High-strength high-impact-toughness titanium alloy used for oil well and gas well, and preparation method thereof

A titanium alloy, high-strength technology, applied in the field of titanium alloy materials, can solve the problems of insufficient corrosion resistance, unfavorable national security of nickel, corrosion leakage, etc., to improve tensile strength and lasting strength, benefit comprehensive performance, and reduce drilling rigs. The effect of power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] 9% pure aluminum beans, 3% Nb blocks, 0.5% Mo blocks, 1% pure sponge Zr, and industrial grade sponge Ti are melted into alloy ingots twice through mixing, pressing electrode rods, and vacuum self-consumption . The transformation point of the alloy is 998°C, the billet is forged at 1150°C, and the forging is changed to Φ150 bar at 970°C. The mechanical properties of the bar at room temperature after annealing are shown in Table 3. The conditions of simulated oil well conditions were used, and the corrosion performance was assessed by bar test pieces. The test conditions and test performance are shown in Table 4.

Embodiment 2

[0035] 5.5% pure aluminum beans, 1% Nb block, 5% Mo block, and 3% pure sponge Zr industrial grade sponge Ti are melted twice into alloy ingots through mixing, pressing electrode rods, and vacuum self-consumption. The phase transition point of the alloy is 1005°C, the billet is forged at 1150°C, and then forged at 980°C to a ?150mm bar. After forming, a ?89×9 pipe is prepared. The mechanical properties of the pipe at room temperature after annealing are shown in Table 3. The simulated oil well working conditions were adopted, and the corrosion performance was assessed by pipe test pieces. The test conditions and test performance are shown in Table 4.

Embodiment 3

[0037] 4% pure aluminum beans, 5% Nb blocks, 3.5% Mo blocks, 5% pure sponge Zr, and industrial grade sponge Ti are melted twice into alloy ingots through mixing, pressing electrode rods, and vacuum self-consumption . The transformation point of the alloy is 993°C, the billet is forged at 1150°C, the slab is reforged at 1020°C to a thickness of 90mm, and the 14mm plate is rolled. The mechanical properties of the plate at room temperature after annealing are shown in Table 3. The simulated oil well working conditions were adopted, and the plate test piece was used for corrosion performance assessment. The test conditions and test performance are shown in Table 4.

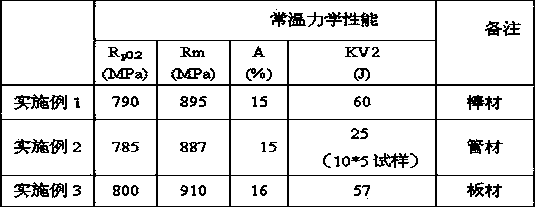

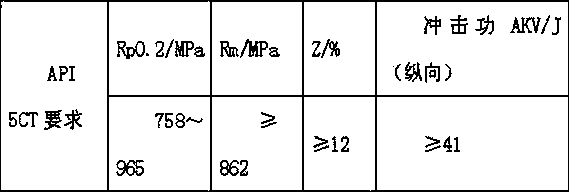

[0038] Table 3 Mechanical properties at room temperature of three examples

[0039]

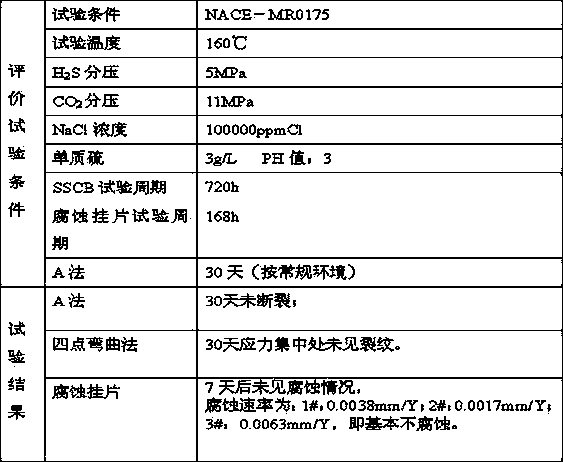

[0040] Table 4 Test conditions and results of simulated working condition evaluation

[0041]

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

| phase transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com