Automatic sand blasting and recycling device for industrial robot

An industrial robot and recycling device technology, which is applied in the field of mechanical processing and manufacturing, can solve the problems of difficulty in effectively recycling sand and dust, low efficiency, waste of resources, etc., and achieves the effects of large sandblasting range, increased qualification rate, and reduced harm

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

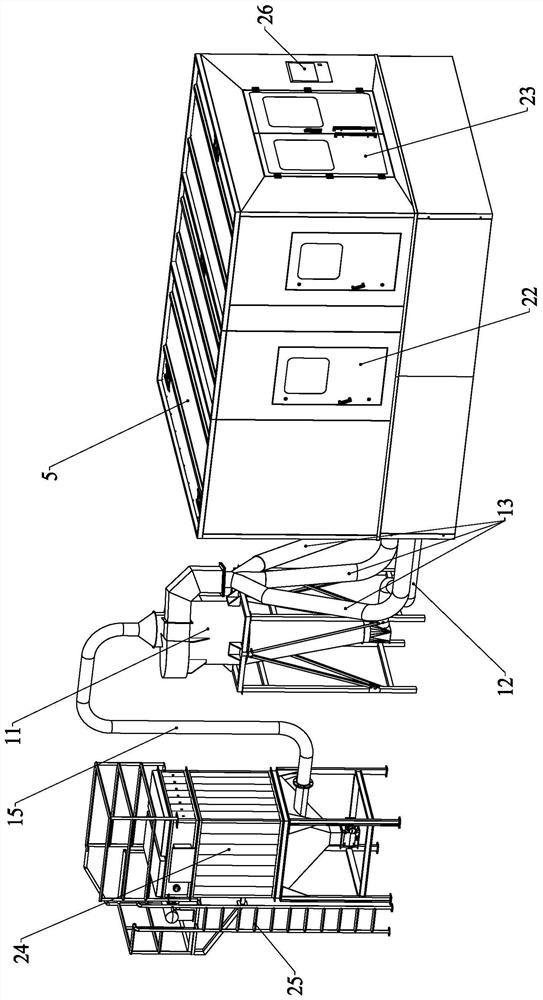

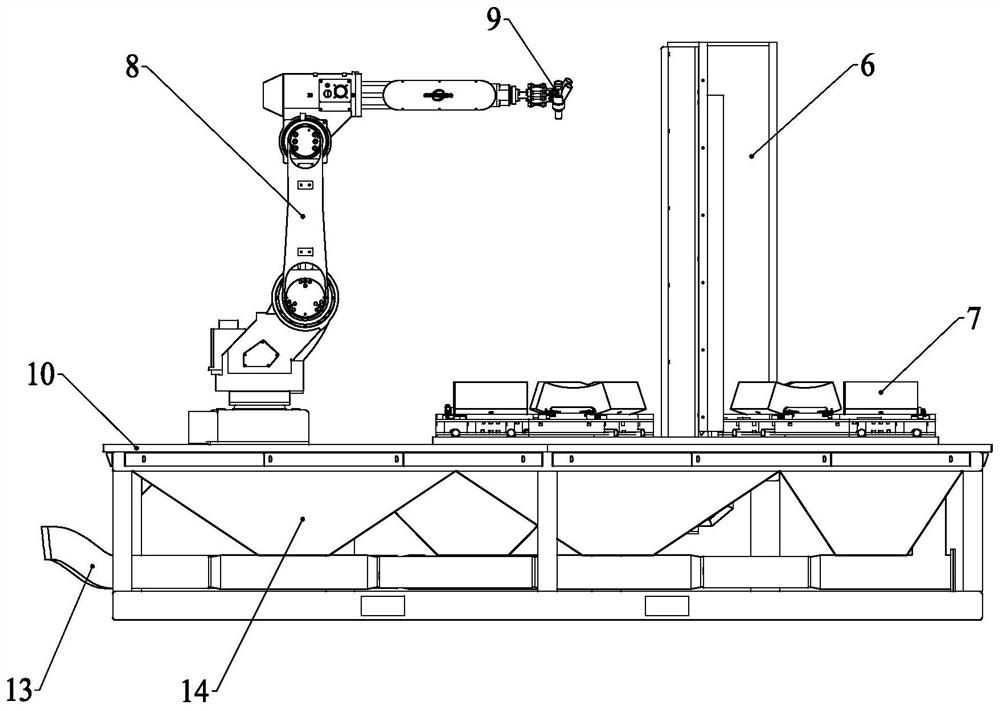

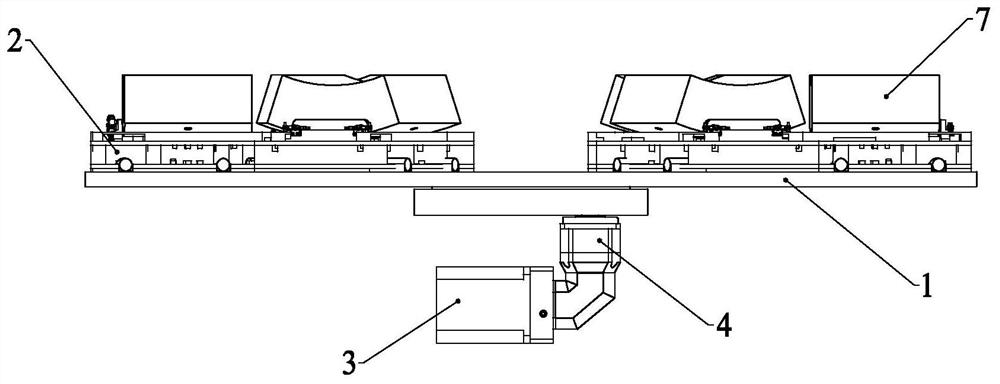

[0023] refer to Figure 1 to Figure 6 , the present embodiment is an automatic sandblasting and recovery device for an industrial robot, including a workpiece loading and unloading and conveying mechanism, a sandblasting mechanism, a sand supply and recovery mechanism, a dust removal mechanism, and a host computer; the workpiece loading and unloading and conveying mechanism includes a conveying turntable 1, a workpiece Tooling 2, laser positioning components, servo motor 3 and reducer 4, the conveying turntable is set inside the sandblasting room 5, and the sandblasting room is divided into a loading and unloading area and a sandblasting area by a partition plate 6 fixed inside the sandblasting room , there is a transparent PVC board in the middle of the partition plate, which is used for manual observation of the sandblasting process, the workpiece tooling is arranged in a circular array on the conveying turntable, and the laser positioning component is arranged inside the san...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com