Mining method for heavy oil reservoir and well network thereof

A technology for heavy oil reservoirs and production methods, which is applied in the fields of production of fluids, earth-moving drilling, wellbore/well components, etc., can solve the problems of slow heat transfer speed, shortened steam flooding life period, and rising water content of production wells, etc. Achieve the effect of improving the mining effect, reducing the drilling cost and improving the utilization of heat

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] In order to have a clearer understanding of the technical features, purposes and effects of the present invention, the specific implementation manners of the present invention will now be described with reference to the accompanying drawings.

[0042] The invention provides a mining method for heavy oil reservoirs. The reservoir conditions applicable to the mining method are: deep burial (1000-1400m), high viscosity of crude oil (5000-10000mPa.s), and relatively large oil layer thickness (40 -60m). Under such reservoir conditions, the superiority of the present invention can be better embodied. The mining method comprises the steps of:

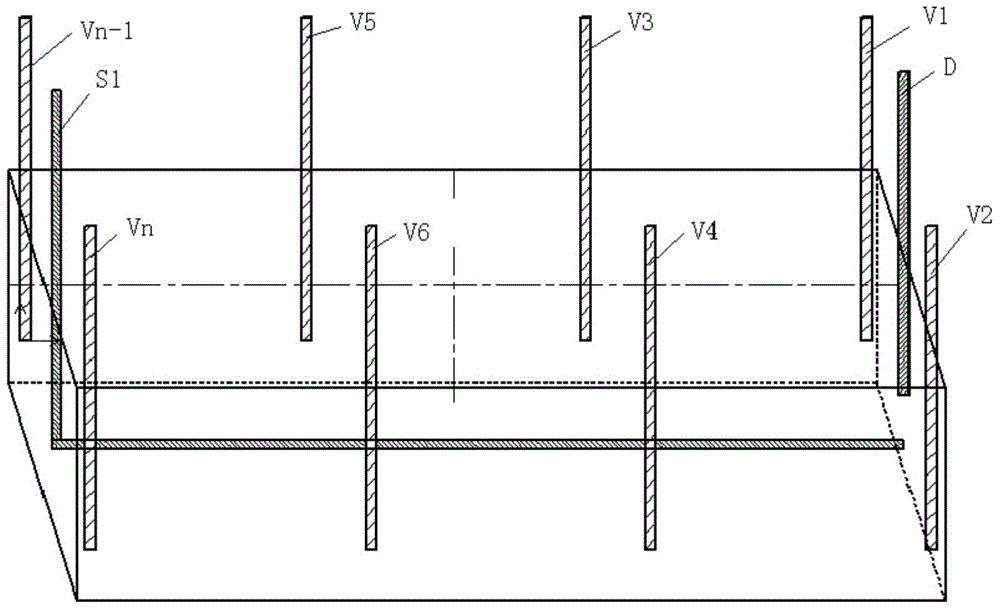

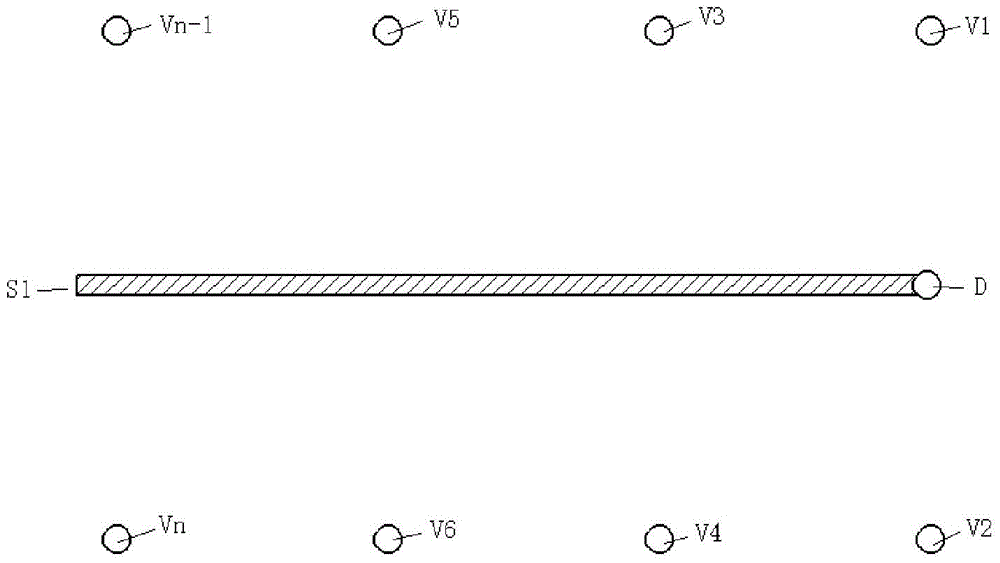

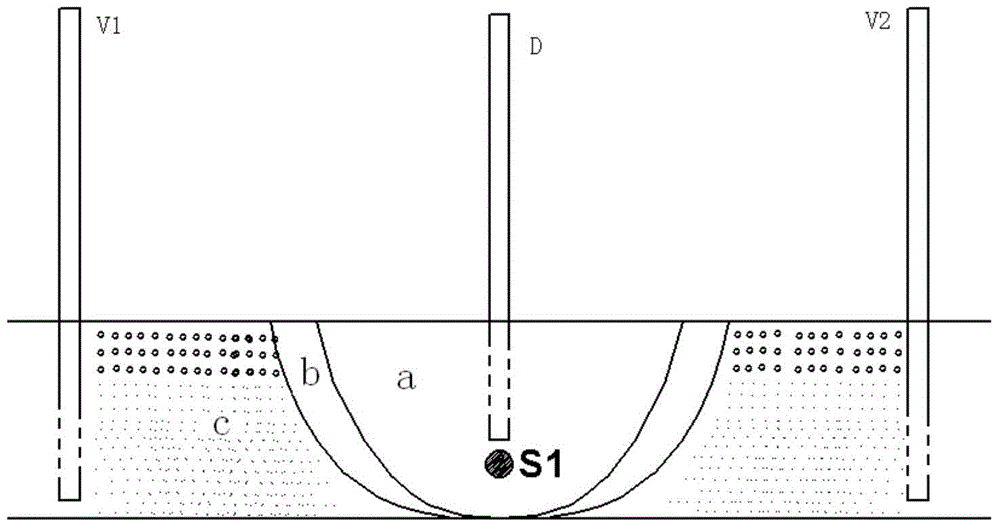

[0043] (1) Set the well pattern, which includes multiple groups of production well groups, such as figure 1 and figure 2 As shown, each production well group includes a horizontal well S1, a middle vertical well D located at the toe of the horizontal well, and a plurality of side vertical wells Vn (n=1, 2, 3, ...) symmetrically dist...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com