Method for extracting thick oil

A heavy oil, cold recovery technology, applied in the direction of production fluid, chemical instruments and methods, earthwork drilling and production, etc., can solve the problems of flowing into the wellbore, etc., achieve the effects of reducing production and operation costs, improving the effect of heavy oil recovery, and improving fluidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] Example 1: Ze 70 heavy oil reservoir in Shennan Oilfield. Qp, Nm, Ng, Ed and Es formations are developed from top to bottom in the reservoir. The oil layers are mainly distributed in Ed. The average middle depth of the oil reservoir is 2400m. The physical properties of the oil layers are For: porosity: 15% to 25.5%; permeability: 208×10-3 ~2290×10 -3 μm 2 ; Ground crude oil viscosity: (50°C) 1157~85085mPa.s; 20°C crude oil density: 0.9442~1.0035g / cm 3 ; Freezing point: 20~40℃; Colloidal asphaltenes: 29.38%~71.23%; Sulfur content: 0.4%~0.82%; Wax content: 1.56~10.75%; Average reservoir temperature: 93.4℃; 100m; original formation pressure: 23.08MPa; pressure coefficient: 0.99, which belongs to normal temperature and normal pressure heavy oil reservoir.

[0038] During the development of this reservoir, the acid value of heavy oil in fault block Ze 70 was measured to be 1.26-1.85mgKOH / g, which belongs to highly active heavy oil. The following steps were taken during the...

Embodiment 2

[0047] Example 2: Well Ze 70-25, surface crude oil viscosity: (50°C) 9886.2mPa.s;

[0048] 1. Step 1 of Example 1 is adopted.

[0049] 2. Step 2 of Example 1 is adopted.

[0050] 3. Use the lifting equipment pumping unit to lift the produced well fluid; and it is detected that the viscosity at 50°C is 9812.3mPa.s (due to different sampling times, the measured viscosity value has certain fluctuations);

[0051] 4. Preparation of viscosity reducer III: The weight ratio of each component of viscosity reducer III: 32% of demulsifier AP121, 6.2% of ethyl acetate, the rest is water, and the sum of the weight percentages of each component is 100%.

[0052] The method for preparing viscosity reducer III: add the three components of demulsifier AP121, ethyl acetate and water into the enamel reaction kettle in proportion under constant stirring. Slowly raise the temperature to 55°C, stop heating after stirring for 60 minutes, stir while cooling to normal temperature, and discharge to ...

Embodiment 3-5

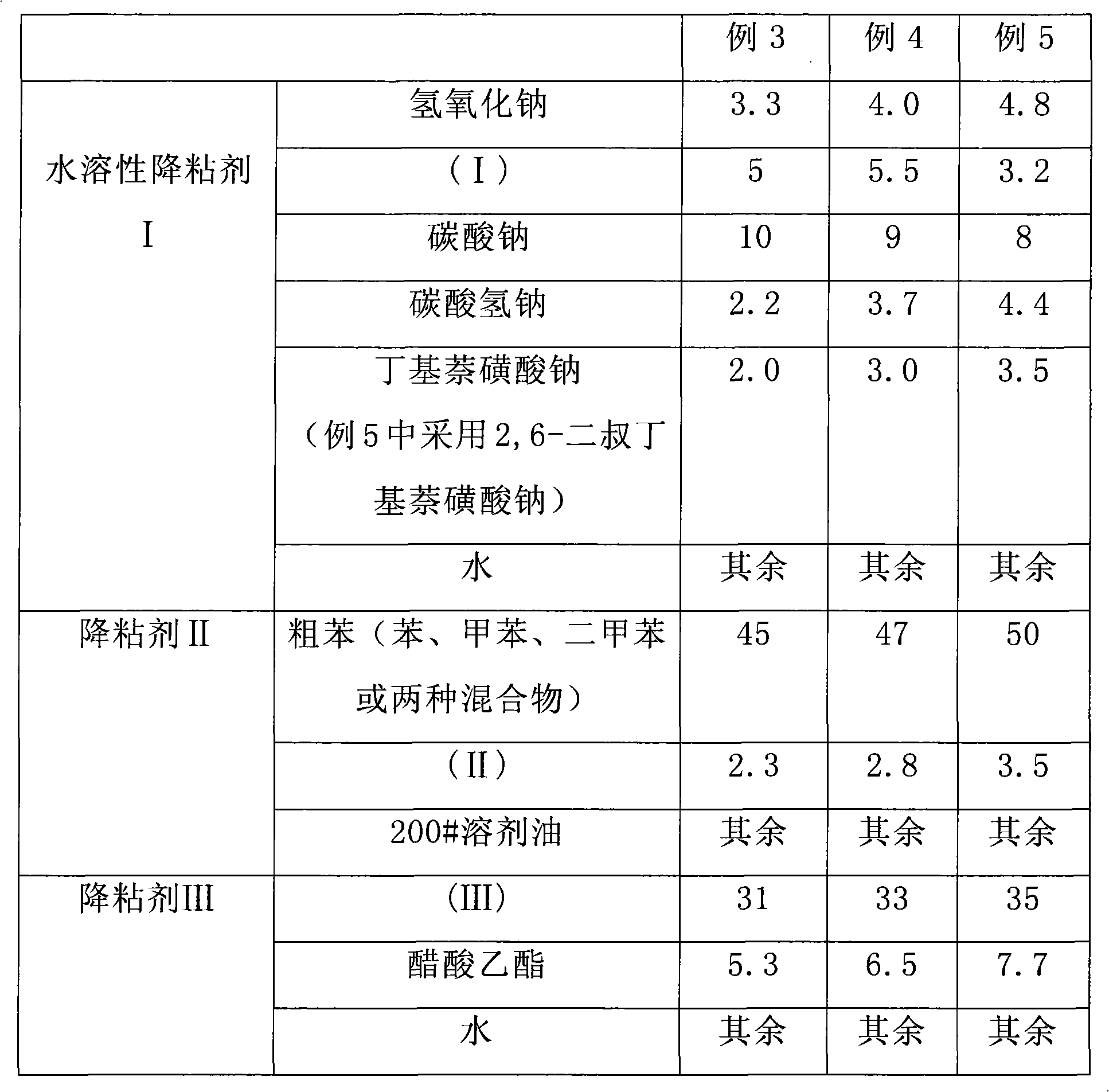

[0055] Embodiment 3-5: The weight percentage of each component is listed as follows: the sum of the weight percentage of each component is 100%. (adopted in embodiment 5 is 2,6-di-tert-butylnaphthalene sodium sulfonate)

[0056]

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| freezing point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com