Method for guiding drilling and bridging of horizontal coal bed methane well

A technology for horizontal wells and coalbed methane, which is applied to wellbore/well components, earthwork drilling, and fluid extraction, etc., can solve the problems of wasting resources and reducing the production volume of coalbed methane, and achieves the effect of increasing the footage of coal seams and improving the mining effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

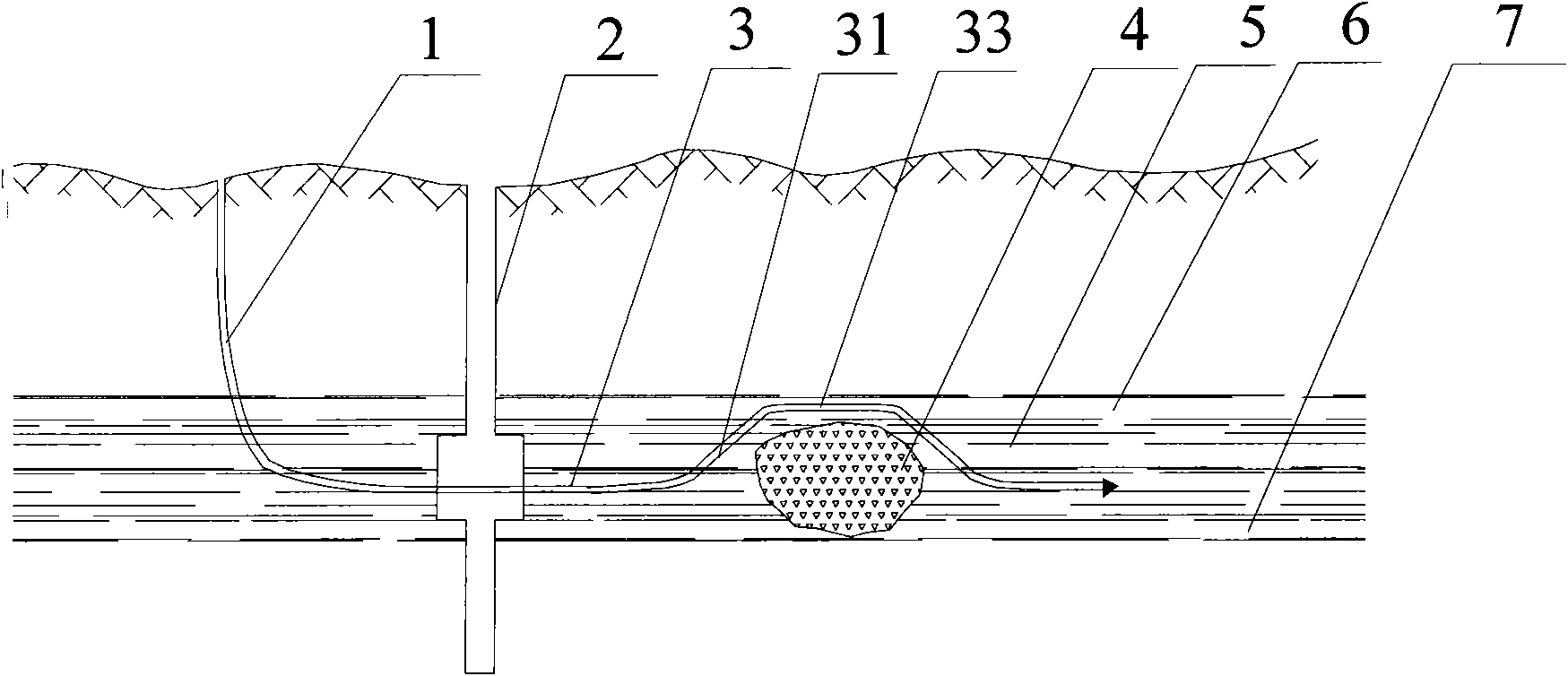

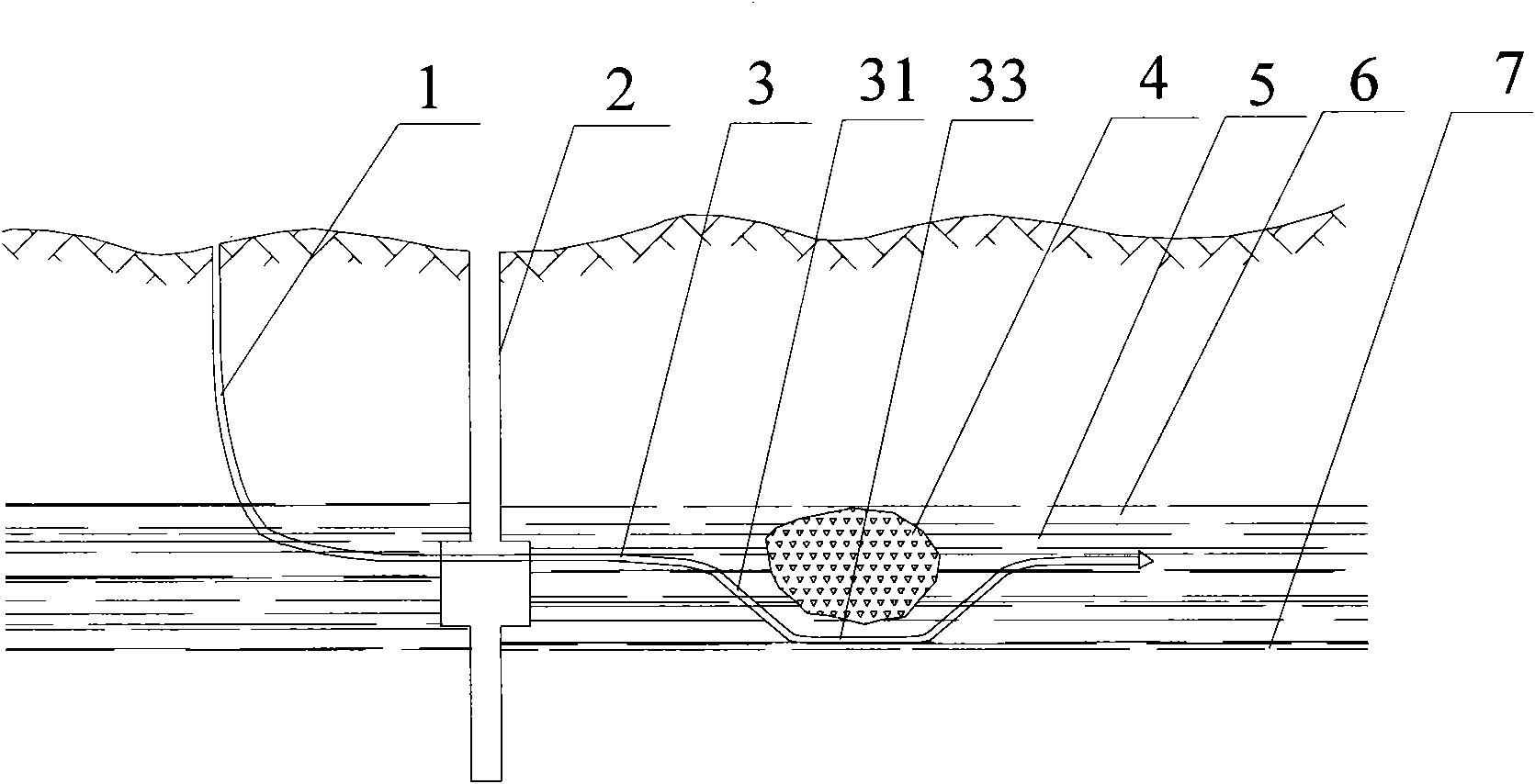

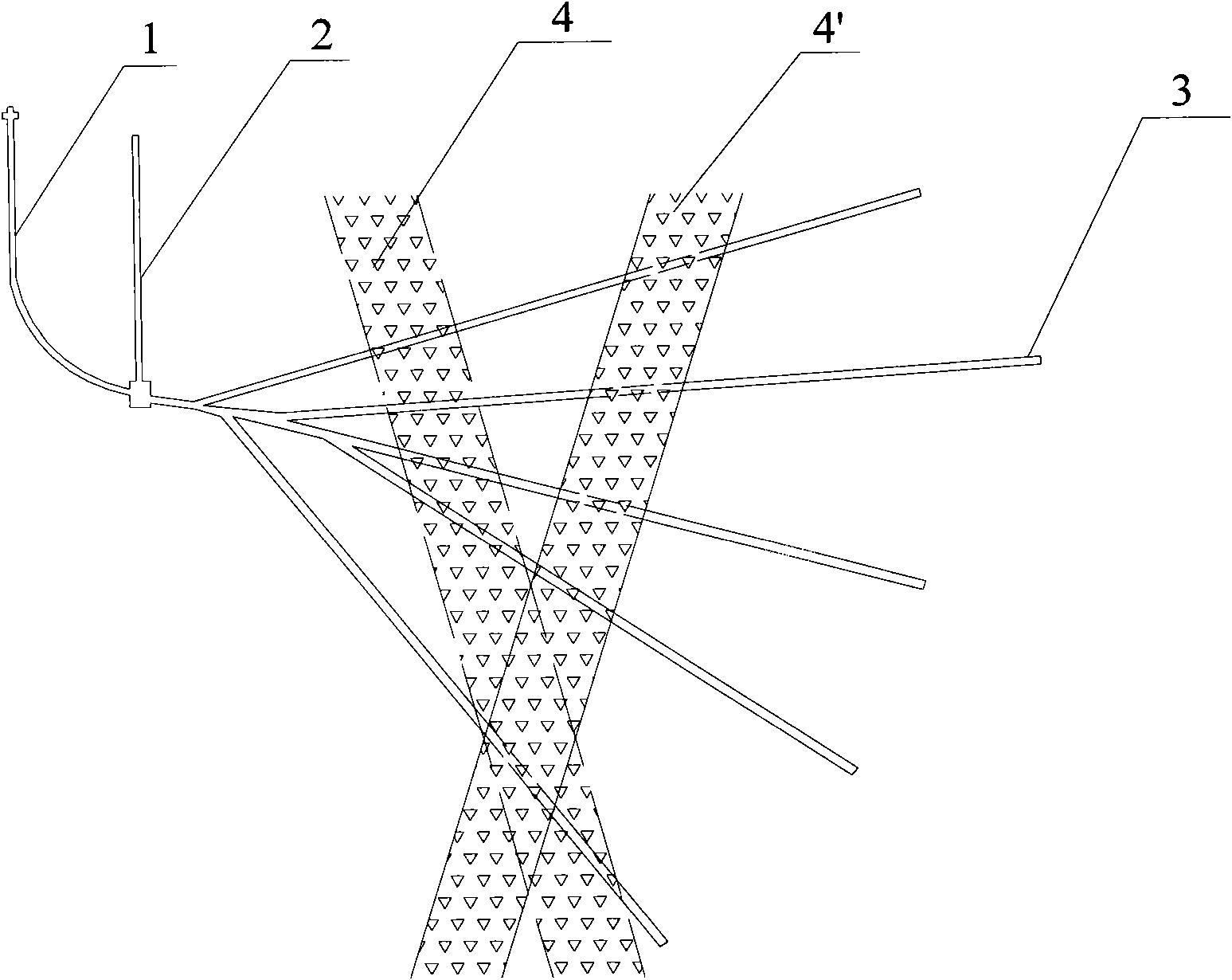

[0022] The embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings. The following embodiments and accompanying drawings are only used to help understand the present invention, but not to limit the protection scope of the present invention. The present invention can be defined and covered by claims. way to implement.

[0023] In order to effectively exploit the coalbed methane in the coal seam while ensuring the total footage or pure coal footage of the horizontal well in the coal seam, then find a method to deal with the coalbed methane in the coal seam on the other side of the fracture zone in the coal seam relative to the horizontal well very important.

[0024] For this reason, the inventor of the present invention has proposed a kind of method of coalbed methane horizontal well drilling and bridging guide, comprising the steps:

[0025] Obtain the regional seismic data of the area to be mined; carry out pre-expl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com