Tunneling blasting method comprehensively utilizing detonator short time difference and empty hole vibration reduction technique

A technology of tunneling and jet lag, which is applied in the field of blasting, can solve the problems of reducing blasting vibration, etc., and achieve the effects of improving shoveling efficiency, good crushing effect, and better blasting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

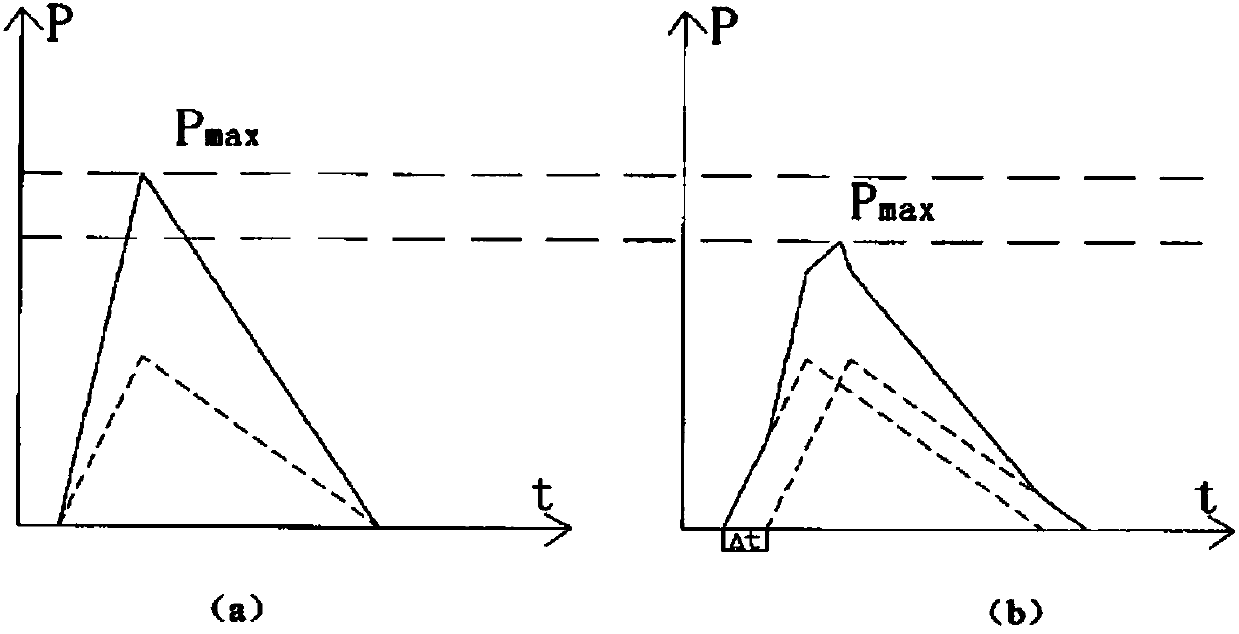

[0029] Delayed blasting technology for vibration reduction is widely used in underground engineering. The delayed initiation method can greatly reduce the total amount of charge for a single initiation, thereby reducing blasting vibration. At the same time, due to the time interval, the seismic wave in the rock and soil forms a phase difference, which avoids the superposition of the peak value of the seismic wave. When the phase is reversed properly, the peak and trough of the seismic wave are superimposed, and the particle vibration velocity will be greatly reduced.

[0030] Such as figure 1 As shown, in the simplified schematic diagram of seismic waves, the dotted line in the figure is the action time course produced by a single explosive source explosion, and the solid line is the action time course produced by the superposition of two explosive sources. As shown in (a): when detonated at the same time, the peak value is equal to twice the peak value of the vibration of a s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com