Transportation device for mining

A technology for transportation devices and mines, applied in transportation and packaging, conveyor control devices, underground transportation, etc., can solve problems such as high work intensity, and achieve the effect of reducing labor intensity and improving ore transportation efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

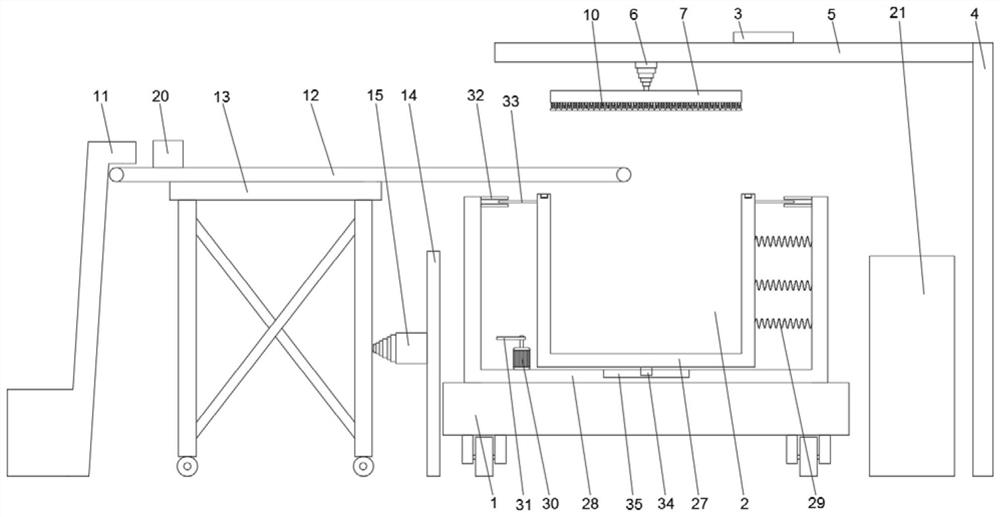

[0022] For a better understanding of the technical content of the present invention, a specific embodiment is provided below, and further described in conjunction with the accompanying drawings.

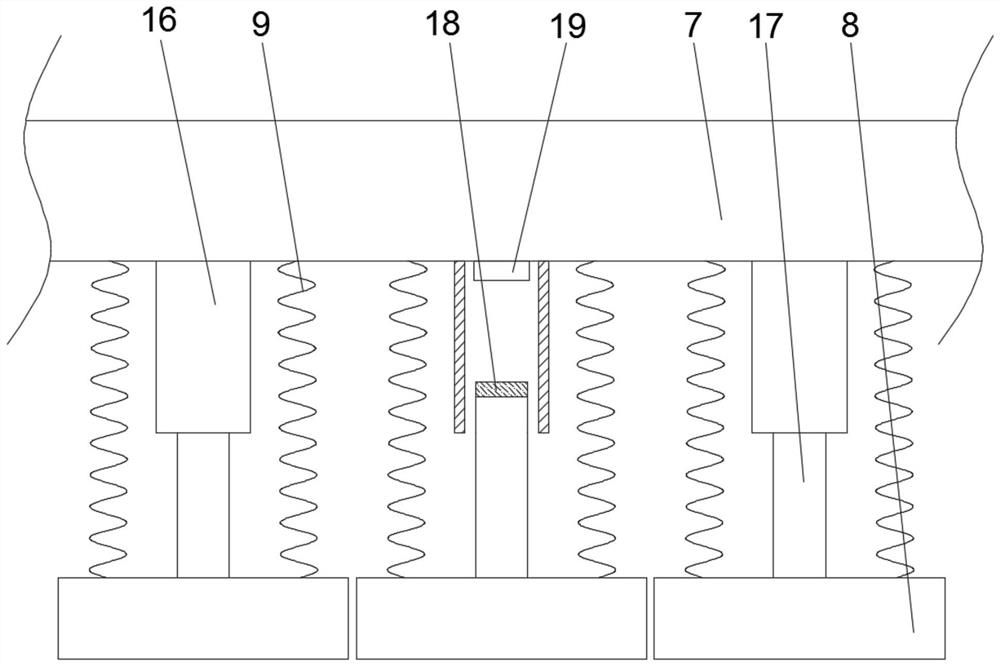

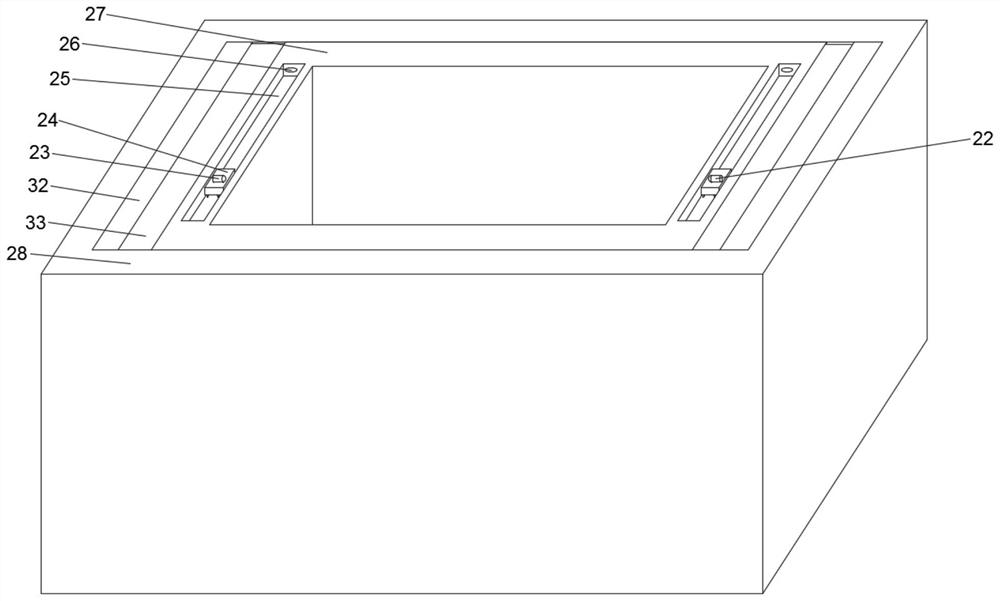

[0023] See Figures 1 through 3 , the present invention provides a transport device for mining mining, comprising a transport vehicle 1, a loading box 2, a main control unit 3, a dent detection mechanism and a feeding mechanism, the loading box 2 is disposed on the transport vehicle 1, the dent detection mechanism comprises a vertical rod 4, a crossbar 5, a lifting motor 6, a lifting plate 7, a push plate 8, a reset spring 9 and a displacement detection mechanism 10, the vertical rod 4 is provided on the side of the transport vehicle 1, the top of which is connected to the crossbar 5, the crossbar 5 is located above the loading box 2, The lifting motor 6 is provided on the bottom surface of the crossbar 5, the output shaft is connected to the bottom surface of the lifting plate 7, several...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com