Method for filling blast holes

A blasthole and filling technology, which is applied in the field of blasting, can solve the problems of complex process, low efficiency, and high cost, and achieve the effect of overcoming large pieces of crushed stone

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

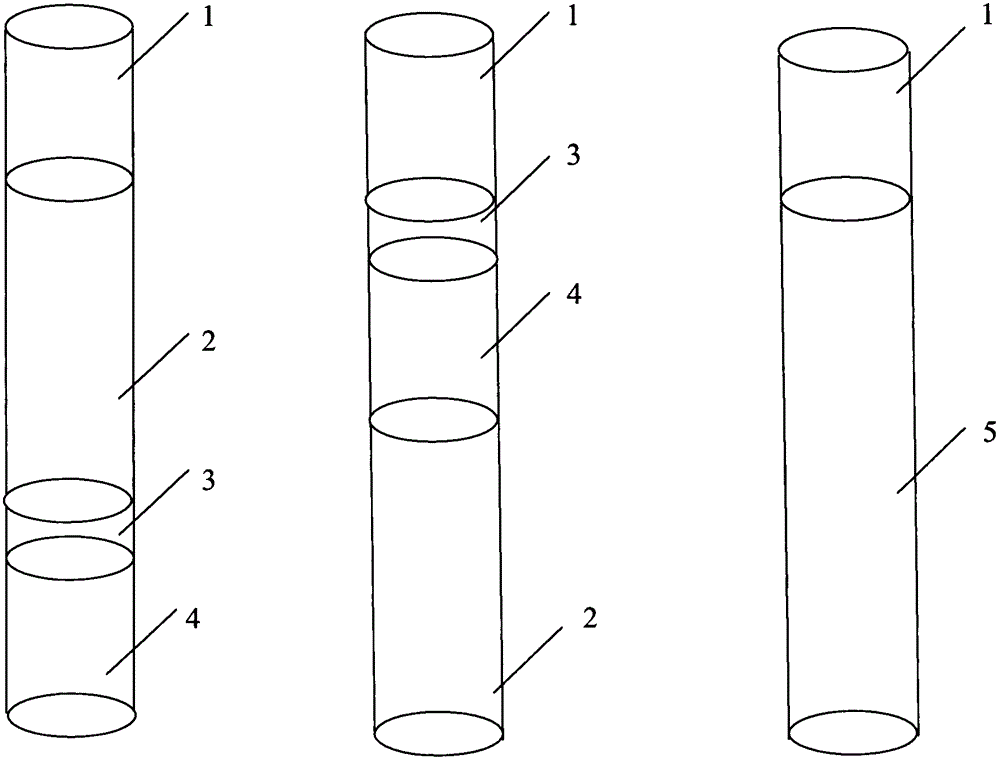

[0028] The following describes with examples. A method of filling the blasthole, namely:

[0029] The first step is to calculate the explosive consumption per unit blast hole or per unit blasting area according to the blasting environment and preset blasting purpose;

[0030] The second step is to preset various explosive densities according to the blasting environment such as rock hardness, rock joints, and water content around the blasthole, or the purpose of blasting, such as the size of the stone diameter after blasting;

[0031] In the third step, according to the preset density of various explosives in the second step, the above-mentioned various blastholes are filled with explosives of various densities at the blasting site;

[0032] The fourth step is to backfill and seal the blast hole.

[0033] The third step adopts the following steps: fill the blast hole with explosives of preset density, fill the blast hole space, cancel the spacer 3, and reserve a certain length of sealin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com