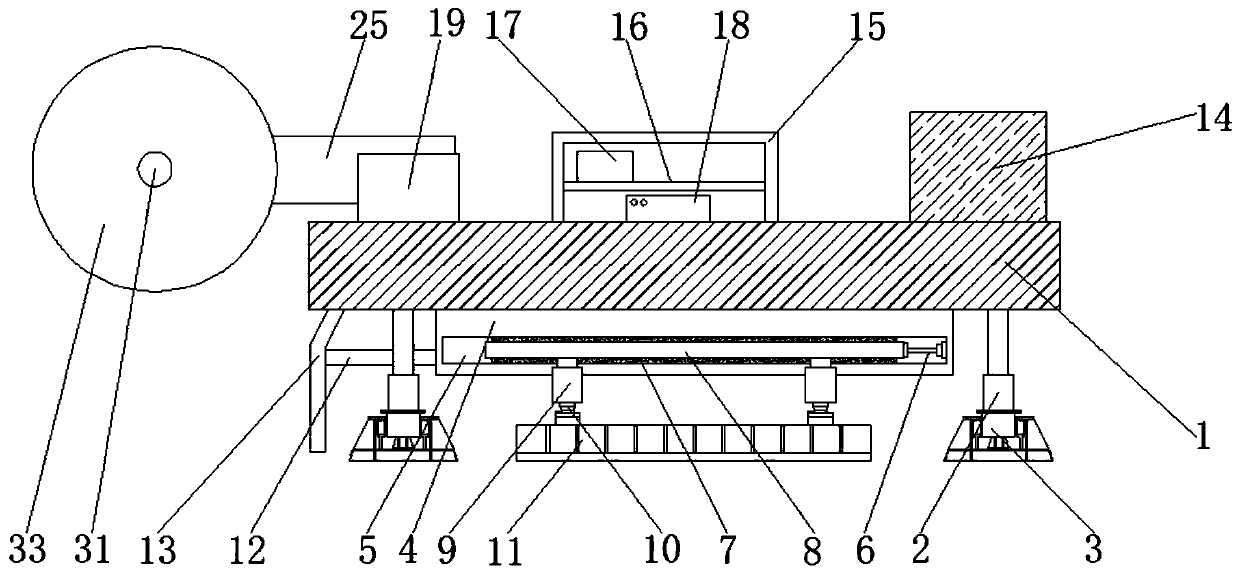

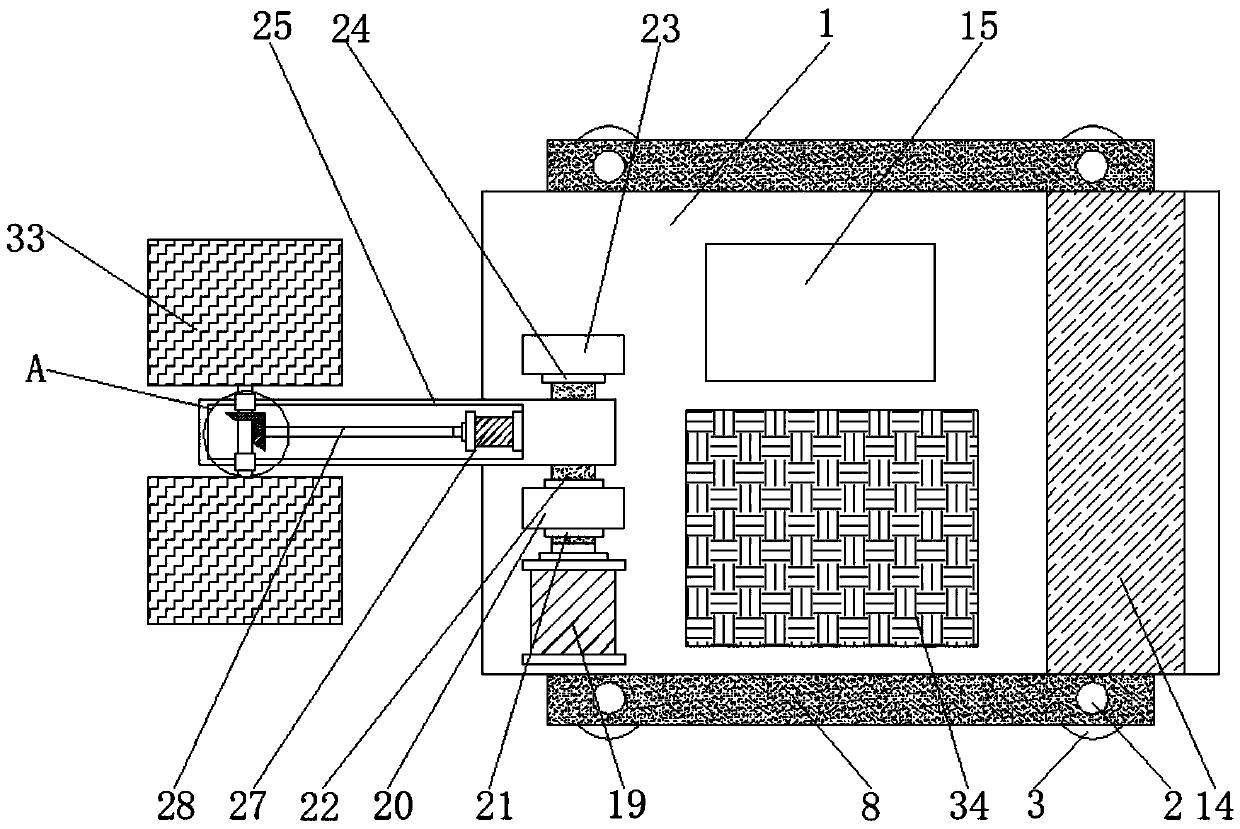

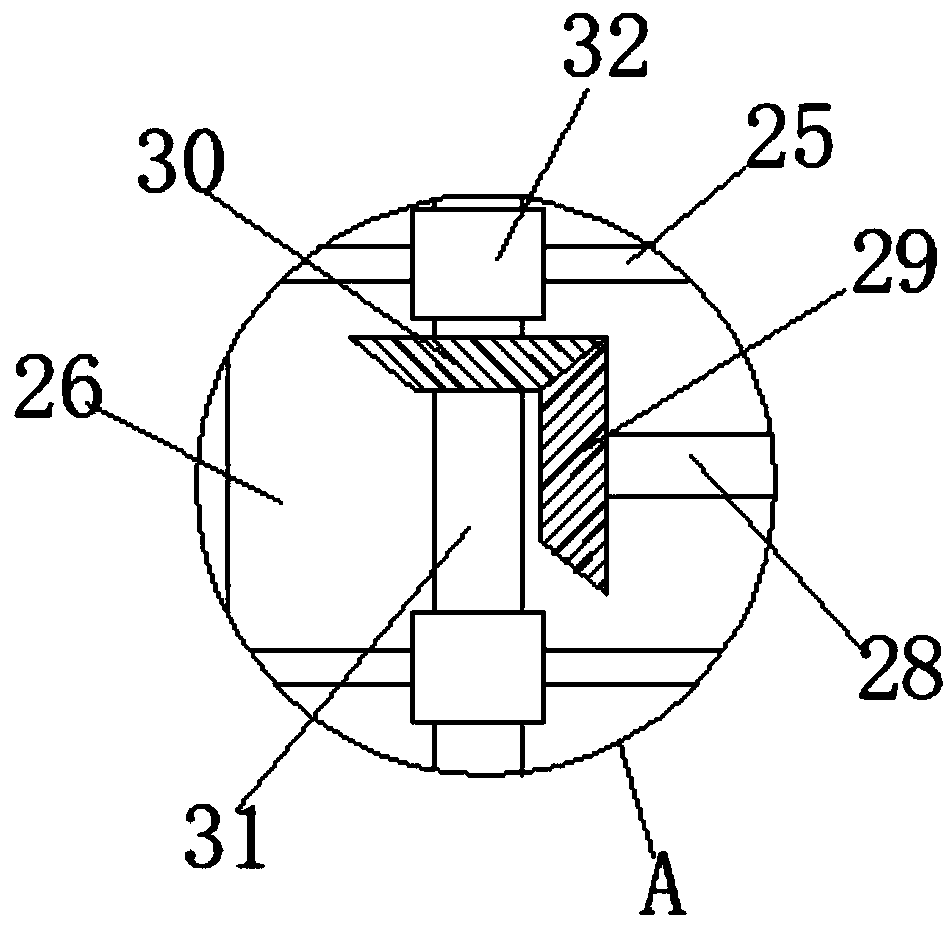

Testing device and method for exploiting natural gas hydrate through carbon dioxide replacement with help of pressure reduction method

ActiveCN110306952AGood mining effectFacilitate experimental researchSurveyConstructionsWater bathsData acquisition

The invention discloses a testing device and method for exploiting a natural gas hydrate through carbon dioxide replacement with the help of a pressure reduction method and relates to the field of natural gas hydrate exploitation. The testing device comprises a reactor, a constant-temperature water bath system, a pressurization air supply system, a stable flow liquid supply system, an overlying stress loading system, a vacuumizing system, a natural gas hydrate product processing and metering system and a data acquisition system. By means of the testing device and method, the generation of thenatural gas hydrate in a quartz sand body and the exploitation environment of an ocean sand rock storage layer are simulated; exploitation is carried out through pressure reduction at the early stage,and afterwards, natural gas hydrate exploitation is carried out through carbon dioxide replacement; the injection of carbon dioxide and the exploitation of the natural gas hydrate are implemented simultaneously by controlling and adjusting the pressure and temperature in the reactor, and the effect of carbon dioxide replacement and natural gas hydrate exploitation is better.

Owner:YANSHAN UNIV

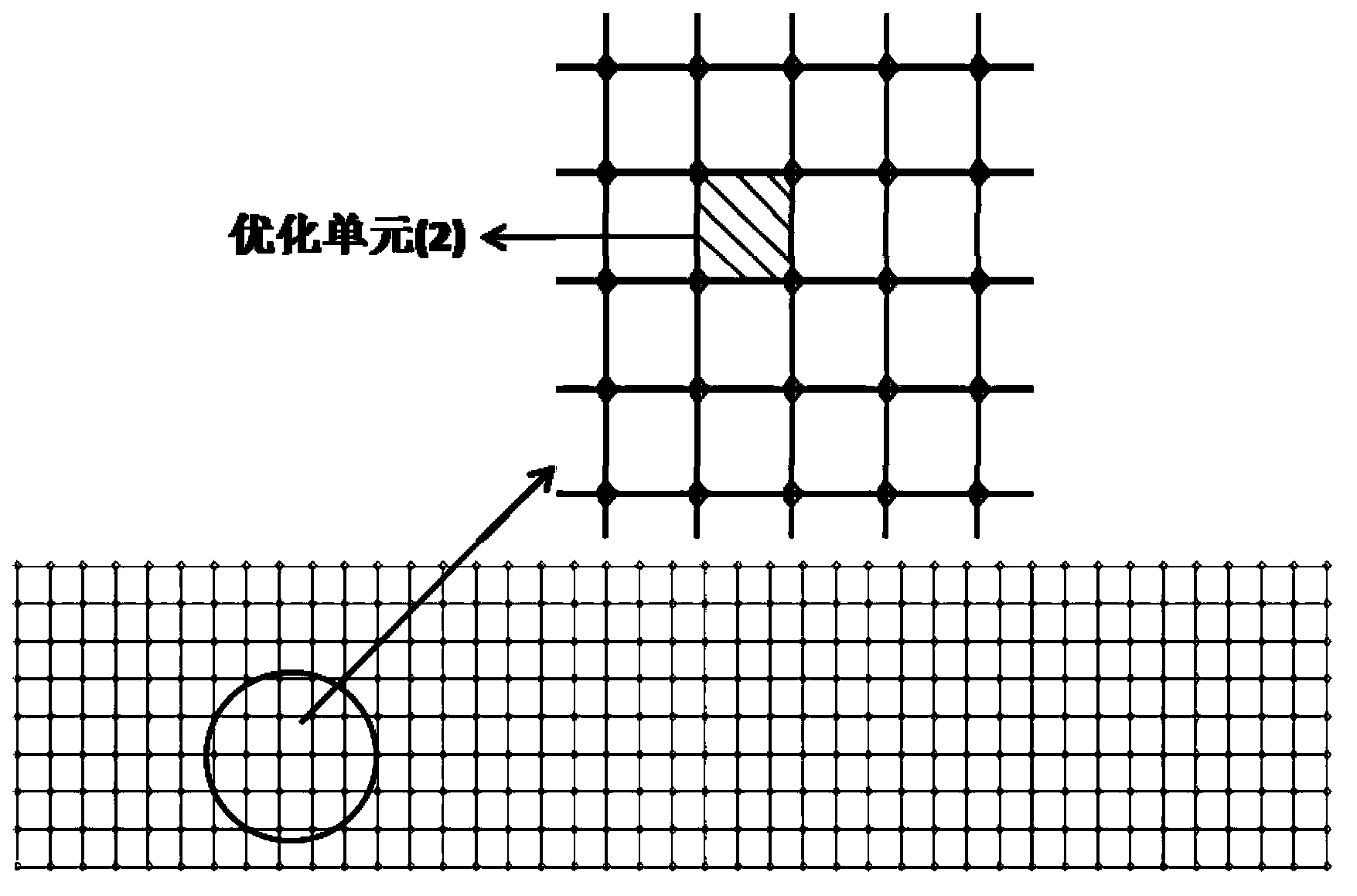

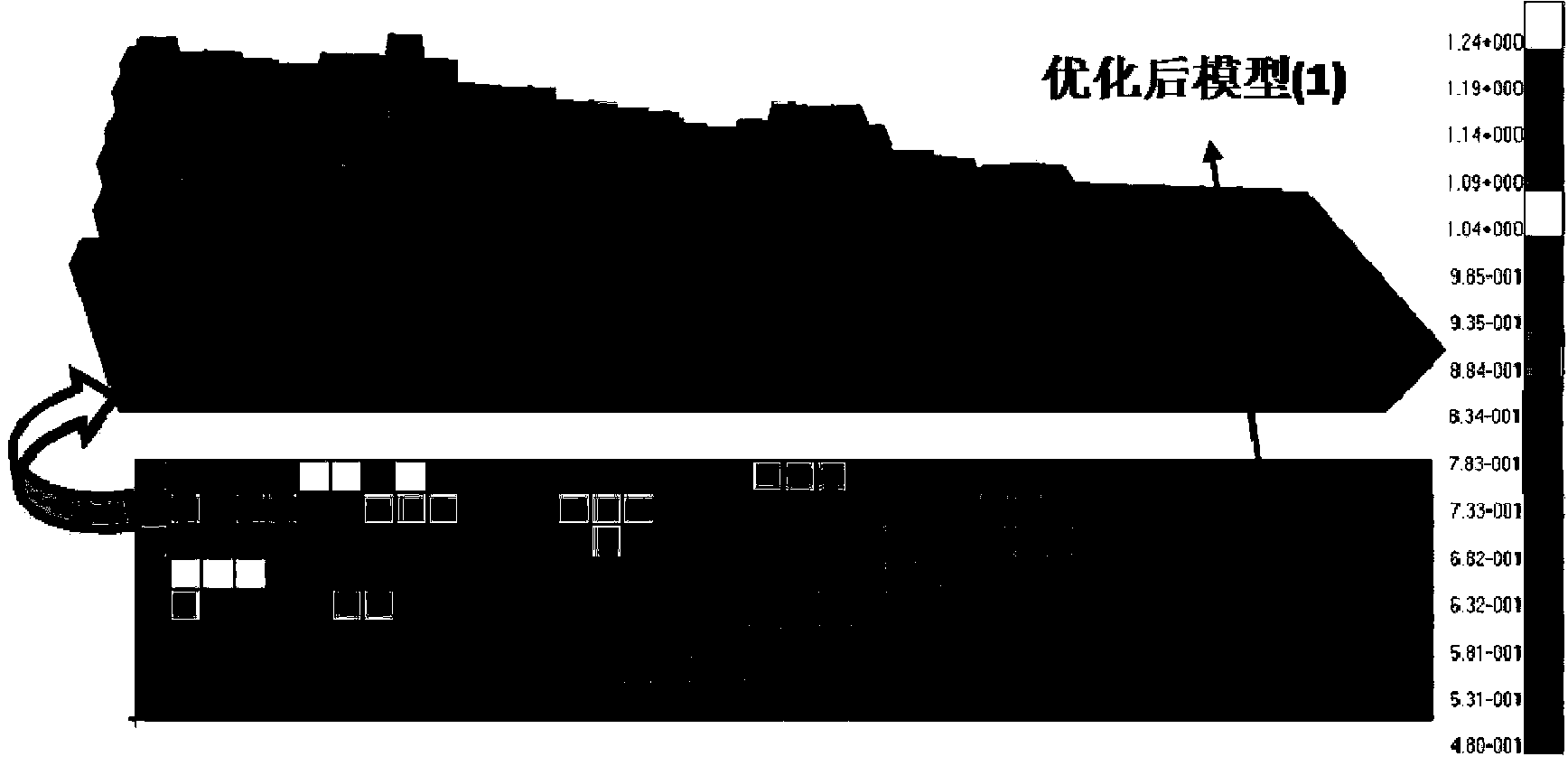

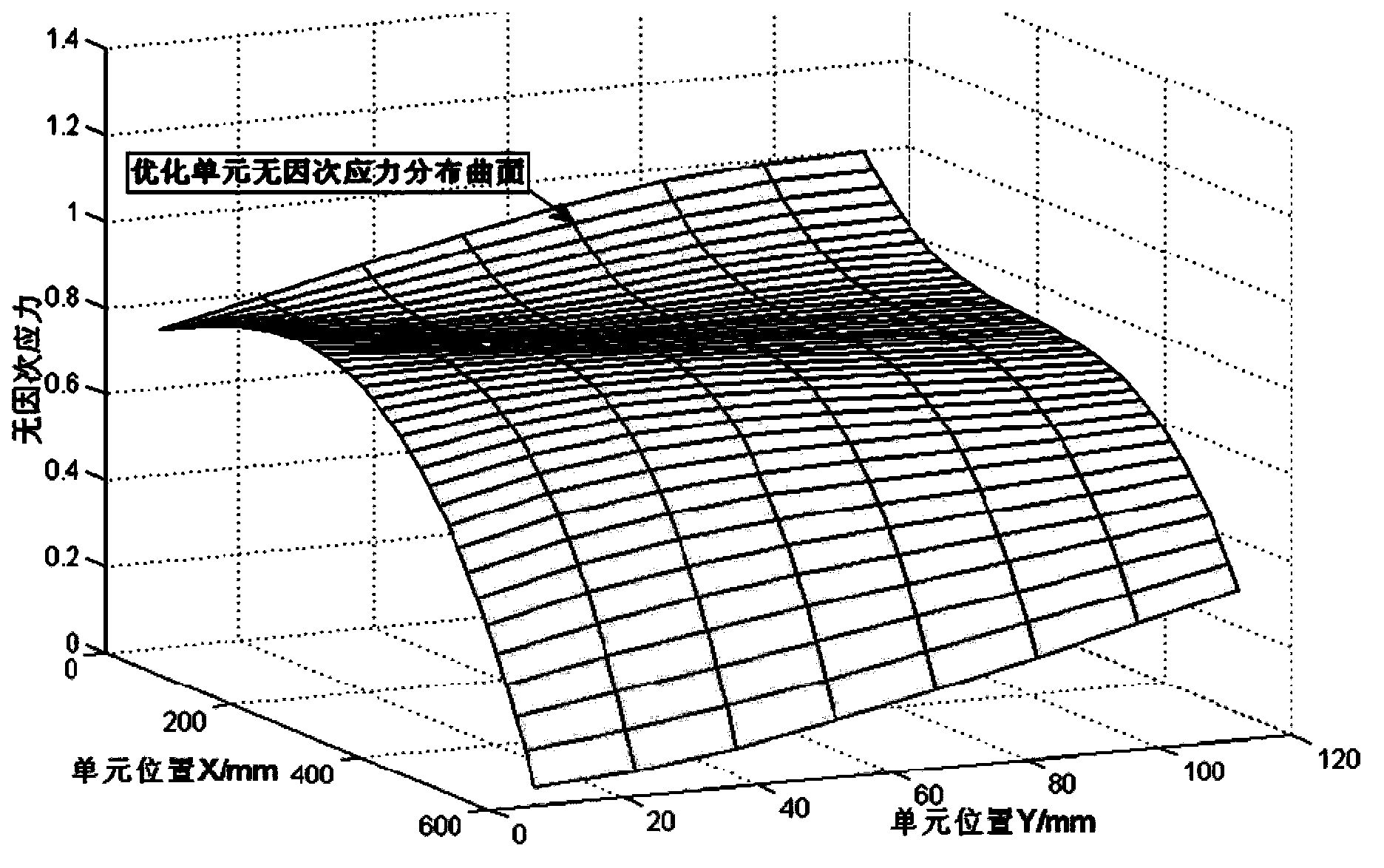

Method for post-processing engineering-based composite material laminated board ply after optimization

ActiveCN103353916AImprove the mining effectBoundary continuous smoothingSpecial data processing applicationsLeast squaresSurface fitting

The invention provides a method for processing engineering-based composite material laminated board ply after optimization. After fine design optimization for the composite material laminated board structure, the method can guarantee smoothness and continuation in the thickness of each optimization unit ply of the laminated board after post-processing, so as to eliminate deformed units such as 'bulge' and 'dent', and realize engineering rationalization for the single layer ply thickness and the ply angle of each optimization unit. The method adopts multinomial surface fitting method based on least-squares method to perform surface fitting in the thickness direction for the design optimization result of the composite material laminated board ply, exerts mechanical constraint, then performs equivalent rigidity conversion for all optimization unit in the composite material laminated board after the fitting processing to ensure that the ply angle of each single layer in each optimization unit is converted to four common angles including 0 DEG, + / -45 DEG, and 90 DEG and that the single layer thickness in each optimization unit is converted to designated single layer thickness, under the condition that each optimization unit of the laminated board is guaranteed to have the same rigidity and basically the same mass.

Owner:中国航空工业集团公司科学技术委员会 +1

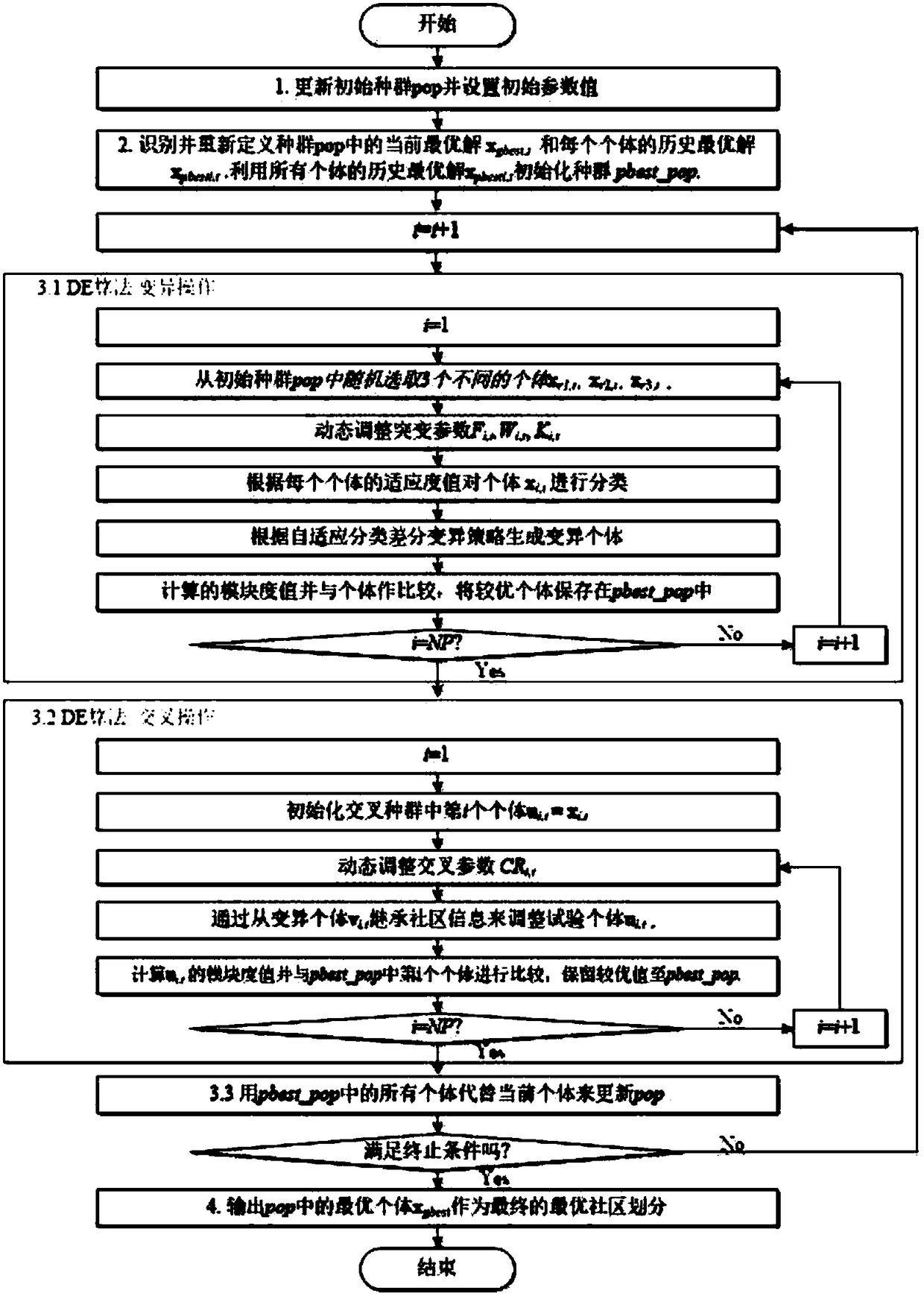

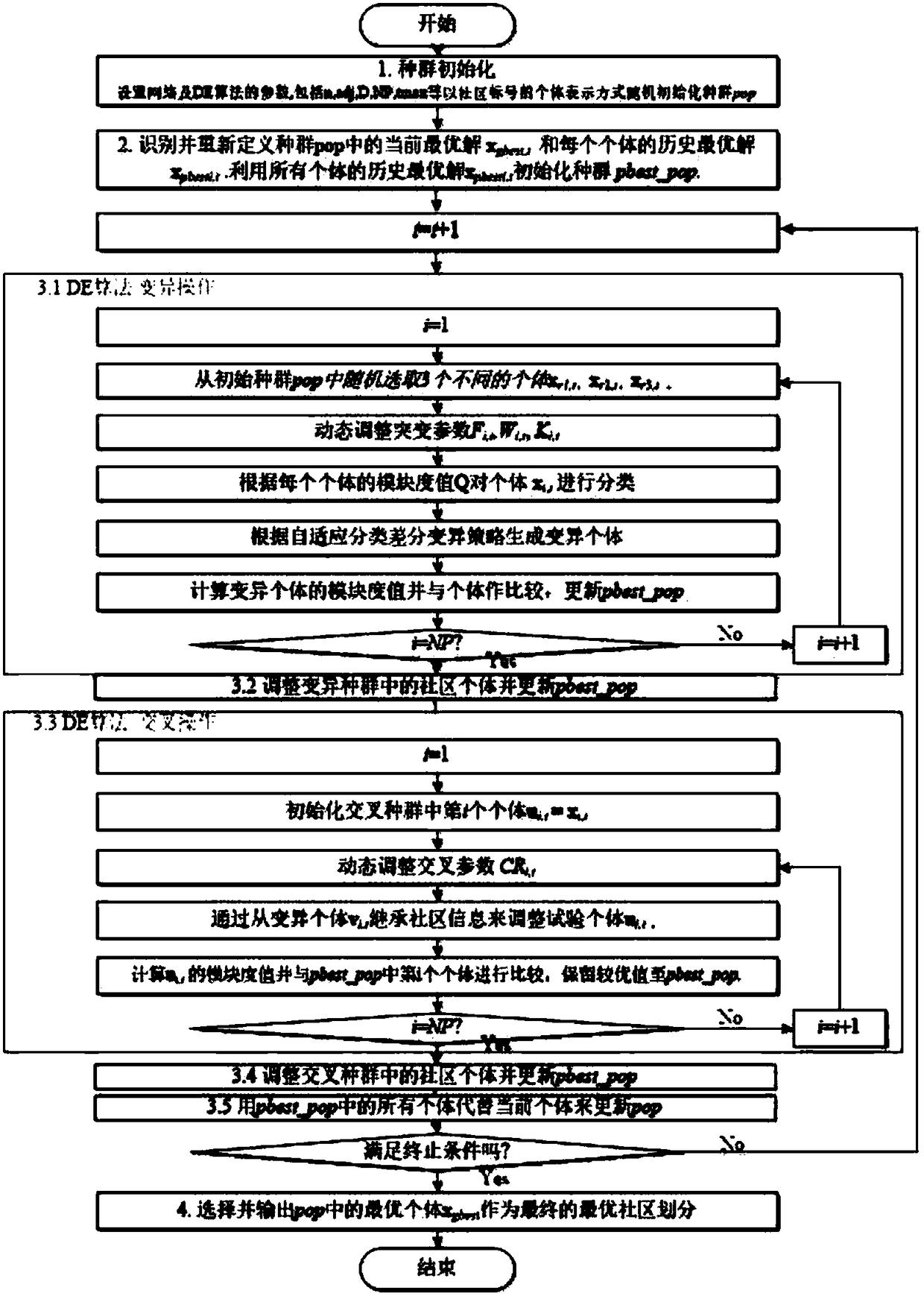

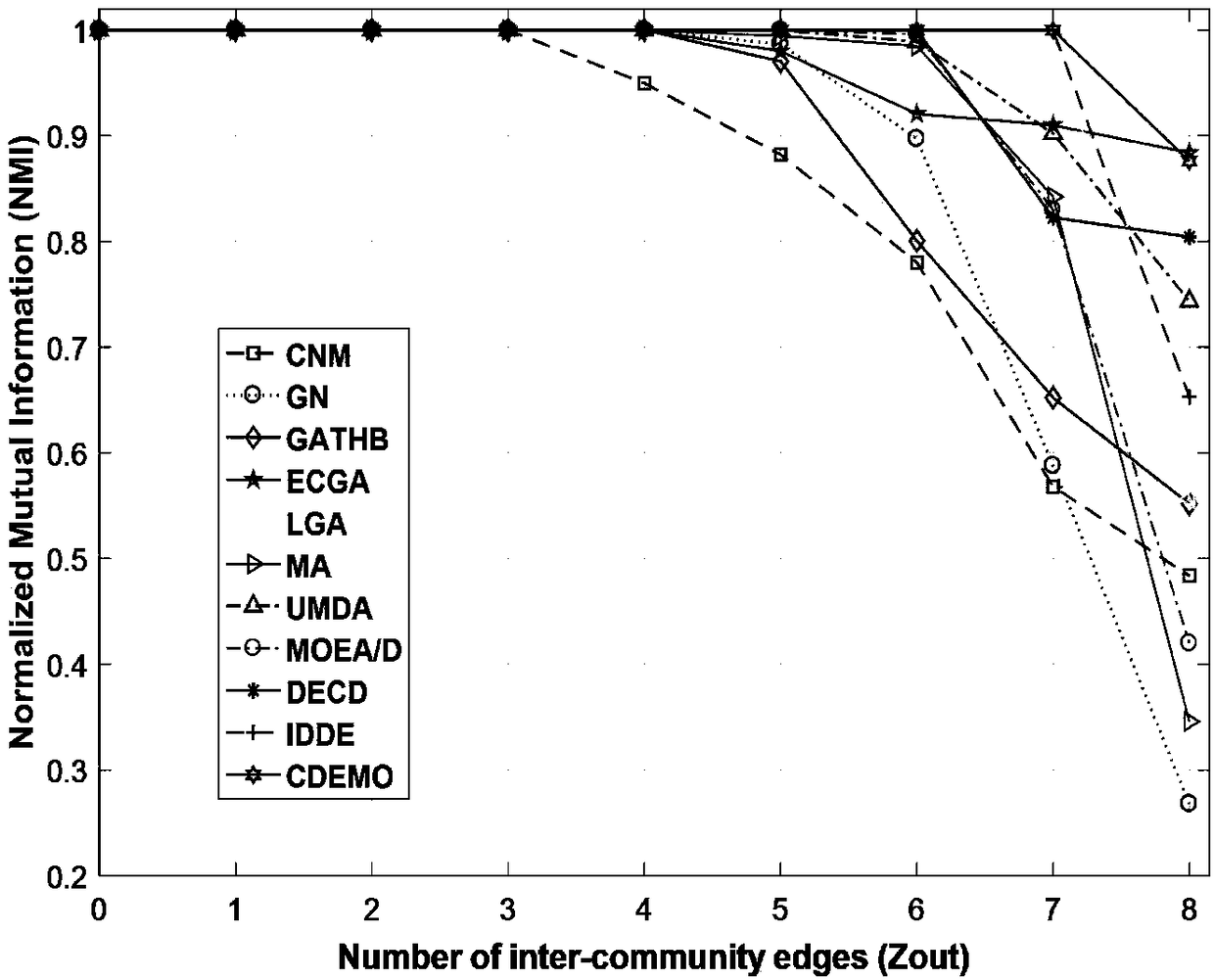

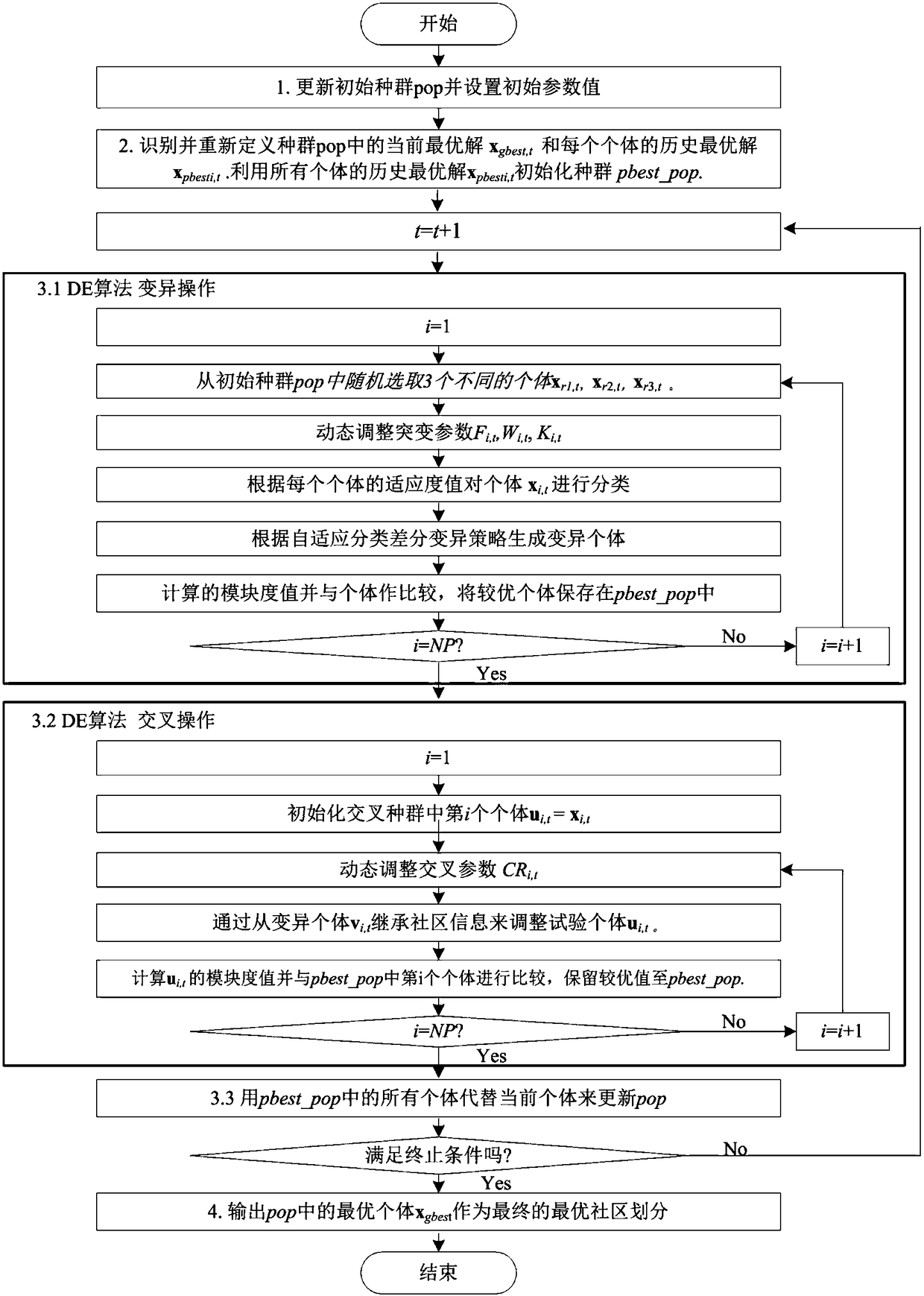

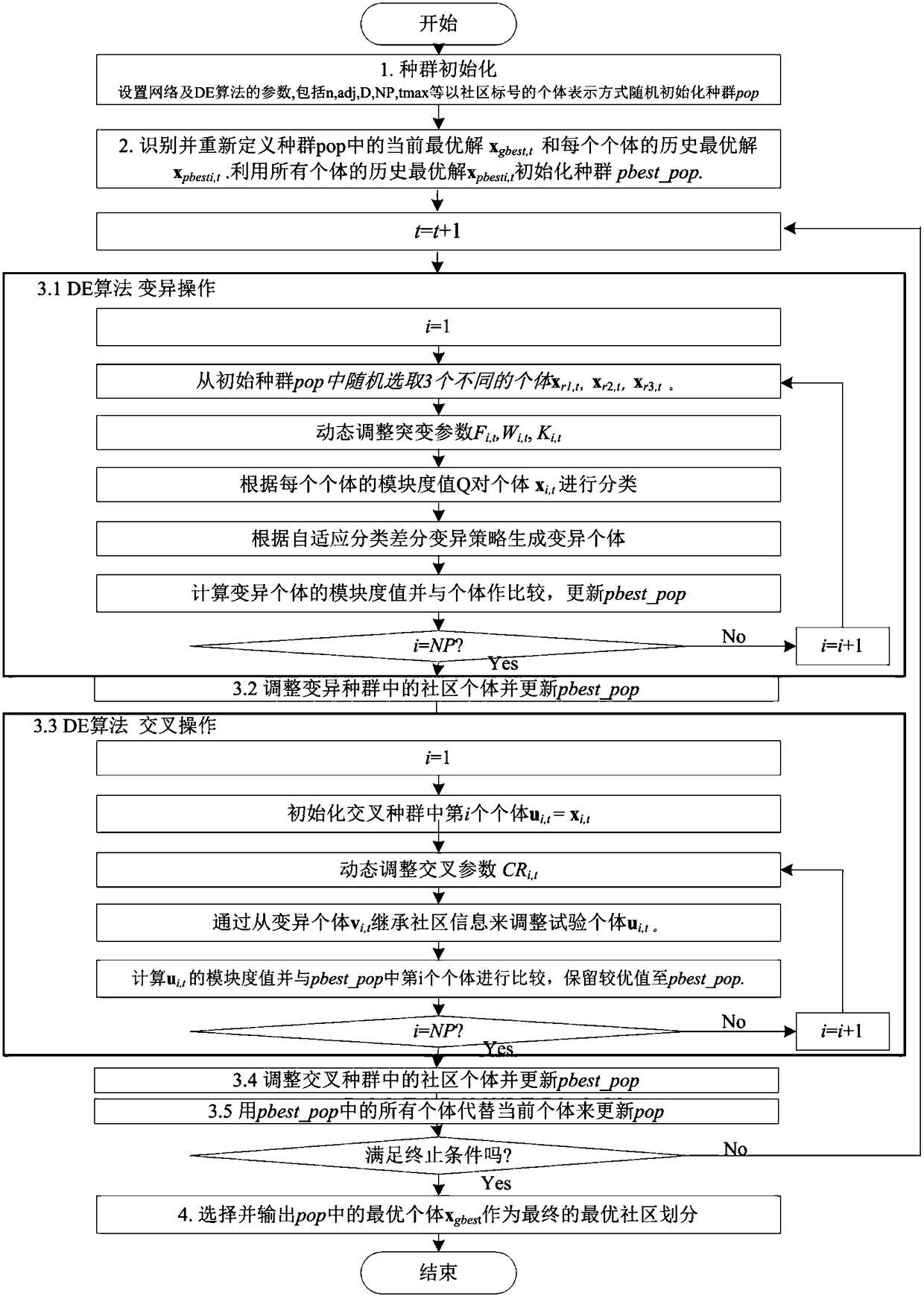

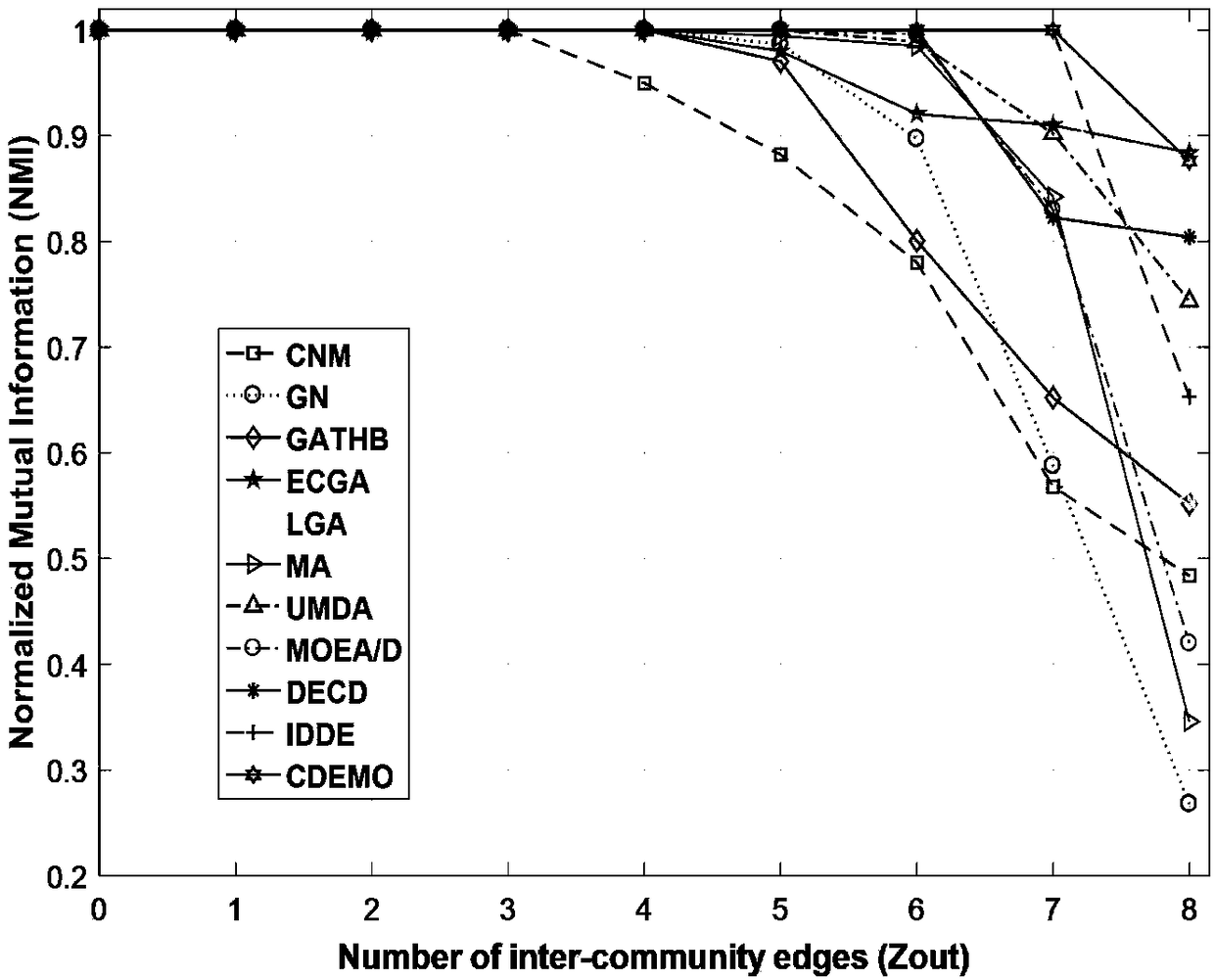

Method for detecting complex network communities

InactiveCN108133272AImprove exploration abilityImprove the mining effectData processing applicationsArtificial lifeModularitySelf adaptive

The invention discloses a method for detecting complex network communities. In order to improve the global convergence performance of a differential evolution algorithm, the method comprises the stepof redesigning three main evolutionary operations: a classification-based self-adaptive mutation strategy, a dynamic self-adaptive parameter adjusting strategy and a history information-based selection operation; on the other hand, in order to make better use of network topology information, proposing an improved neighborhood information-based community adjusting strategy to ensure that sufficientsearch space is provided for global optimal community division while the DE (Differential Evolution) search space is reduced at the same time; and finally, proposing a new modularity optimizing algorithm CDEMO (C Differential Evolution for Multiobjective Optimization) based on the DE algorithm.

Owner:DALIAN NATIONALITIES UNIVERSITY

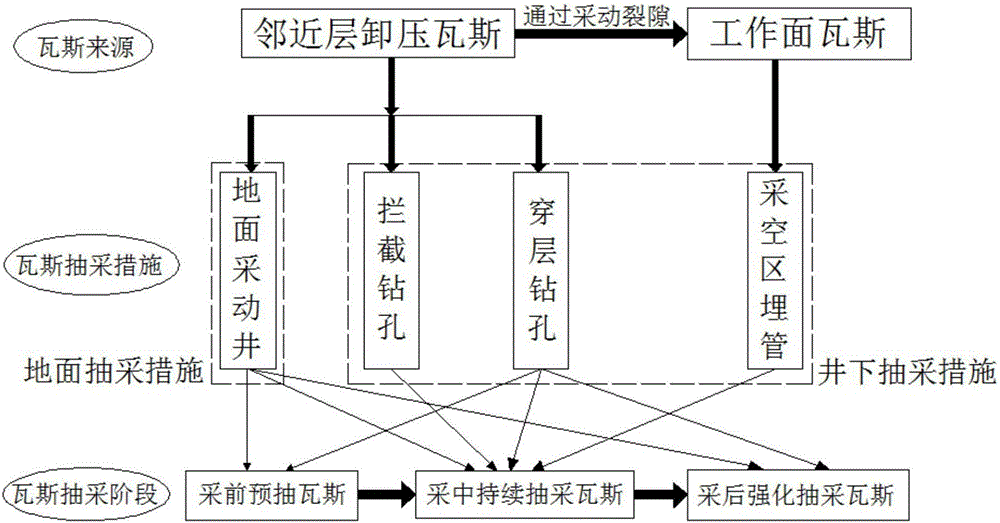

Stereoscopic comprehensive pressure-relief gas drainage method suitable for extraction of soft rock protective layer

ActiveCN106761902AEfficient extractionDraining is reasonableFluid removalGas removalMining engineeringCoal

The invention discloses a stereoscopic comprehensive pressure-relief gas drainage method suitable for extraction of a soft rock protective layer. The stereoscopic comprehensive pressure-relief gas drainage method comprises the steps of determining developing heights of roof and floor fissure zones after extraction of the soft rock protective layer according to cover rock structure characteristics in a stope; and determining construction conditions by analyzing specific zoning ranges of overlying and underlying protected seams. The stereoscopic comprehensive pressure-relief gas drainage method suitable for extraction of the soft rock protective layer puts forward an omnibearing stereoscopic comprehensive pressure-relief gas drainage method from overground to underground, from coal seam gas pre-extraction before mining, continuous pressure-relief gas drainage during mining to pressure-relief drainage strengthening after mining, so that effective linking and supplementing on the aspects of time, space and function are achieved; and various pressure-relief gas drainage measures are reasonably combined and fully used and mutually complement, so that relief-pressure gas drainage of protected seams is more reliable, reasonable, economical and effective.

Owner:ANHUI UNIV OF SCI & TECH

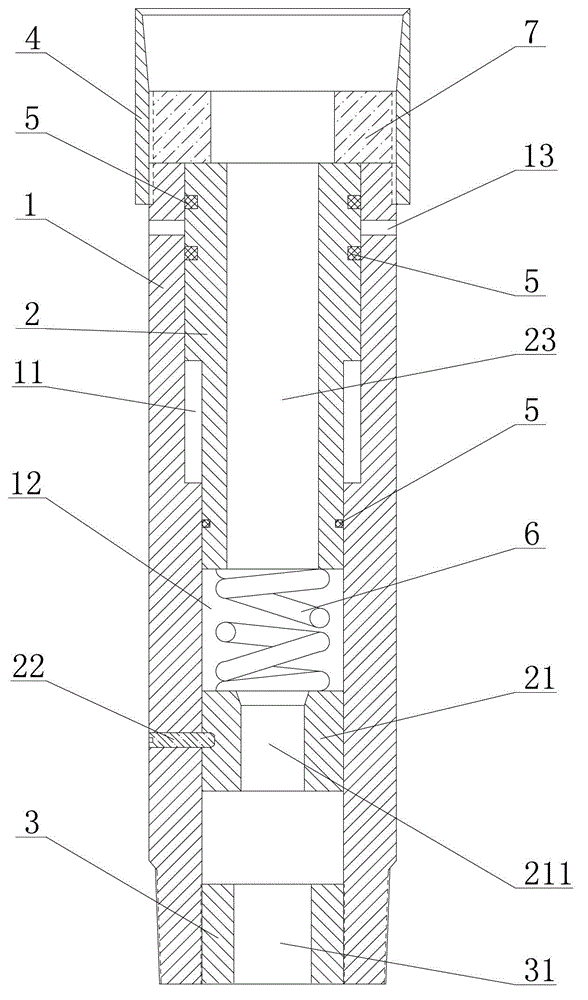

Pulsed steam distributing valve

InactiveCN103147721AImprove the mining effectRealize the purpose of steam injectionFluid removalFlushingEngineeringValve seat

The invention discloses a pulsed steam distributing valve, which comprises valve bodies, valve cores and valve seat limiting rings, wherein upper connectors are connected to the upper ends of the valve bodies; the valve bodies are provided with first through holes and a second through hole, which are axially communicated; oil filling holes are formed in the side walls at the upper ends of the valve bodies; the oil filling holes are communicated with the first through holes; the valve cores can be hermetically arranged in the first through holes and the second through hole in an axial movement way; valve seats are arranged at the lower ends of the valve cores; the valve seats are connected into the valve bodies through cutting pins; and the valve seat limiting rings are positioned at the bottom of the second through hole and connected onto the valve bodies. According to the pulsed steam distributing valve, an oil layer can be intermittently filled with steam, so that the casing wall and the near-wellbore region are effectively washed and the raw oil extraction effect is improved.

Owner:PETROCHINA CO LTD

A kind of surfactant and its preparation and application

ActiveCN102274701AHigh molecular weightGood film formingTransportation and packagingMixingFuel oilViscosity

The invention relates to a surfactant and a preparation and an application thereof; The surfactant is obtained by copolymerization of a monomer (A) and a monomer (B); the monomer (A) is one or more than one unsaturated monomer with strong lipophilic groups, and has a general formula as shown in the following formula (1), wherein R, R1 and R2 are same or different, and represent H or C1-C12 alkyl; the monomer (B) is one or more than one unsaturated monomer with week hydrophilic groups, and has a general formula as shown in the following formula (2), wherein R3 represents H or C1-C4 alkyl; A represents COOM, OM, or SO3M, and M represents H, Na+, K+, C1-C8 alkyl, C1-C8 alkyl ether, or C1-C8 alkyl ester; the content of the monomer (A) is 10-90% of the total weight of the monomer (A) and the monomer (B); the content of the monomer (B) is 10-90% of the total weight of the monomer (A) and the monomer (B); the surfactant is applicable to the exploitation, gathering and transportation of heavy oil with viscosity more than 2000 mPa.S.

Owner:PETROCHINA CO LTD +1

Method for extracting thick oil

ActiveCN101328798BImprove liquiditySolve the problem of difficult flow into the wellboreFluid removalDrilling compositionOil productionScrew pump

The invention provides a heavy oil cold production method applied to the production of oilfield heavy oil reservoirs at normal temperature and pressure. The method is characterized by comprising: a. a step of preparing water-soluble viscosity reducer I; b. a step of preparing viscosity reducer II; c. a step of preparing viscosity reducer III; d. a step of squeezing the water-soluble viscosity reducer I into oil reservoirs; and e. a step of using an oil pumping unit or screw pump lifting equipment to lift produced well fluid and adding the pitshaft viscosity reducer II or the pitshaft viscosity reducer III from an annular space between an oil pipe and an casing pipe of an oil well according to the different viscosity of produced fluid crude oil. The method has the advantages that: a chemical method is adopted to reduce the viscosity of heavy oil in the oil reservoirs and well fluid inside pitshafts, so as to improve heavy oil production effect; and the method has the continuous production time of the oil wells far more than that of the production methods in the prior art, greatly reduces production operation cost, and is obviously superior to the prior heavy oil production technology.

Owner:PETROCHINA CO LTD

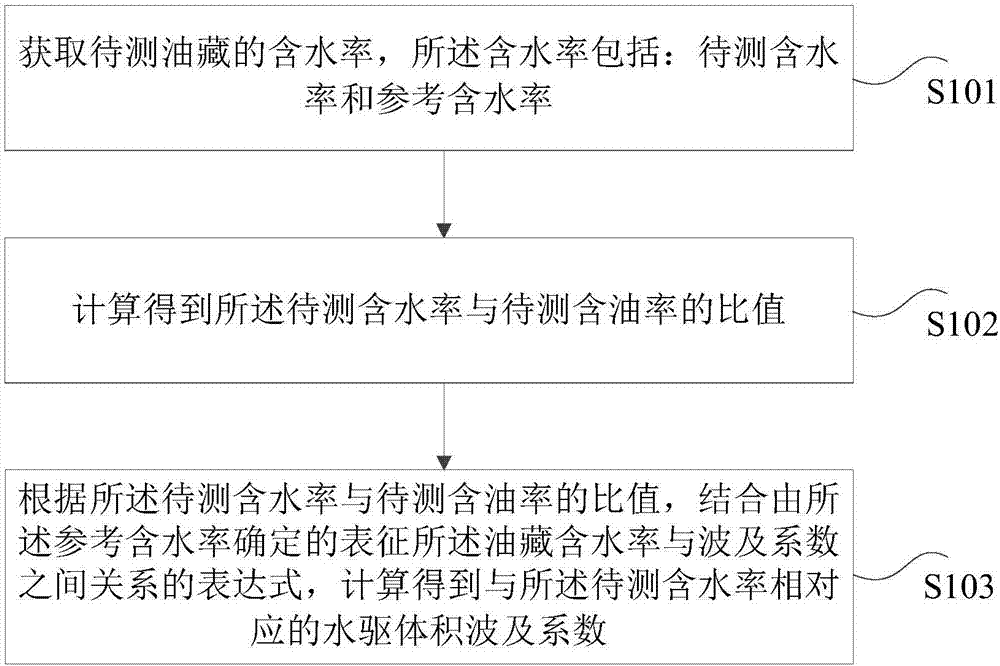

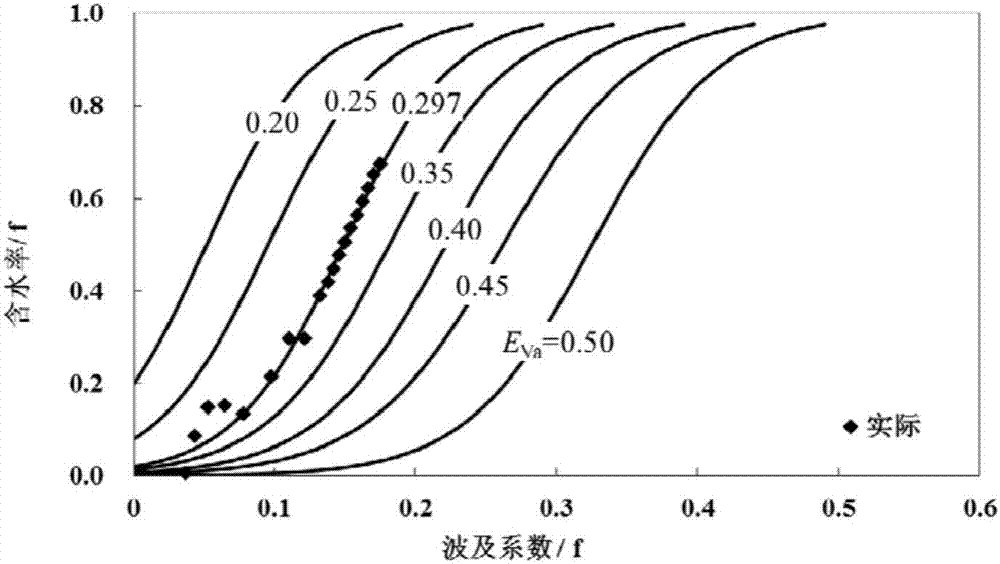

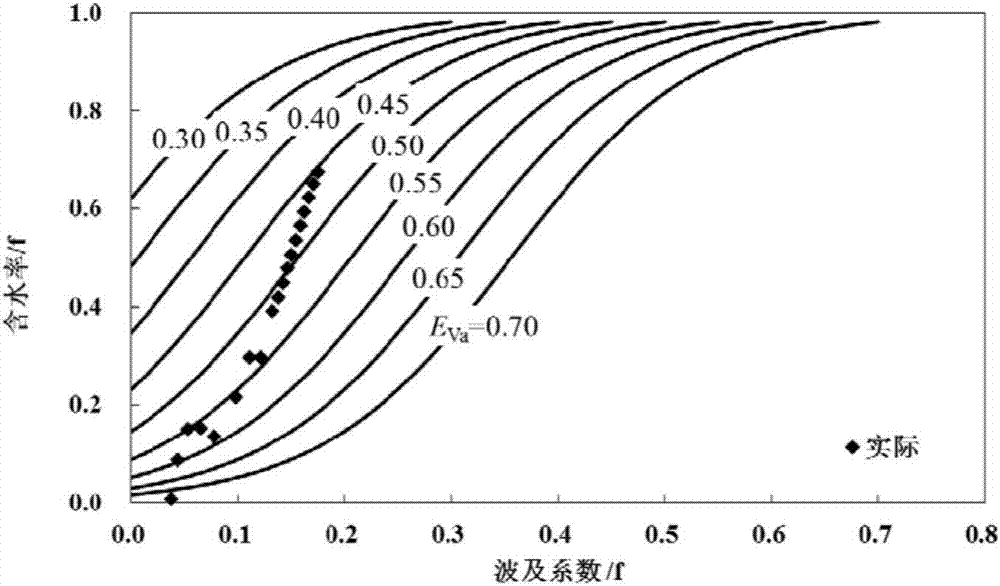

Method, device and system for determining water flooding volume waves and coefficients of oil deposits

ActiveCN107194180AImprove the development effectGood mining effectInformaticsSpecial data processing applicationsWater floodingVolume wave

The invention provides a method, device and system for determining water flooding volume waves and coefficients of oil deposits. The method comprises the following step of: obtaining water content of a to-be-measured oil deposit, wherein the water content comprises to-be-measured water content and reference water content; calculating a ratio of the to-be-measured water content to to-be-measured oil content; and calculating a water flooding volume wave and a water flooding coefficient corresponding to the to-be-measured water content by combining an expression which is determined by the reference water content and represents the relationship between the water content of the oil deposit and waves and coefficients according to the ratio of the to-be-measured water content to the to-be-measured oil content. According to the method, the water flooding volume waves and coefficients are determined by utilizing the water content, describing the instant features of oil deposits, of oil deposits, so that the efficient development of oil fields can be better instructed and the oil field water flooding development effect is improved.

Owner:PETROCHINA CO LTD

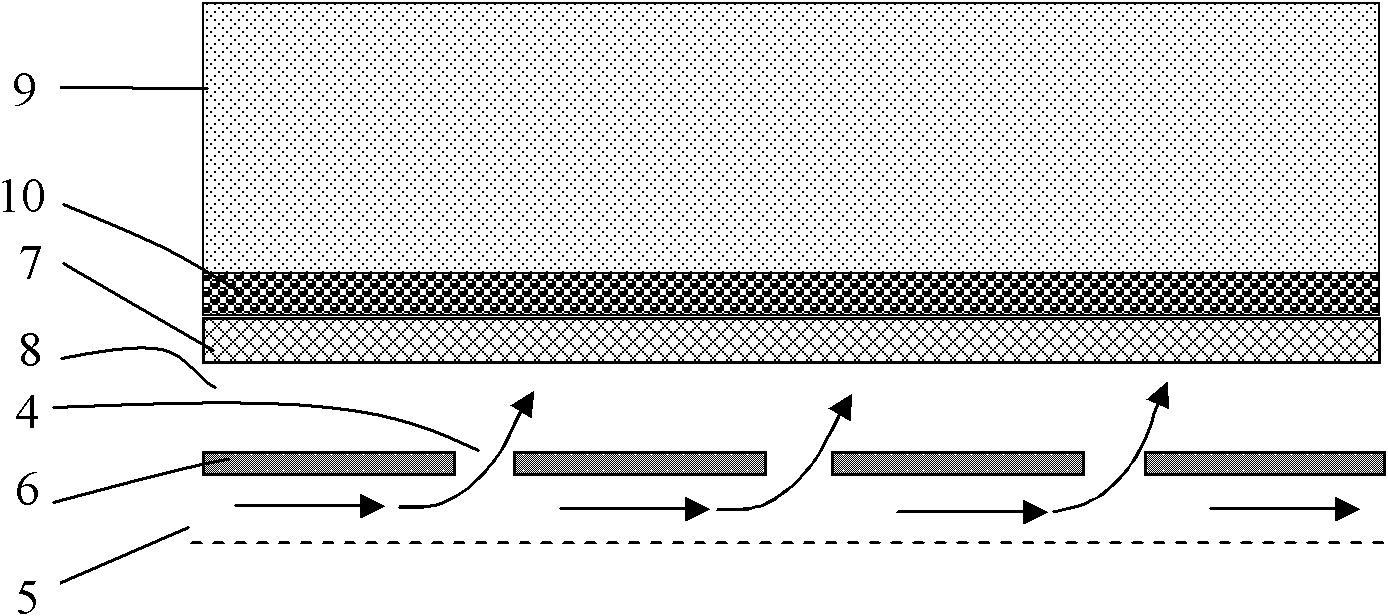

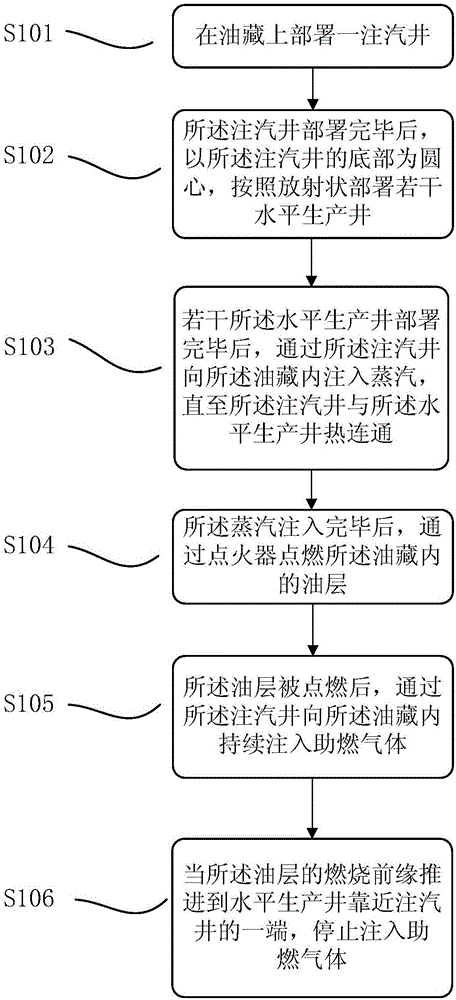

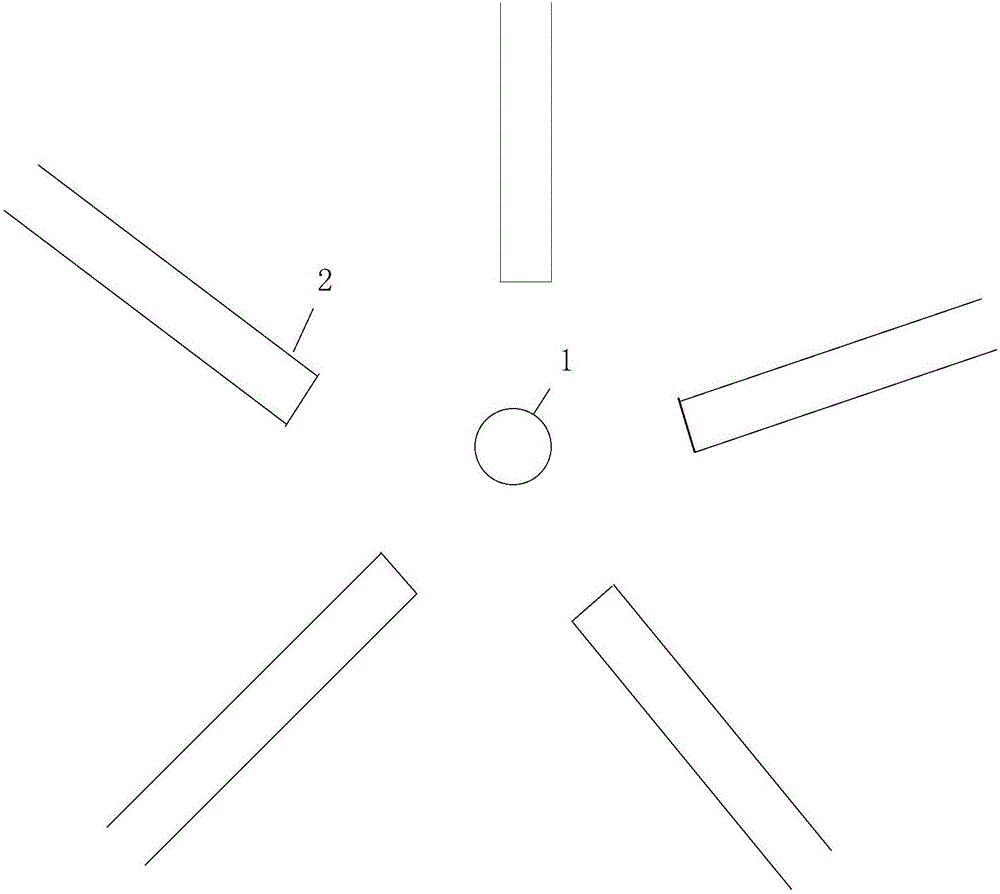

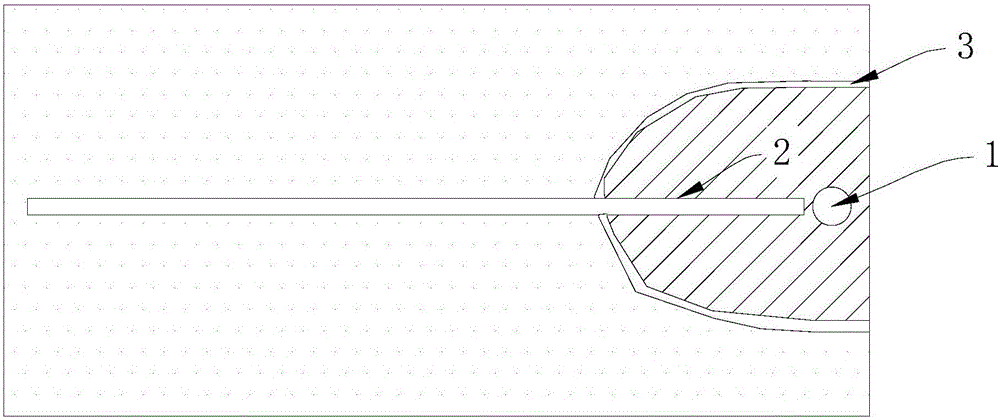

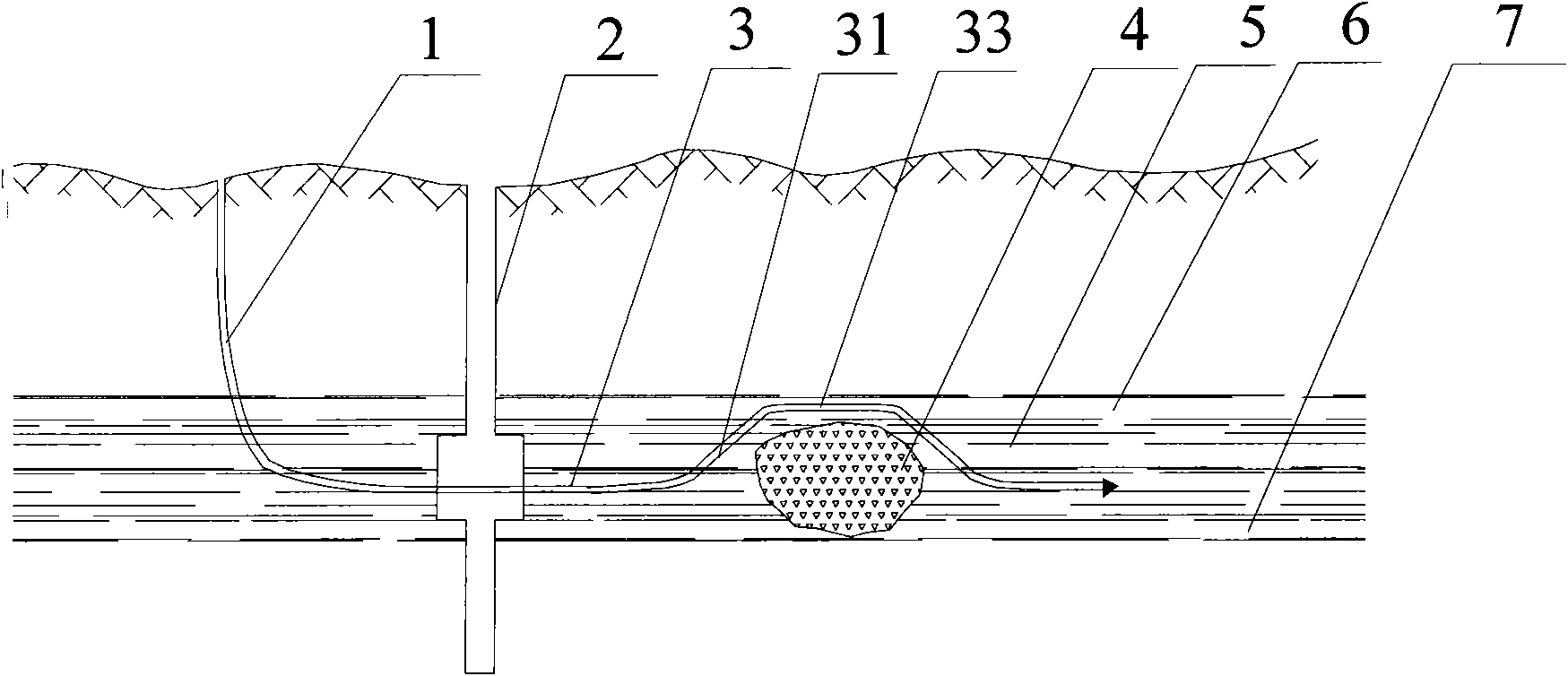

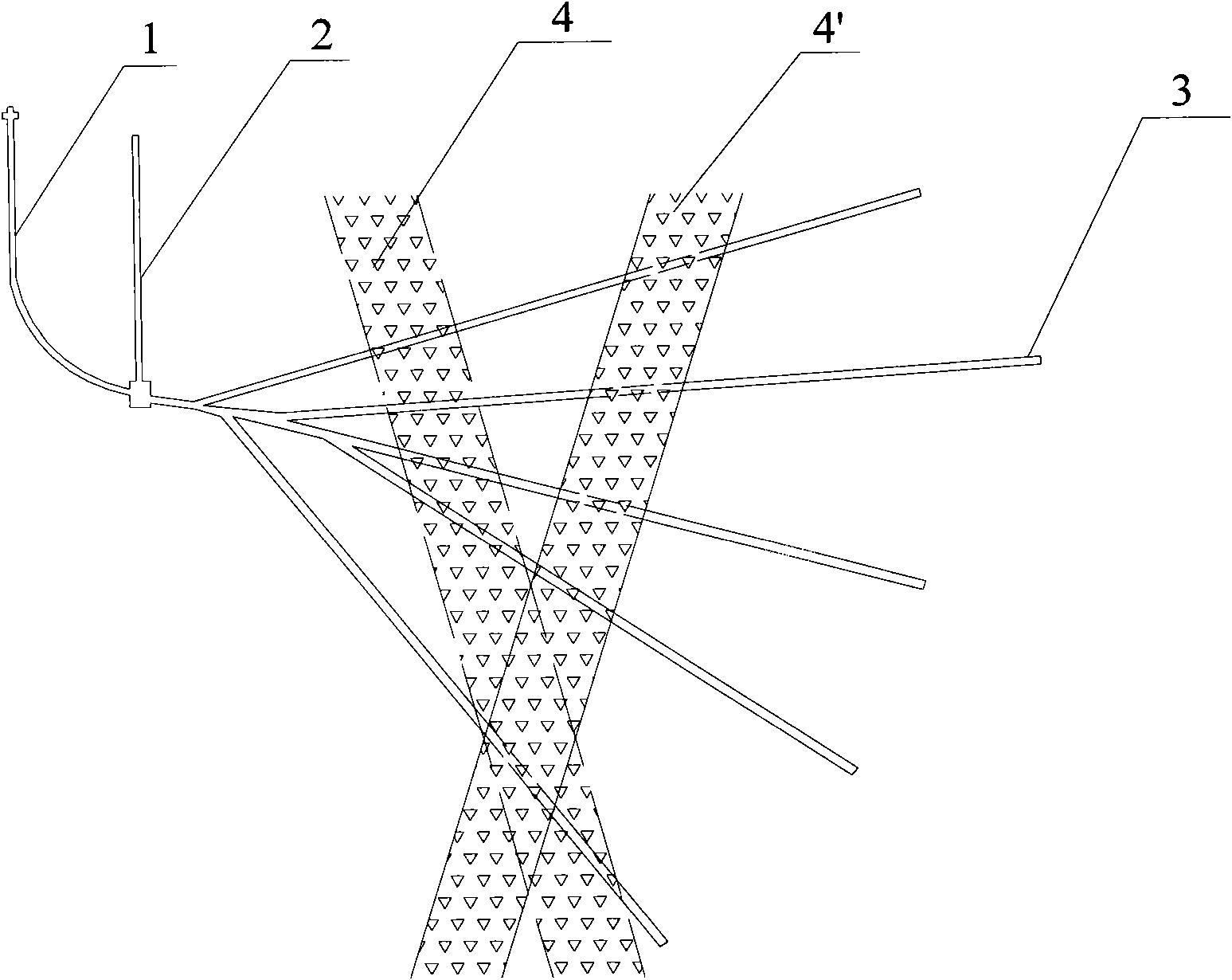

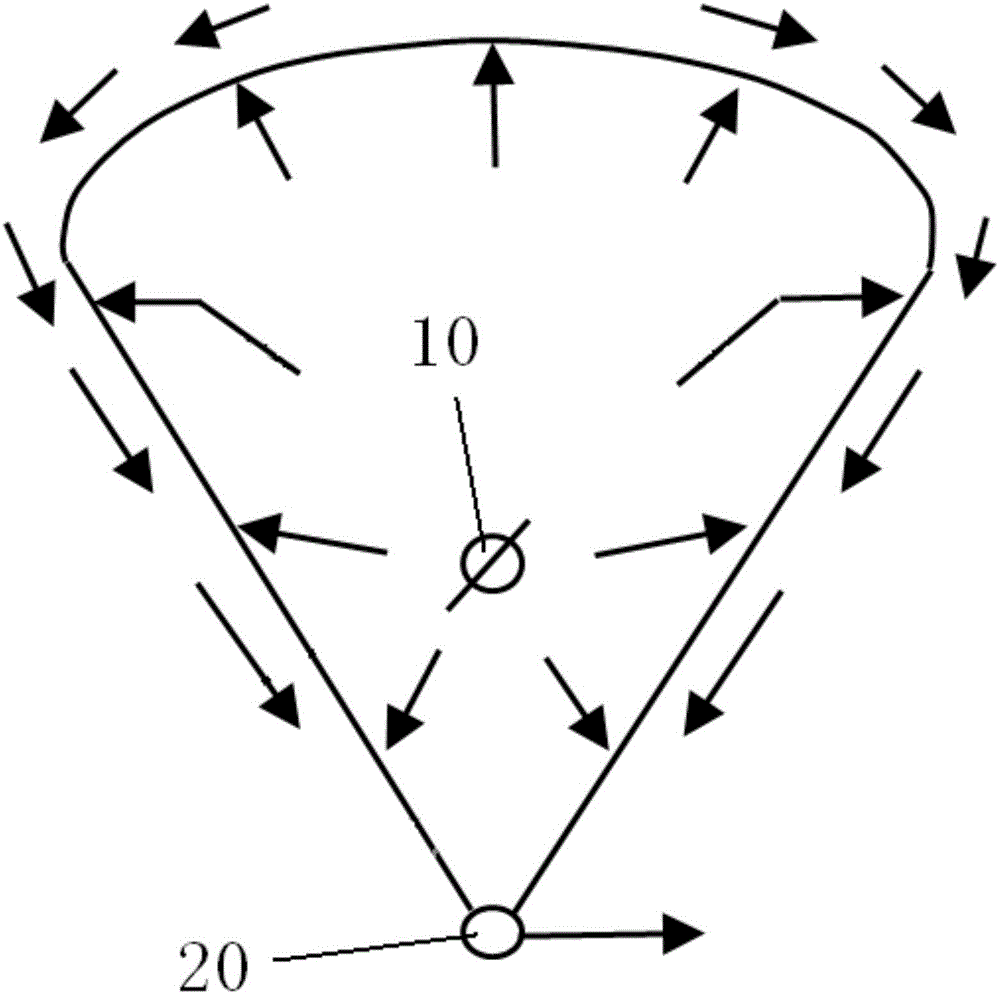

Oil production method and well pattern

ActiveCN106761631AExpand the affected volumeReduced chance of flameoutConstructionsFluid removalCombustionFlue gas

The invention discloses an oil production method and a well pattern. The oil production method includes the following steps that a steam injection well is deployed on an oil pool; the bottom of the steam injection well serves as a center of a circle, and a plurality of horizontal producing wells are deployed in a radial pattern; after deploying the plurality of producing wells, steam is injected in the oil pool through the steam injection wall; after the steam injection, oil layers in the oil pool are ignited by an igniter; after the oil layers are ignited, combustion-supporting gases are continuously injected into the oil pool through the steam injection well. According to the method, the development of a fire chamber is no longer in the direction of a single horizontal producing well, and the fire chamber is uniformly developed in the directions of the various horizontal producing wells arranged in a radial pattern, so that the firing range in the whole oil pool is gradually expanded and the probability of flame out is reduced. Meanwhile, flue gases, movable oil, firing lines and the like can move along the plurality of horizontal producing well, and therefore the firing lines uniformly advance towards multiple directions, the swept volume of combustion is enlarged, the exploiting effect is improved, and the oil production efficiency is improved.

Owner:PETROCHINA CO LTD

Method for guiding drilling and bridging of horizontal coal bed methane well

ActiveCN101936154AIncrease coal seam footageImprove the mining effectFluid removalCoalEnvironmental geology

The invention provides a method for guiding the drilling and bridging of a horizontal coal bed methane well, which is characterized by comprising the following steps of: acquiring regional earthquake data of an area to be exploited; pre-exploring a straight well according to the regional earthquake data of an area to be exploited, and measuring the actual condition of a coal bed; pre-exploring a horizontal well according to the measured actual condition of the coal bed, and measuring actual information parameters of a shatter zone in the coal bed; determining a bridging route according to the actual condition of the coal bed, the actual information parameters of the shatter zone and the deflecting capacity of a drilling tool; and moving round the position of the shatter zone by using the drilling tool according to the determined bridging route. By drilling the horizontal well according to the method for guiding the drilling and bridging of the horizontal well, the coal bed methane in a coal bed area on the other side of the horizontal well relative to the shatter zone can be reasonably utilized, the coal bed footage of the horizontal well is increased, and the yield of the coal bed methane is improved.

Owner:BEIJING ORION ENERGY TECH DEV

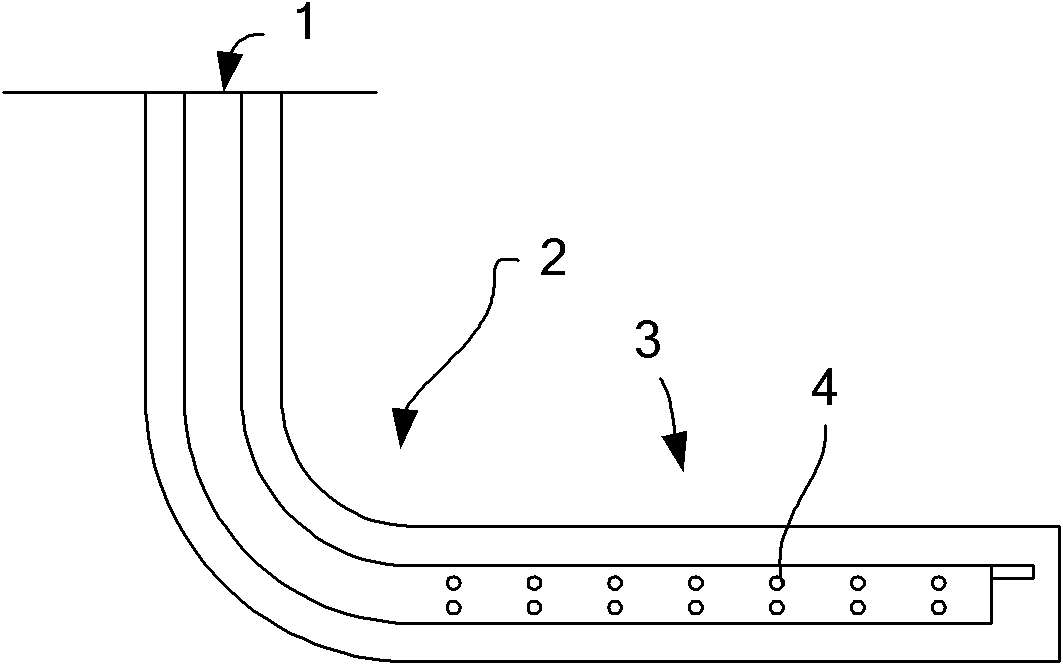

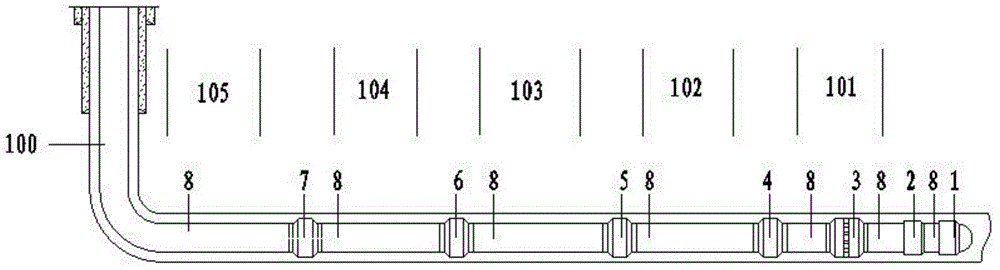

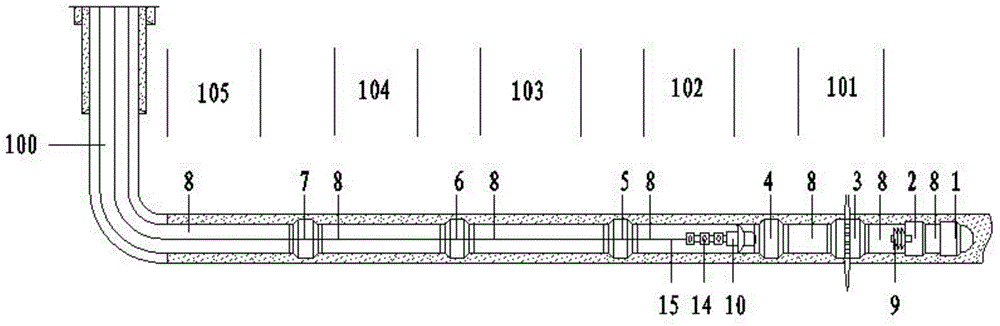

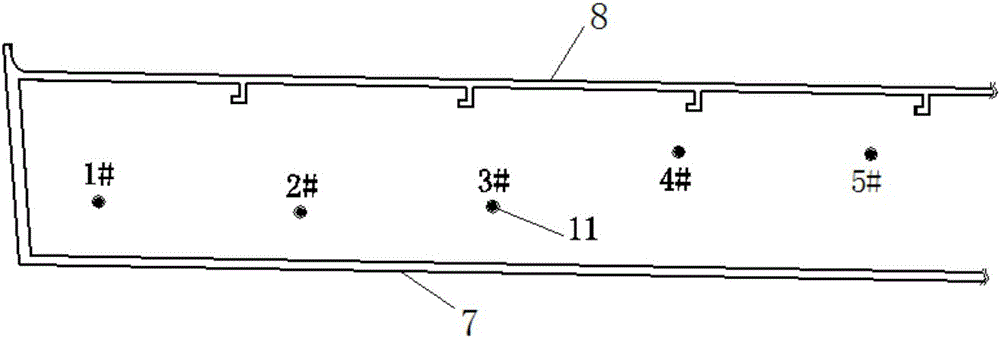

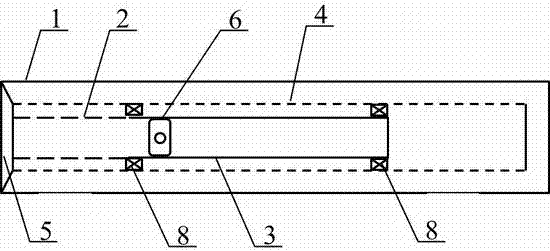

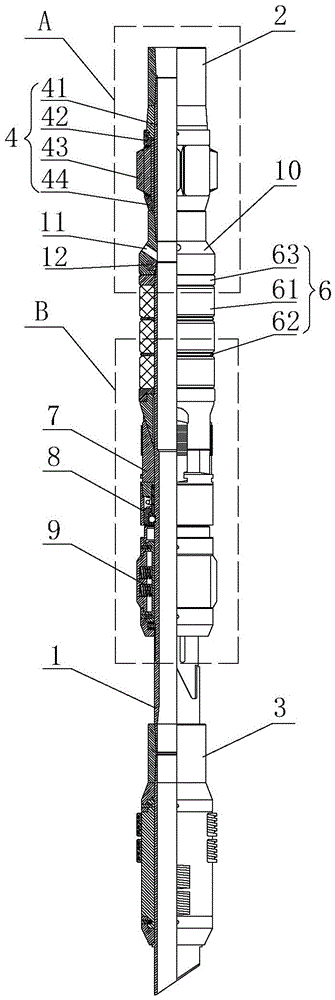

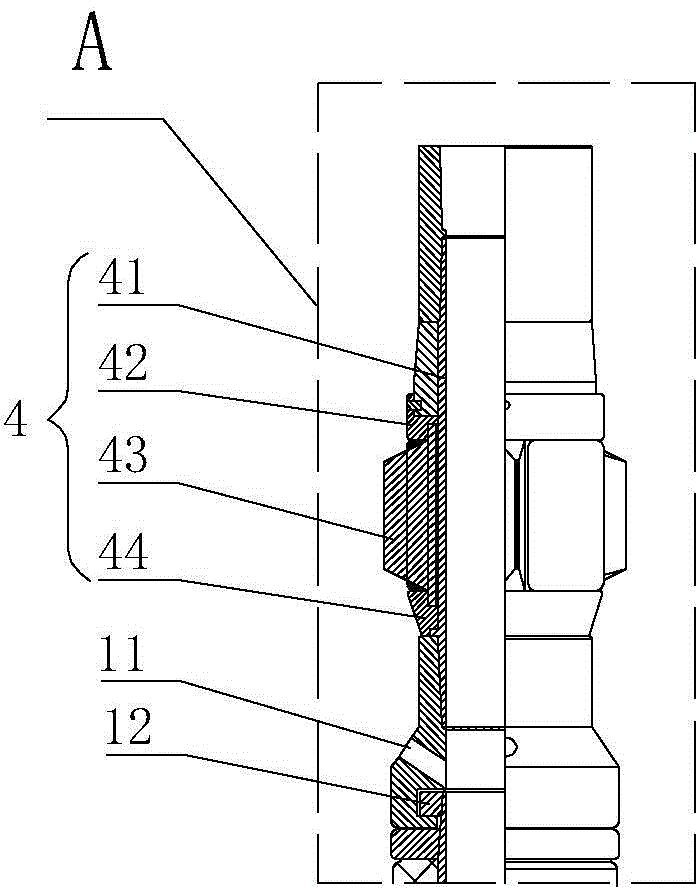

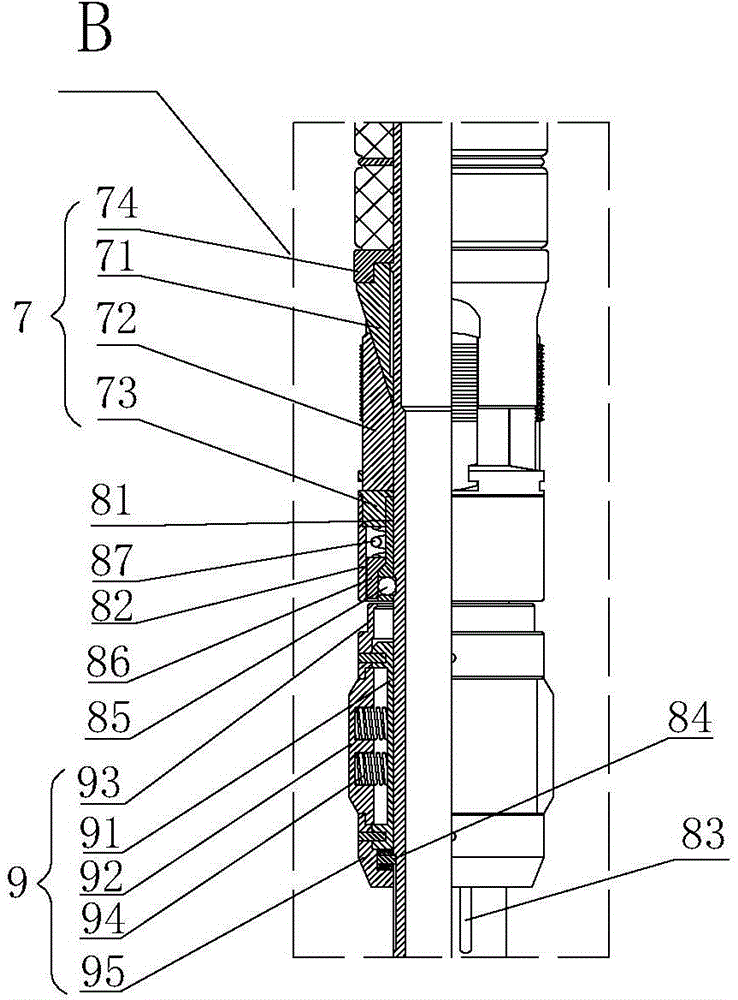

Integrated intelligent well completion design method of horizontal well

InactiveCN107025346AImprove the mining effectImprove development efficiencyData processing applicationsDesign optimisation/simulationBottom hole pressureHorizontal wells

The invention discloses an integrated intelligent well completion design method of a horizontal well. The method comprises the steps as follows: 1) preparing basic data; 2) performing optimized design on a central tube structure; 3) determining whether to trip a packer (8) as well as the tripping position and mounting number; 4) designing the flow of each phase control valve (6) according to the fluid property and the yield; 5) optimizing the valve distribution mode of the phase control valves (6); 6) determining the best number of the phase control valves (6) according to the number of the phase control valves (6) as well as the relation between the flowing bottom hole pressure and the moisture content reduction amount; 7) evaluating the water reduction effect, yield increase effect and economic benefit of a final water control scheme. The method has the benefits as follows: water control well completion optimization design can be performed on the phase control valves, water control scheme design can be performed on ICD and AICD, the design method is applicable to water control well completion in both early and later periods, and water control scheme design can be performed on horizontal wells no matter whether packers are arranged in the horizontal wells or not.

Owner:SOUTHWEST PETROLEUM UNIV

Multi-functional flap anchor

ActiveCN104453758ASimple structureImprove efficiencyBorehole/well accessoriesEngineeringService efficiency

The invention provides a multi-functional flap anchor. The anchor comprises a central pipe, wherein both ends of the central pipe are respectively connected with an upper contact and a lower contact, an anchor sheet component is arranged between the upper contact and the end part of the central pipe, one side of the anchor sheet component is rotationally connected with the end part of the central pipe through a connector in a circumferential direction, the lower end of the lower contact is connected with a scraping component, a rubber tube sealing component, a slip component and a slip sliding driving component successively and movably sleeve the central pipe between the connector and the lower contact from top to bottom, and the reciprocating sliding of the slip sliding driving component on the central pipe successively drives the slip component to be used for clamping sealing and unsealing of the slip component, and the sealing and unsealing of the rubber tube sealing component. According to the invention, the functions of creep prevention, sealing, deflection resisting, and scraping pipes under a well are realized, the structure of a pipe column is simplified, the complex degree of construction operation is reduced, the service efficiency of the flap anchor is improved, and further the exploitation effect of individual wells is improved.

Owner:PETROCHINA CO LTD

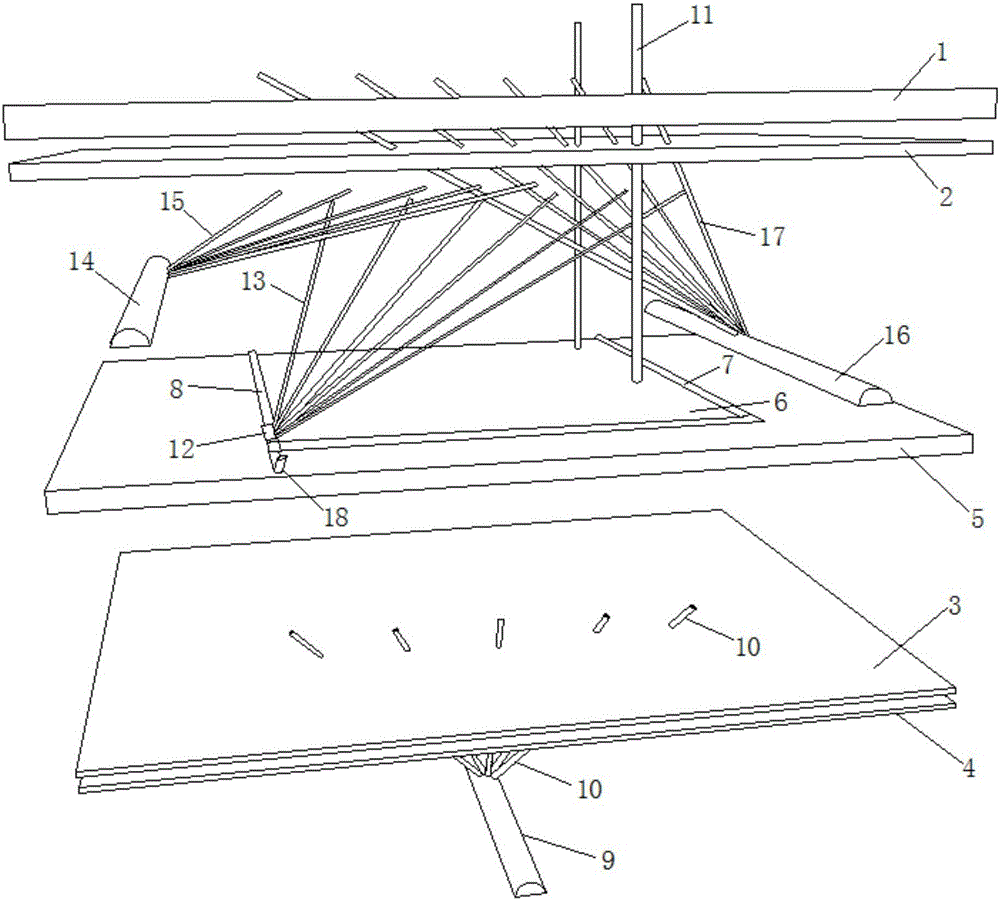

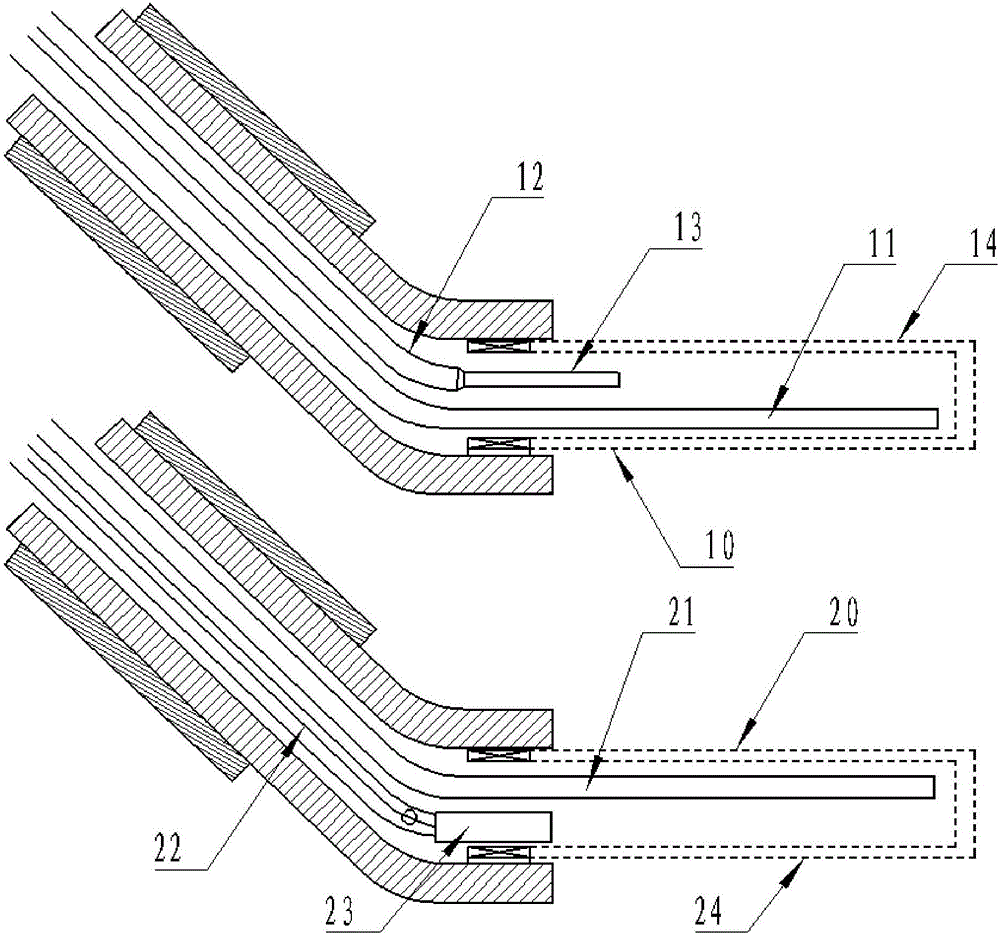

Dual-horizontal-well superheated steam assisted gravity oil drain well net and exploitation method

The invention provides a dual-horizontal-well superheated steam assisted gravity oil drain well net and an exploitation method. The dual-horizontal-well superheated steam assisted gravity oil drain well net comprises a first horizontal well (10) and a second horizontal well (20); a first long pipe column (11) and a first short pipe column (12) are arranged in the first horizontal well (10); and a second long pipe column (21) and a second short pipe column (22) are arranged in the second horizontal well (20). According to the dual-horizontal-well superheated steam assisted gravity oil drain well net and the exploitation method, a superheated steam assisted gravity oil drain mode is adopted, the problems that in the wet and saturated steam injection process, the heat utilization rate is low, the oil-steam ratio is low, and a reservoir stratum is damaged are solved, the heat utilization rate and the oil-steam ratio are increased, and the exploitation effects of a super heavy oil reservoir and a oil sand reservoir stratum are improved.

Owner:PETROCHINA CO LTD

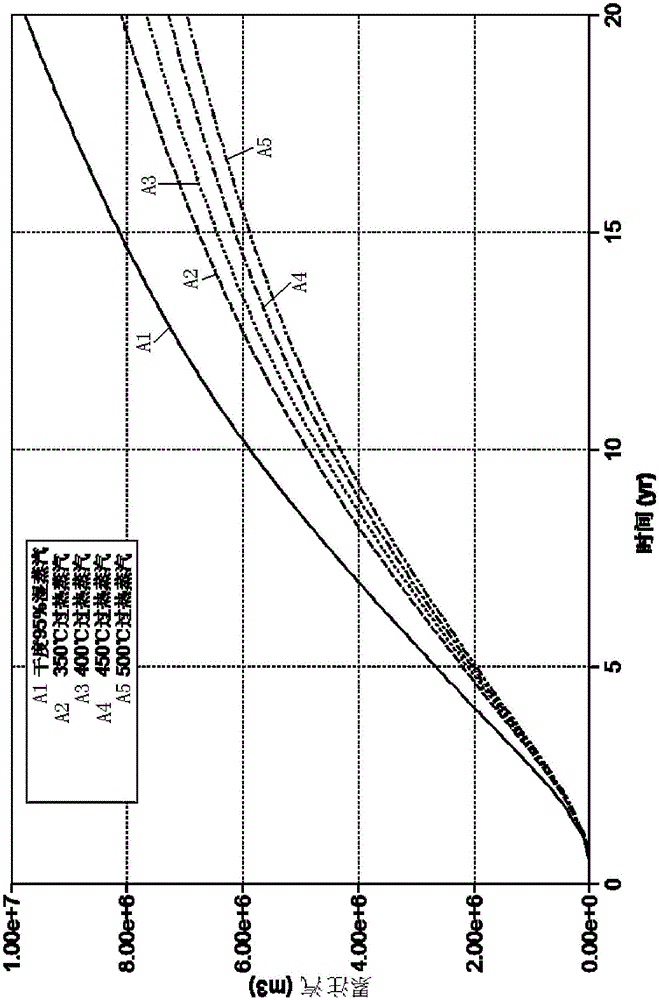

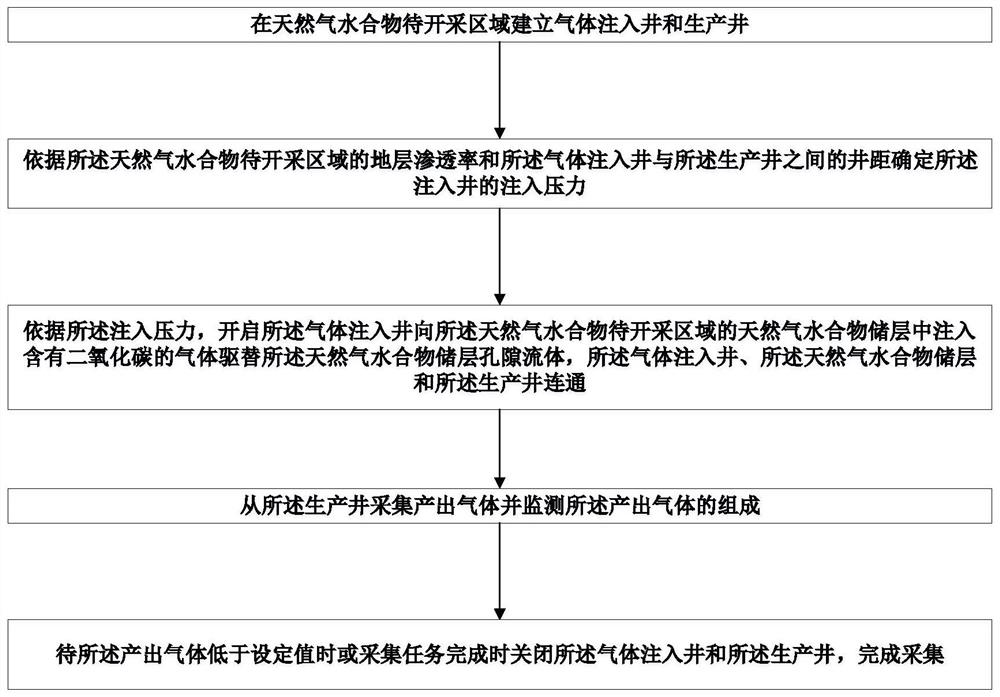

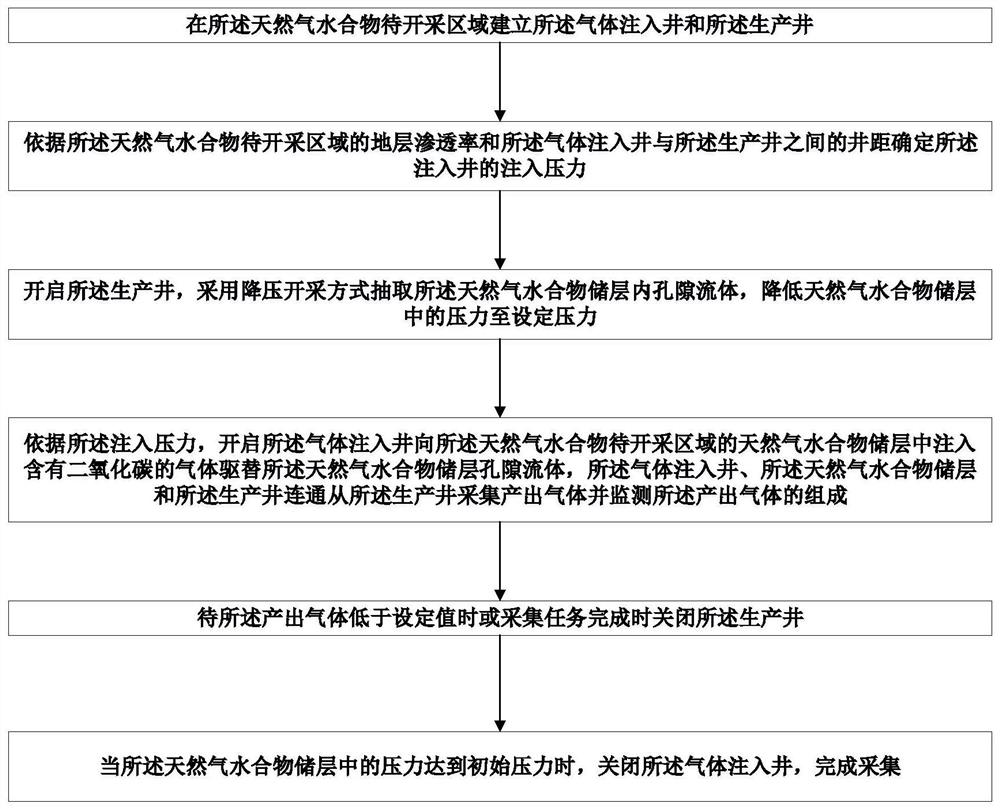

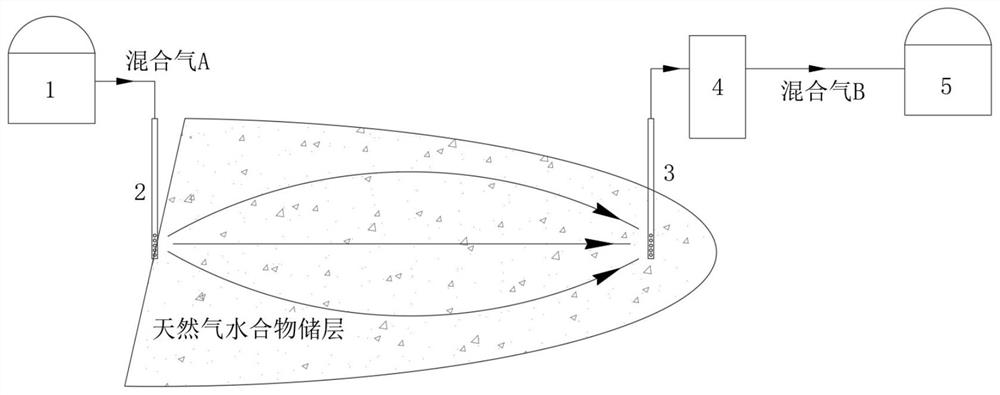

Method for exploiting natural gas hydrate

ActiveCN112901121AHigh decomposition driving forcePrevent intrusionSurveyOther gas emission reduction technologiesPore fluidInjection well

The invention provides a method for exploiting natural gas hydrate. The method comprises the following steps that a gas injection well and a production well are built in a natural gas hydrate to-be-exploited area; according to the formation permeability of the natural gas hydrate to-be-exploited area and the well spacing between the gas injection well and the production well, the injection pressure of the injection well is determined; according to the injection pressure, the gas injection well is opened to inject gas containing carbon dioxide into a natural gas hydrate reservoir of the natural gas hydrate to-be-exploited area to displace pore fluid of the natural gas hydrate reservoir, and the gas injection well, the natural gas hydrate reservoir and the production well communicate with one another; the produced gas is collected from the production well, and the composition of the produced gas is monitored; and when the produced gas is lower than a set value or the collection task is completed, the gas injection well and the production well are closed to complete the collection. High-pressure gas displaces pore fluid to reduce natural gas partial pressure in a pore fluid phase, meanwhile, the high-pressure gas effectively inhibits invasion of a peripheral water phase, and the exploiting effect is improved.

Owner:SHENZHEN GRADUATE SCHOOL TSINGHUA UNIV

Heavy oil thermal recovery chemical synergist and preparation method of same

InactiveCN105315981AImprove the mining effectSimple construction processDrilling compositionComponents of crude oilSURFACTANT BLEND

The invention provides a heavy oil thermal recovery chemical synergist and a preparation method of same. The synergist is prepared by compounding a small cationic quaternary ammonium salt, a surfactant, alkali, wherein the small cationic quaternary ammonium salt accounts for 10-40% by weight, the surfactant accounts for 5-25% by weight, the alkali accounts for 1-5% by weight, and the balanced being water. The preparation method includes the following steps: 1) dissolving sodium hydroxide, sodium carbonate, or a mixture composed of sodium hydroxide and sodium carbonate; and 2) adding the surfactant at 20-40 DEG C and mixing and stirring the mixture for 1-2 h, and adding the small cationic quaternary ammonium salt with stirring for 1-2 h. The small cationic quaternary ammonium salt can separate out adsorbed water among lattices of clay so that expanded clay can be dehydrated and shrunk and strata permeability is recovered, wherein a part of decomposable gases can generate a high pressure and driving energy under a vapor temperature. Hydrogen bonds in the surfactant can be combined with the hydrogen bonds in colloids and asphaltene, so that the colloids, the asphaltene and other heavy components which are deposited on surface of rocks can be diluted and stripped away under the effect of vapor. The synergist has the effects of both increasing oil displacement efficiency and enlarging vapor swept volume, has significant application effects and is suitable for vapor exploitation of heavy oil reservoir.

Owner:新疆贝肯科技开发有限公司

Walking rock excavator

ActiveCN109653744AUninterrupted miningGuaranteed stabilityDriving meansPropulsionEffective actionEngineering

The invention belongs to the technical field of mining equipment in a mining industry, and particularly relates to a walking rock excavator which comprises a body, four first electric hydraulic push rods, long ship legs, a movable table and sliding grooves. The four first electric hydraulic push rods are fixedly connected to the lower end of the body and sequentially arranged at the lower end of the body. By the aid of the long ship legs, the stability of the walking rock excavator can be ensured in the moving process, the walking rock excavator is prevented from inclination in the moving process and can normally move forwards or backwards under the effective action of third electric hydraulic push rods, the sliding grooves and sliders on the surface of the movable table, the purpose of the walking rock excavator is achieved, mined rocks cannot affect movement of the walking rock excavator under the action of a striker plate, and the advancing capacity of the walking rock excavator isensured.

Owner:广西恒为建材科技有限公司

Differential evolution algorithm-based modularity optimization method

InactiveCN108171331AImprove accuracyImprove stabilityNeural learning methodsCommunity structureModularity

The invention discloses a differential evolution algorithm-based modularity optimization method. The method comprises the steps of initializing a population; setting network parameters including a node number n, an adjacent matrix adj and a community correction threshold delta; setting DE algorithm parameters including an individual dimension D, a population size NP, a population iteration frequency t and a maximum iteration frequency tmax; randomly initializing the population pop in an individual representation mode of a community label; then identifying and recording an optimal solution; when the population iteration frequency is smaller than the maximum population iteration frequency, automatically adding 1 to the population iteration frequency, and when the condition is met, ending thecirculation of 3.1-3.5; performing community correction based on neighborhood information; and outputting Xgbest in the pop, wherein t serves as final optimal community division. The method improvesthe accuracy, stability and expandability of the optimal community division; and complex networks with very fuzzy community structures are involved.

Owner:DALIAN NATIONALITIES UNIVERSITY

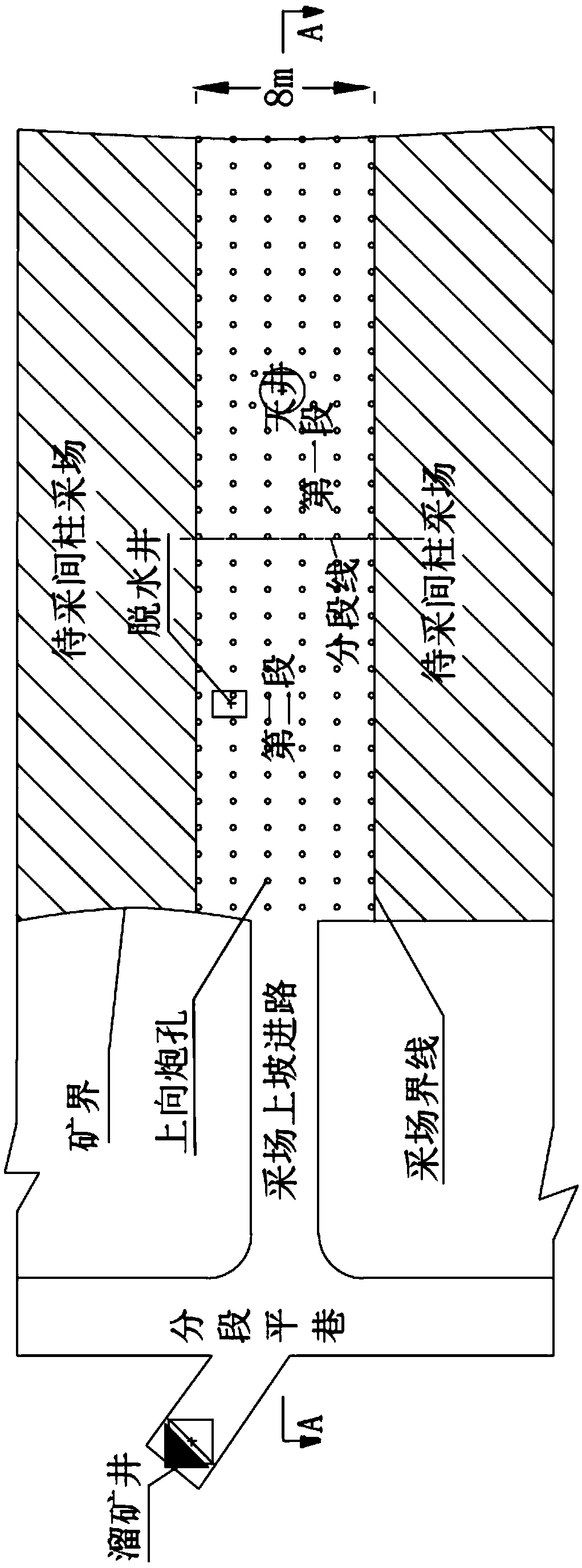

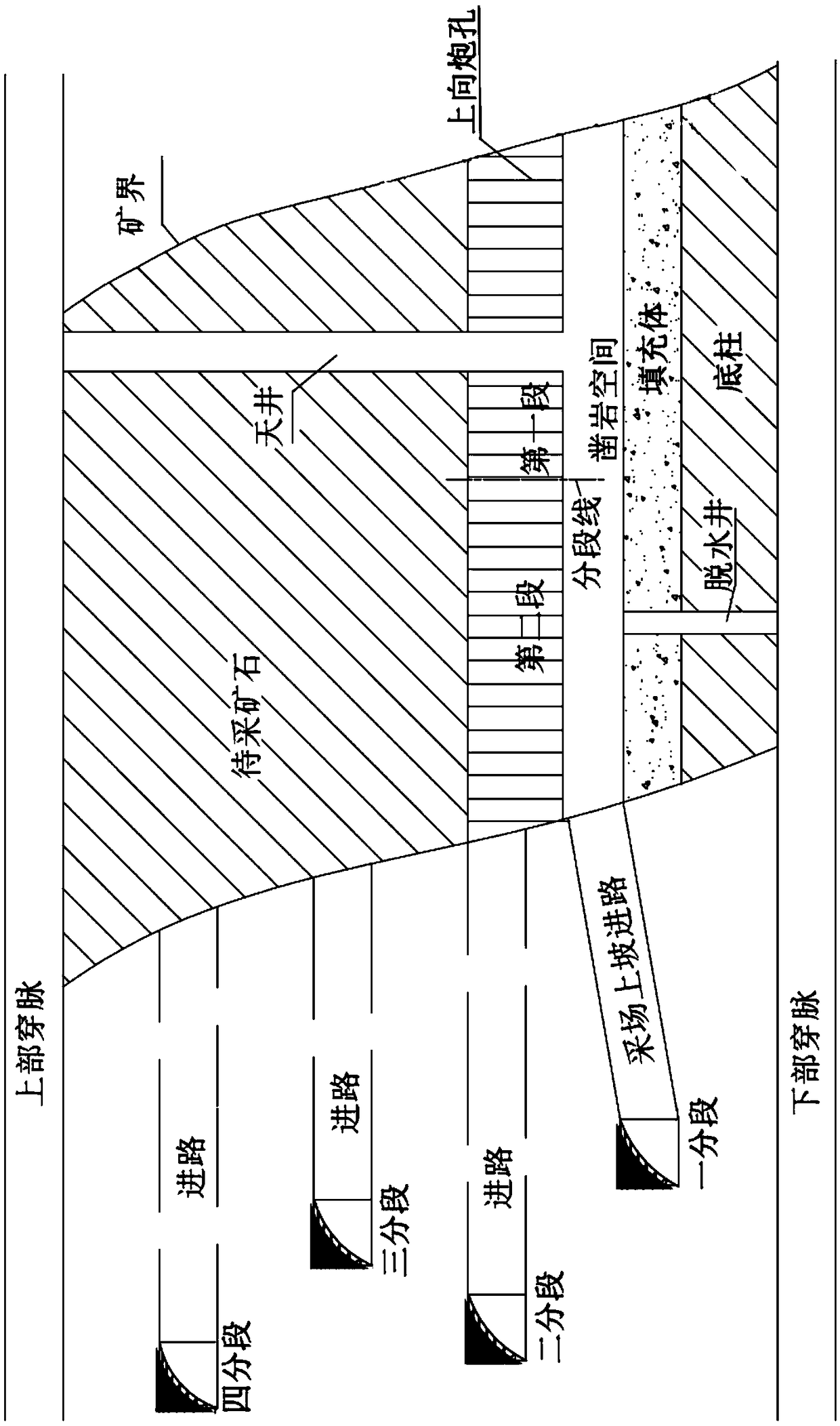

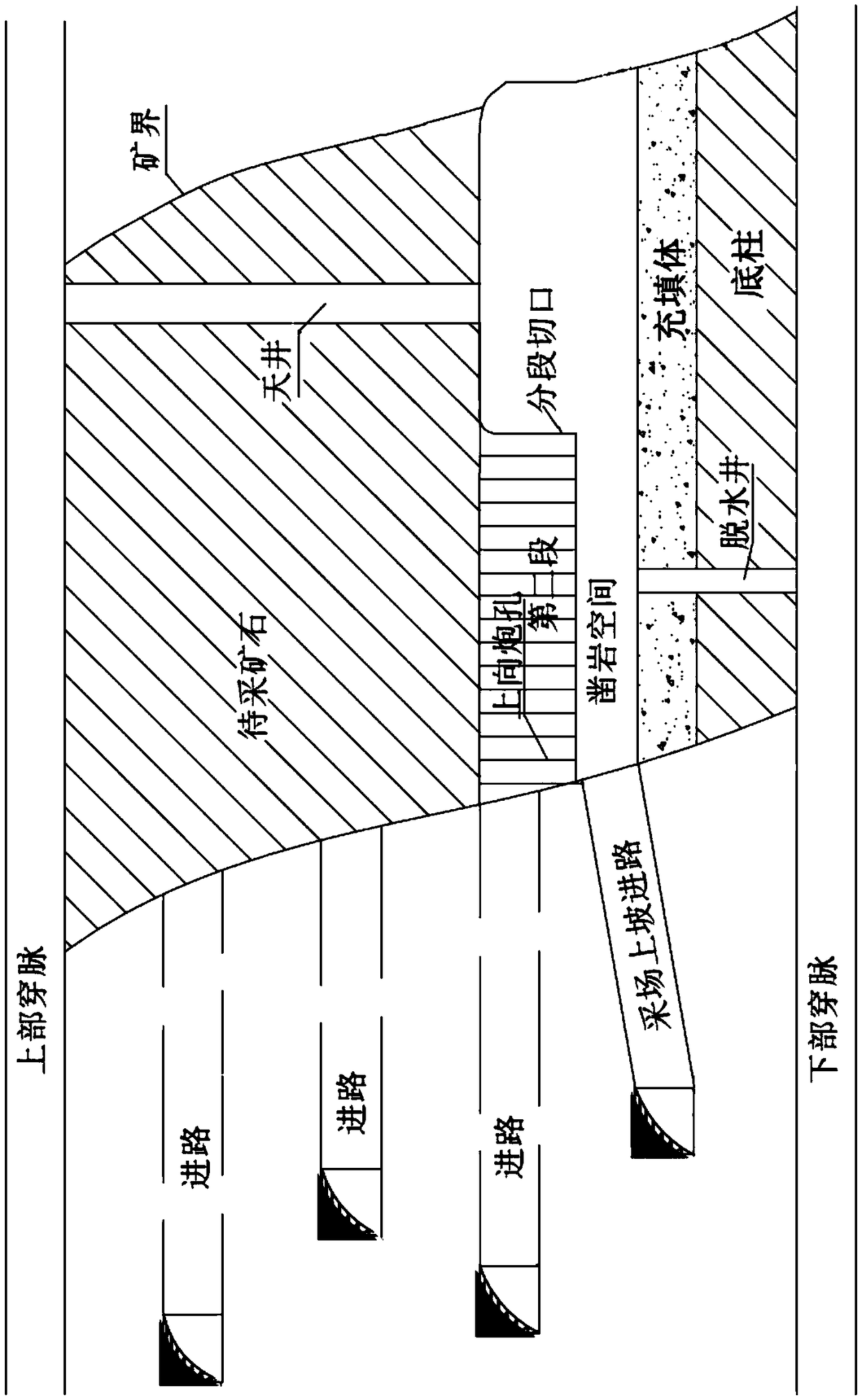

Mechanized upward segmental recovery method

ActiveCN108708721AEliminate potential safety hazardsImprove securityUnderground miningSurface miningRecovery methodComputer science

The invention relates to a mechanized upward segmental recovery method. The recovery method includes the following steps of (1) conducting segmentation on a recovery field; (2) conducting arrangementof blast holes, wherein the 0-th row of blast holes are distributed along a segmentation line of the recovery field, the -1-th row, -2-th row...and -i-th row of blast holes and the 1-st row, 2-nd row...and n-th row of blast holes are sequentially distributed in a first segment and a second segment respectively in the direction away from the 0-th row of blast holes, the orifices of the 0-th row ofblast holes are positioned in the segmentation line, the array pitch between the 0-th row and the orifices of the -1-th row of blast holes is 1.4 m, the array pitch between the 0-th row and the orifice bottoms of the -1-th row of blast holes is 0.8 m, the array pitch between the 1-st row and the orifices of the 0-th row of blast holes is 2.3 m, the array pitch between the 1-st row and the orificebottoms of the 0-th row of blast holes is 1.4 m, the array pitch between the 2-nd row and the orifices of the 1-st row of blast holes is 0.5 m, the array pitch between the 2-nd row and the orifice bottoms of the 1-st row of blast holes is 1.5 m, the array pitch between the 3-rd row and the orifices of the 2-nd row of blast holes is 1.0 m, the array pitch between the 3-rd row and the orifice bottoms of the 2-nd row of blast holes is 1.5 m, the -1-th row, -2-th row and -i-th row of blast holes and the 3-rd row, 4-th row and n-th row of blast holes are all vertical blast holes facing upwards, andthe array pitch of these rows is 1.4 m; (3) conducting segmental blasting for discharging ore. The recovery method has the advantages that the safety is high, the recovery effect is great, and damageof the ore is small.

Owner:深圳市中金岭南有色金属股份有限公司凡口铅锌矿 +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com