Oil production method and well pattern

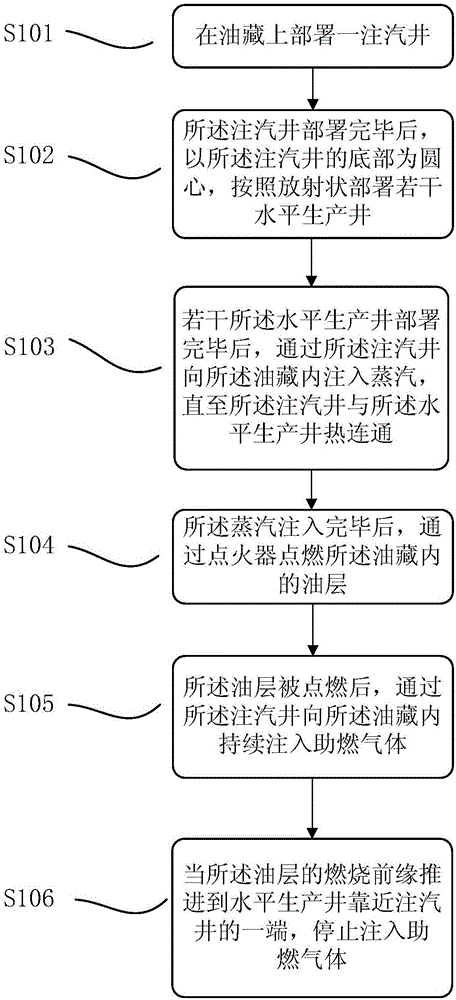

A technology for oil production wells and oil reservoirs, applied in the field of oil production methods and well patterns, can solve problems such as low recovery rate, low cumulative oil production, and production termination, and achieve the effects of expanding swept volume, increasing utilization rate, and saving costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0057] Reservoir in an oilfield: reservoir depth 280m; average formation pressure of the reservoir 2.8MPa; formation temperature 17.4°C; oil layer thickness 25m; porosity 30%; oil layer permeability 1266mD; average crude oil viscosity at formation temperature 210090mPa.s; Crude oil density 0.9662g / cm 3 ; Oil saturation 75.2%.

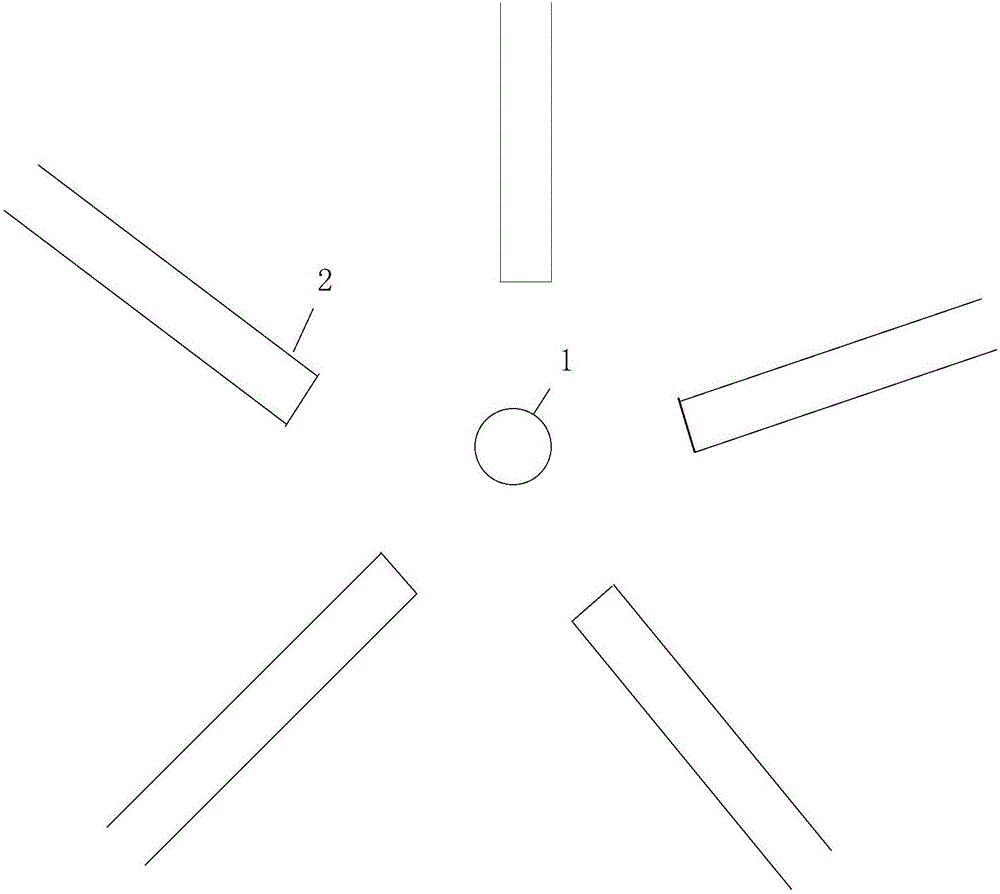

[0058] (1) First deploy a steam injection well in the center of the reservoir, perforate the steam injection well 1, and deploy 5 horizontal production wells 2 with a length of 500m at equal radial intervals with the center of the well bottom point;

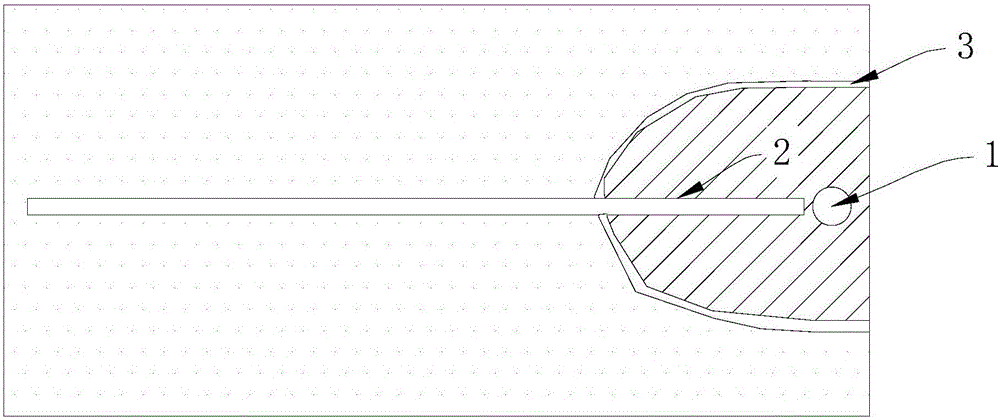

[0059] (2) The steam injection well first injects steam huff and puff for two rounds to realize thermal communication with the surrounding horizontal production well 2, and a total of 20,000 tons of steam are injected. After the huff and puff is over, an electric igniter is used to inject high-temperature air at 500°C to ignite the upper oil layer that has been shot, and then continuously inject normal-te...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com