Mechanized upward segmental recovery method

A segmented line and segmented blasting technology, which is applied in surface mining, earthwork drilling, underground mining, etc., can solve the problems of hidden safety hazards, short distances, and high space, so as to ensure the blasting effect, reduce hidden dangers, and improve the distribution The effect of hole efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

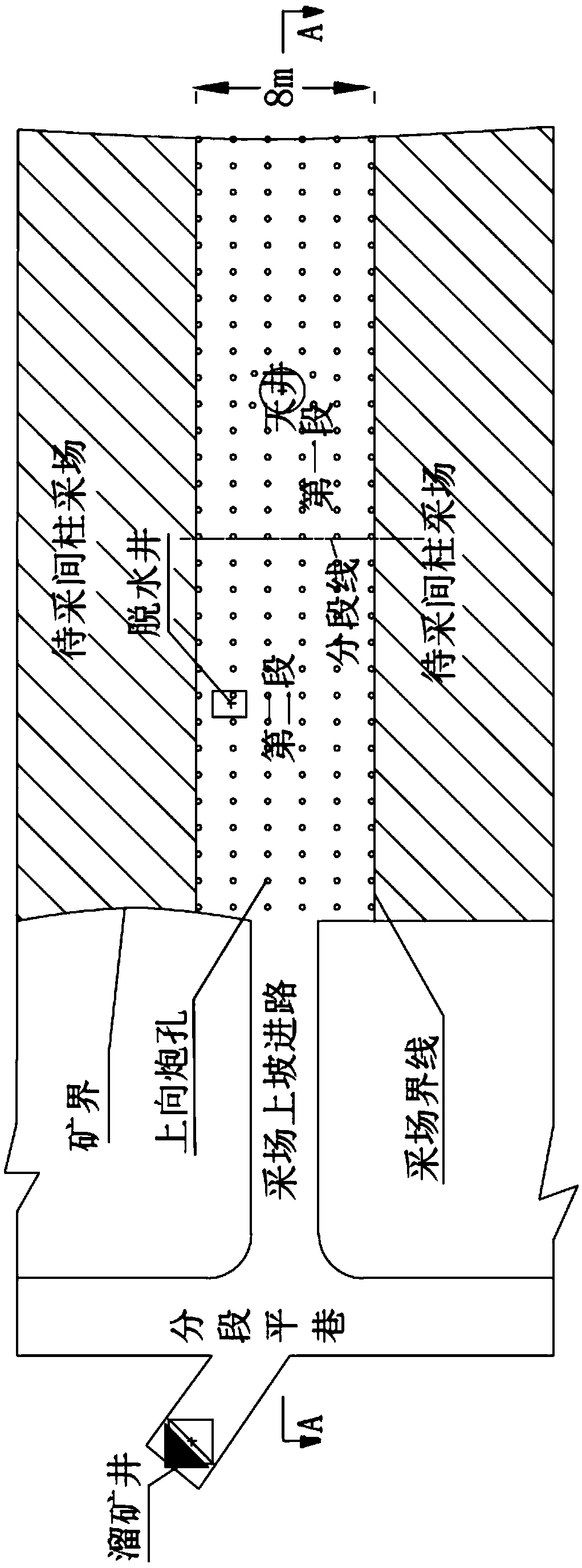

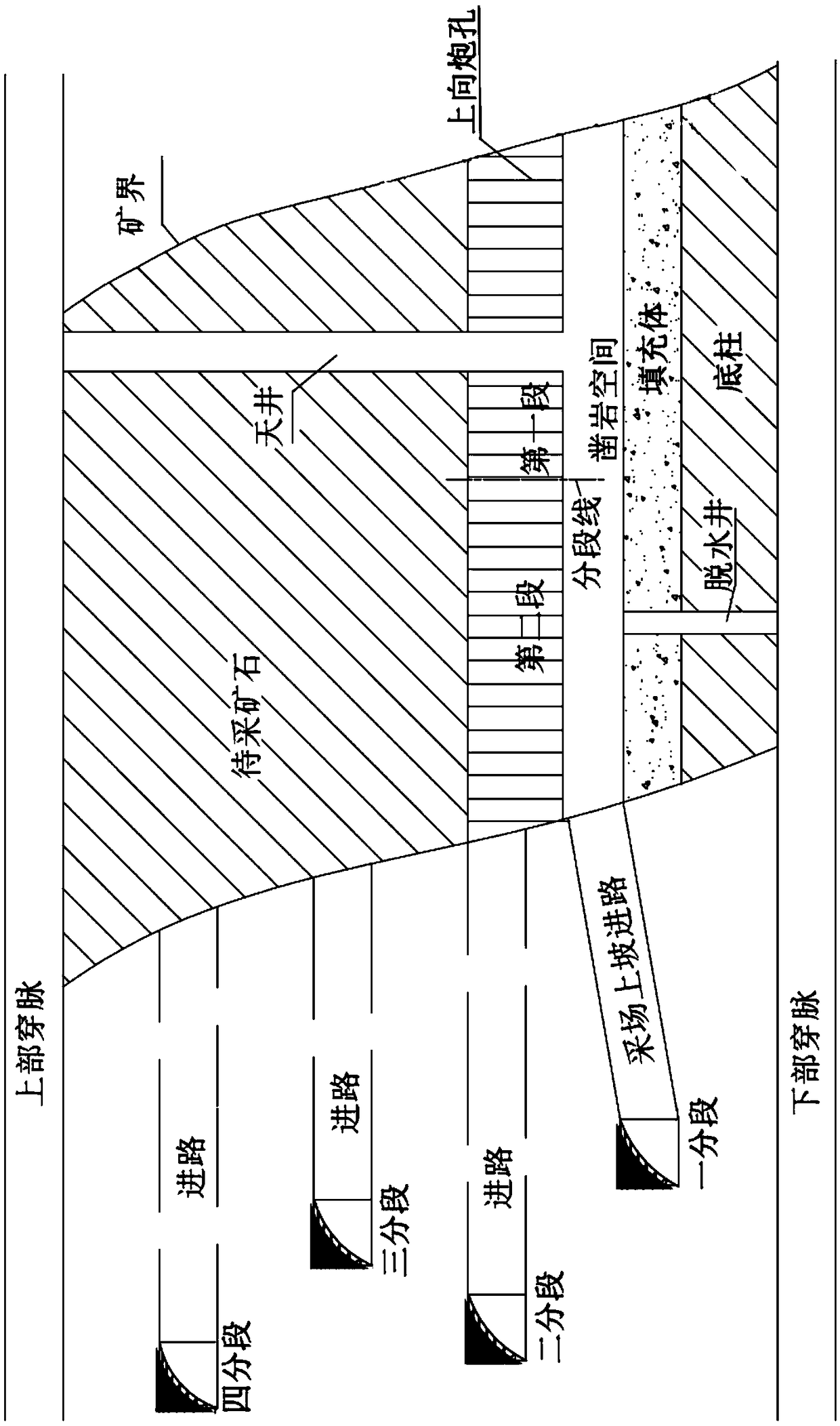

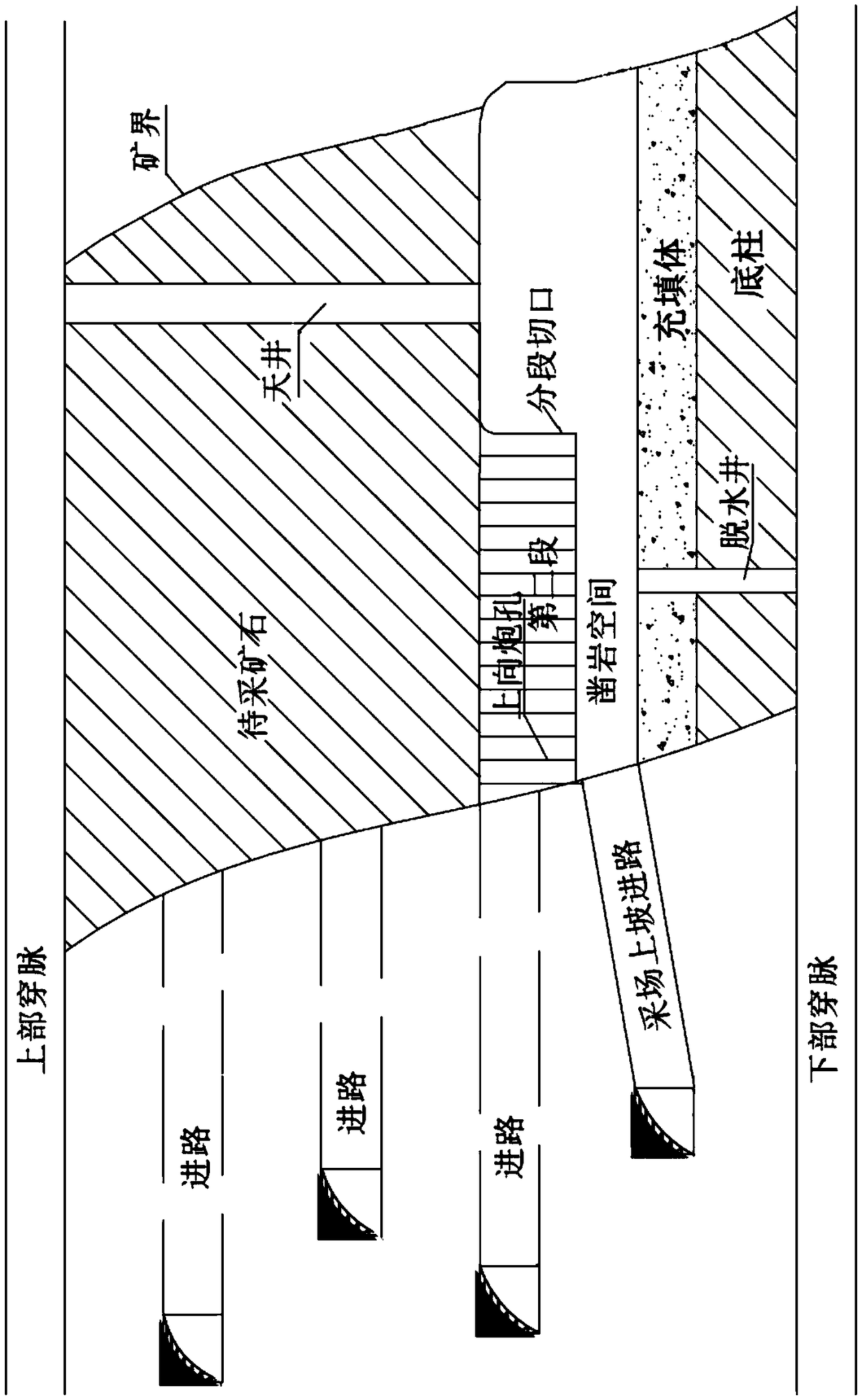

[0033] Please also see Figure 4 with Figure 5 , Figure 4 It is the plan view of blast hole opening layout before the first section blasting of the recovery method of the present invention, Figure 5 for Figure 4 B-B longitudinal section view.

[0034] Using the high-layer mechanized upward mining method of the present invention to recover a stope with a length exceeding 50m, specifically comprises the following steps:

[0035] (1) Stope segmentation:

[0036] According to the length direction of the stope, the stope is divided into the first section and the second section from the inside to the outside, and a segment line is drawn between the first section and the second section. The first section is far from the stope approach, and the second section is closer to the stope approach.

[0037] (2) Blast hole layout:

[0038] The 0th row of blastholes is arranged along the section line of the stope, and the -1st row, the -2nd row, ..., the No. -i row of gun holes, i ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com