Layered mining method for ultra-thick coal seam containing dirt band layer in middle

A layered mining and thick coal seam technology, applied in ground mining, mining equipment, earthwork drilling and mining, etc., can solve problems such as low recovery rate, loss of coal loss, and reduced recovery rate, so as to reduce the impact of disturbance and reduce the degree of fragmentation High, improve the effect of recovery rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The implementation of the present invention will be described in detail below in conjunction with the drawings and examples.

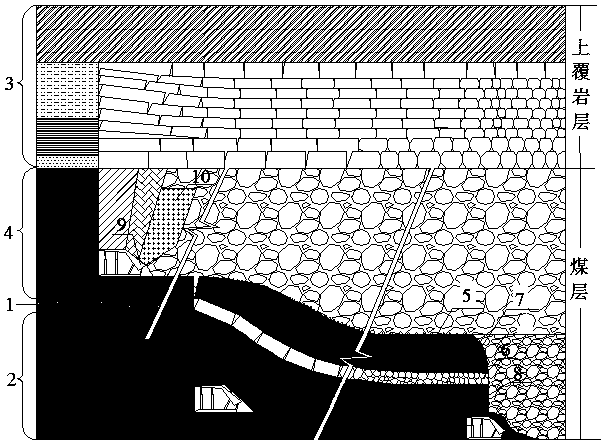

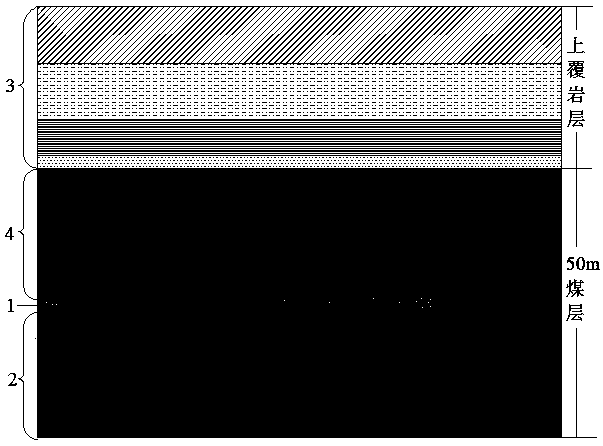

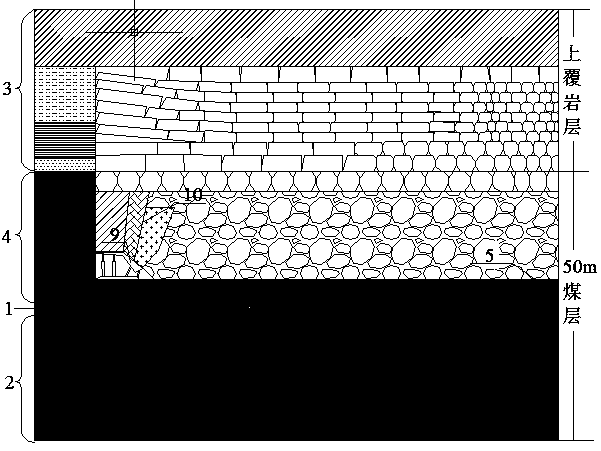

[0021] Such as Figure 2 to Figure 5 As shown, taking a 50m thick coal seam with a 2m gangue layer in the middle of a mine in Xinjiang as the engineering background, the specific implementation methods are as follows:

[0022] a. Divide the coal seam into 3 layers ( figure 2 ), the first layer is located at the top of the coal seam, the mining thickness is 20m, the second layer is located at the lower part of the gangue layer at 5.5-19m, the mining thickness is 13.5m, the bottom layer is at the bottom of the coal seam, and the machine mining height is 5m, of which the upper part of the gangue layer is left There is a coal body with a thickness of 4m, and a coal body with a thickness of 5.5m is left in the lower part;

[0023] b. The first layer adopts the method of fully mechanized caving mining, the machine mining height is 5m, the coal sett...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com