Layer-by-layer extrusion and smooth blasting mining method for underground mine

A technology of smooth blasting and mining method, which is applied in the field of smooth blasting mining and layer-by-layer extrusion in underground mines. It can solve the problems of high safety risks for operators, high construction costs, and high block rate, and achieves the improvement of ore transportation efficiency. The effect of low filling cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

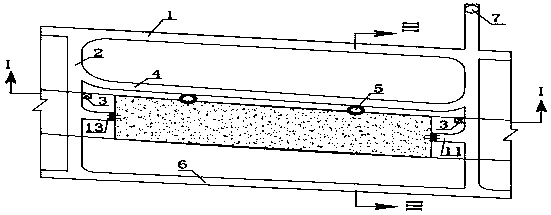

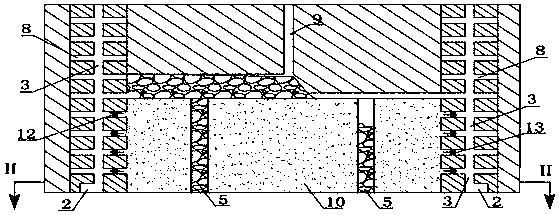

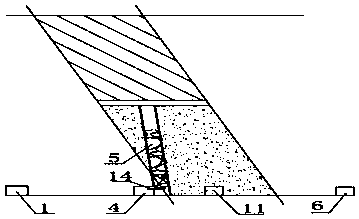

[0027] See attached picture.

[0028] The ore body is irregular and the ore rock is stable. A mining method of layer-by-layer extrusion blasting and smooth blasting is adopted. The specific implementation steps are as follows:

[0029] Stope layout

[0030] The ore block is divided into ore chambers and pillars along the direction of the ore body. The middle shaft 7 is arranged on the other side of the footwall along the vein 1, parallel to the ore body along the vein, and the two ends of the stope are piercing veins 2, which are arranged in In the ore pillar, a pedestrian patio 3 is arranged at both ends of the stope, a stope chute 5 is arranged by the ore body footwall, a vibrating ore drawing machine 11 is installed at the bottom of the chute, and a mine transport roadway 4 is constructed near the stope chute. A filling well 9 is arranged in the middle of the stope. The length of the stope is 66m, the width is 16.5m in thickness of the ore body, and the height of the sto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com