Patents

Literature

37results about How to "Small block" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

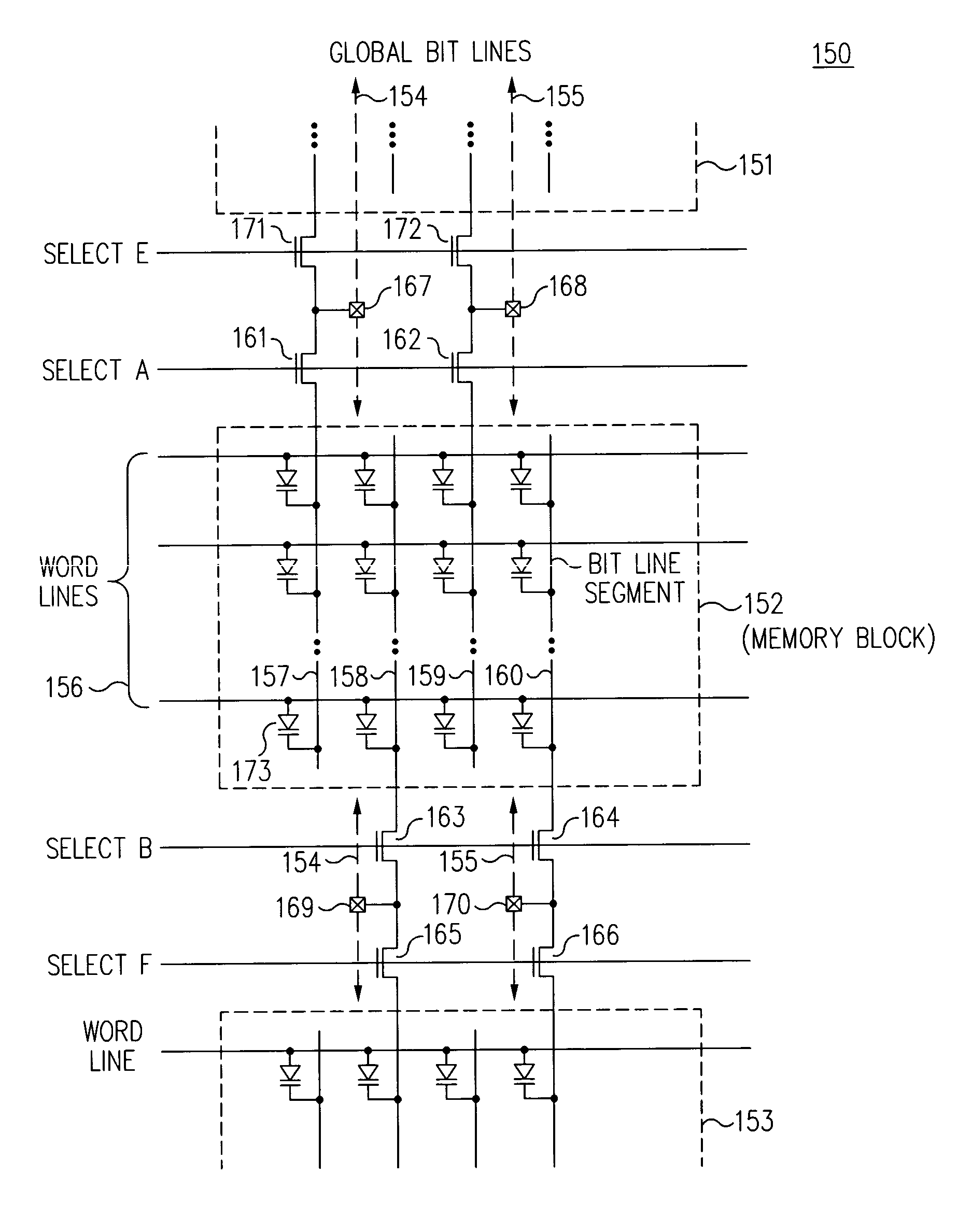

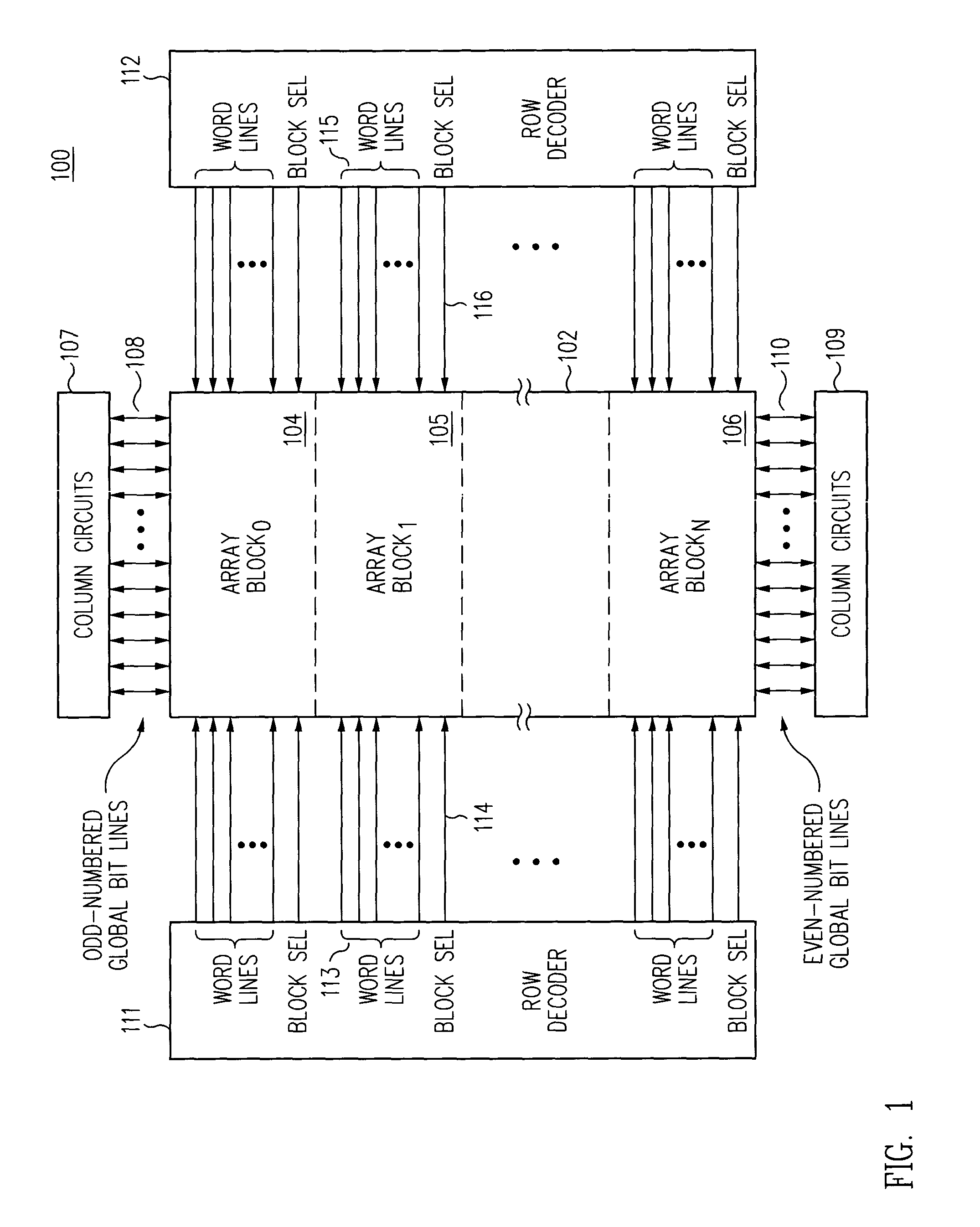

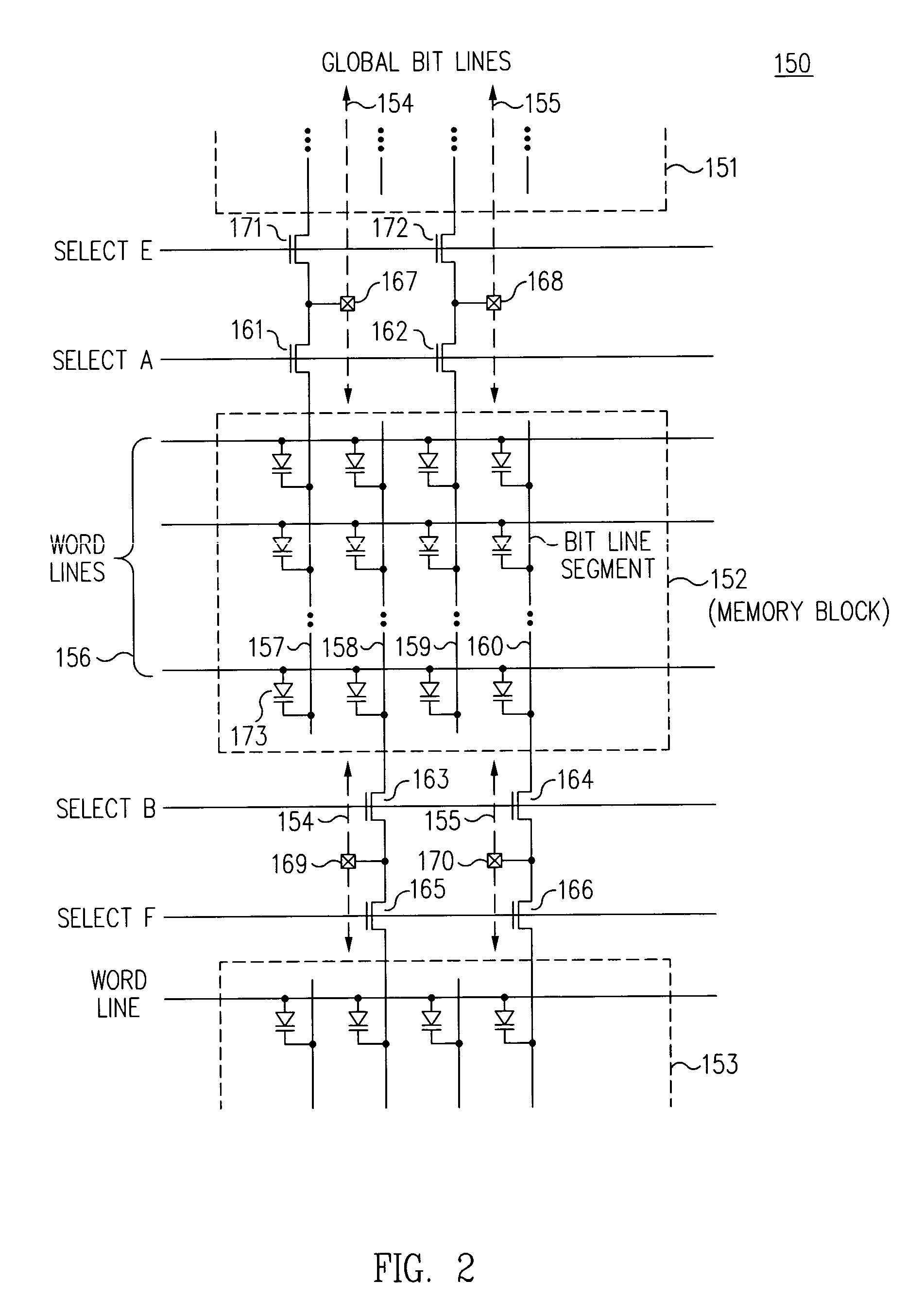

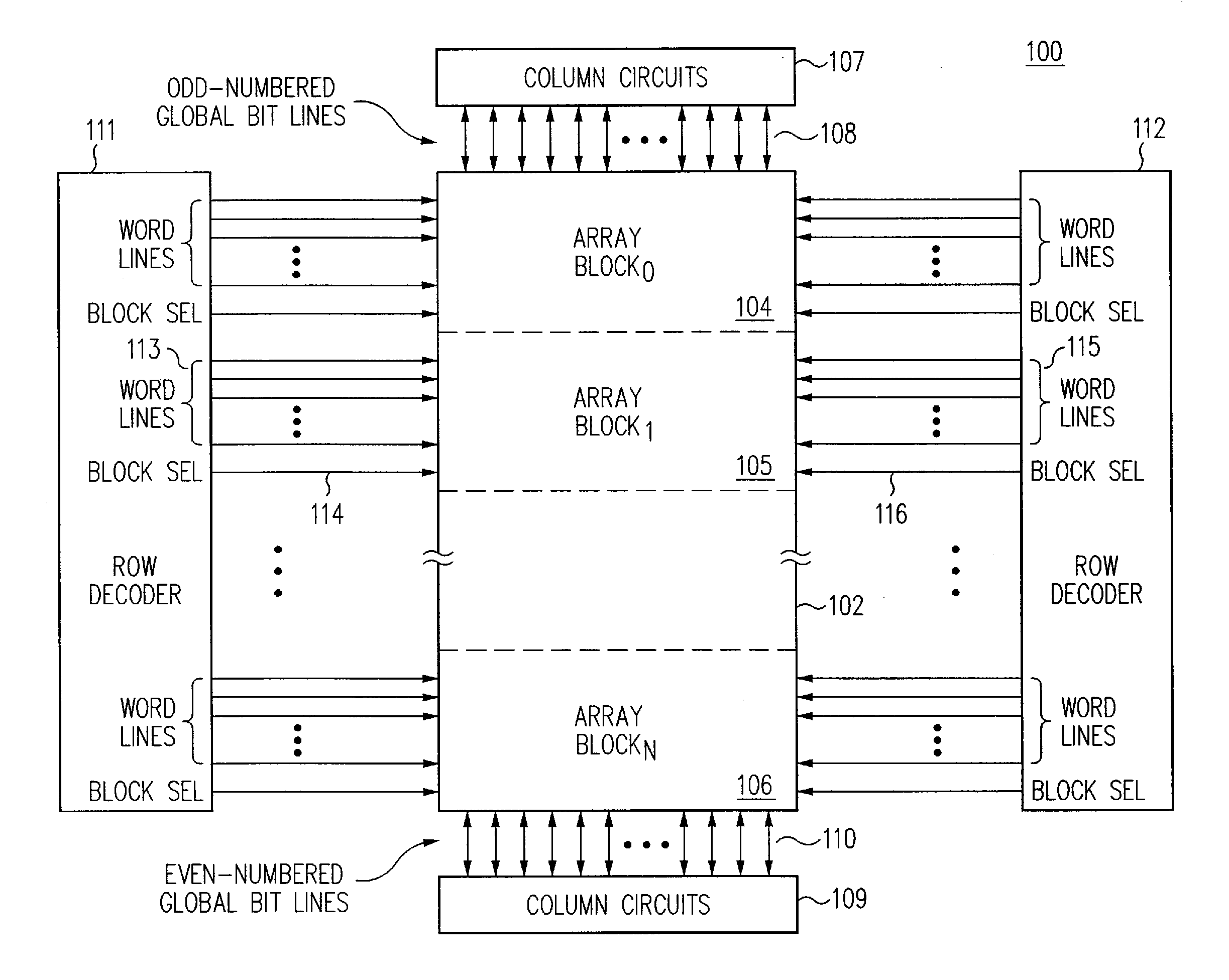

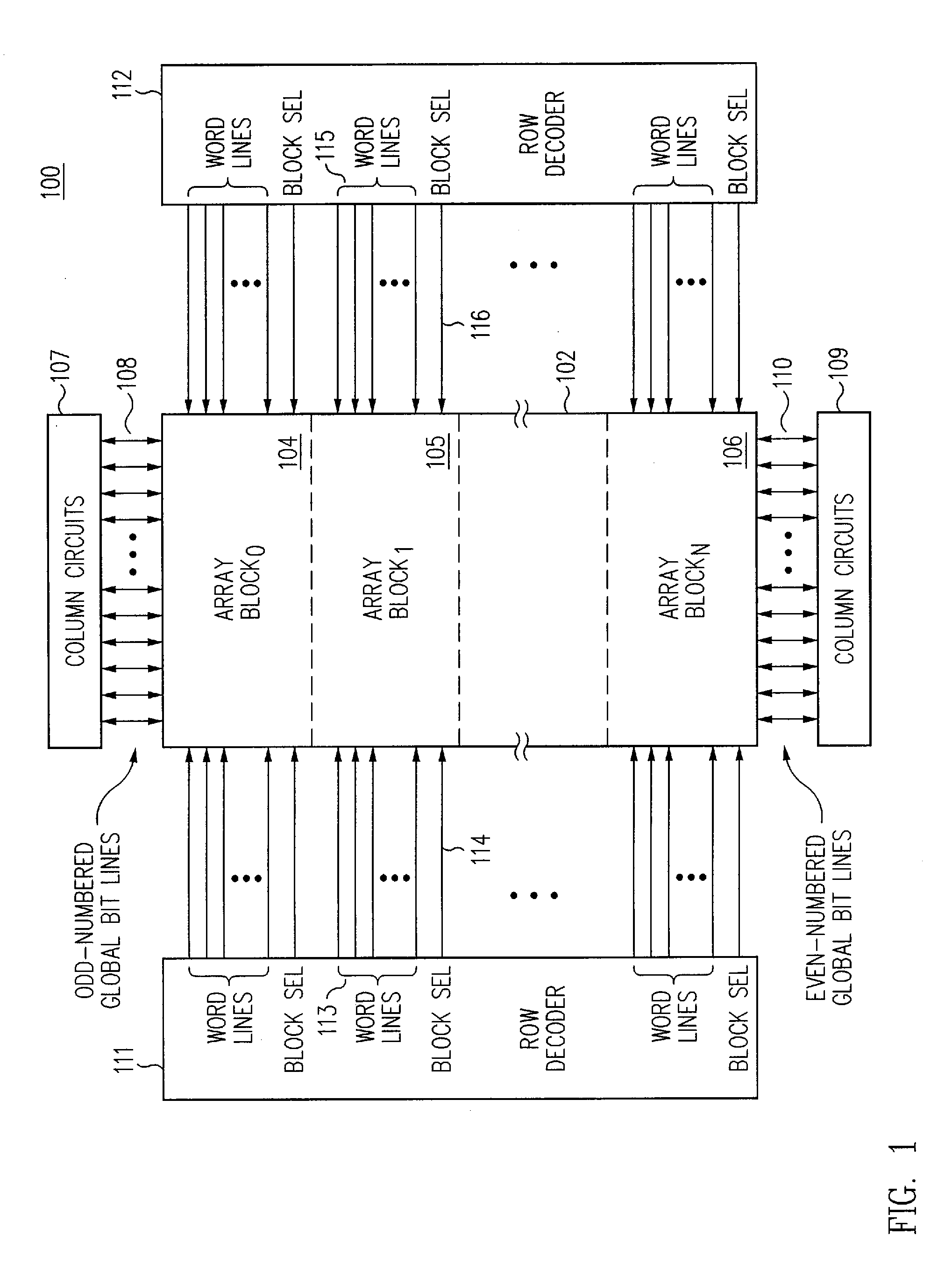

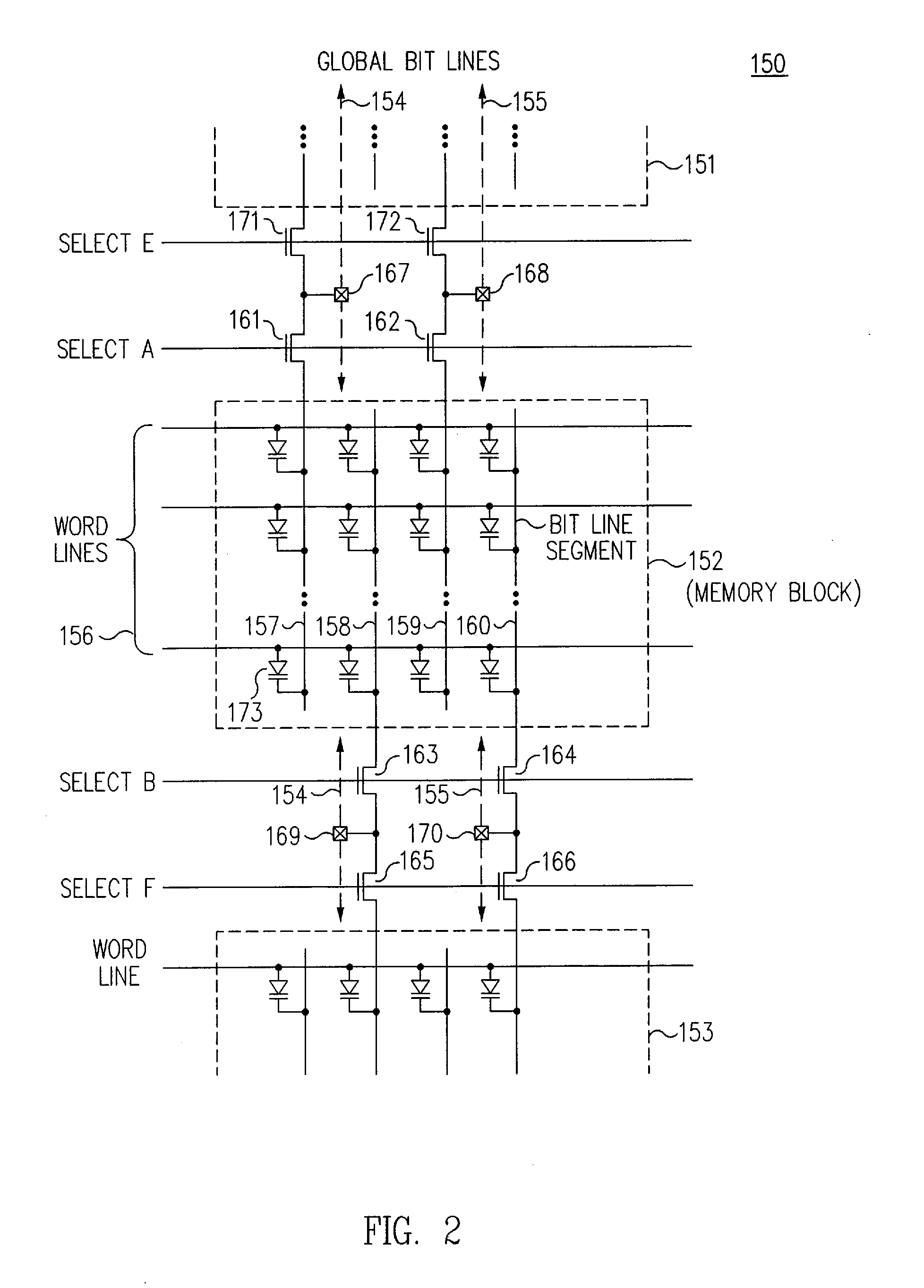

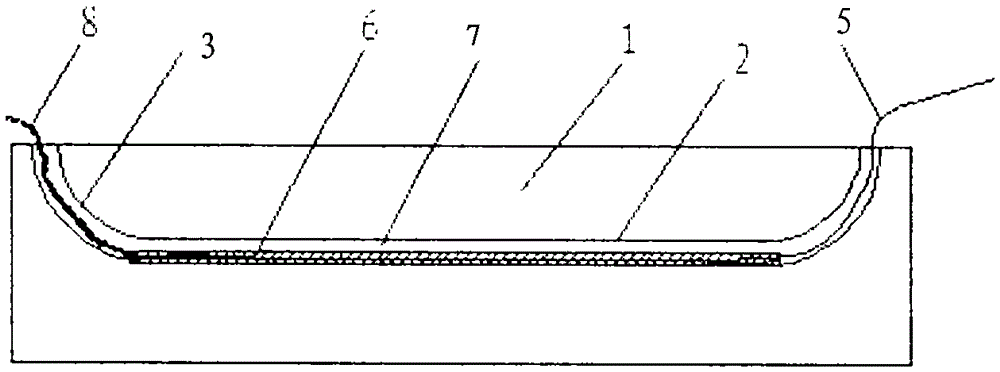

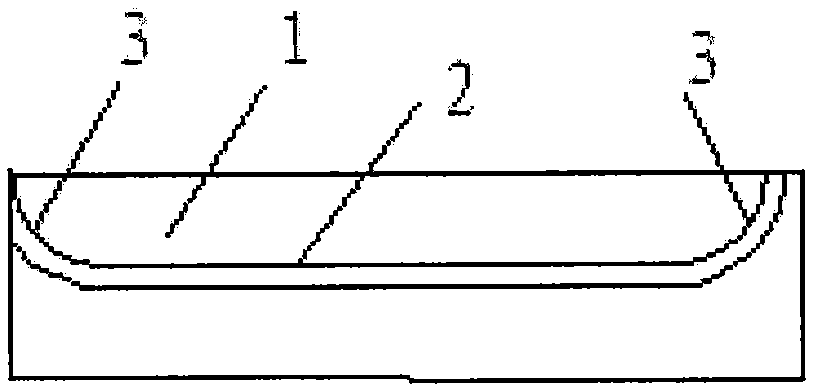

Three-dimensional memory device incorporating segmented bit line memory array

InactiveUS7233024B2Reduce capacitanceShorten overall length of unitSolid-state devicesRead-only memoriesBit lineHigh density

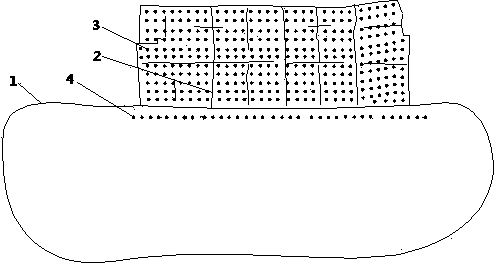

A three-dimensional (3D) high density memory array includes multiple layers of segmented bit lines (i.e., sense lines) with segment switch devices within the memory array that connect the segments to global bit lines. The segment switch devices reside on one or more layers of the integrated circuit, preferably residing on each bit line layer. The global bit lines reside preferably on one layer below the memory array, but may reside on more than one layer. The bit line segments preferably share vertical connections to an associated global bit line. In certain EEPROM embodiments, the array includes multiple layers of segmented bit lines with segment connection switches on multiple layers and shared vertical connections to a global bit line layer. Such memory arrays may be realized with much less write-disturb effects for half selected memory cells, and may be realized with a much smaller block of cells to be erased.

Owner:WODEN TECH INC

Three-dimensional memory device incorporating segmented array line memory array

ActiveUS20070263423A1Reduce capacitanceShorten the lengthSolid-state devicesRead-only memoriesBit lineHigh density

A three-dimensional (3D) high density memory array includes multiple layers of segmented bit lines (i.e., sense lines) with segment switch devices within the memory array that connect the segments to global bit lines. The segment switch devices reside on one or more layers of the integrated circuit, preferably residing on each bit line layer. The global bit lines reside preferably on one layer below the memory array, but may reside on more than one layer. The bit line segments preferably share vertical connections to an associated global bit line. In certain EEPROM embodiments, the array includes multiple layers of segmented bit lines with segment connection switches on multiple layers and shared vertical connections to a global bit line layer. Such memory arrays may be realized with much less write-disturb effects for half selected memory cells, and may be realized with a much smaller block of cells to be erased.

Owner:WODEN TECH INC

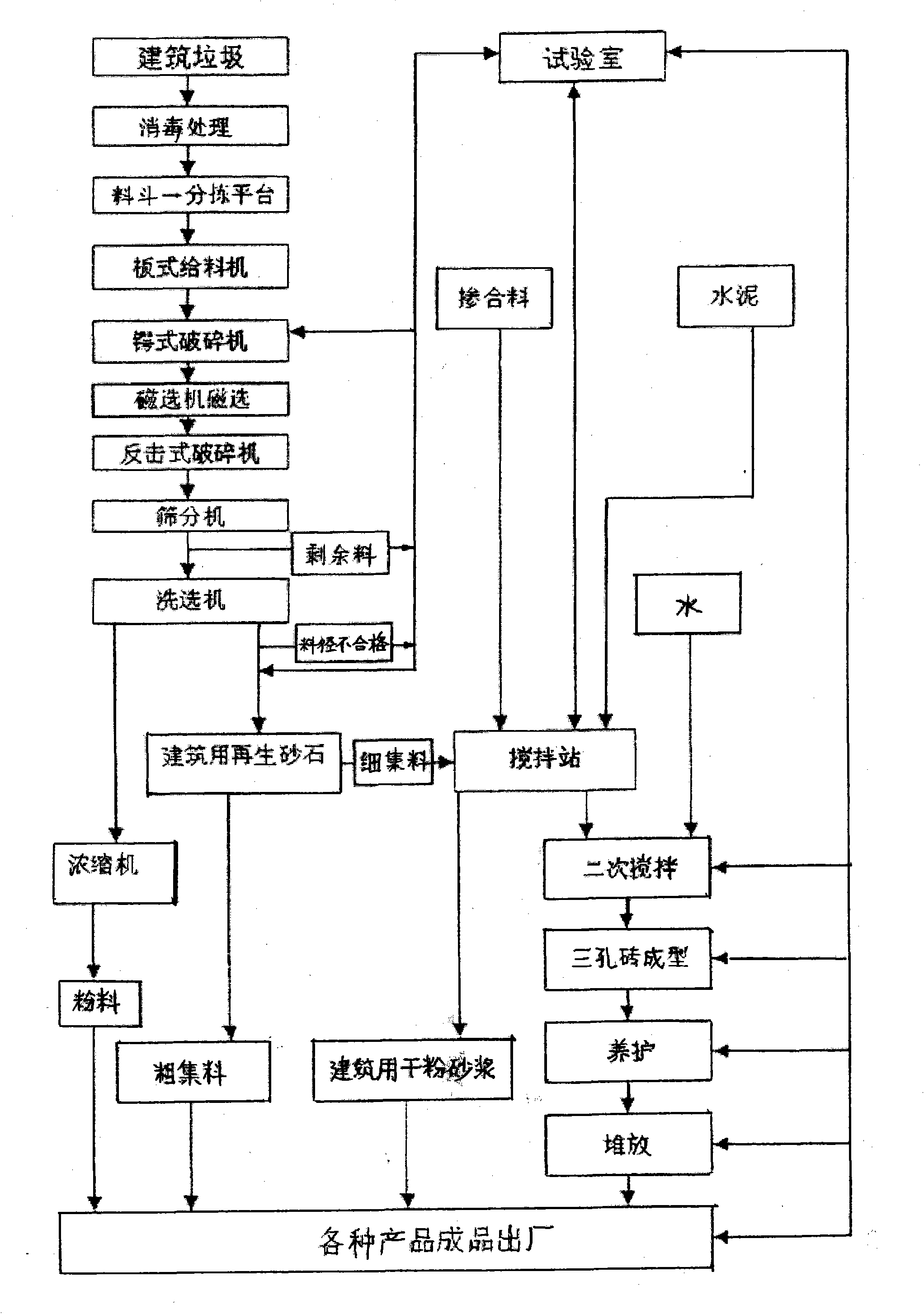

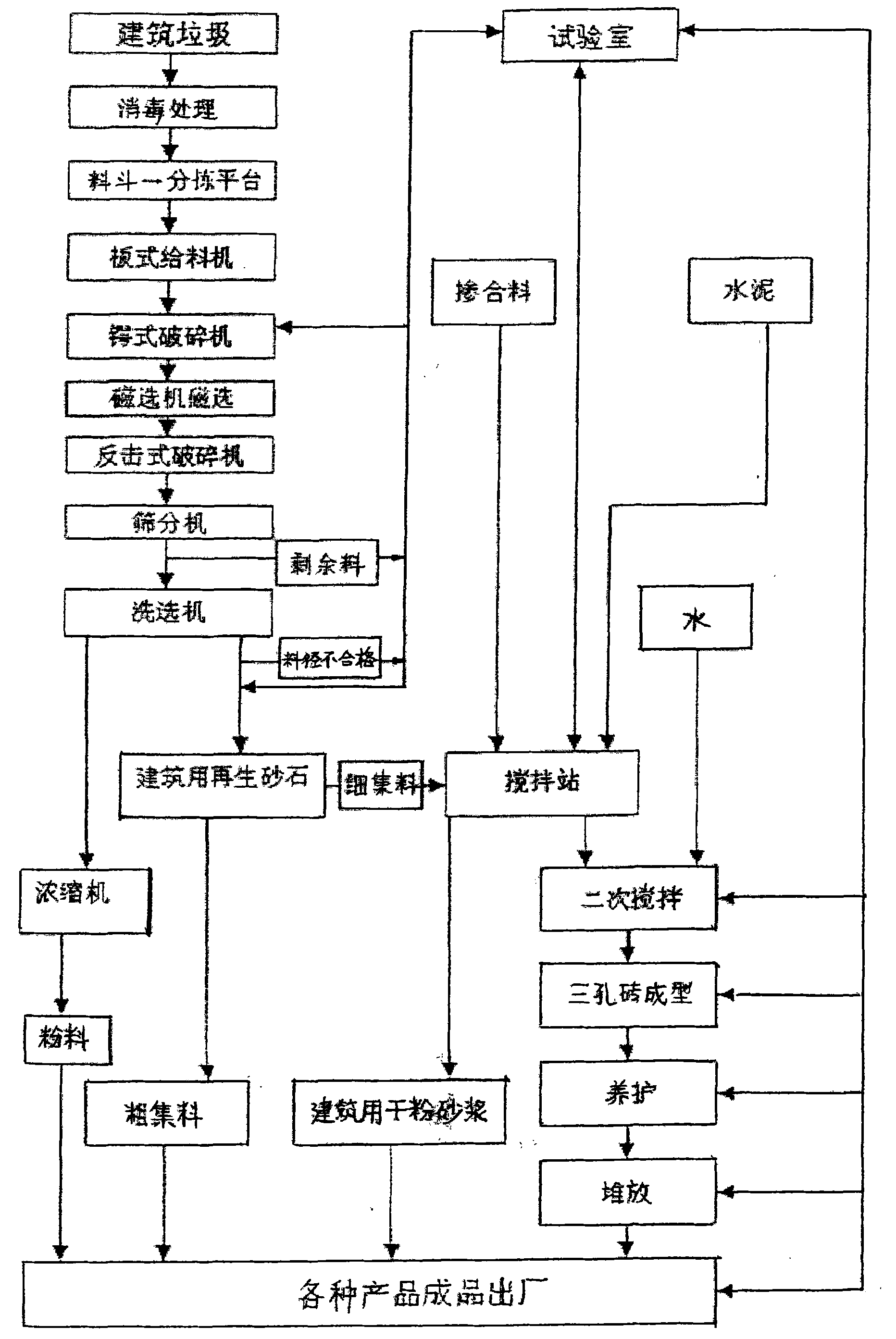

Method for comprehensively treating construction waste

The invention relates to a method for comprehensively treating construction waste, which comprises the following steps of: 1. disinfecting the construction waste to be treated by adopting a chlorine dioxide disinfectant; 2. loading the construction waste obtained from the step 1 to a hopper and conveying to a sorting platform to sort out impurities; 3. feeding the sorted construction waste to an edge-type crusher through a plate feeder to crush initially; 4. feeding the initially crushed construction waste to a hopper of an impact crusher after magnetic separation by a magnetic separator and crushing the construction waste finally by the impact crusher; 5. screening and peeling out sandstone materials from concrete and feeding the sandstone materials after being washed by a washer to a coarse aggregate bin, wherein the aggregate separated from the washed fine powder washed is used as raw materials of dry mortar or ready mixed mortar or three-hole brick of concrete. The invention ensures that the construction waste resources are utilized comprehensively, and the ordering management, the resource management and the harmless treatment of the construction waste are achieved, thereby achieving the purposes of saving land and reducing secondary pollution.

Owner:YUNNAN CONSTR ENG GRP +2

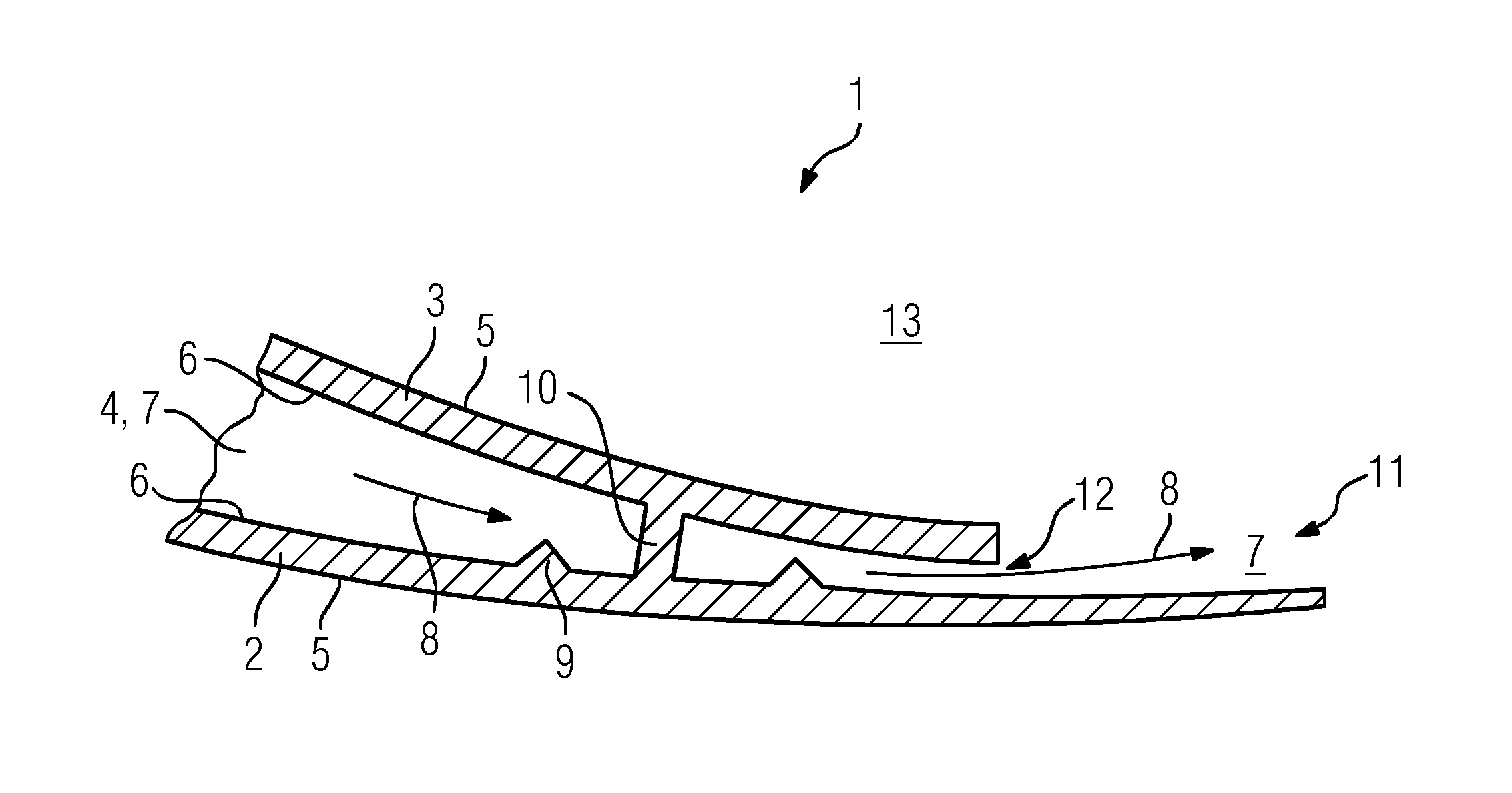

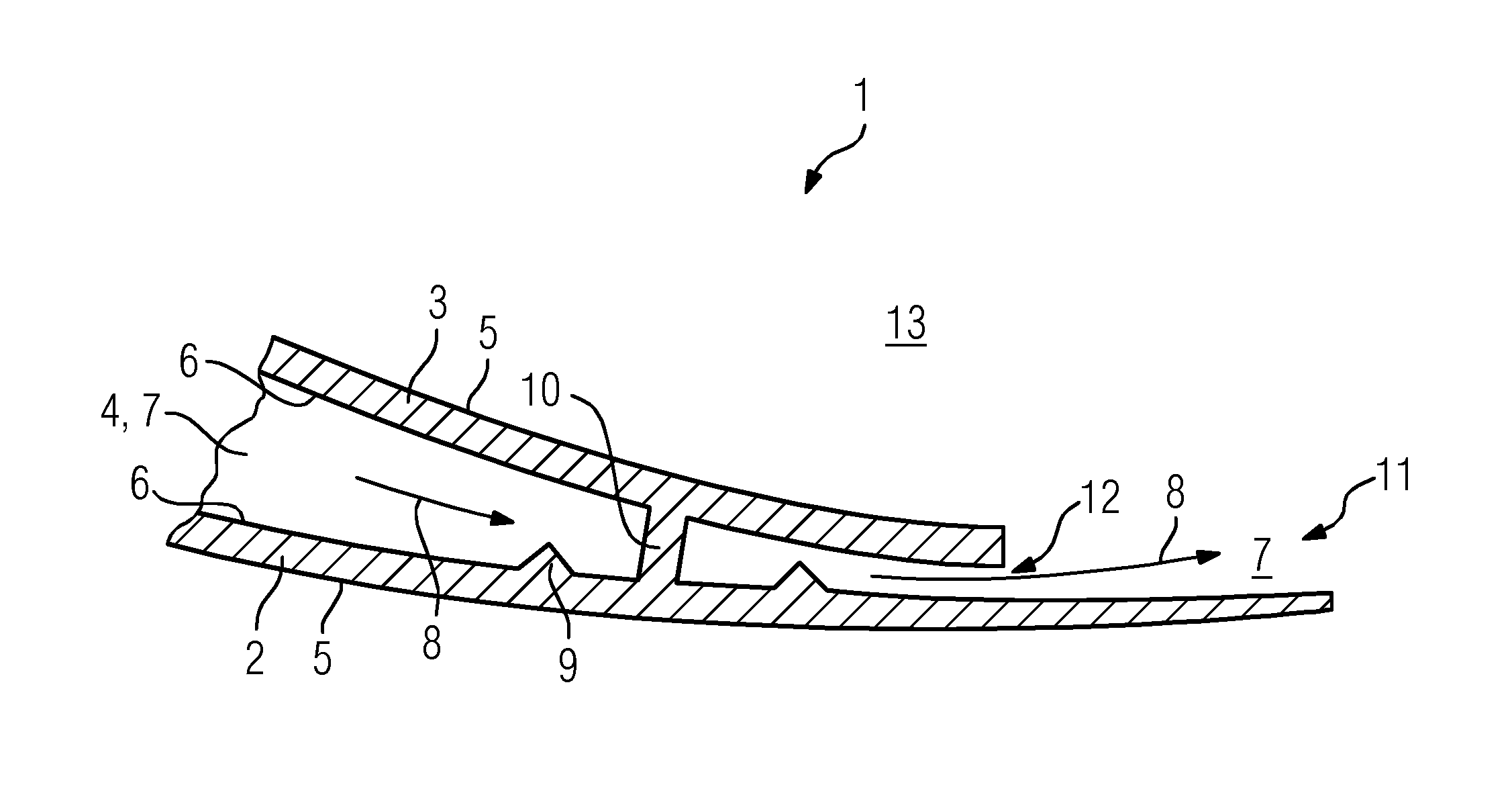

Cooled turbine guide vane or blade for a turbomachine

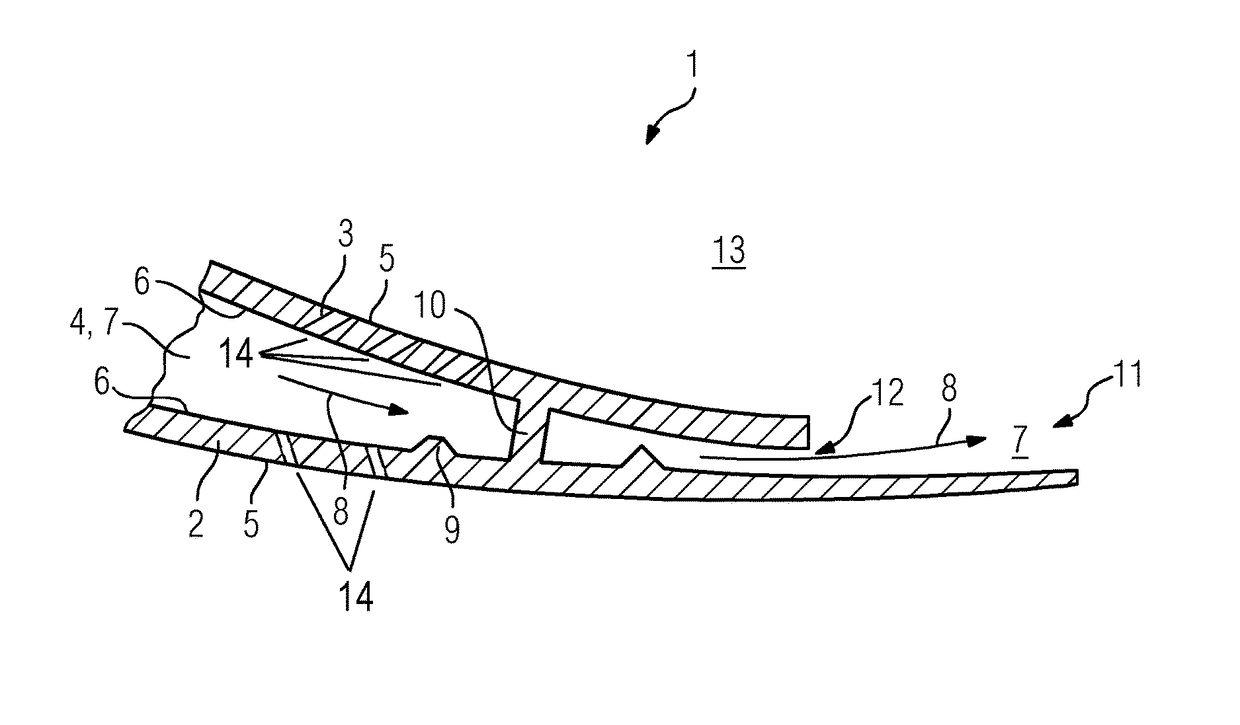

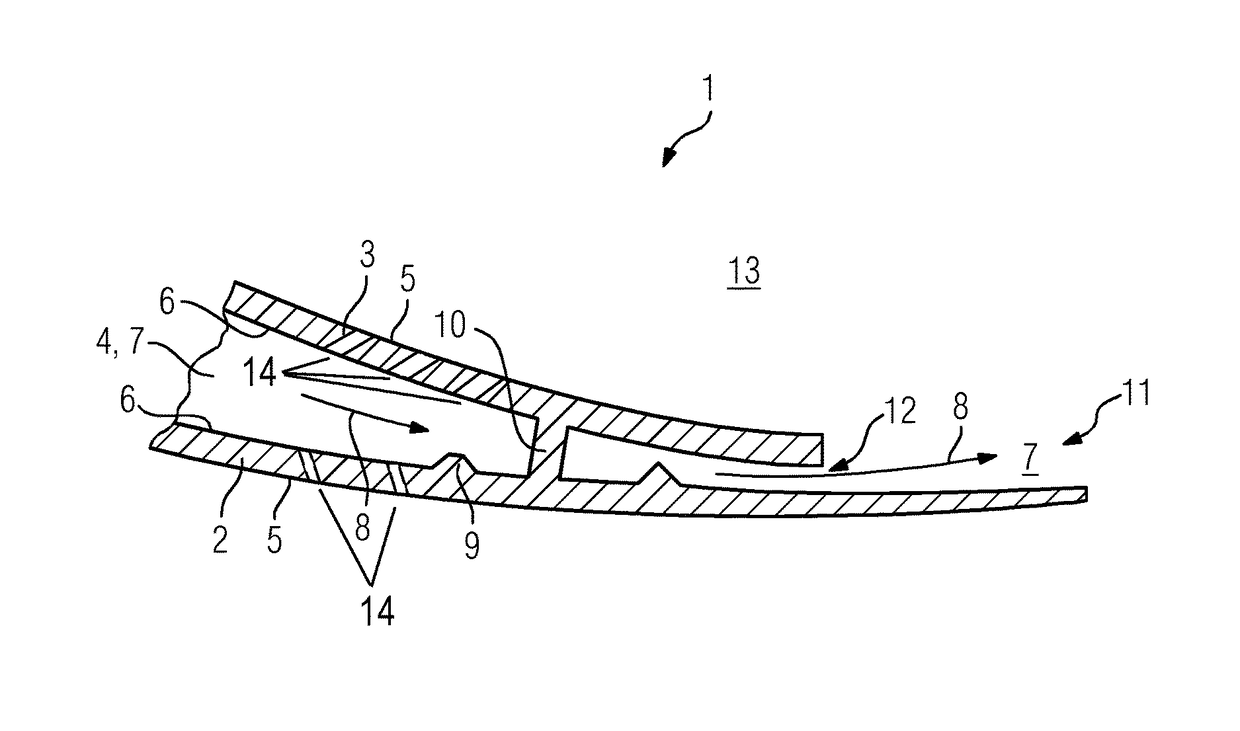

InactiveUS9896942B2Improve heat transfer performanceReduce the amount requiredEngine fuctionsBlade accessoriesSuction stressEngineering

A turbine airfoil has a suction side wall and a pressure side wall of an airfoil cavity, through which a cooling fluid flows for cooling of the side walls. The suction side wall has one or more protrusions extending therefrom into the airfoil cavity. The protrusions are arranged such that: a number of the one or more protrusions on the suction side wall is higher than a number of protrusions on the pressure side wall; and / or a protrusion density on the suction side wall is higher than a protrusion density on the pressure side wall, and / or a total protrusion surface area on the suction side wall is larger than a total protrusion surface area on the pressure side wall, so that the heat transfer from the suction side wall to the cooling fluid is higher compared to that of the pressure side wall during operation of the turbomachine.

Owner:SIEMENS ENERGY GLOBAL GMBH & CO KG

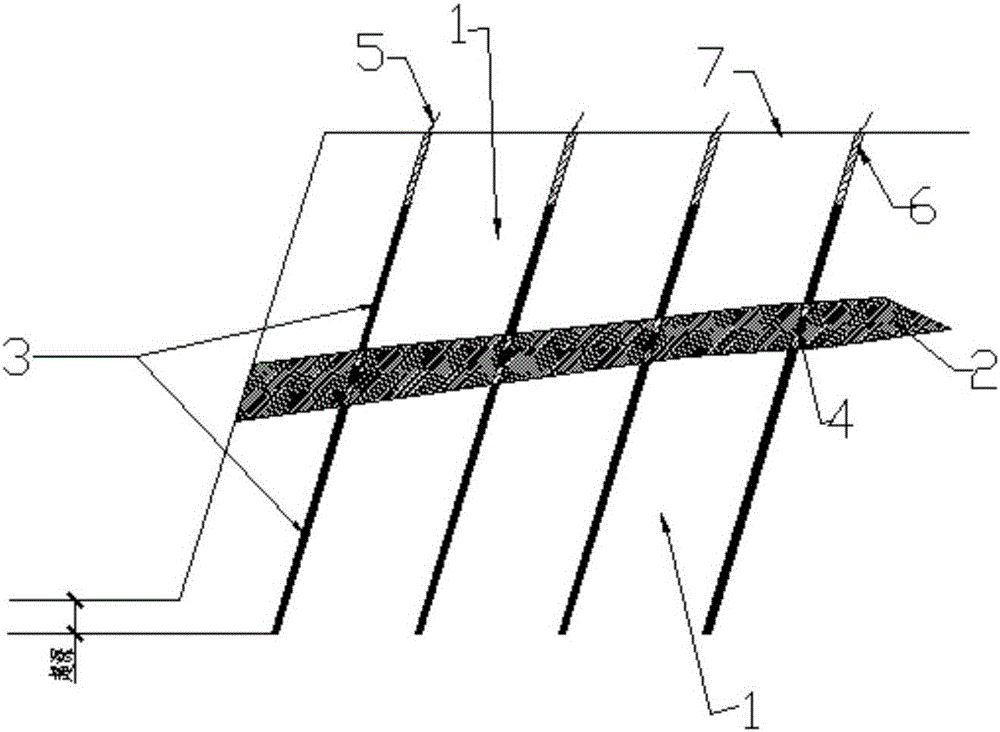

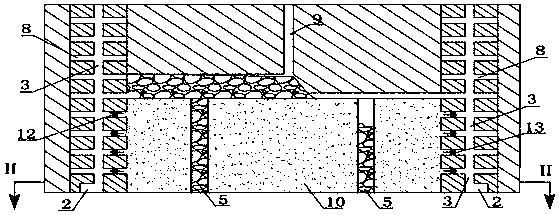

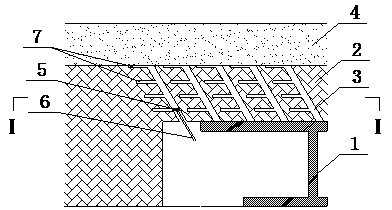

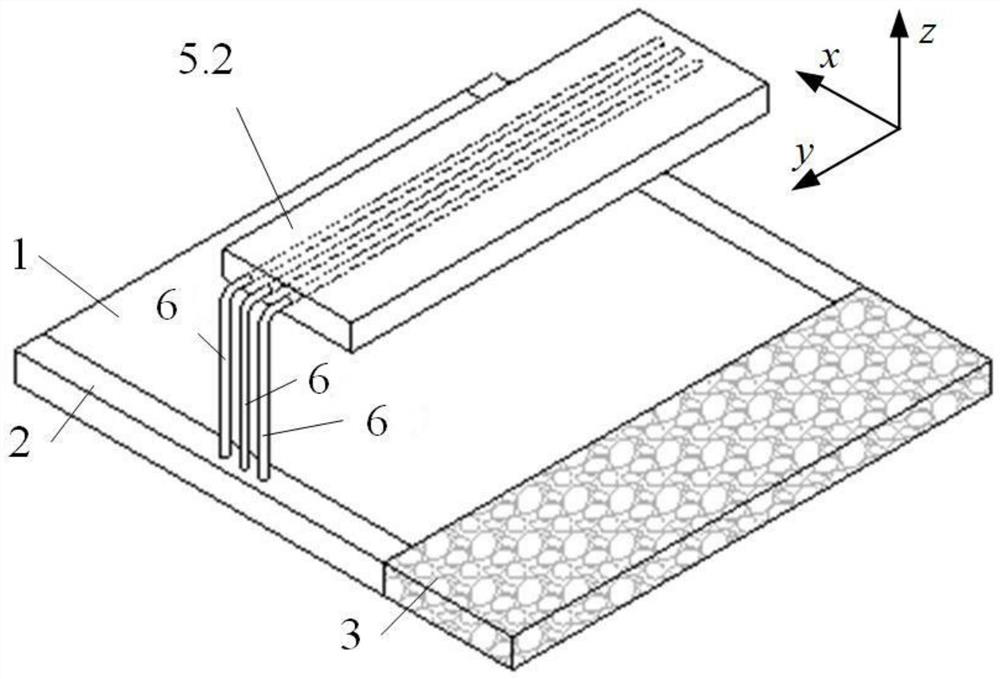

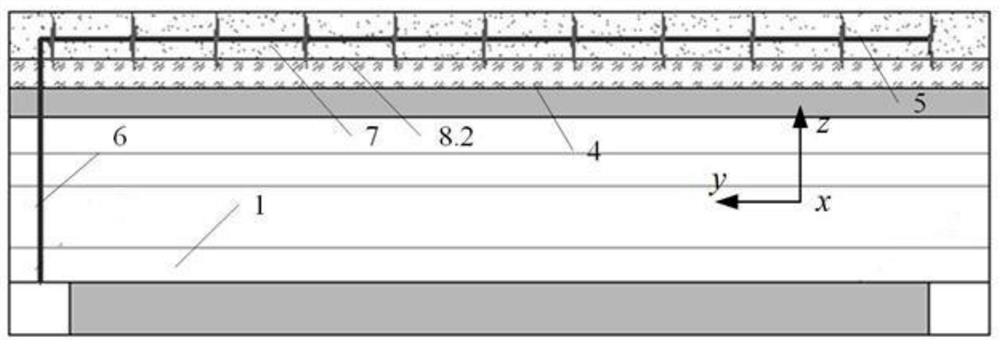

Water-coupled charging blasting demolition method for reinforced concrete beam or column

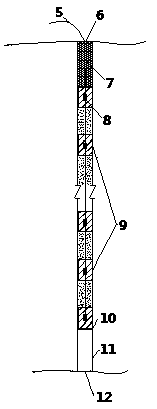

ActiveCN105571418AReduce charge resistanceCharge smoothlyBuilding repairsBlastingShock waveReinforced concrete

The invention discloses a water-coupled charging blasting demolition method for a reinforced concrete beam or column. The process that blast holes are formed along the axis of the reinforced concrete beam or column and water is poured into the blast holes is adopted, and the aims of reducing resistance of deep hole charging, achieving accurate charging, efficiently utilizing water pressure blasting energy, effectively controlling the strength and amount of vibration of blasting, blasting flyrock, air shock waves and poisonous blasting gas and reducing blasting dust are achieved. According to the method, the process is simple, operation is easy, the application range is wide, and the method is an ideal construction method for demolition of the reinforced concrete beam and column.

Owner:程大春

Method for comprehensive treatment of building garbage

InactiveCN107540254AOrderly managementSave landSolid waste managementCeramic materials productionBrickResource utilization

The present invention relates to a method for comprehensive treatment of building garbage. The method comprises: a, disinfecting building garbage to be treated with an agent; b, loading the building garbage obtained in the step a into a material hopper, transporting to a sorting platform, and sorting out debris; c, feeding the sorted building garbage into a jaw crusher through a plate type material feeder, and carrying out primary crushing; d, carrying out magnetic separation on the building garbage obtained in the step c with a magnetic separation machine, feeding into the material hopper ofan impact crusher, and carrying out final crushing with the impact crusher; and e, carrying out screening and peeling on the building garbage obtained in the step d by using a screening machine so asto obtain the sand and stone aggregate in concrete, feeding into a cleaning separation machine, carrying out cleaning separation, feeding into a coarse aggregate bin, and separating to obtain fine powder, wherein the fine aggregate separated by the cleaning separation is used as the raw material for dry powder mortar or pre-mixed mortar or concrete three-hole brick. According to the present invention, with the method, the building garbage resources can be subjected to comprehensive utilization, such that the building garbage can achieve ordered management, resource utilization and harmless treatment, and the purposes of land saving and secondary pollution reducing can be achieved.

Owner:王志凤

Cooled turbine guide vane or blade for a turbomachine

InactiveUS20150016961A1Improve heat transfer performanceReduce the amount requiredPropellersPump componentsSuction stressEngineering

A turbine airfoil for a turbomachine is provided. The airfoil includes a suction side wall and a pressure side wall bordering an airfoil cavity, which receives a cooling fluid for cooling the airfoil. The suction side wall includes one or more protrusions extending inside the cavity. The number of protrusions on the suction side may be higher than the number of protrusions on the pressure side. The density of protrusions on the suction side may be higher than the density of protrusions on the pressure side and / or the surface of protrusions on the suction side may be larger than the surface of protrusions on the pressure side, so that heat transfer from the suction side to the cooling fluid is higher compared to heat transfer from the pressure side to the cooling fluid during operation of the turbomachine.

Owner:SIEMENS ENERGY GLOBAL GMBH & CO KG

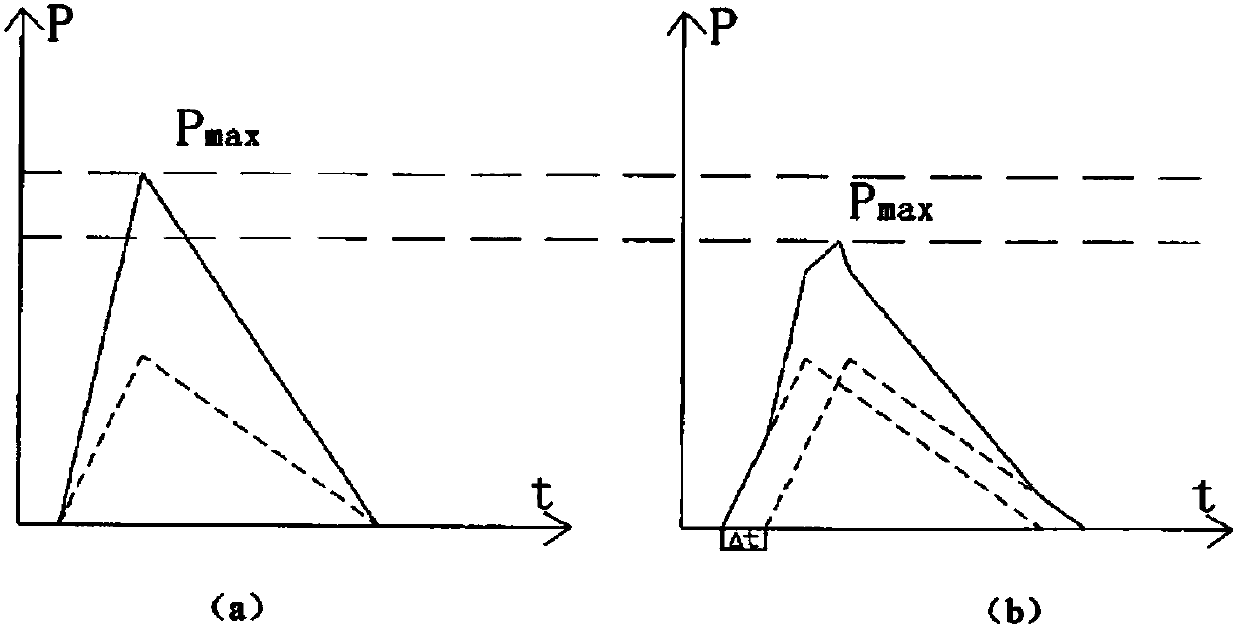

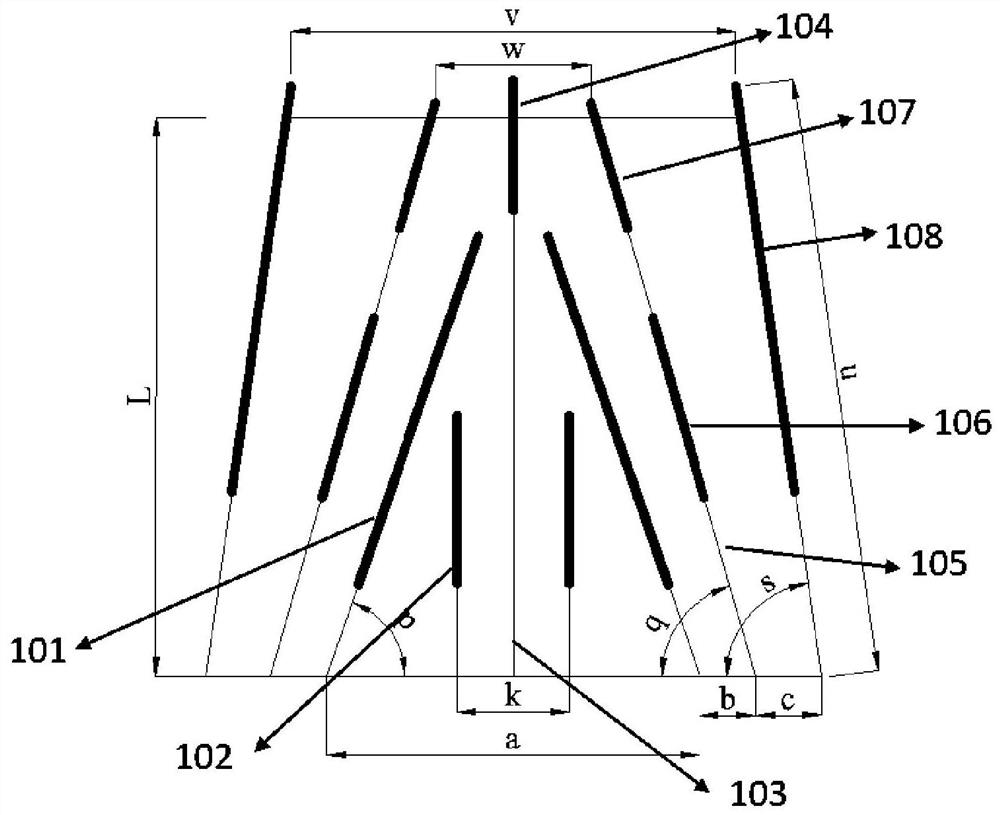

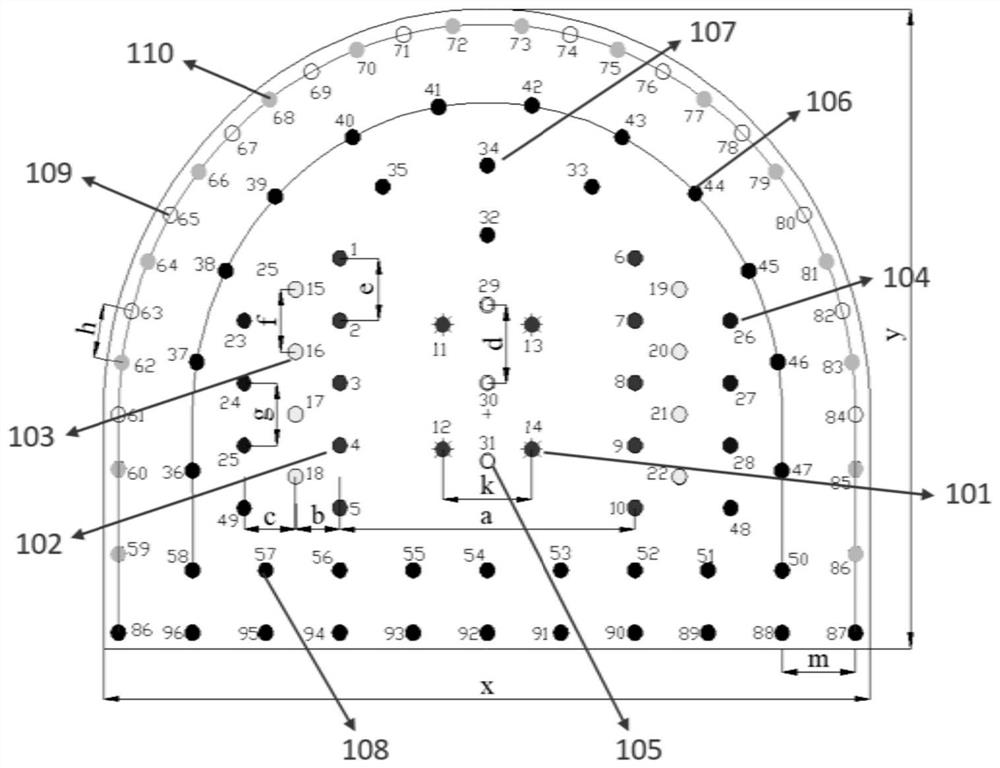

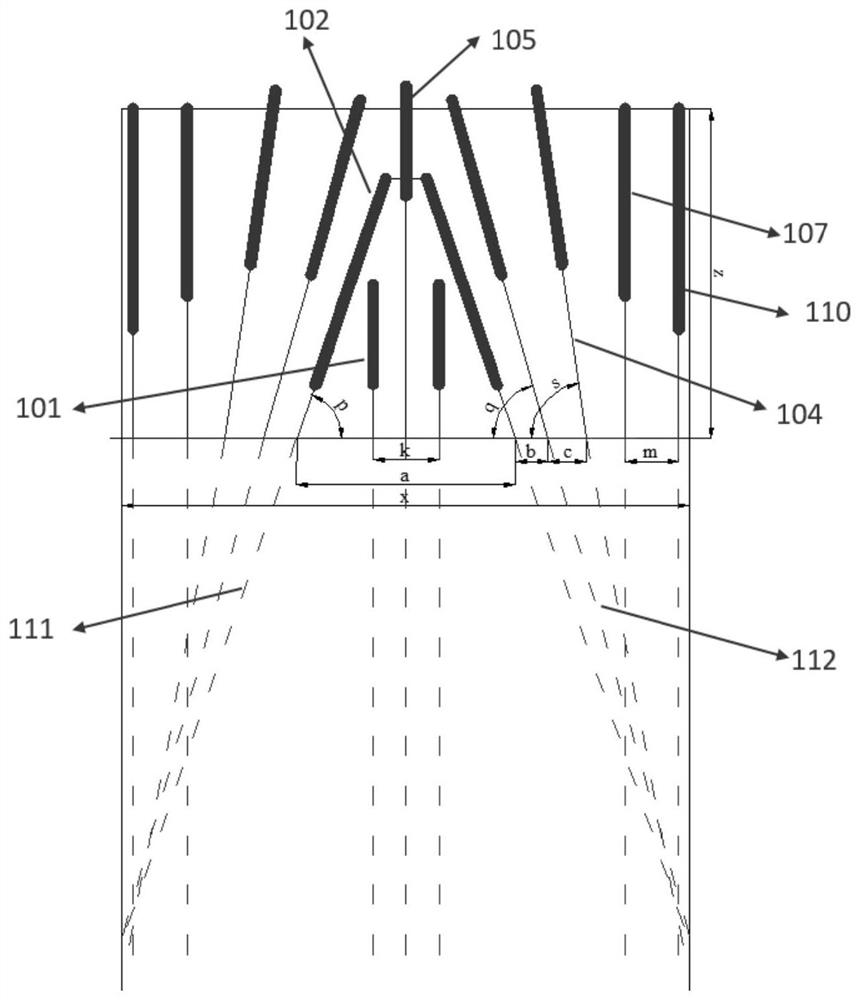

Tunneling blasting method comprehensively utilizing detonator short time difference and empty hole vibration reduction technique

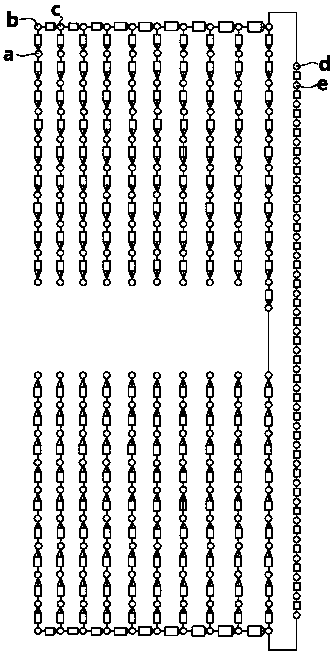

InactiveCN108592725AGuaranteed blasting effectAvoid the disadvantage of large blasting vibrationBlastingDetonatorEngineering

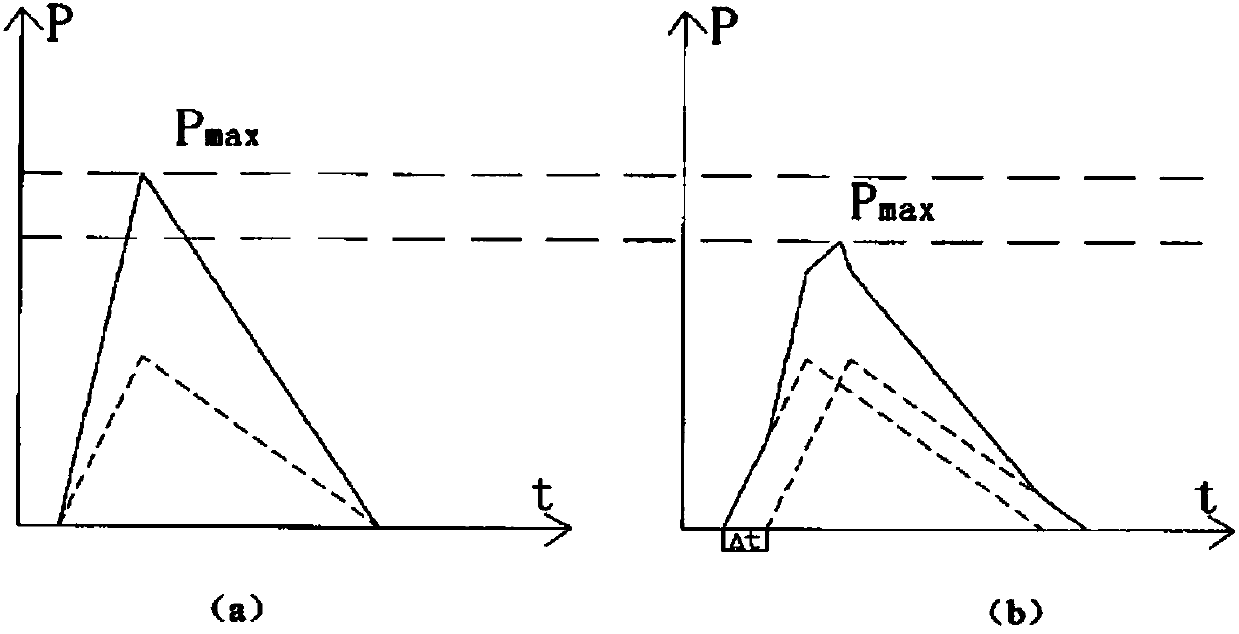

The invention discloses a tunneling blasting method comprehensively utilizing the detonator short time difference and an empty hole vibration reduction technique. The center line of a tunnel face of ablasted tunnel serves as the boundary, and the blasted area is divided into a left region and a right region, wherein the left region and the right region are symmetrical to each other; the two sidesof the center line are provided with a plurality of slotting holes, auxiliary holes and peripheral holes correspondingly, wherein the slotting holes, the auxiliary holes and the peripheral holes aresymmetrical to one another, a vibration reduction hole linear array is arranged on the ground between the blasted area and a building, and in the implementation process, the same row of holes are blasted hole by hole in a symmetrical and delayed manner. Hole-by-hole sequential blasting is performed through electronic detonators, and targeted to different types of blastholes, through the setting ofthe optimal delay time of the electronic detonators, vibration waves transferred to the ground interfere with one another and are counteracted partially; and meanwhile, vibration reduction holes of optimized design are formed on the ground, and 50% of blasting vibration can be effectively lowered. Through the combined measure, the blasting effect of a constructed smooth surface can be guaranteed,the defect that traditional smooth surface blasting is large in vibration can also be overcome, and finally influences on the surface buildings are reduced.

Owner:厦门爆破工程有限公司 +1

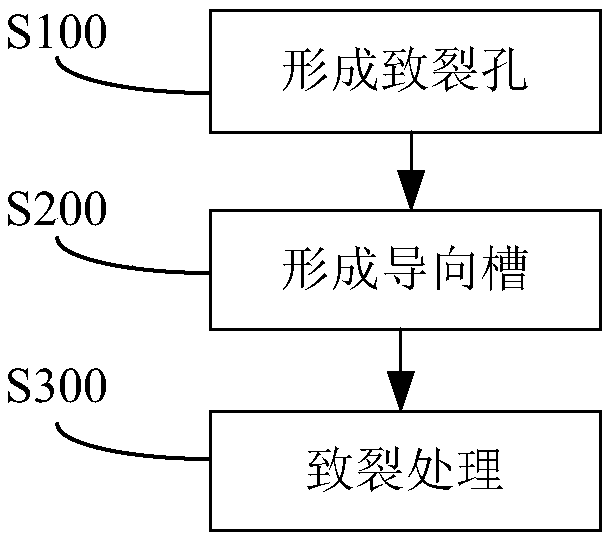

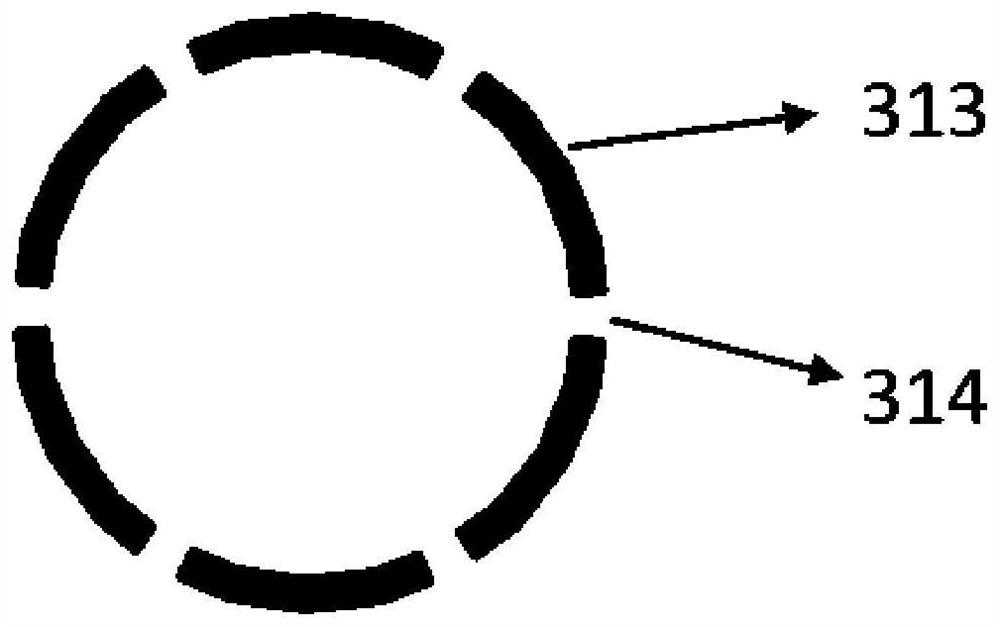

Pretreatment method for ore rock

InactiveCN109026004ASolve the problem of poor collapsibilityIncreased crack developmentDisloding machinesUnderground miningPretreatment methodFracturing fluid

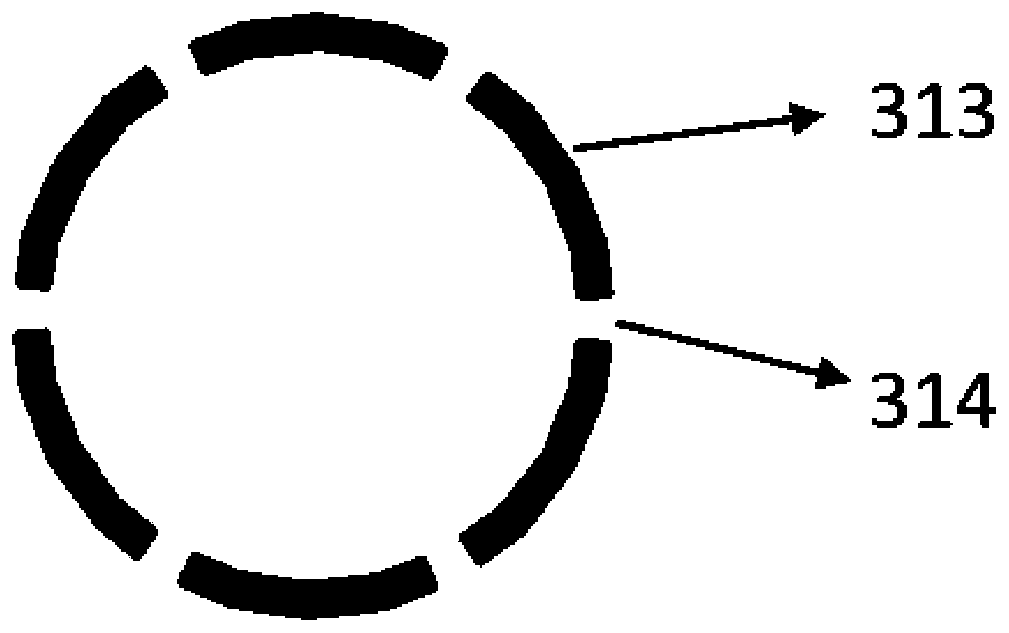

The invention discloses a pretreatment method for an ore rock. The method includes: forming a plurality of cracking holes in the ore rock; forming guiding grooves on the inner walls of the cracking holes, wherein the guiding grooves are circumferentially disposed along the inner walls of the cracking holes; and fracturing the cracking holes in order to cause the ore rock to produce directional fractures. By forming the cracking holes in the ore rock, forming the guiding grooves on the inner walls of the cracking holes, and injecting a high-pressure fracturing fluid to cause the ore rock to produce directional hydraulic fractures under the action of the guiding grooves, the development degree of the fractures inside the rock mass of the ore rock can be increased, and the problems of poor collapsibility of the ore rock and large size of the caved ore rock when a natural caving mining method is applied to medium hard rock, hard rock, highly-hard rock and other high-hardness metal mines can be solved.

Owner:CHINA ENFI ENGINEERING CORPORATION

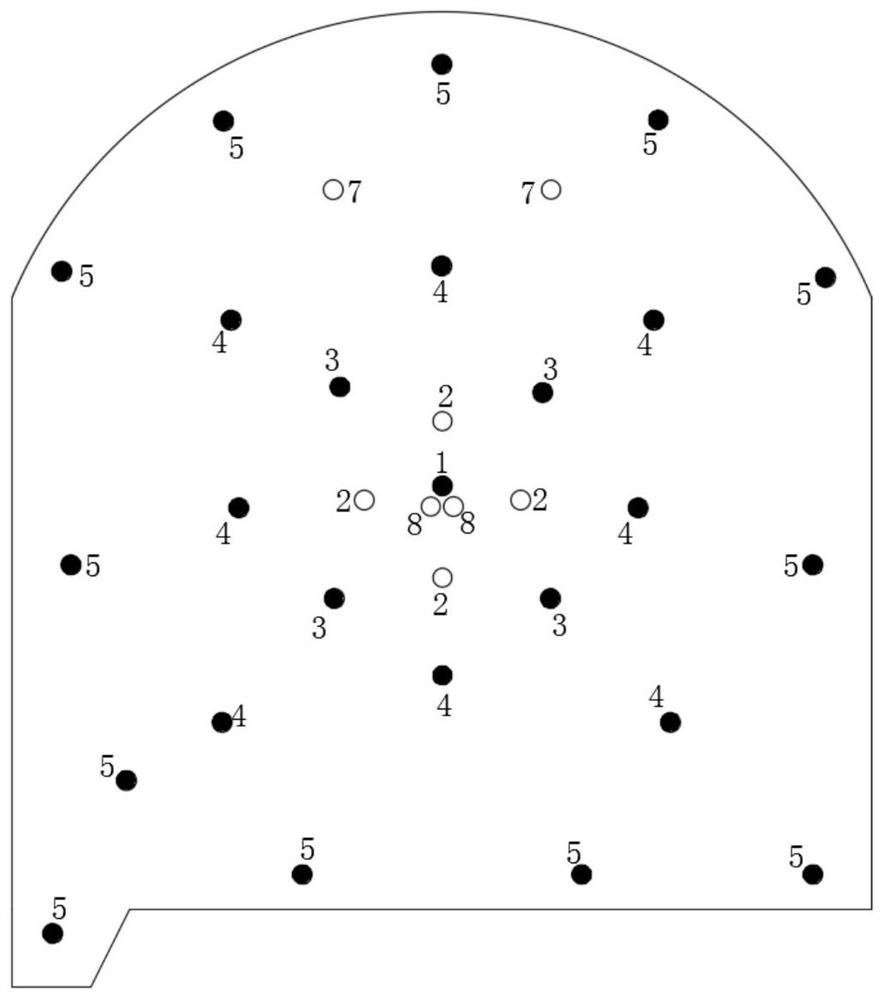

Rock roadway deep-hole multi-wedge straight-hole internal subsection micro-difference cutting blasting method

The invention discloses a rock roadway deep-hole multi-wedge straight-hole internal subsection micro-difference cutting blasting method. A multi-wedge straight-hole inter-subsection micro-difference blasting technology is adopted to realize progressive enlargement of a cutting cavity and progressive deepening of the cutting cavity, a deep-hole column-shaped charge subsection micro-difference blasting technology is adopted to solve the belly phenomenon at the bottom of the cutting cavity, and the deep-hole cutting blasting method can realize the effects that a large cutting cavity and a cuttingcavity 3.0 m deep can be obtained, the percentage of large gangue dumped by cutting is small and the throwing distance of waste rock is reduced to 25-30 m. Sequential initiating is performed according to a primary oblique hole + a six-direction energy-gathering straight hole I section detonator, a secondary oblique hole first section + a central straight hole hollow hole II section detonator, a secondary oblique hole second section + a central straight hole bottom charging section + a tertiary oblique hole III section detonator to form a final cutting cavity, then auxiliary holes, caving holes and bottom holes are initiated by adopting a IV section detonator, and peripheral holes are initiated by adopting a V section detonator to complete full-section blasting; and the large cutting cavity can be provided, the free surface is enlarged, and the blasting efficiency is improved.

Owner:CHINA UNIV OF MINING & TECH (BEIJING)

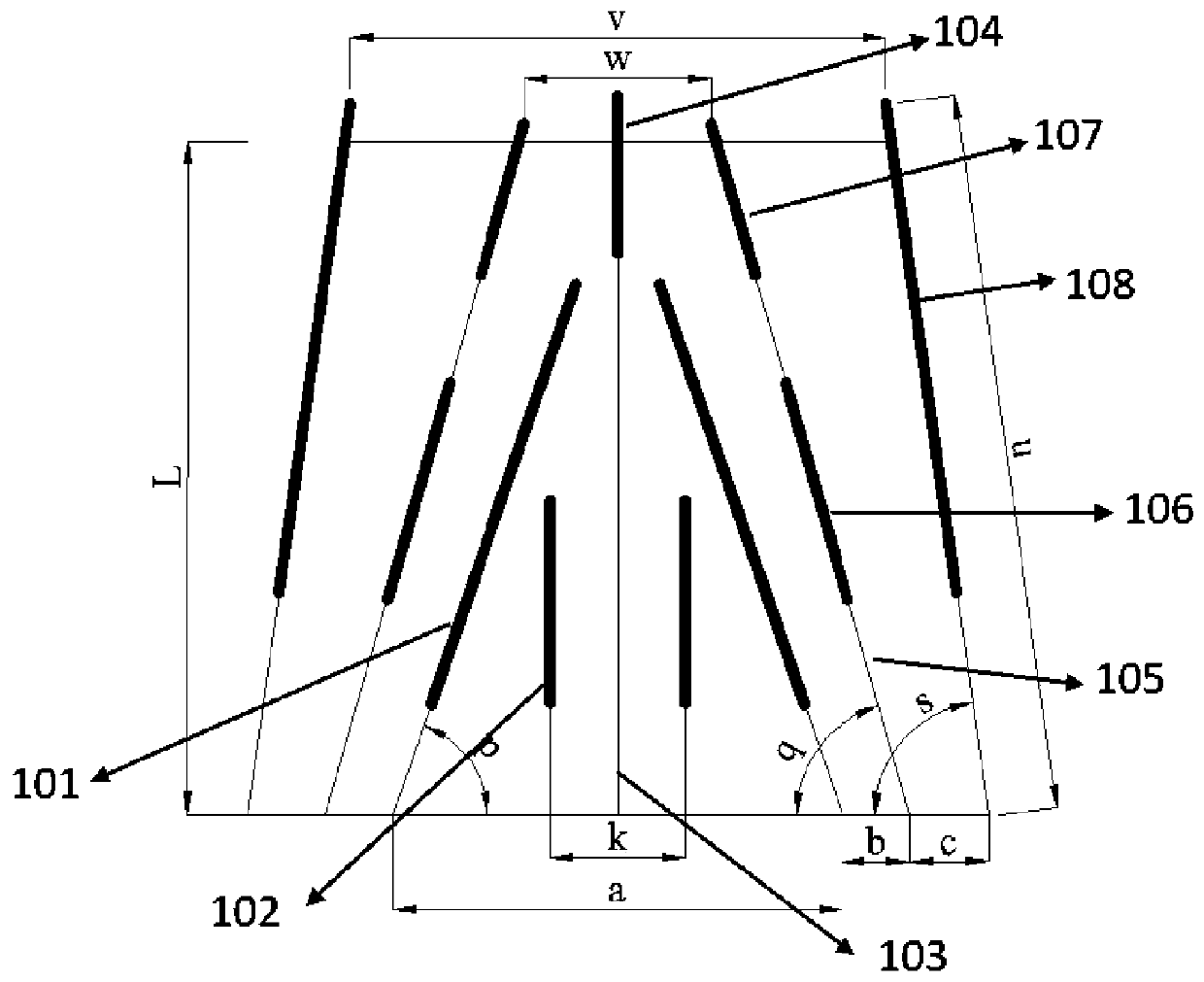

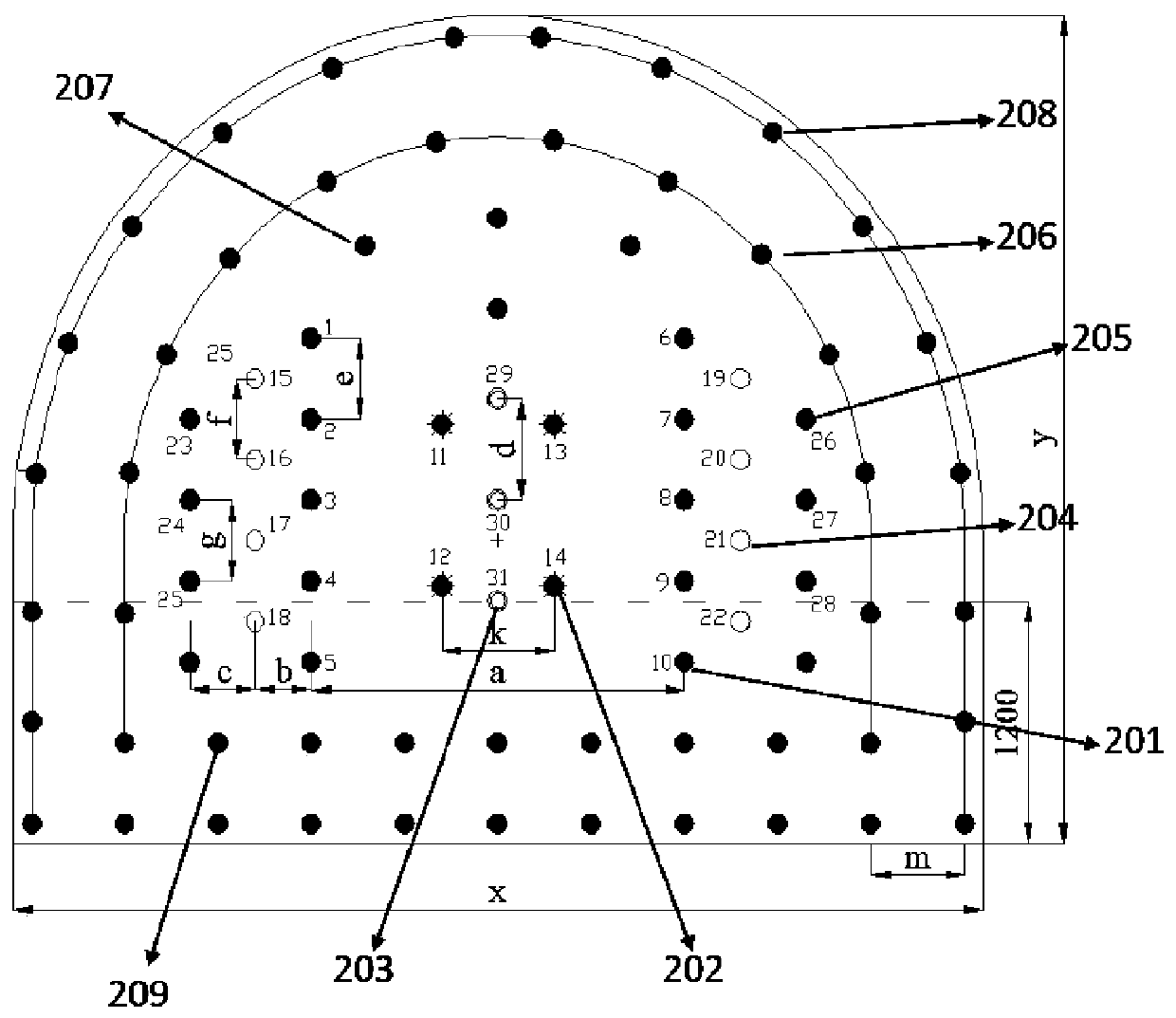

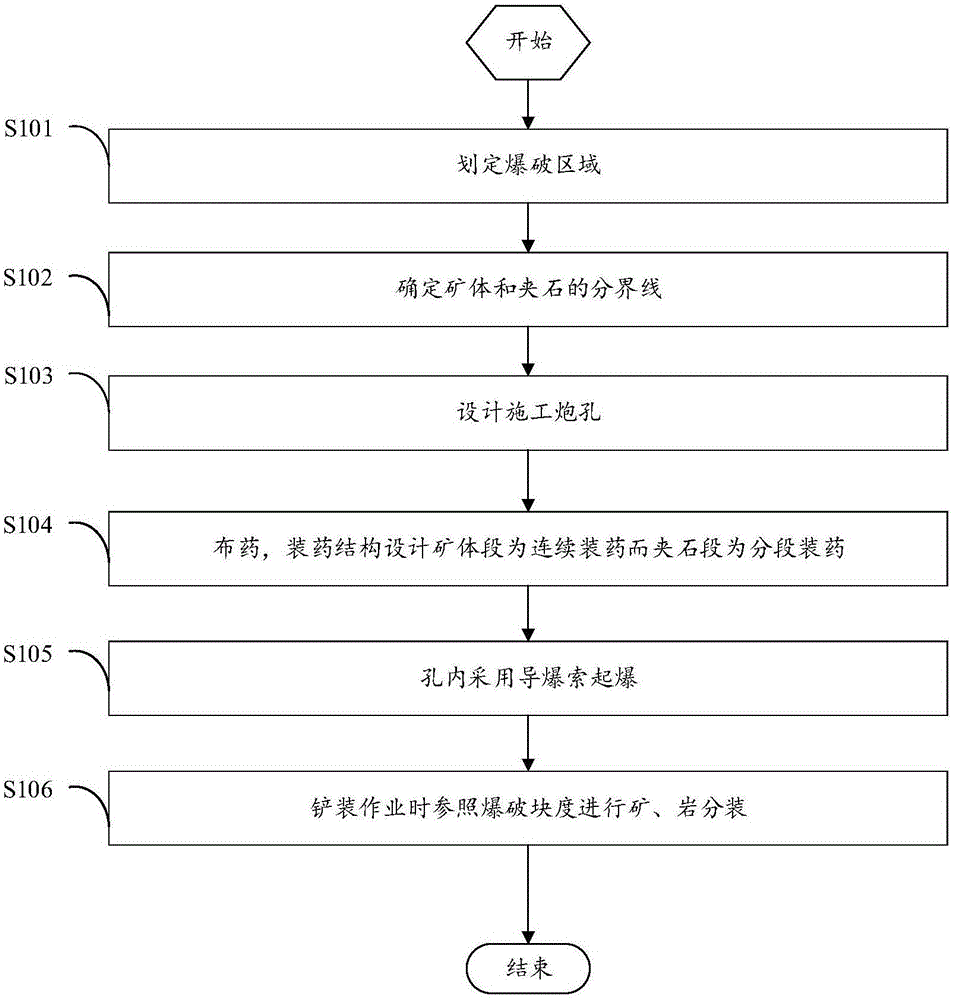

Method for reducing mine loss dilution through differentiation charge structure control blasting

The invention discloses a method for reducing mine loss dilution through differentiation charge structure control blasting. Different explosive unit consumptions are achieved by changing a blast hole charge structure, the lumpiness of ores obtained after blasting is obviously smaller than that of dead rock, the mutual covering and mixing degree of the ores and the rock is decreased, identifying and sorting are convenient, and mine loss dilution of the ores is reduced. The method comprises the specific steps that a blasting area is delimited; the boundary between an ore body and dunn basses is determined; construction blast holes are designed; explosives are arranged, wherein the ore body segment of the charge structure is designed to be a continuous charge segment, and the dunn bass segment of the charge structure is designed to be a segmented charge segment; detonating is conducted in the holes through detonating cords; when shovel mucking operation is conducted, ore and rock split charging is conducted by referring to the blasting lumpiness.

Owner:福建省新华都工程有限责任公司

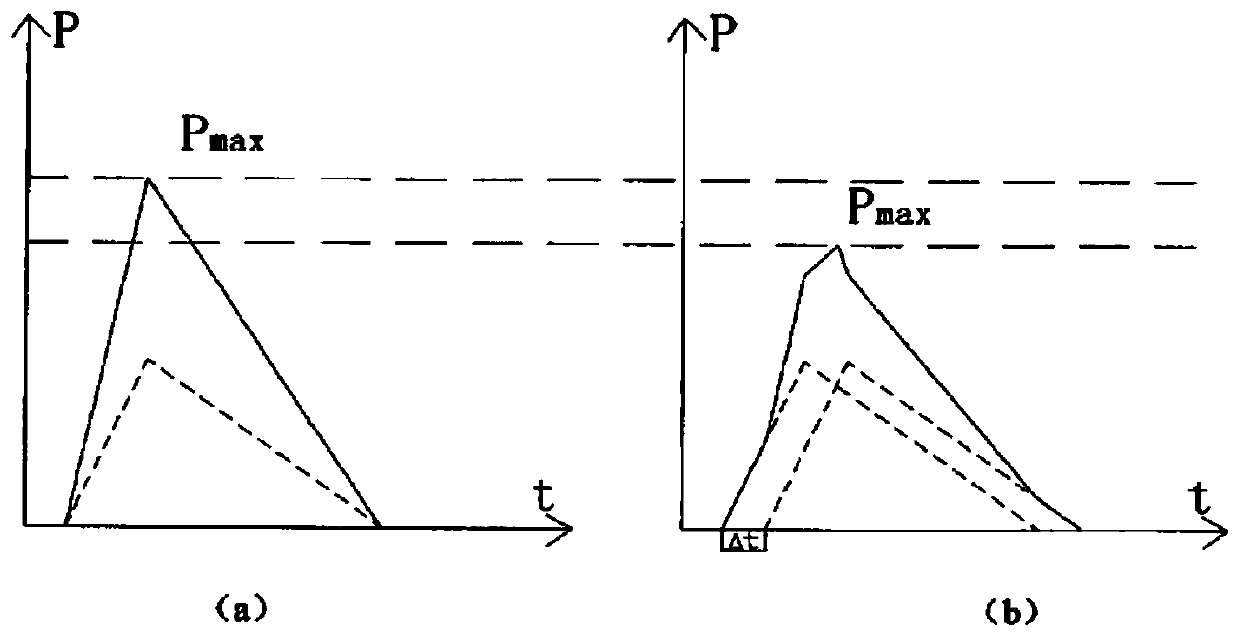

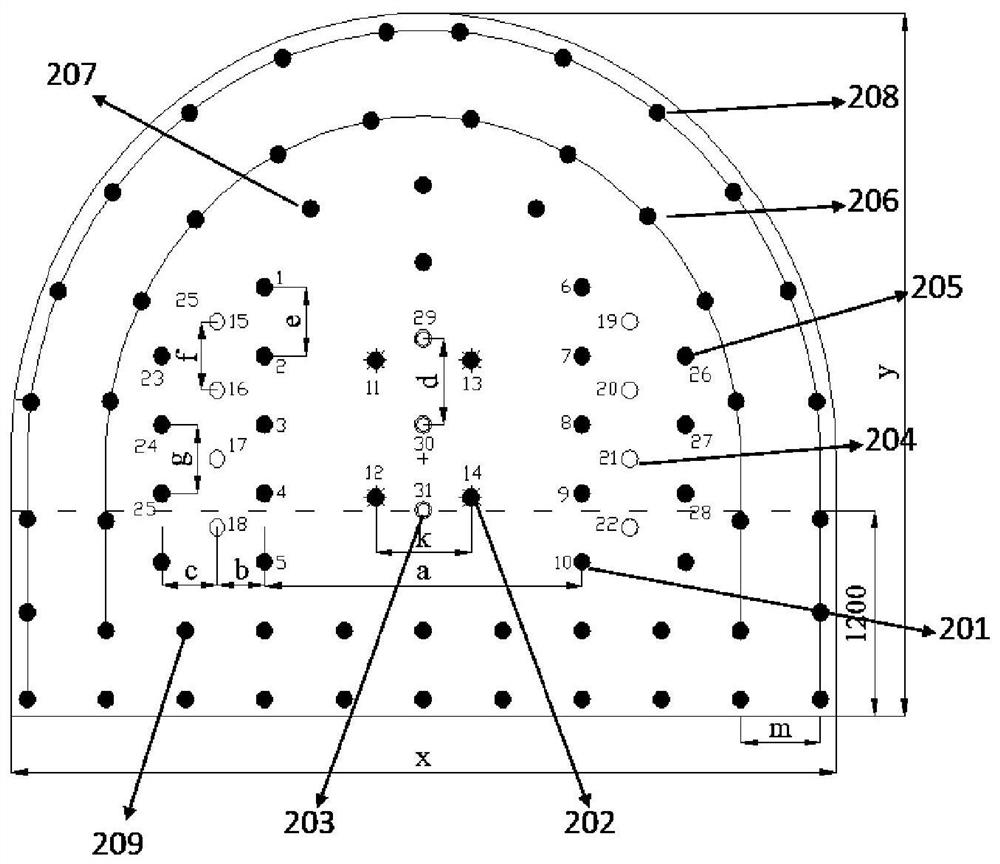

Detonator short-interval detonation blasting method for reducing ground blasting vibration

InactiveCN108592724AGuaranteed blasting effectAvoid the shortcomings of traditional blasting vibrationBlastingDetonatorDetonation

The invention discloses a detonator short-interval detonation blasting method for reducing ground blasting vibration. The blasting area is divided into two symmetric areas on the left and the right with the center line of a tunnel face of a blasting tunnel as the boundary. The two sides of the center line are provided with a plurality of symmetric underholing holes, auxiliary holes and peripheralholes, wherein the underholing holes are formed in the center area of the tunnel face, the peripheral holes are formed in the periphery of the tunnel face, the auxiliary holes are formed between the underholing holes and the peripheral holes, and during implementation, in the same row, hole-by-hole symmetric delayed detonation is conducted. According to the detonator short-interval detonation blasting method, electronic detonator hole-by-hole sequential detonation is adopted, for different types of cannon holes, vibration waves transmitted to the ground interfere with one another and are partially offset through setting of the optimal delay time of electronic detonators, the blasting effect of the construction smooth surface can be guaranteed, the defect that traditional smooth surface blasting vibration is large can be overcome, and influences on ground buildings are finally reduced.

Owner:厦门爆破工程有限公司 +1

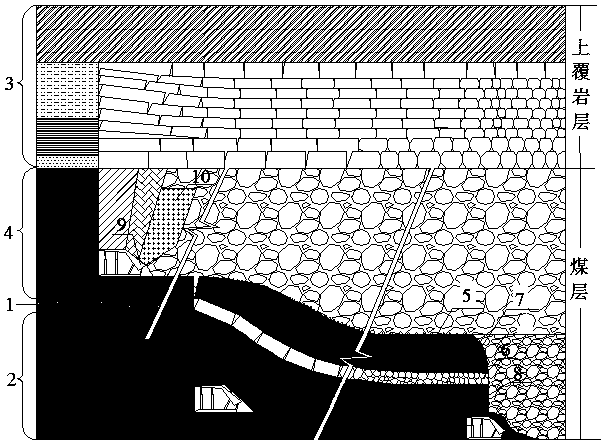

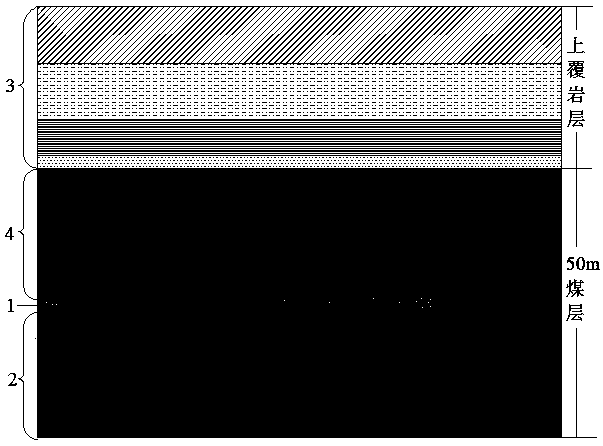

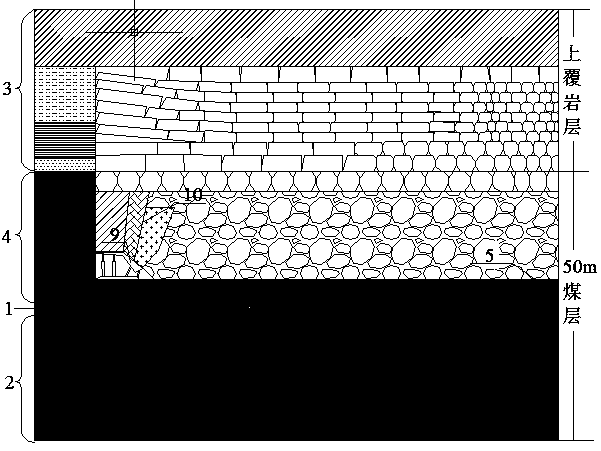

Layered mining method for ultra-thick coal seam containing dirt band layer in middle

ActiveCN110630263AReduce the impact of disturbanceFacilitated releaseUnderground miningSurface miningCoalMetal

The invention discloses a layered mining method for an ultra-thick coal seam containing a dirt band layer in the middle, and belongs to the technical field of efficient mining of ultra-thick coal seams. The layered mining method comprises the four steps including layer dividing, first layer mining, second layer mining and bottom layer mining. During layer dividing, with the starting point of the high efficiency and the high recovery rate and the principle of reducing the mining disturbance influence, the layering positions and thicknesses are determined according to the broken-expansion coefficient of coal mass and the coal drawing height; a first layer is subjected to full-mechanized caving mining, and a metal net is laid at the bottom of a work face; a second layer is subjected to full-mechanized caving mining, and a goaf is filled maximally by utilizing the loose broken-expansion characteristics of the dirt band layer and the coal mass with a certain thickness on the upper part andthe lower part of the dirt band layer; and during bottom layer mining, all the coal mass subjected to broken-expansion is drawn at a time. According to the layered mining method, disturbance of layered mining of the ultra-thick coal seam on an overlying rock stratum can be reduced, middle dirt band and the coal mass near the dirt band are broken through two times of mining, thus drawing is easy, and the recovery rate can be increased effectively.

Owner:CHINA UNIV OF MINING & TECH

Roadway blasting structure and blasting method

PendingCN113340165AThe size of the blasting space is reasonableIncrease compensation spaceBlastingTunnelsStructural engineeringMechanical engineering

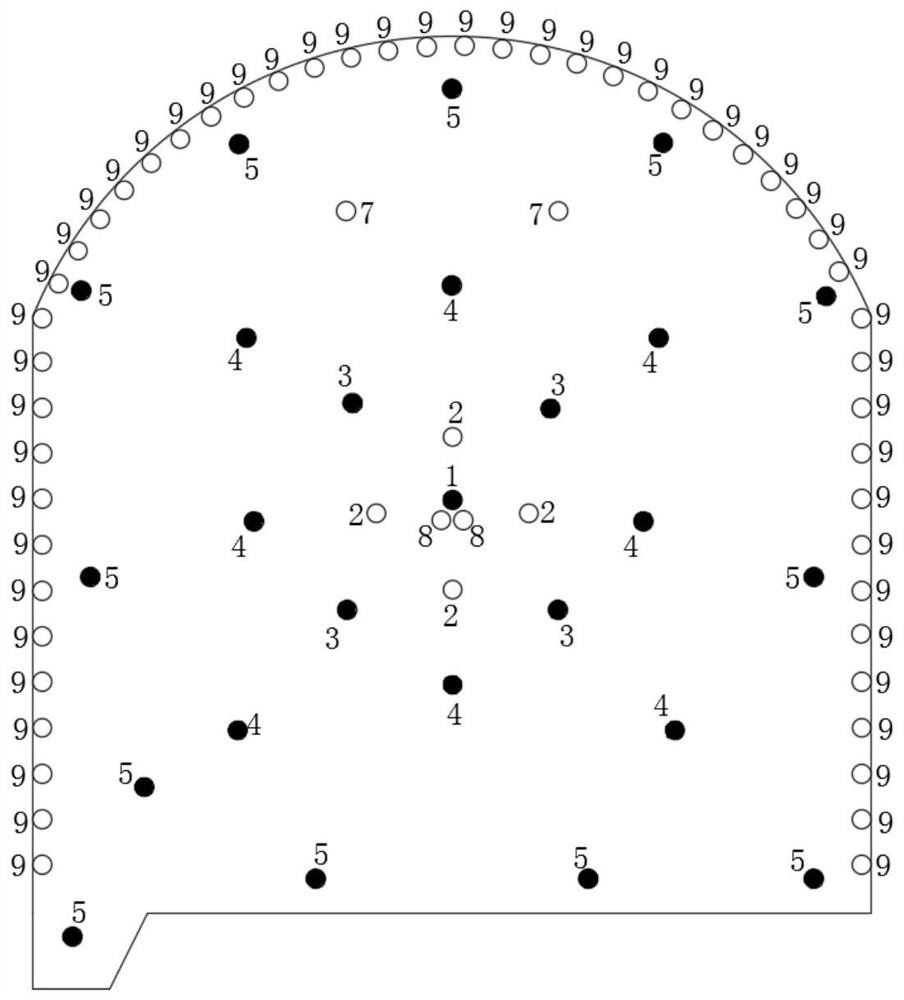

The invention provides a roadway blasting structure and a blasting method, and relates to the technical field of roadway construction. The roadway blasting structure comprises a plurality of hole groups which comprise a first hole group consisting of a slotting central hole, a second hole group consisting of a plurality of slotting holes, a third hole group consisting of a plurality of blasting buffer holes, a fourth hole group consisting of a plurality of auxiliary holes and a fifth hole group consisting of a plurality of peripheral holes; the first hole group, the second hole group, the third hole group, the fourth hole group and the fifth hole group are sequentially arranged from inside to outside, and the distance between every two adjacent hole groups is gradually increased from inside to outside, so that the overall hole position arrangement of a section of a roadway is optimized, and a blasting space is more reasonable, and; and the blasting buffer holes are formed between the slotting holes and the auxiliary holes; and through the extrusion blasting effect of the blasting buffer holes, the blasting compensation space of the auxiliary holes is increased, so that secondary blasting is generated, a blasting free surface space of a middle area is increased, miss-fire blasting is prevented, and safety is guaranteed.

Owner:嵩县金牛有限责任公司

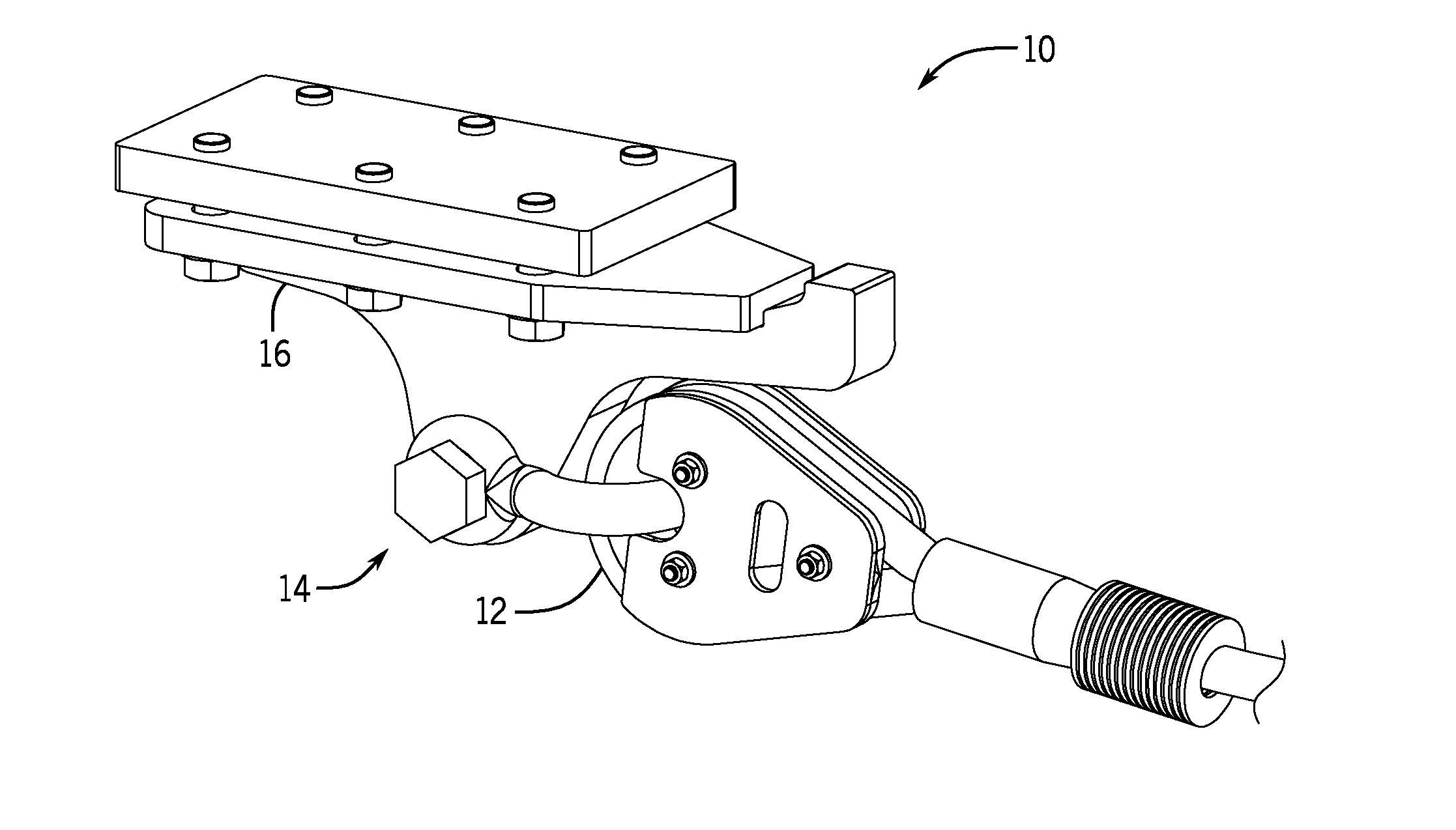

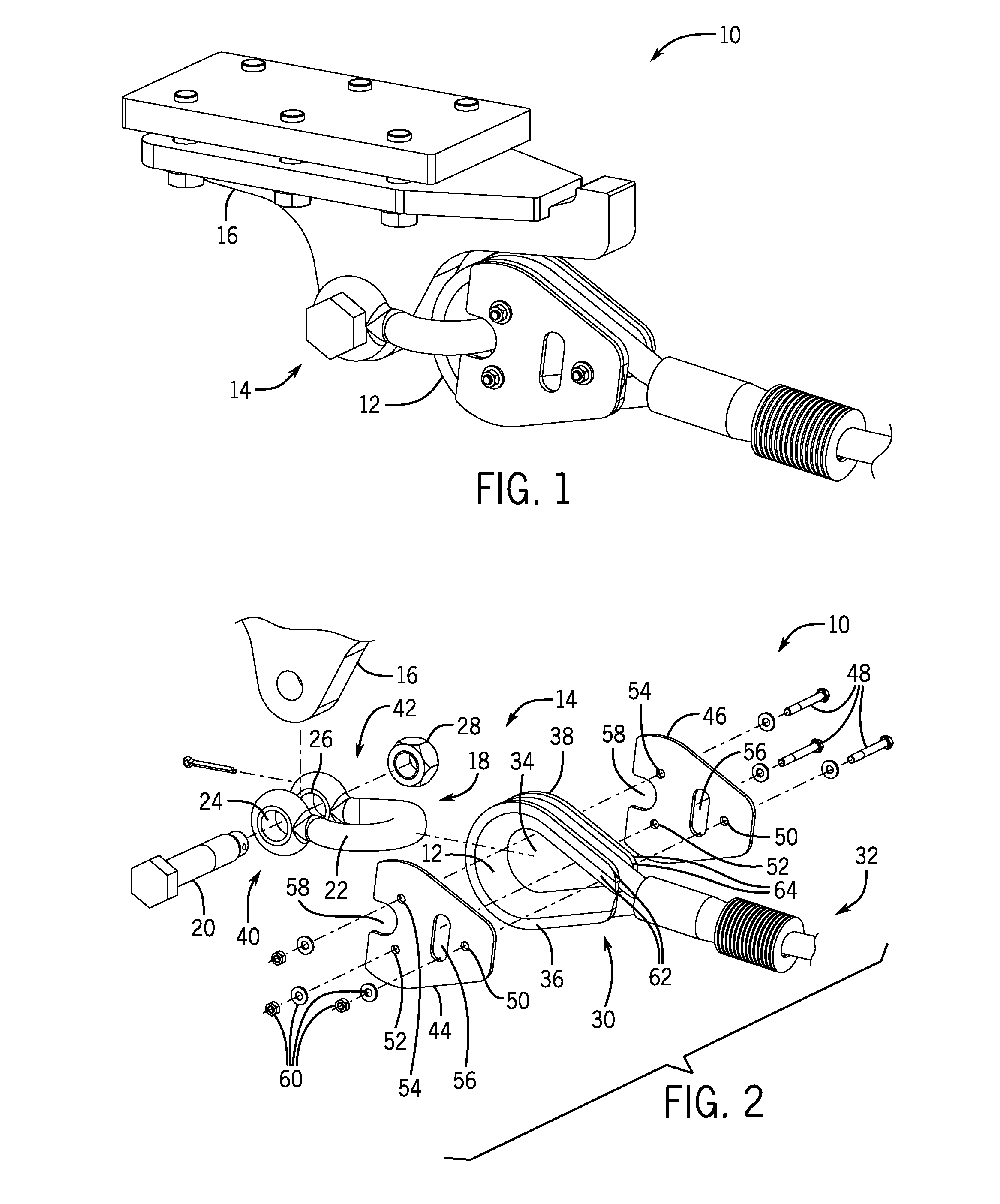

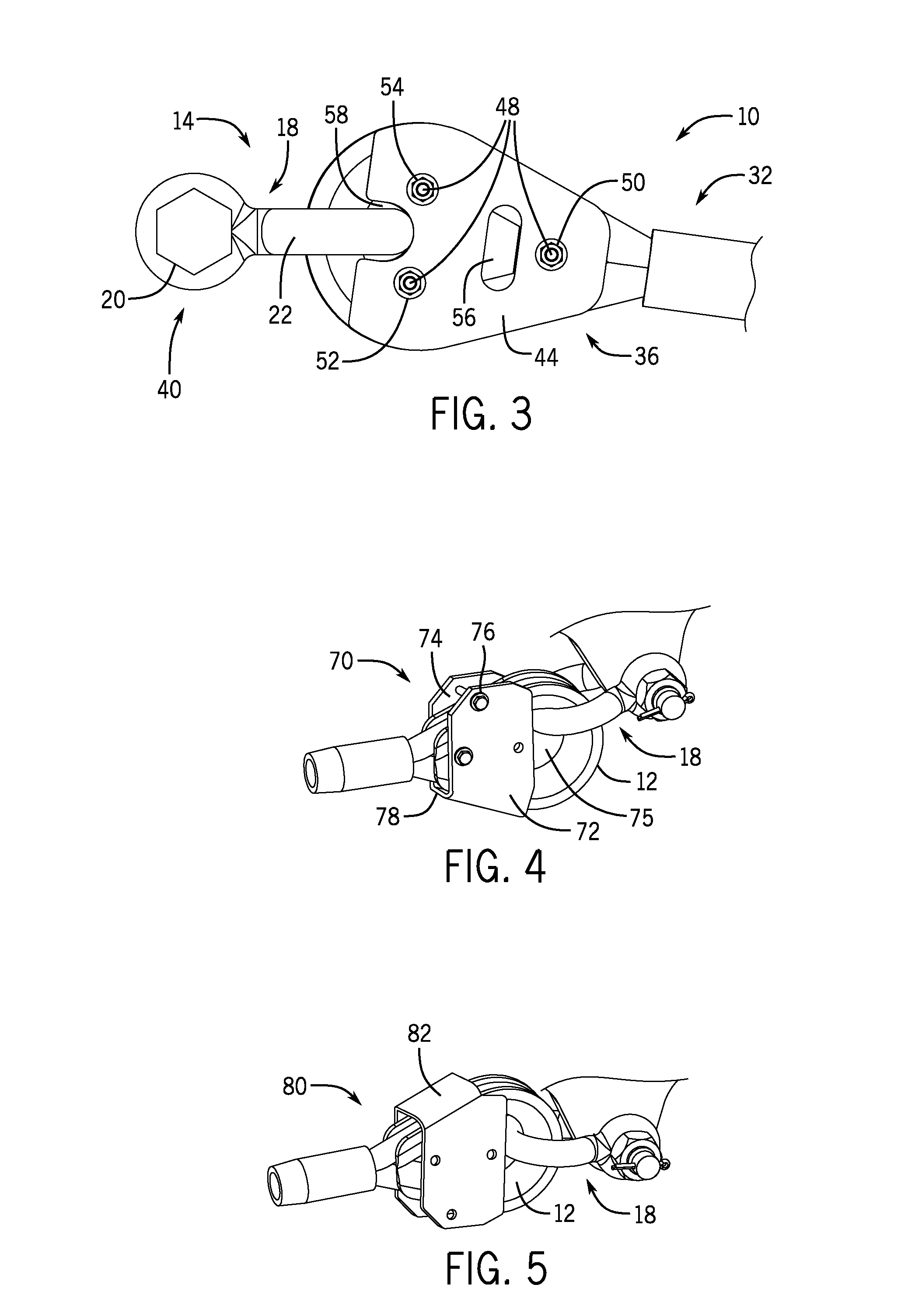

Cable end loop Anti-fouling system

A system to prevent fouling in rigging is provided that includes a first plate configured to be received on a first side of a thimble for a cable end, and a second plate configured to be received on a second side of the thimble. The first plate and second plate are configured to enable the thimble to receive a ring of a shackle assembly, but to block at least one end of the shackle assembly from entering an eye of the thimble while the first and second plates are on the first and second sides of the thimble.

Owner:BLUE LEAF I P

Layer-by-layer extrusion and smooth blasting mining method for underground mine

ActiveCN109025996AImprove ore transportation efficiencyLower filling costsUnderground miningBlastingEngineeringTailings

The invention discloses a layer-by-layer extrusion and smooth blasting mining method for an underground mine. The method includes the steps of: arranging a hanging wall air return way and a footwall following-vein transportation way along the ore body trend. The footwall following-vein transportation way is parallel to the ore body trend, and an orepass is disposed on the other side. Transverse drifts perpendicular to the ore body trend are disposed at both ends of an ore block. The length of stope is 40-100m, the width is the ore body thickness 5-20m and the height is 40-60m. The stope miningadopts a bottom-up layer-by-layer extrusion and smooth blasting way. By means of the layer-by-layer extrusion and smooth blasting technology, extrusion blasting is firstly carried out, then stope roof smooth blasting is carried out, through layer-by-layer extrusion, the lump ore rate is small, and the blasting cost is low. Layer-by-layer smooth blasting reduces disturbance to surrounding rock andmaintains the stability of surrounding rock, the stope roof is relatively flat, and workers are safe during construction in the stope. Layer-by-layer upward full tailing filling is low in filling cost.

Owner:周伟永

Rock roadway deep hole multi-wedge parallel cutting accumulative smooth blasting method

ActiveCN111238322AReduce throwing distanceSingle cycle footage heightBlastingClassical mechanicsCrushed stone

The invention provides a rock roadway deep hole multi-wedge parallel cutting accumulative smooth blasting method. According to the method, multi-wedge parallel cutting technology is adopted to achievea large-groove cavity with a groove cavity opening of 3.2-3.4 m and a deep-hole groove cavity with the depth of 3.0m or more, and the tunneling single-circulation footage of a rock roadway is improved; by adopting peripheral T-shaped accumulative blasting technology, the functions that the peripheral blasting is small in diameter, the explosive density is low, two-way full-hole deep cutting is performed along the periphery to the two sides to form a smooth surface, broken stones are cut in the radial direction, and tangential guiding and peripheral damping are generated by hollow holes are realized, and the effects that back break is reduced, the gangue block degree is reduced, the smooth surface forming is good, and the support is stable are achieved; and on the basis of the two kinds ofkey technology, the full-face blasting process and parameters are set, so that the deep hole smooth blasting effect that the expected blasting depth of the rock roadway reaches 3.0m is wholly realized.

Owner:CHINA UNIV OF MINING & TECH (BEIJING)

Blasting demolition method for reinforced concrete water retaining cofferdam

InactiveCN108132004ASafe blasting demolitionSafe useBlastingFoundation engineeringDetonationReinforced concrete

The invention relates to blasting demolition method for a reinforced concrete water retaining cofferdam, and belongs to the technical field of blasting engineering. The method includes the steps of 1)arranging, and drilling blastholes of a seepage-proofing pile, a top ring beam, a middle ring beam, a bottom ring beam and an anchor block; 2) charging; 3) arranging a blasting network and detonationmethods; 4) blasting and the like. Various detonation methods are adopted, and blasting demolition can be safely and efficiently conducted on the reinforced concrete water retaining cofferdam; various charging methods are adopted, blasting energy can be effectively utilized, crushing effects are smaller, and lumpiness is smaller; segmentation arrangement of the blastholes is adopted to reduce single-hole dose, blasting vibration, blasting flying stones and water-hammer waves are effectively controlled, and blasting dust is reduced; steps are simple, operation is easy, and the method is suitable for large-area popularization and application.

Owner:GUIZHOU XINLIAN BLAST ENG GRP

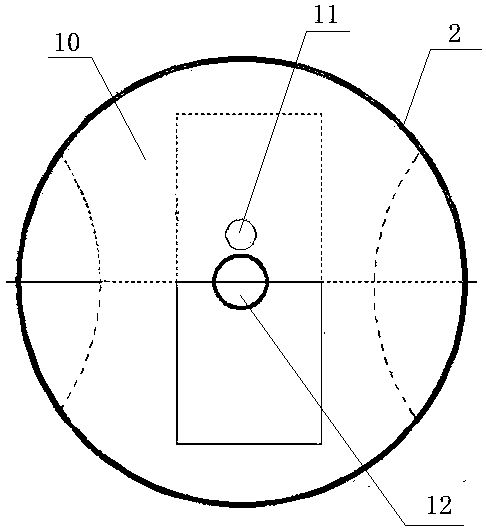

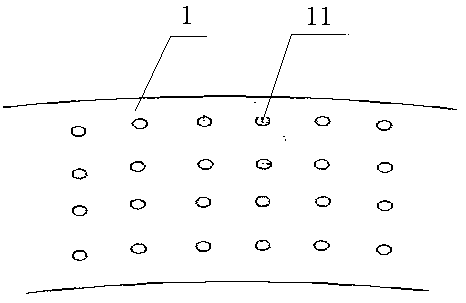

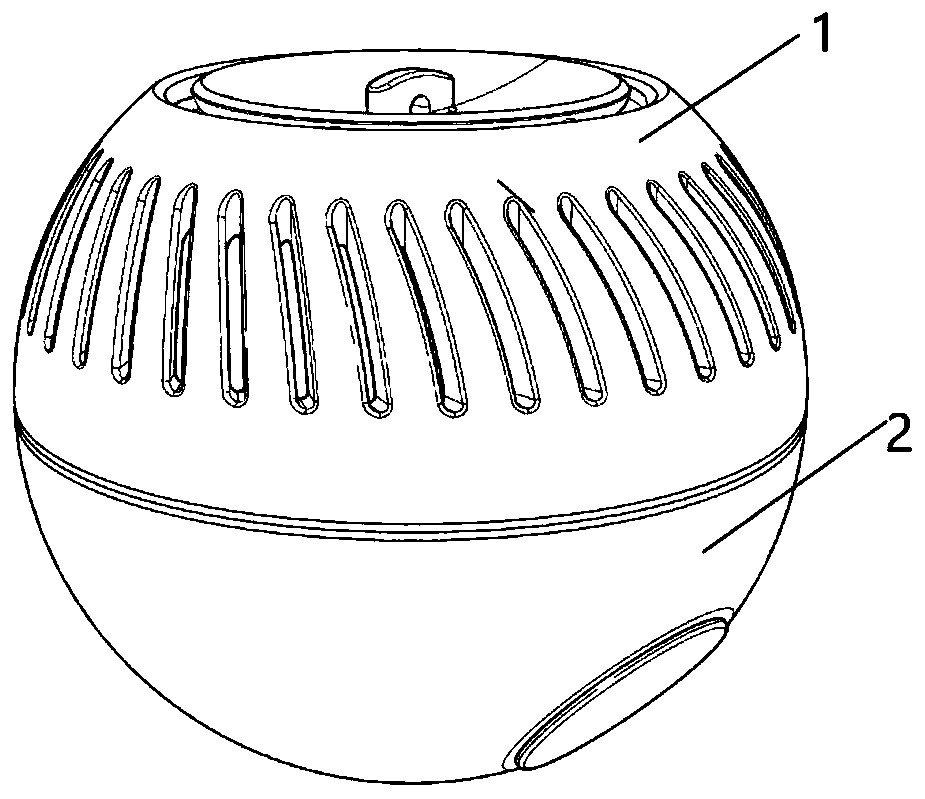

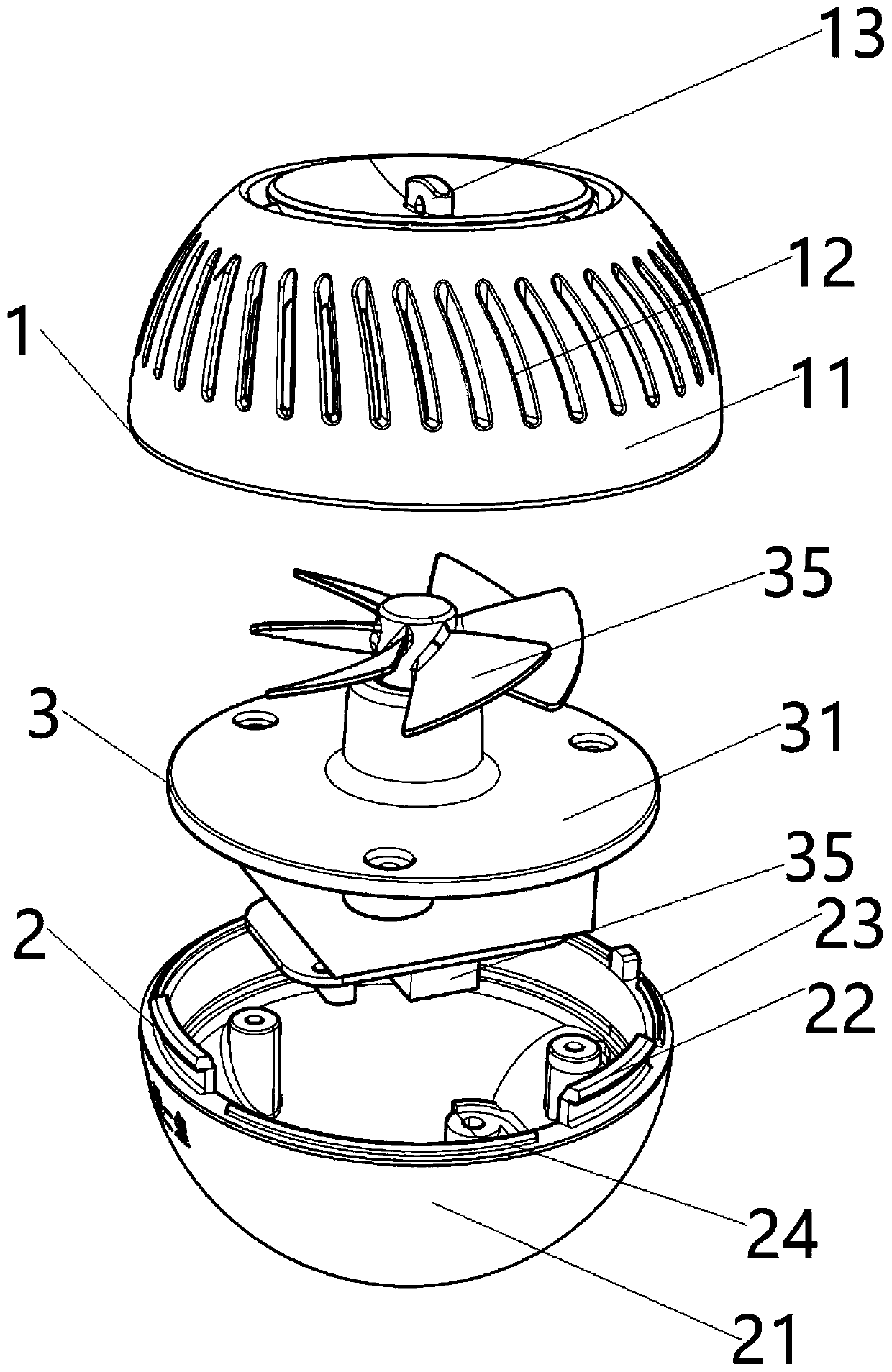

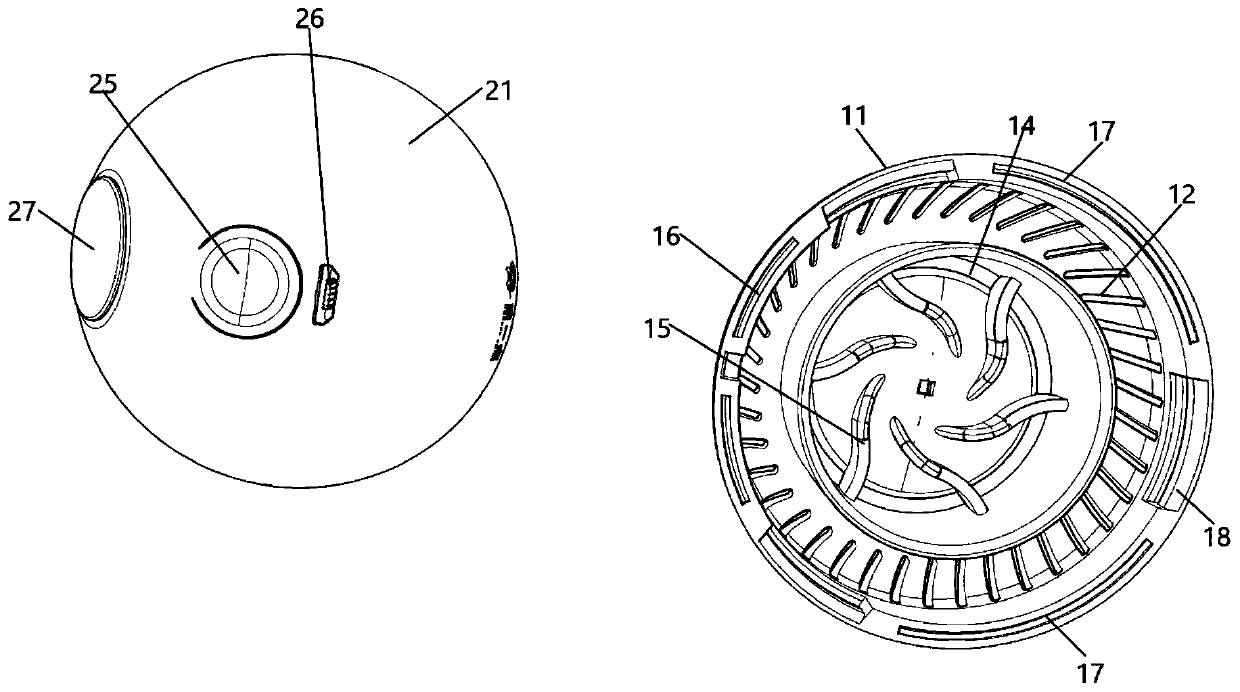

Mini bladeless fan in multifunctional usage mode

InactiveCN110374895AReduce volumeLarge air volumePump componentsMechanical energy handlingComputer engineeringFastener

The invention relates to the technical field of daily supplies, in particular to a mini bladeless fan in a multifunctional usage mode. The mini bladeless fan comprises an upper component, a lower component and a fan structure. The upper component and the lower component are connected in a clamped connection manner. The fan structure is arranged in the upper component and the lower component. The upper component comprises an upper shell. The upper shell is a hemispheric shell. Multiple sets of air inlets are formed in the outer side face of the upper shell. A rope hanging fastener is arranged in the middle of the top of the upper shell. Annularly-arranged air outlets are arranged at the top of the upper shell, and multiple sets of annularly-symmetric air baffles are arranged on the inner wall of the top of the upper shell. The mini bladeless fan is small in size and large in air output quantity, the air inlets and the air outlets are on the same plane, due to the fact that the air outlets surround the upper shell by 180 degrees and the air outlets are on an arc face, the air input state is achieved all around, and therefore the probability that the air outlets of the fan are all blocked by objects is quite small.

Owner:GUANGZHOU YIKEKE INTELLIGENT TECH CO LTD

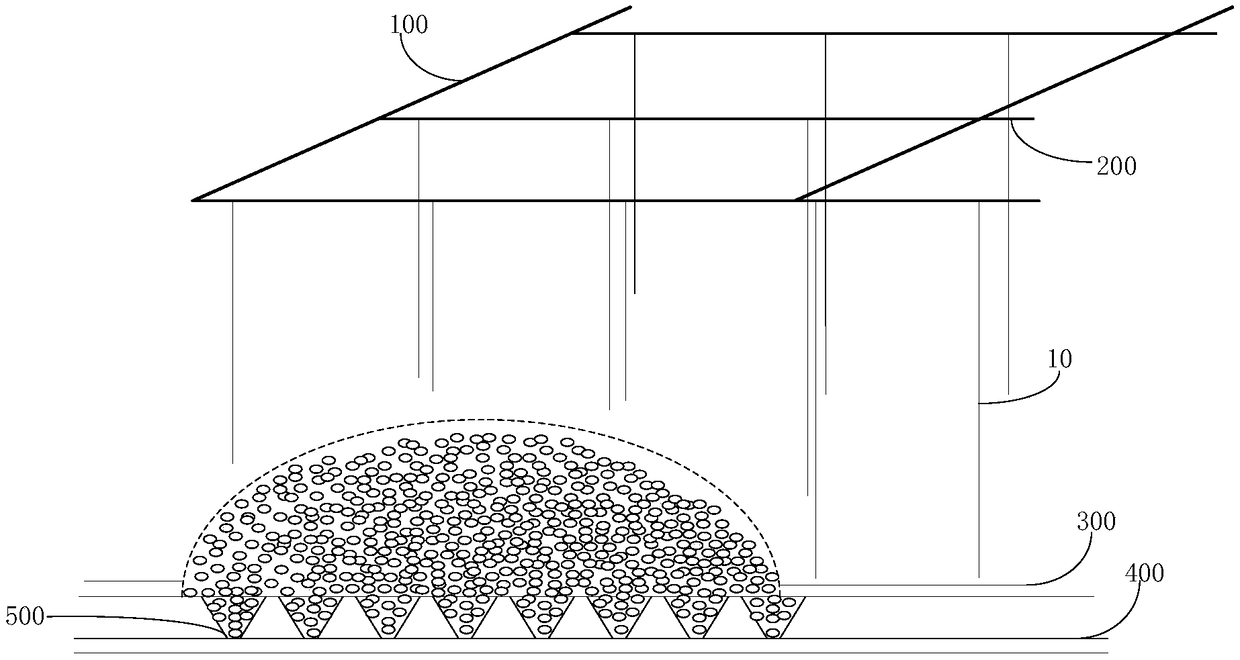

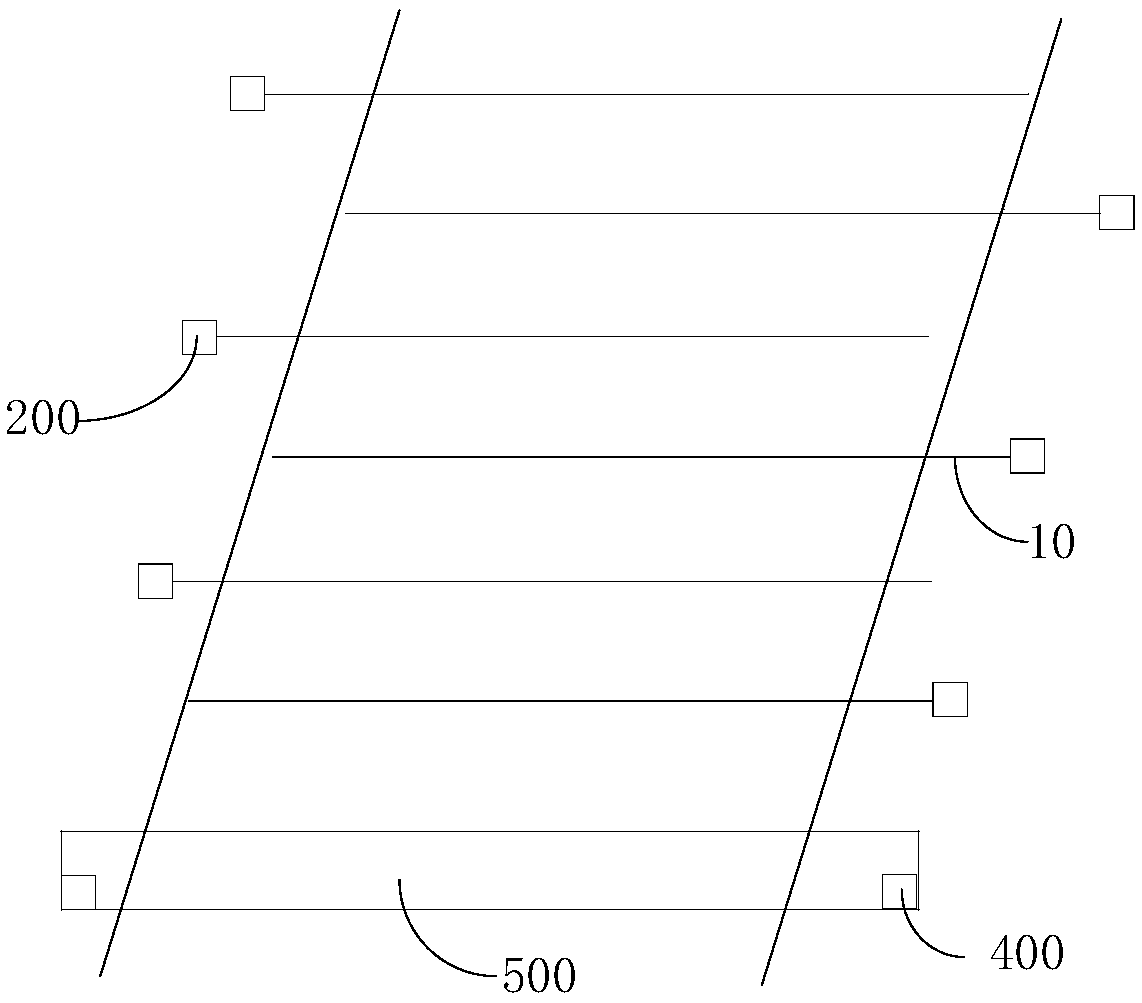

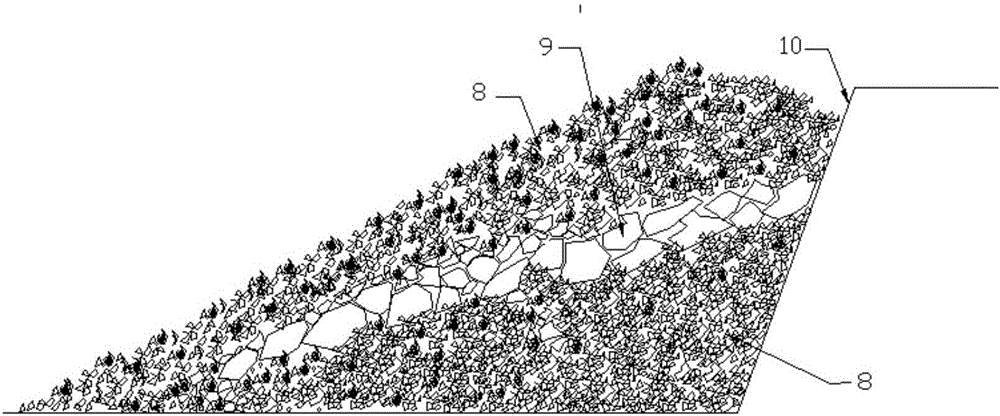

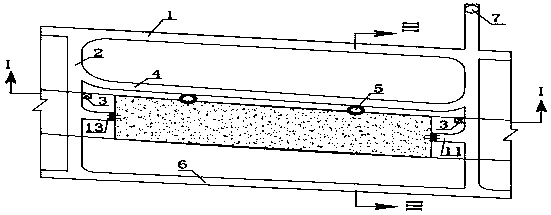

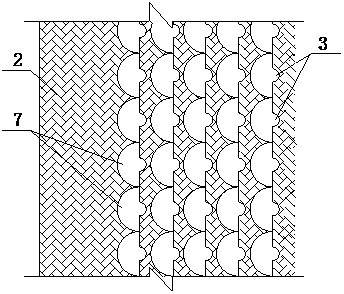

Method for cutting and pre-breaking top coal to improve mining efficiency by utilizing water power

The invention relates to a method for cutting and pre-breaking top coal to improve mining efficiency by utilizing water power, which solves the problem that a relatively hard and complete roof coal seam, particularly a coal seam tightly attached to an upper rock body, is difficult for top coal caving, large in coal falling lumpiness and not high in mining efficiency. The method comprises the following steps of: drilling advanced boreholes in a roof coal body to a coal rock boundary surface on a mining working surface by utilizing a drilling machine; extending a high-pressure water pipe in the boreholes; and cutting a plurality of subhorizontal semicircular transverse slots by utilizing the impact force of high-pressure water from top to bottom in the top coal. A plurality of yielding regions are formed by the boreholes in linear distribution in the roof coal body, the mechanical conditions in the coal body are changed, the hard and complete coal body is promoted to be deformed and broken under the effect of advanced concentrated stress, and a plurality of cracks are generated; the coal-rock and coal-coal contact areas are reduced through the transverse slots, and the coal body on the boundary surface is further extruded under the effect of roof high stress, so that the coal body is broken, the adhesive power is lost, manual layering is achieved, and coal is convenient to fall. The method is simple and quick, high in operability and good in timeliness, the coal mining speed can be efficiently increased, and the mining efficiency of the top coal is improved.

Owner:CHINA UNIV OF MINING & TECH

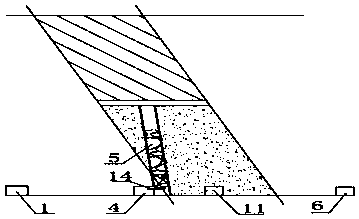

Gently-inclined extremely-thin gold vein mining method

ActiveCN113482614AEnsure safetyAvoid affecting the working face widthUnderground miningClimate change adaptationMineral SourcesMining engineering

The invention discloses a gently-inclined extremely-thin gold vein mining method. A chamber structure is arranged in the mode that a plurality of standard ore blocks are divided in the vein trend; the length of the ore block is 50m, the vertical height of the middle section is 25m, the width is the natural extension inclined length of the middle section with the vertical height of 25m along the vein; the mining preparation cutting method comprises the following steps that a lower-stage haulage roadway is arranged at the end part of the lower middle section of the ore block along the vein trend; an upper-stage haulage roadway is arranged at the end part of the upper middle section of the ore block along the vein trend; and in-vein cutting rises are arranged at intervals of 10m perpendicular to the trend of the vein, and stoping operation is carried out along the in-vein cutting rises; The gently-inclined extremely-thin gold vein mining method has the advantages of being low in mining preparation, cutting and filling engineering cost, high in mechanization degree, high in production efficiency and small in dilution loss, and still has excellent economic benefits even if the mining method is used for mining the gently-inclined extremely-thin gold vein with the inclination angle smaller than 30 degrees and the thickness smaller than 0.8 m, so that mineral resources are fully and effectively utilized.

Owner:河南发恩德矿业有限公司

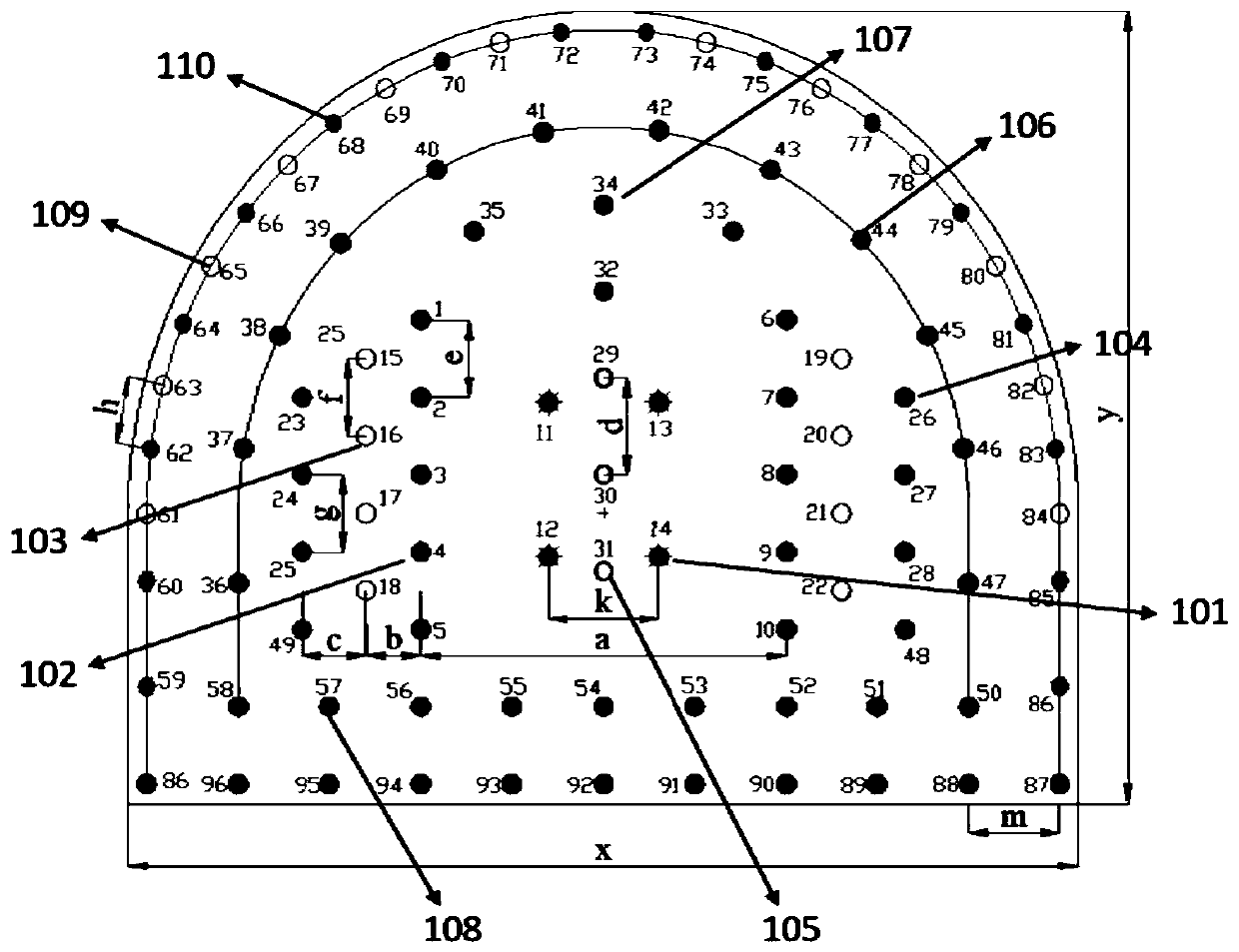

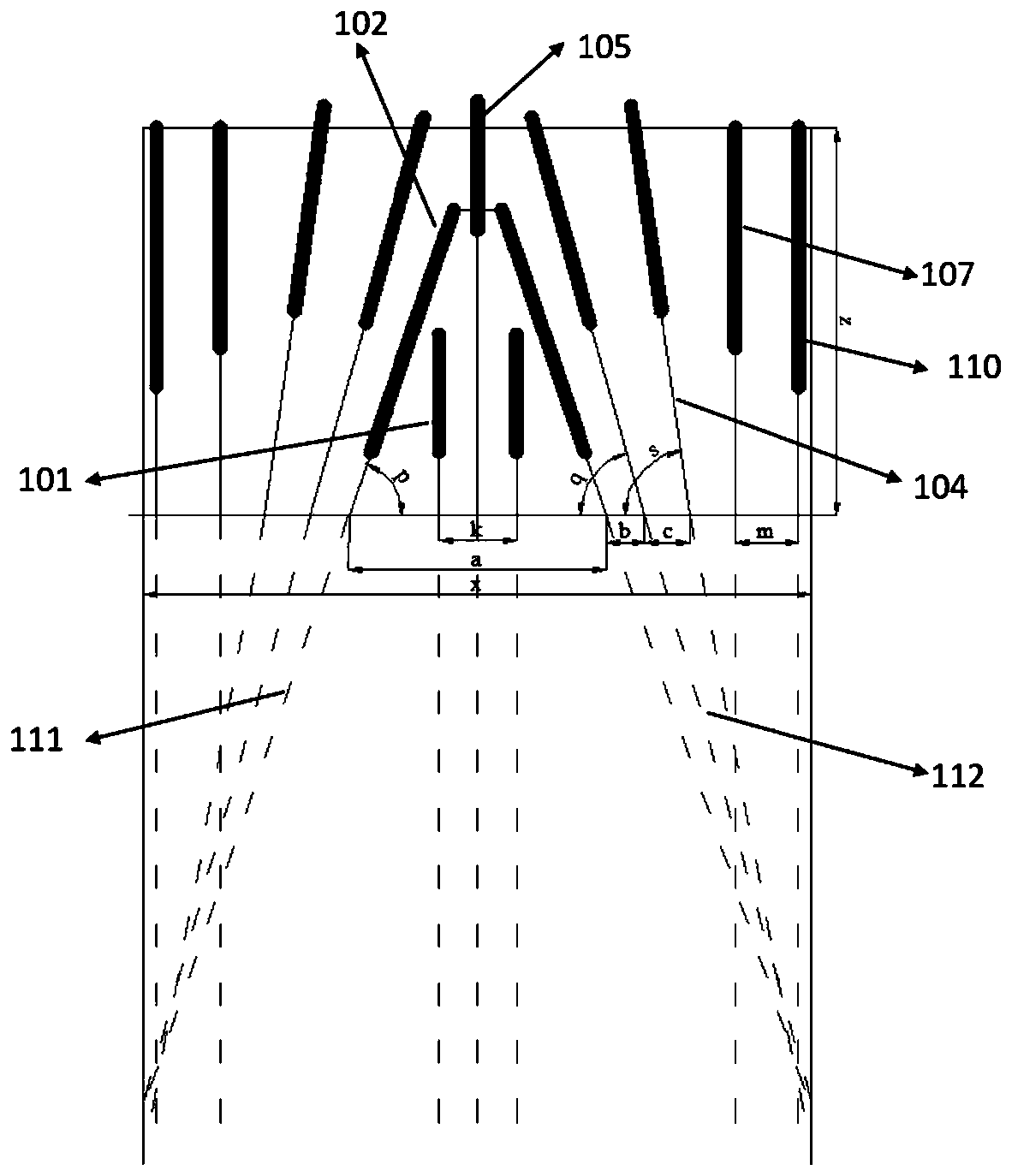

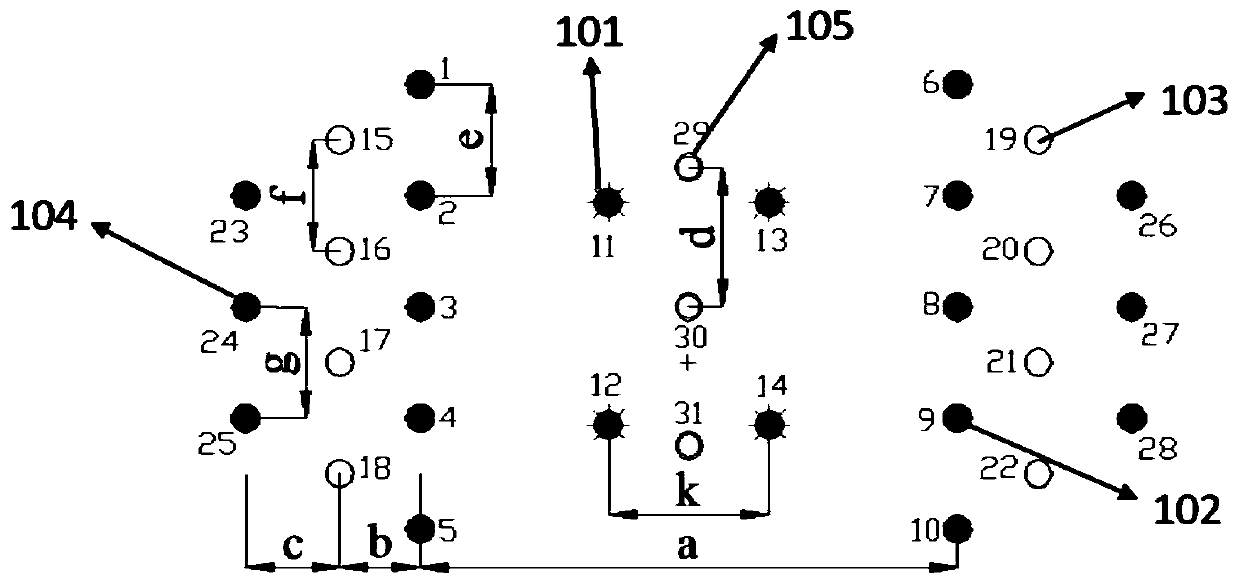

Tunnel Excavation Blasting Method Using Detonator Short Time Difference and Hole Vibration Reduction Technology Comprehensively

InactiveCN108592725BGuaranteed blasting effectAvoid the disadvantage of large blasting vibrationBlastingDetonatorBlasting vibration

The invention discloses a tunneling blasting method comprehensively utilizing the detonator short time difference and an empty hole vibration reduction technique. The center line of a tunnel face of ablasted tunnel serves as the boundary, and the blasted area is divided into a left region and a right region, wherein the left region and the right region are symmetrical to each other; the two sidesof the center line are provided with a plurality of slotting holes, auxiliary holes and peripheral holes correspondingly, wherein the slotting holes, the auxiliary holes and the peripheral holes aresymmetrical to one another, a vibration reduction hole linear array is arranged on the ground between the blasted area and a building, and in the implementation process, the same row of holes are blasted hole by hole in a symmetrical and delayed manner. Hole-by-hole sequential blasting is performed through electronic detonators, and targeted to different types of blastholes, through the setting ofthe optimal delay time of the electronic detonators, vibration waves transferred to the ground interfere with one another and are counteracted partially; and meanwhile, vibration reduction holes of optimized design are formed on the ground, and 50% of blasting vibration can be effectively lowered. Through the combined measure, the blasting effect of a constructed smooth surface can be guaranteed,the defect that traditional smooth surface blasting is large in vibration can also be overcome, and finally influences on the surface buildings are reduced.

Owner:厦门爆破工程有限公司 +1

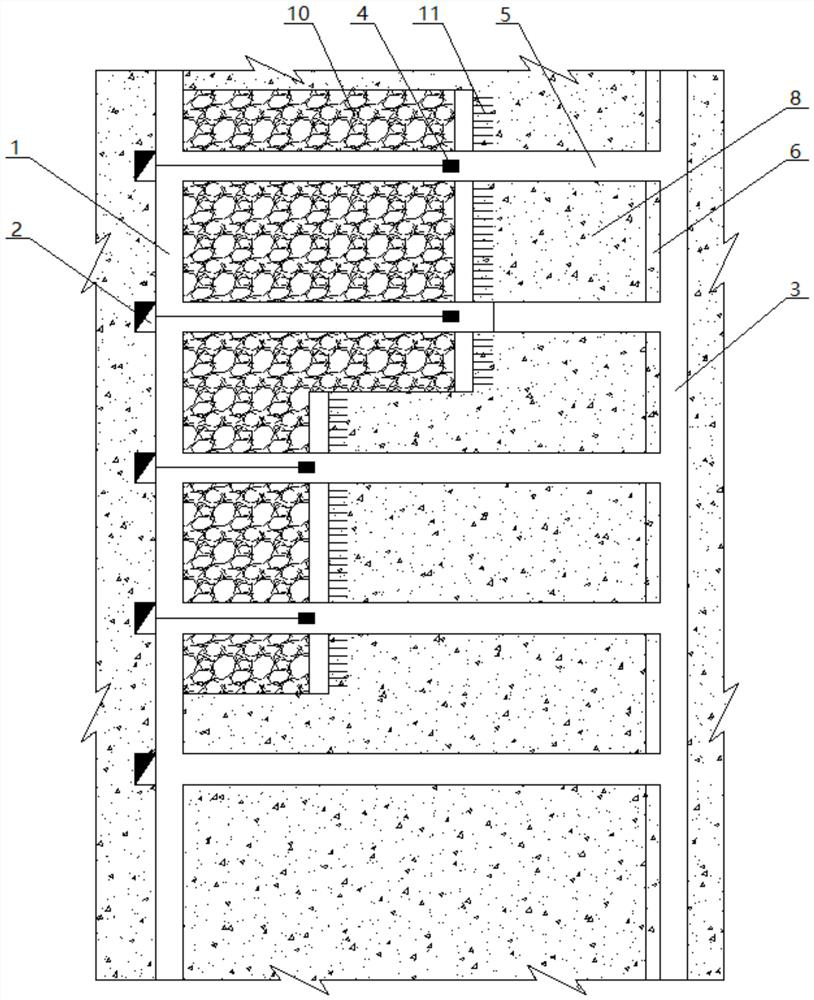

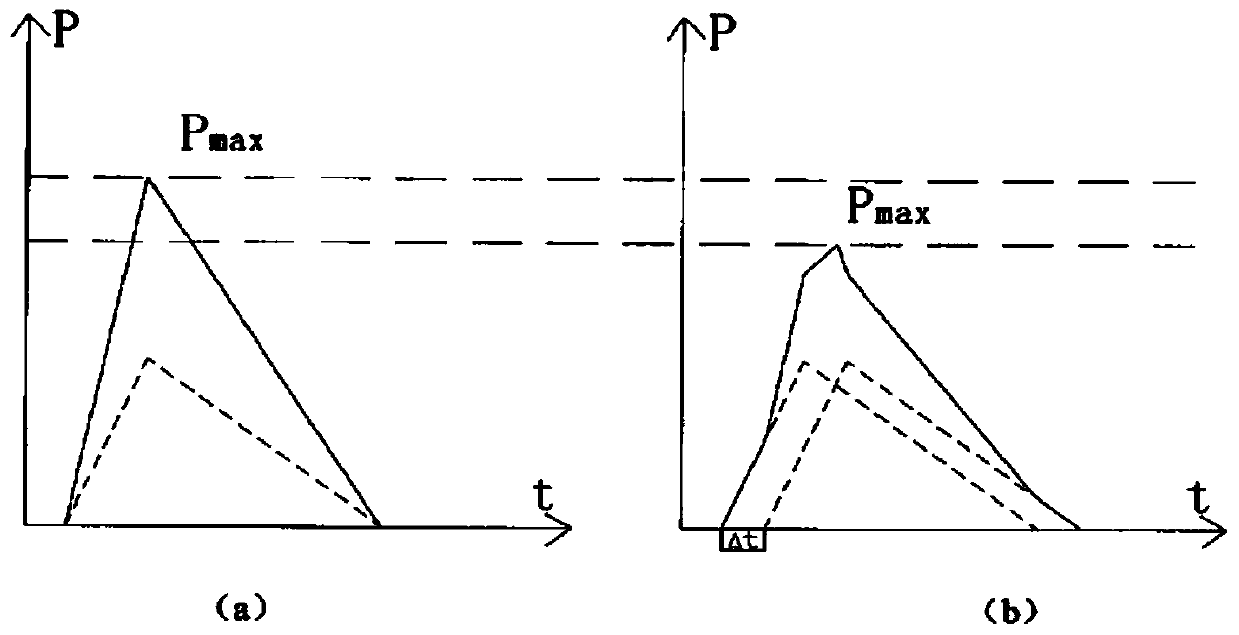

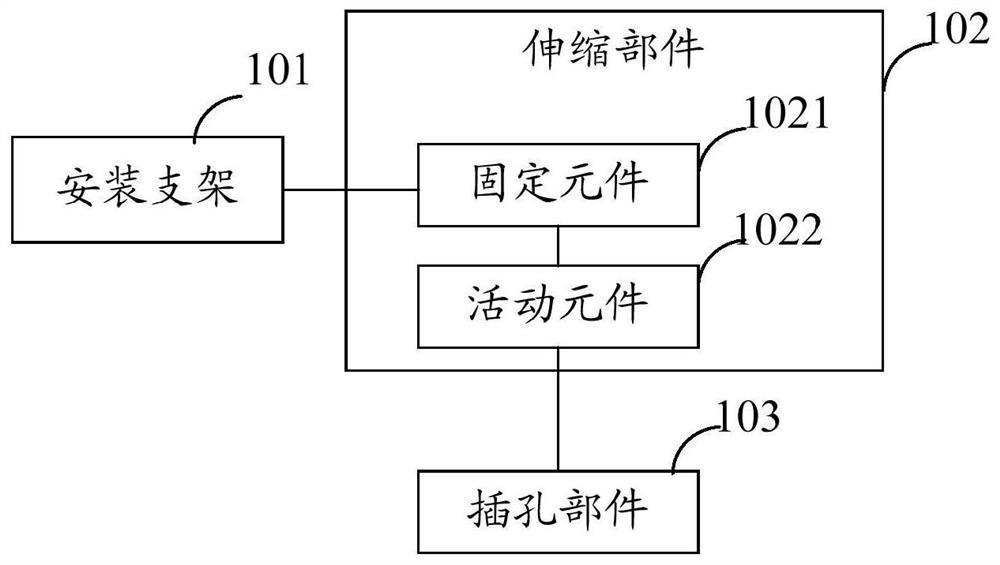

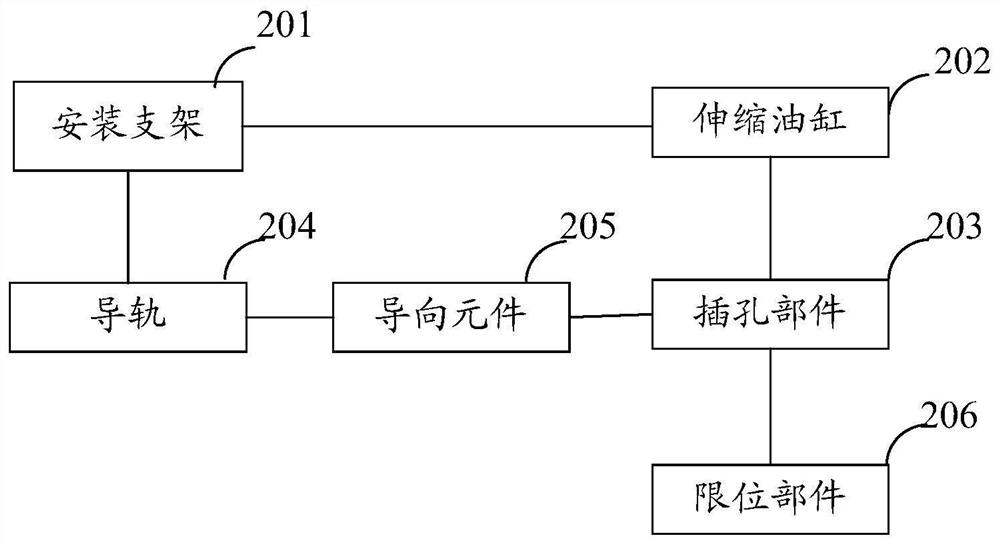

Socket device for tamping coke oven system and tamping coke oven system

The invention discloses a jack device for a stamping coke oven system and the stamping coke oven system. The jack device comprises a mounting bracket fixedly connected with a preset assembly in the tamping coke oven system; a telescopic assembly fixedly arranged on the mounting bracket, wherein the telescopic assembly further comprises a fixing element fixedly connected with the mounting bracket,and a movable element capable of reciprocating relative to the fixing element; and a jack assembly which is fixedly connected with the movable element contained by the telescopic assembly, and can perform a jack operation on stamping molded briquettes in the stamping coke oven system when the movable element reciprocates relative to the fixing element. The jack device has a wide range of application scenes, can be applied for a long period of time, and is convenient in operation, and can easily reduce the lumpiness of coke.

Owner:TAIYUAN HEAVY IND

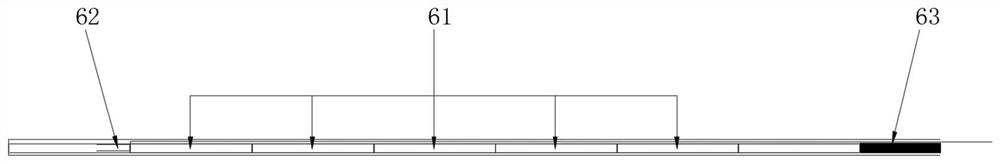

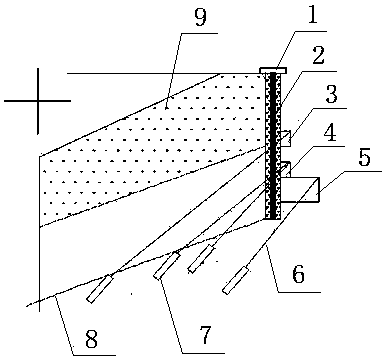

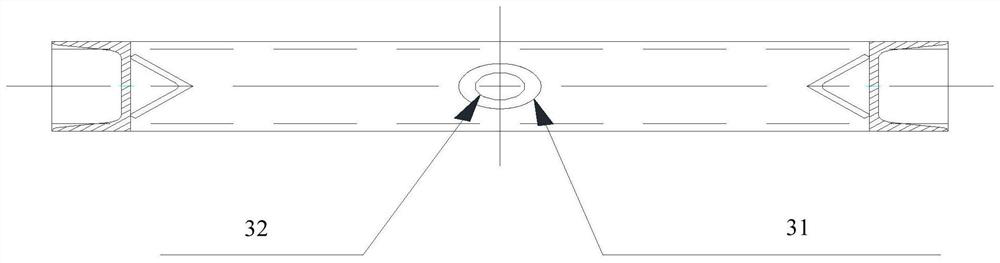

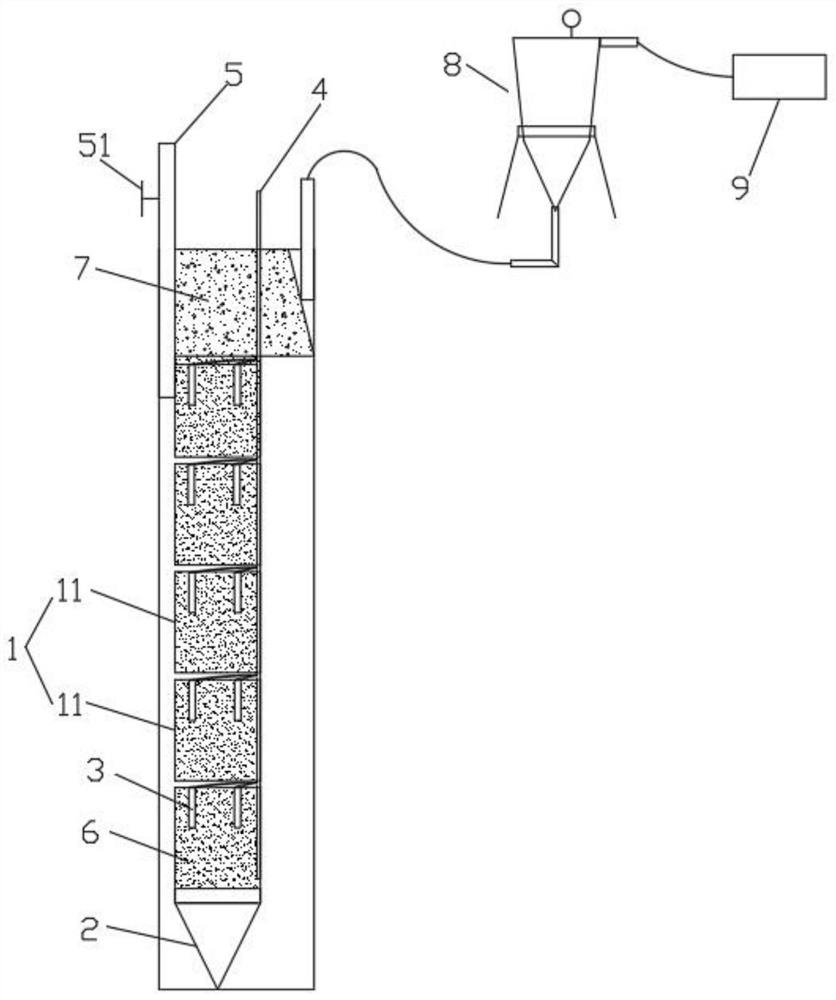

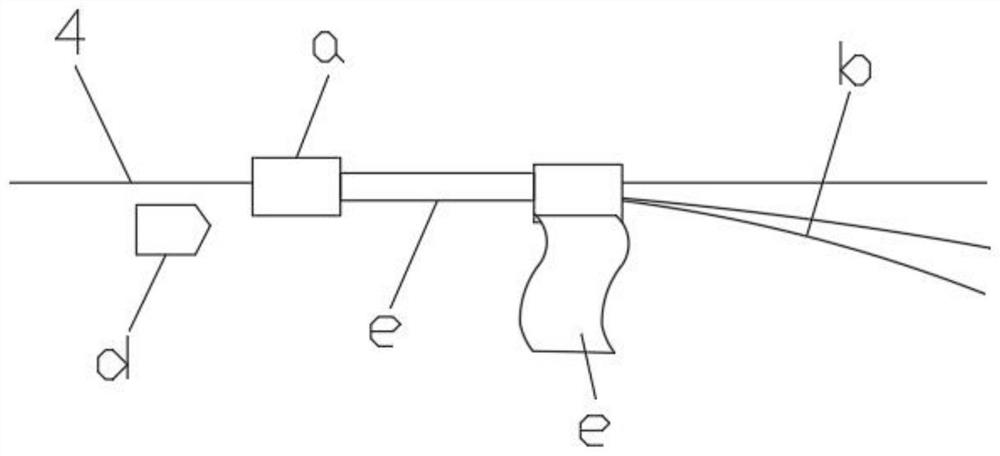

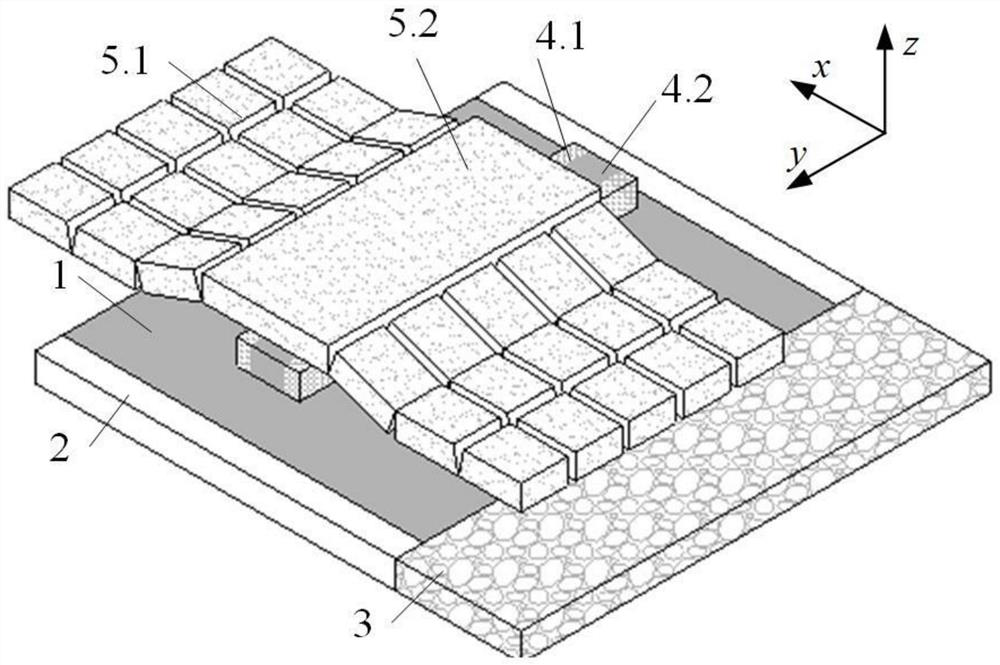

Deep hole uncoupled charge aqueous medium extruding and loosening blasting assembly and blasting method

PendingCN112097582ANormal propulsion has little impactSmall blockBlastingTEX-explosiveMining engineering

The invention relates to a coal (rock) body loosening blasting technology, in particular to a deep hole uncoupled charge aqueous medium extruding and loosening blasting assembly and a blasting method.The deep hole blasting method provided by the invention comprises the following steps of S1: drilling construction; S2, charging, comprising mounting a charging guider at an end part of one end of atube and fixing the same; mounting an explosive in the tube; placing a plurality of groups of initiators in a spaced manner along a long axis direction of the tube in the explosive, and placing a mother wire, and connecting a wire of each group of initiator to the mother wire; placing the tube charged with the explosive, together with the mother wire, in a drilled hole; and communicating a water injection pipe to a water injection cavity; S3, sealing an orifice of the drilled hole for reinforcement; S4, injecting water into the water injection cavity fully; and S5, connecting the mother wire to finish blasting. The assembly and method have the advantages that normal advancement the working face is less affected, so that the advancing speed and efficiency of the exploring working face are guaranteed; stope face equipment and facilities are not damaged easily, so that the equipment maintenance cost is lowered; and the blast rocks are small in lumpiness and uniform, so that the rocks arecut favorably by a coal cutter.

Owner:刘德成

A detonator short-spaced blasting method for reducing ground blasting vibration

InactiveCN108592724BGuaranteed blasting effectAvoid the shortcomings of traditional blasting vibrationBlastingDetonatorDetonation

The invention discloses a detonator short-interval detonation blasting method for reducing ground blasting vibration. The blasting area is divided into two symmetric areas on the left and the right with the center line of a tunnel face of a blasting tunnel as the boundary. The two sides of the center line are provided with a plurality of symmetric underholing holes, auxiliary holes and peripheralholes, wherein the underholing holes are formed in the center area of the tunnel face, the peripheral holes are formed in the periphery of the tunnel face, the auxiliary holes are formed between the underholing holes and the peripheral holes, and during implementation, in the same row, hole-by-hole symmetric delayed detonation is conducted. According to the detonator short-interval detonation blasting method, electronic detonator hole-by-hole sequential detonation is adopted, for different types of cannon holes, vibration waves transmitted to the ground interfere with one another and are partially offset through setting of the optimal delay time of electronic detonators, the blasting effect of the construction smooth surface can be guaranteed, the defect that traditional smooth surface blasting vibration is large can be overcome, and influences on ground buildings are finally reduced.

Owner:厦门爆破工程有限公司 +1

Phosphorus-doped aluminum alloy and manufacture method thereof

The present invention relates to the field of an aluminum-base alloy adopting silicon as a subordinate main component, and specifically to a phosphorus-doped aluminum alloy and a manufacture method thereof. The phosphorus-doped aluminum alloy comprises aluminum and silicon, wherein a mass ratio of the silicon to the aluminum is 0.12-0.15. The phosphorus-doped aluminum alloy is characterized in that: the phosphorus-doped aluminum alloy further comprises phosphorus, wherein a mass ratio of the phosphorus to the aluminum is 0.008-0.012%. The manufacture method for the phosphorus-doped aluminum alloy sequentially comprises five steps of material preparing, melting, stirring, degassing and casting, and is characterized in that: the method further comprises: adding phosphor-copper, wherein the phosphor-copper adding step is performed between the stirring step and the degassing step, and the aluminum liquid temperature is controlled to 855-885 DEG C during the phosphor-copper adding process. With the present invention, the shrinking speed is rapid during casting, and the mechanical property of the cast is high.

Owner:SHANGHAI WANTAI ALUMINUM

A Subsection Micro-differential Cutting Blasting Method in Deep Hole Multiple Wedge Straight Hole in Rock Roadway

A method of segmented micro-differential cutting blasting in multi-wedge straight holes in deep holes in rock roadways, that is, the segmental micro-differential blasting technology between multi-wedge straight deep hole cutting holes is used to realize step-by-step expansion of the cavity and step-by-step deepening of the cavity, The deep-hole columnar charge segmental differential blasting technology is used to solve the phenomenon of bulging at the bottom of the cavity. This deep-hole cutting blasting method can realize a large cavity and a 3.0m deep cavity, and the rate of cutting large pieces of gangue is small. , The effect of shortening the throwing distance of gangue to 25-30m. According to the detonator of the first squint + six-direction energy-concentrating straight eye section I, the second squint first section + the center straight eye hole II detonator, the second squint second section + the center straight eye bottom charging section + the third squint section III detonator Sequentially detonate to form the final cut cavity, and then use the fourth section detonator to detonate the auxiliary eye, avalanche eye, and bottom eye, and use the fifth section detonator to detonate the peripheral eye to complete the full-section blasting; it can provide a large cavity, expand the free surface, and improve the blasting efficiency. efficiency.

Owner:CHINA UNIV OF MINING & TECH (BEIJING)

Large collapse rock blasting method under precise control of digital electronic detonators

The invention belongs to the technical field of blasting, and particular relates to a large collapse rock blasting method under precise control of digital electronic detonators. The method includes steps of designing parameters of a hole network and distributing holes; drilling holes by cutting drills; charging and blocking; and networking and detonating. The digital electronic detonators are used for precisely controlling blasting, the hole network is designed to be subjected to detonation in parallel and detonation layer by layer, powder charges on the same layer are detonated from two sides to the center obliquely hole by hole, and millisecond delay of powder charges on different layers is realized according to a sequence from bottom to top in the holes. The implementing scheme of adopting the electronic detonators to detonate during blasting of collapse rocks in complicated environments is determined. According to tests of blasting utilizing the electronic detonators to detonate, the technical method of utilizing the electronic detonators to realize precise delay detonation for improving blasting lumpiness is researched, a guarantee is provided for controlling collapse accumulation range of broken rock after blasting, shocks to surrounding rock are reduced greatly on safety blasting conditions of the collapse rock, and secondary disasters are avoided.

Owner:CHONGQING BLASTING CONSTR +1

Underground construction method of hydraulic fracturing on high roof of coal seam group

ActiveCN111608630BReduce overhang lengthSmall blockSurveyFluid removalMining engineeringStructural engineering

The invention discloses a hydraulic fracturing underground construction method for a high-position roof of a coal seam group, which belongs to the field of coal mining; the steps include: confirming the high-position roof of an upper coal seam; calculating the size of the suspended roof of the high-position roof and the bearing area and rupture area of the upper coal pillar; Determine the coordinates of the fracturing point and construct the L-shaped fracturing drilling; complete the hydraulic fracturing construction of the high-level roof; wherein, the drilling construction and hydraulic fracturing parameters vary with changes in mine geological conditions; through the implementation of the present invention, It can reduce the overhang length and broken block degree of the high-level roof, alleviate the strong dynamic load pressure on the working face and reduce the risk of roof cutting and press frame accidents. It is an economical, reasonable, safe and feasible hydraulic fracturing underground construction method.

Owner:CHINA UNIV OF MINING & TECH

A method of energy-gathering smooth surface blasting with multiple wedge straight cuts in deep holes in rock roadways

ActiveCN111238322BReduce throwing distanceSingle cycle footage heightBlastingTEX-explosiveCrushed stone

A method of energy-gathering smooth surface blasting with multiple wedge straight cuts in deep holes in rock roadways. The method adopts multiple wedge straight cutting technology to realize a large cavity with a cavity opening of 3.2-3.4m and a deep hole cavity with a depth of more than 3.0m, which improves the single-cycle footage of rock roadway excavation; adopts peripheral T-shaped energy-concentrating blasting technology, realize the small diameter and low explosive density of peripheral blasting, and the two-way full-hole deep slits along the tangential direction on both sides form a smooth surface, and the gravel is cut along the radial direction. Small super-under-excavation, reducing gangue lumpiness, good smooth surface formation, and stable support effects; on the basis of these two key technical solutions, the full-section blasting process and parameters are set to achieve the expected rock roadway blasting depth of 3.0m as a whole Deep hole glossy blasting effect.

Owner:CHINA UNIV OF MINING & TECH (BEIJING)

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com