Large collapse rock blasting method under precise control of digital electronic detonators

A digital electronic detonator and precise control technology, applied in the field of blasting, can solve the problems of inability to effectively reduce the size of the rock after blasting, difficult to achieve precise control of blasting projects, and potential safety hazards, so as to avoid secondary disasters and improve safety. stability and reliability, low vibration effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

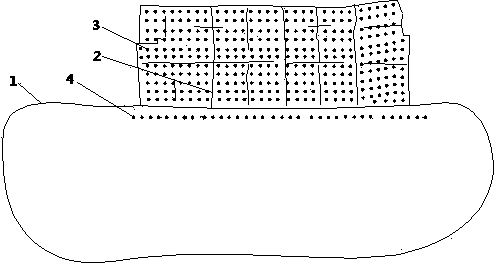

[0026] In this specific embodiment, there are a large number of buildings that need to be protected under the tall and dangerous rock mass, and most of the falling paths of the dangerous rock mass are steep slopes. It will continue to accelerate and roll down the mountain. Therefore, the disintegration of tall and dangerous rocks is required to be thorough and the size of the rock should be particularly small.

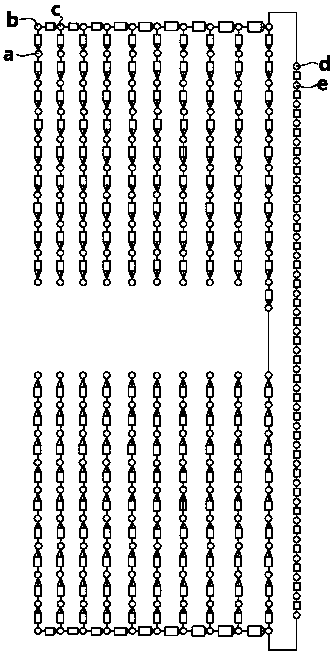

[0027] The precise control blasting method of digital electronic detonator for tall and dangerous rock mass includes the following steps:

[0028] (1) Design the parameters of the hole mesh and the hole arrangement. The parameter design includes the design of the hole diameter, hole depth, hole spacing and row spacing. The holes are arranged in rows and columns;

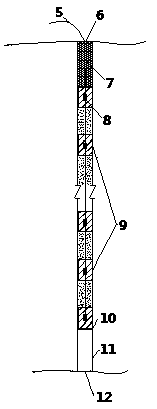

[0029] (2) Acceptance of drilling and hole forming, drilling is drilled with a cutting drill, and a light blast hole is drilled on the parent rock;

[0030] (3) For charging and blocking, each hole is equipp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com