Integrated intelligent well completion design method of horizontal well

A design method and technology for intelligent completion, applied in design optimization/simulation, calculation, special data processing application, etc., to achieve the effect of improving the mining effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

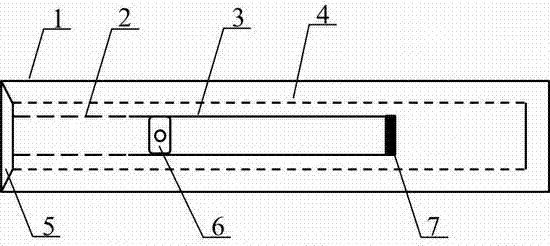

[0025] This embodiment is an illustration of the water control design method when no packer is installed. Such as figure 1 As shown, the central pipe of the horizontal well is installed on the variable buckle joint 5 at the end of the wellbore 1. The central pipe includes a central pipe body connected by the pre-hole pipe 2 and the blind pipe 3. The pipe wall of the central pipe body is installed with The phase control valve 6 is equipped with a plug 7 at the end of the central pipe body, and a screen pipe 4 is set outside the central pipe body, and the end of the screen pipe 4 is installed on the variable button joint 5 of the wellbore 1 .

[0026] The integrated intelligent water control design method for horizontal wells provided by the present invention comprises the following steps:

[0027] 1) Preparation of basic parameters: including: reservoir physical parameters (reservoir size, reservoir permeability, reservoir porosity, reservoir pressure, etc.), reservoir fluid p...

Embodiment 2

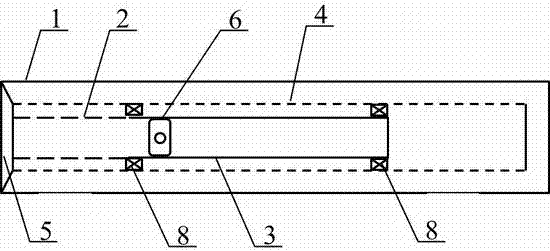

[0036] This embodiment is an illustration of the water control design method when the packer is installed. Such as figure 2 As shown, the central pipe of the horizontal well is installed on the variable buckle joint 5 at the end of the wellbore 1. The central pipe includes a central pipe body connected by the pre-hole pipe 2 and the blind pipe 3. The pipe wall of the central pipe body is installed with The phase control valve 6 is equipped with a screen 4 on the outside of the central pipe body, and the end of the screen pipe 4 is installed on the variable buckle joint 5 of the wellbore 1, and a packer is installed on the outer side of the central pipe body and the inner annulus of the screen pipe 4 8.

[0037] The integrated intelligent water control design method for horizontal wells provided by the present invention comprises the following steps:

[0038] 1) Preparation of basic parameters: including: reservoir physical parameters (reservoir size, reservoir permeability,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com