Gently-inclined extremely-thin gold vein mining method

A mining method and a gently tilting technology, applied in the field of gently tilting extremely thin gold vein mining, can solve the problems of high mining accuracy, cutting and filling costs, limited operating space, restricting the development of mine production, etc., so as to improve the efficiency of mining operations and ensure safety effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

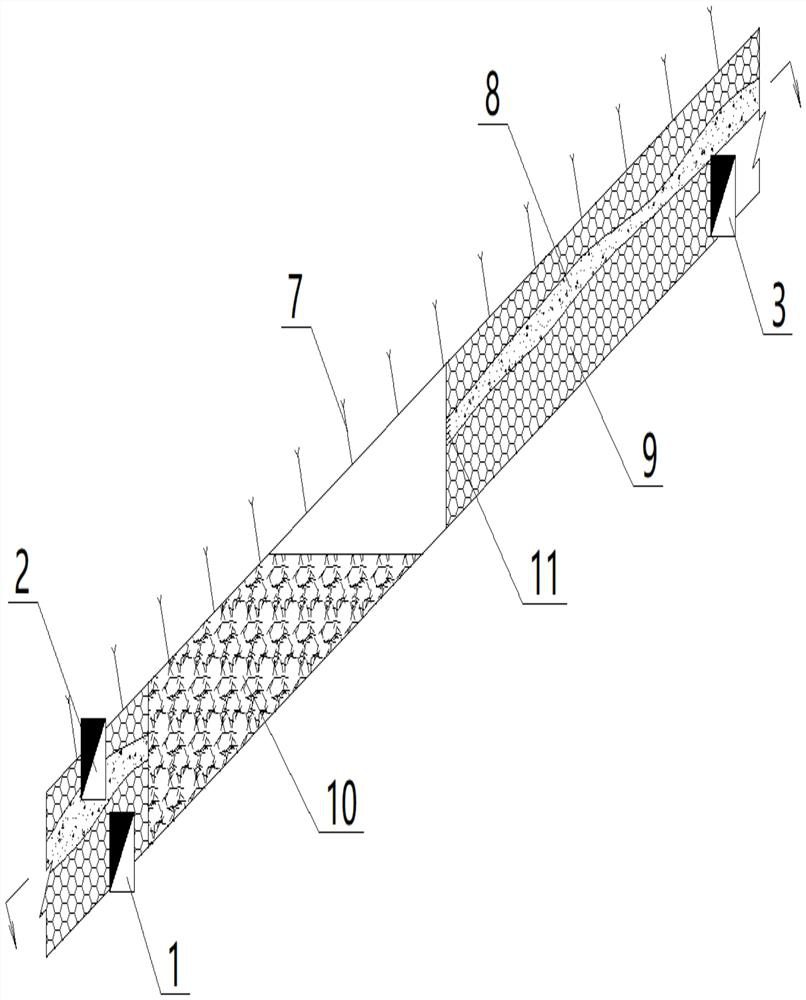

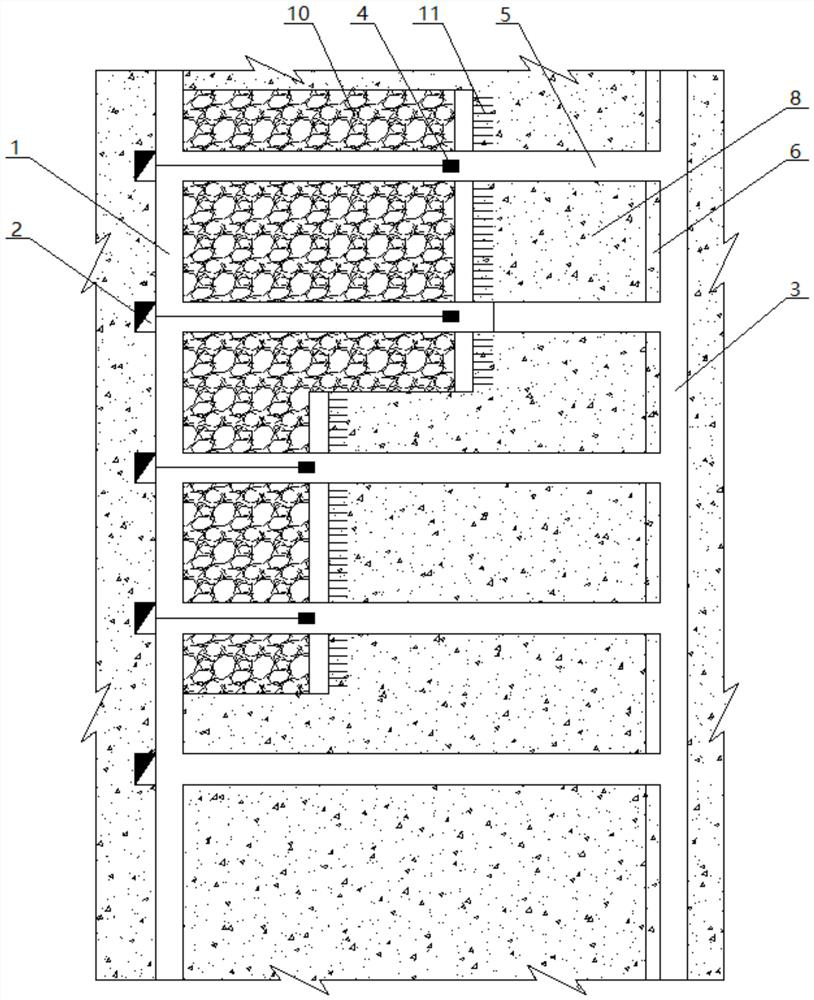

[0023] The present invention can be explained in detail through the following examples, and the purpose of disclosing the present invention is to protect all technical improvements within the scope of the present invention.

[0024] A mining method for gently inclined extremely thin gold veins, the structure of which is set as follows: a number of standard ore blocks are divided along the direction of the vein; the length of the ore block is 50m, the vertical height of the middle section is 25m, and the width is the natural extension along the vein 8 at the vertical height of the middle section of 25m Inclined length; 3m top pillars 6 are reserved, no inter- and bottom pillars are set, and point pillars are randomly set according to the ore body conditions;

[0025] Mining and cutting: At the end of the lower middle section of the ore block, the next stage transportation roadway 1 is arranged along the direction of ore vein 8; at the end of the upper middle section of the ore b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com